Global Emulsion Polymer Market

Market Size in USD Billion

CAGR :

%

USD

36.27 Billion

USD

48.13 Billion

2024

2032

USD

36.27 Billion

USD

48.13 Billion

2024

2032

| 2025 –2032 | |

| USD 36.27 Billion | |

| USD 48.13 Billion | |

|

|

|

|

Global Emulsion Polymer Market Size

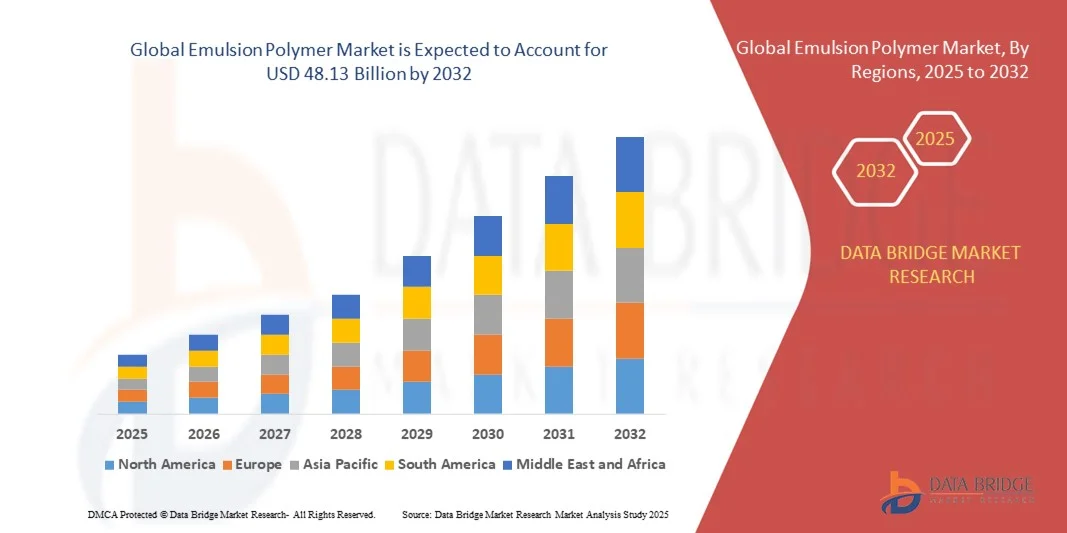

- The global Emulsion Polymer Market size was valued at USD 36.27 billion in 2024 and is projected to reach USD 48.13 billion by 2032, growing at a CAGR of 3.60% during the forecast period.

- Market expansion is primarily driven by increasing demand across industries such as paints & coatings, adhesives, textiles, and construction, where emulsion polymers enhance product performance and sustainability.

- Additionally, advancements in polymerization technologies and growing environmental regulations favoring water-based and low-VOC products are propelling the adoption of emulsion polymers, further accelerating market growth.

Global Emulsion Polymer Market Analysis

- Emulsion polymers, widely used in paints, adhesives, textiles, and construction, are essential components in enhancing product durability, flexibility, and environmental compliance across various industries worldwide.

- The rising demand for eco-friendly, water-based polymer solutions and increasing industrial applications in emerging economies are key factors driving the growth of the emulsion polymer market.

- Asia-Pacific dominated the Global Emulsion Polymer Market with the largest revenue share of 36.6% in 2024, supported by advanced manufacturing infrastructure, stringent environmental regulations favoring low-VOC products, and a strong presence of major polymer manufacturers focusing on innovation and sustainability.

- North America is anticipated to be the fastest-growing region in the Global Emulsion Polymer Market during the forecast period, attributed to rapid industrialization, expanding construction activities, and growing demand for advanced coatings and adhesives.

- The Acrylics segment dominated the market with the largest revenue share of 43.2% in 2024, owing to its excellent weather resistance, durability, and versatility across end-use industries like paints & coatings, construction, and adhesives.

Report Scope and Global Emulsion Polymer Market Segmentation

|

Attributes |

Emulsion Polymer Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Emulsion Polymer Market Trends

Innovation in Bio-Based and High-Performance Emulsion Polymers

- A significant and accelerating trend in the global Emulsion Polymer Market is the rising innovation in bio-based and high-performance formulations. These advanced materials are being developed to meet growing environmental regulations and evolving customer expectations for sustainability, durability, and safety across end-use industries such as construction, automotive, and packaging.

- For Instance, leading manufacturers such as BASF and Arkema have introduced bio-based acrylic emulsions that reduce reliance on fossil fuels and lower carbon footprints without compromising on performance. These eco-friendly alternatives are particularly gaining traction in paints, adhesives, and coatings applications.

- Innovations in polymerization technology, such as controlled radical polymerization and hybrid emulsions, are also enabling tailored performance characteristics—like improved adhesion, water resistance, and flexibility—making them ideal for demanding environments and specialized industrial applications.

- As regulatory bodies across regions like the U.S., Europe, and Asia-Pacific tighten restrictions on volatile organic compounds (VOCs), there is increased demand for water-based emulsion polymers that meet stringent emission standards while delivering superior functionality.

- To stay competitive, companies such as Wacker Chemie AG and Synthomer are investing heavily in R&D to develop next-generation emulsions that combine renewable raw materials with high-performance properties. These include low-VOC vinyl acetate-ethylene (VAE) emulsions and modified acrylic copolymers designed for high durability and reduced environmental impact.

- This shift toward sustainable, bio-based, and high-performance emulsion polymers is fundamentally reshaping the competitive landscape of the industry. As customers across sectors prioritize greener alternatives, manufacturers that offer innovative, regulation-compliant, and performance-driven products are experiencing increased market traction and long-term growth opportunities.

Global Emulsion Polymer Market Dynamics

Driver

Growing Demand Driven by Environmental Regulations and Industry-Specific Applications

- The increasing implementation of stringent environmental regulations, especially those targeting VOC emissions, is a significant driver of growth in the global Emulsion Polymer Market. These policies are prompting industries such as paints & coatings, adhesives, textiles, and construction to transition from solvent-based to water-based emulsion polymer solutions.

- For instance, regulatory frameworks such as the U.S. EPA’s Clean Air Act and the EU’s REACH legislation have encouraged companies to adopt low-VOC, eco-friendly polymers, boosting demand for acrylics, styrene-butadiene, and vinyl acetate-based emulsions.

- As manufacturers and end-users prioritize sustainability, emulsion polymers provide a safer, non-toxic alternative with excellent film-forming capabilities, durability, and cost-efficiency—making them well-suited for industrial and commercial applications.

- In parallel, the growing infrastructure development and urbanization in emerging economies such as India, China, and Brazil are accelerating the use of emulsion polymers in concrete additives, waterproofing systems, and decorative coatings. This regional momentum is further reinforced by rising consumer awareness around eco-labels and green building standards.

- The increasing demand for high-performance adhesives, automotive coatings, packaging inks, and nonwoven textiles is also driving innovation and customization in emulsion polymer formulations, enabling them to meet specific mechanical, thermal, and aesthetic requirements. Market players are leveraging this trend to diversify product portfolios and cater to niche applications.

Restraint/Challenge

Raw Material Volatility and Limited Performance Under Extreme Conditions

- Volatility in the prices of raw materials, especially petrochemical-based monomers like butadiene and acrylates, poses a major challenge for the emulsion polymer market. These fluctuations can directly impact production costs and profit margins, making it difficult for manufacturers to offer stable pricing, particularly in price-sensitive markets.

- For instance, supply chain disruptions and geopolitical tensions have led to sharp price increases in key feedstocks, pressuring manufacturers to find alternative sources or invest in bio-based solutions, which are still comparatively expensive and less widely adopted.

- Moreover, while emulsion polymers are effective in a wide range of applications, they may have performance limitations under extreme environmental or mechanical conditions, such as high heat, chemical exposure, or heavy abrasion. This can restrict their use in certain industrial segments, where more specialized or solvent-based polymers may still be preferred.

- Companies must continuously invest in R&D to improve the resilience, thermal stability, and mechanical strength of water-based emulsions to address these limitations and expand their applicability.

- To maintain competitiveness, manufacturers are also focusing on long-term supply agreements, backward integration strategies, and the development of hybrid polymer systems that combine the best features of multiple chemistries while complying with environmental standards. Overcoming raw material dependency and enhancing performance characteristics will be essential for ensuring sustained growth and broader market adoption.

Global Emulsion Polymer Market Scope

The emulsion polymer market is segmented on the basis of product and application.

- By Product

On the basis of product, the Global Emulsion Polymer Market is segmented into Acrylics, Styrene-Butadiene Latex, Vinyl Acetate Polymers, Polyurethane Dispersions, and Others. The Acrylics segment dominated the market with the largest revenue share of 43.2% in 2024, owing to its excellent weather resistance, durability, and versatility across end-use industries like paints & coatings, construction, and adhesives. Acrylic emulsions are widely preferred for their superior film-forming ability, color retention, and environmental compliance, particularly in applications requiring low-VOC formulations.

The Polyurethane Dispersions (PUDs) segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by their increasing use in high-performance coatings, textiles, and automotive applications. PUDs offer advantages such as excellent abrasion resistance, flexibility, and environmental friendliness, making them ideal for replacing solvent-based systems. The demand for advanced polymers with better mechanical and thermal properties continues to boost the adoption of polyurethane dispersions globally.

- By Application

On the basis of application, the Global Emulsion Polymer Market is segmented into Paints and Coatings, Paper and Paperboard Coatings, Adhesives and Sealants, and Others. The Paints and Coatings segment held the largest market revenue share in 2024, driven by the growing demand for water-based, eco-friendly paints in both residential and industrial sectors. Emulsion polymers enhance the performance of coatings by improving durability, adhesion, and resistance to weather and chemicals. The segment benefits from rising construction activities and the growing trend of sustainable building materials.

The Adhesives and Sealants segment is expected to witness the fastest CAGR from 2025 to 2032, fueled by increased use in packaging, automotive, and electronics industries. Emulsion-based adhesives offer advantages such as low toxicity, easy handling, and excellent bonding strength on diverse substrates. The surge in demand for high-performance, cost-effective bonding solutions in emerging markets is expected to further accelerate growth in this segment.

Global Emulsion Polymer Market Regional Analysis

- Asia-Pacific dominated the Global Emulsion Polymer Market with the largest revenue share of 36.6% in 2024, driven by the region’s well-established industrial base, stringent environmental regulations, and high demand for eco-friendly, water-based polymer solutions.

- Industries across the U.S. and Canada are rapidly transitioning to low-VOC and sustainable alternatives, significantly boosting the use of emulsion polymers in paints & coatings, adhesives, and paper applications.

- This dominance is further supported by substantial investments in R&D, presence of key market players, and consumer preference for durable, high-performance products, positioning emulsion polymers as essential materials in North America's growing construction, automotive, and packaging sectors.

U.S. Emulsion Polymer Market Insight

The U.S. emulsion polymer market captured the largest revenue share of 81% in North America in 2024, driven by stringent environmental regulations, increasing demand for sustainable products, and the presence of major industry players. The U.S. leads in the adoption of water-based, low-VOC emulsion polymers in applications such as paints & coatings, adhesives, and paper coatings. The growing focus on green building materials and eco-friendly packaging further fuels market growth. Additionally, high R&D investment and technological advancements in polymer chemistry continue to strengthen the U.S. position as a key innovation hub in the global emulsion polymer landscape.

Europe Emulsion Polymer Market Insight

The Europe emulsion polymer market is projected to expand at a substantial CAGR during the forecast period, supported by robust regulatory frameworks like REACH and increasing emphasis on circular economy practices. The demand for bio-based and waterborne polymers is rising across industries such as construction, automotive, and packaging. Urban redevelopment, sustainability goals, and rising consumer awareness around environmental issues are further accelerating the shift toward eco-friendly emulsion polymers. European countries are witnessing steady adoption in both industrial and decorative coatings, with a growing number of manufacturers transitioning to greener alternatives in compliance with EU mandates.

U.K. Emulsion Polymer Market Insight

The U.K. emulsion polymer market is anticipated to grow at a noteworthy CAGR, fueled by sustainability-driven construction trends, strong demand in packaging and paints, and rising adoption of VOC-free coating technologies. U.K. industries are increasingly opting for water-based adhesives and coatings to meet both regulatory standards and consumer expectations. Government initiatives encouraging low-emission infrastructure and the growing focus on carbon-neutral building materials support this transition. Additionally, the market benefits from innovations in bio-based polymer formulations and the country's strategic position in the European supply chain.

Germany Emulsion Polymer Market Insight

The Germany emulsion polymer market is expected to expand at a considerable CAGR during the forecast period, driven by the country’s leadership in green manufacturing, chemical innovation, and industrial sustainability. Germany's stringent environmental laws and commitment to reducing industrial emissions have made water-based emulsion polymers a preferred solution across sectors like automotive, textiles, and construction. German manufacturers are investing in advanced polymerization technologies to enhance performance characteristics while aligning with environmental goals. The push for digital transformation in manufacturing (Industry 4.0) is also enabling smarter production processes in polymer development.

Asia-Pacific Emulsion Polymer Market Insight

The Asia-Pacific emulsion polymer market is poised to grow at the fastest CAGR of 24% from 2025 to 2032, driven by rapid industrialization, infrastructure development, and rising consumer demand in economies like China, India, and Southeast Asia. Government initiatives promoting sustainable construction and local production of eco-friendly materials are fostering growth. Increasing foreign investment and expansion of the manufacturing base for paints, adhesives, and textiles further support market momentum. The availability of cost-effective raw materials and skilled labor positions the region as a major global supplier and consumer of emulsion polymers.

Japan Emulsion Polymer Market Insight

The Japan emulsion polymer market is gaining traction, driven by high environmental awareness, a focus on advanced materials, and the need for low-emission industrial solutions. Japanese manufacturers prioritize innovation in low-VOC and high-durability polymers, particularly for applications in electronics, packaging, and automotive industries. The country’s commitment to carbon neutrality and smart infrastructure development also supports the transition to sustainable chemical solutions. Moreover, Japan’s aging infrastructure is prompting demand for renovation-friendly coatings and adhesives, where emulsion polymers offer eco-conscious, high-performance alternatives.

China Emulsion Polymer Market Insight

The China emulsion polymer market accounted for the largest revenue share in Asia Pacific in 2024, driven by its expanding construction sector, rising environmental regulations, and a well-established chemical manufacturing ecosystem. As one of the world’s largest producers and consumers of emulsion polymers, China benefits from government-backed sustainability programs and rapid urbanization. Demand is particularly strong in paints & coatings, textiles, and packaging, where water-based solutions are replacing solvent-based products. Domestic companies are rapidly scaling up production to meet both domestic and international demand, while also investing in bio-based and high-performance polymer innovations.

Global Emulsion Polymer Market Share

The Emulsion Polymer Market is primarily led by well-established companies, including:

• BASF SE (Germany)

• The Dow Chemical Company (U.S.)

• Arkema Group (France)

• Wacker Chemie AG (Germany)

• Celanese Corporation (U.S.)

• Clariant AG (Switzerland)

• Synthomer plc (U.K.)

• Trinseo (U.S.)

• DIC Corporation (Japan)

• Asahi Kasei Corporation (Japan)

• 3M Company (U.S.)

• H.B. Fuller Company (U.S.)

• Scott Bader Company Ltd. (U.K.)

• Lubrizol Corporation (U.S.)

• Reichhold LLC (U.S.)

• Eni SpA (Italy)

• ZEON Corporation (Japan)

What are the Recent Developments in Global Emulsion Polymer Market?

- In May 2023, BASF SE launched a new range of bio-based acrylic emulsion polymers under its "Acronal® ECO" line, specifically designed for low-VOC paints and coatings. This strategic move aims to support the growing demand for sustainable and environmentally friendly solutions in the construction and decorative coatings industries. The product launch reinforces BASF’s commitment to innovation and climate-friendly chemistry, while strengthening its competitive position in the expanding Global Emulsion Polymer Market.

- In April 2023, Wacker Chemie AG announced the expansion of its production capacity for vinyl acetate-ethylene (VAE) dispersions at its South Korean plant. This expansion addresses the surging demand for high-performance, water-based polymers across Asia-Pacific, particularly in adhesives and construction applications. The investment supports Wacker’s global strategy of regionalizing supply chains and meeting the growing sustainability standards in emerging markets.

- In March 2023, Arkema Group introduced a new low-carbon footprint emulsion polymer developed through advanced polymerization techniques using renewable raw materials. This innovation is targeted toward the packaging and textile industries, where sustainability and regulatory compliance are critical. The initiative reflects Arkema’s long-term vision of delivering high-performance, eco-conscious solutions and reinforces its role as a leader in sustainable materials innovation.

- In February 2023, Synthomer plc unveiled a strategic partnership with a leading global coatings manufacturer to co-develop next-generation emulsion binders for high-durability exterior coatings. The collaboration focuses on improving UV resistance, water repellency, and adhesion, enabling enhanced product performance in extreme weather conditions. This partnership highlights Synthomer’s focus on customer-driven innovation and its commitment to delivering application-specific emulsion solutions.

- In January 2023, Celanese Corporation completed the acquisition of a specialty emulsion polymer business to strengthen its product portfolio in adhesives and sealants. The deal enables Celanese to offer a more diversified range of vinyl acetate and acrylic-based emulsions, expanding its footprint in North America and Europe. This acquisition is part of the company's broader strategy to drive growth through targeted investments in high-value performance materials within the emulsion polymer space.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Emulsion Polymer Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Emulsion Polymer Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Emulsion Polymer Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.