Global Epoxy Glass Flake Coating Market

Market Size in USD Million

CAGR :

%

USD

925.60 Million

USD

1,409.77 Million

2024

2032

USD

925.60 Million

USD

1,409.77 Million

2024

2032

| 2025 –2032 | |

| USD 925.60 Million | |

| USD 1,409.77 Million | |

|

|

|

|

Epoxy Glass Flake Coating Market Size

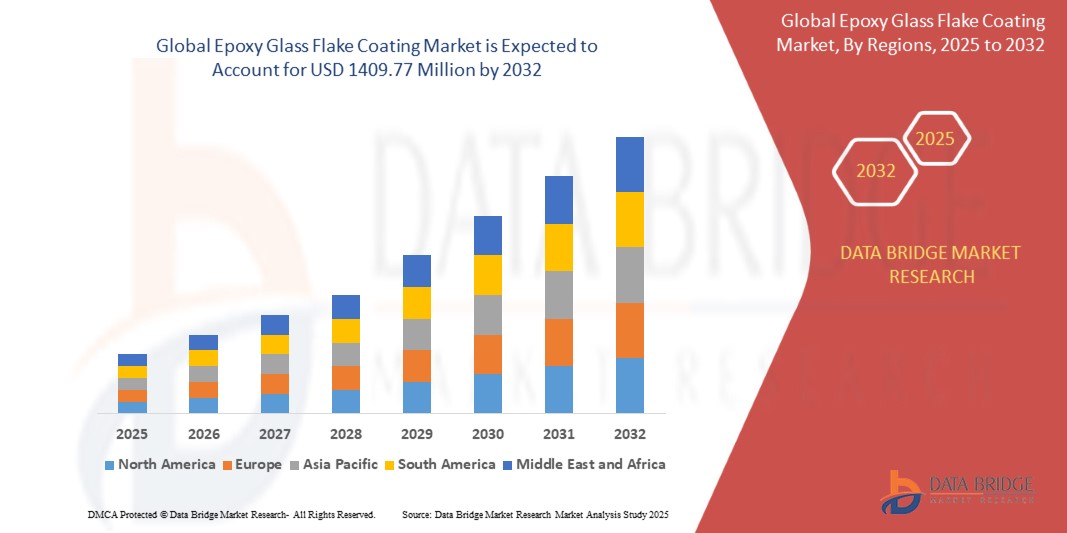

- The global epoxy glass flake coating market size was valued at USD 925.60 million in 2024 and is expected to reach USD 1409.77 million by 2032, at a CAGR of 5.40% during the forecast period

- The market growth is largely fuelled by the rising demand for corrosion-resistant coatings across marine, oil and gas, and industrial applications, coupled with increasing investment in infrastructure and maintenance activities

- The expanding application scope in chemical processing plants and wastewater treatment facilities, where chemical resistance and surface durability are critical, is also contributing to long-term market growth

Epoxy Glass Flake Coating Market Analysis

- The market is witnessing steady growth due to the exceptional chemical and abrasion resistance offered by epoxy glass flake coatings, making them ideal for harsh and corrosive environments

- The growing adoption of long-lasting and durable protective coatings in storage tanks, pipelines, and offshore platforms is driving the demand across sectors

- North America dominated the epoxy glass flake coating market with the largest revenue share of 38.44% in 2024, driven by the increasing demand for high-performance anti-corrosion coatings across industries such as oil and gas, power generation, and marine infrastructure

- Asia-Pacific region is expected to witness the highest growth rate in the global epoxy glass flake coating market, driven by urbanization, rising construction activities, and supportive government initiatives promoting industrial development and sustainable protective solutions

- The epoxy segment dominated the market with the largest revenue share in 2024, attributed to its excellent corrosion resistance, superior adhesion properties, and long-lasting protection in aggressive environments. Epoxy-based coatings are widely utilized in heavy-duty applications such as offshore platforms, pipelines, and marine vessels due to their proven performance in withstanding harsh chemicals and saltwater exposure. The demand for epoxy resin is also driven by its strong compatibility with glass flake fillers, which enhance the barrier effect and increase the coating’s lifespan

Report Scope and Epoxy Glass Flake Coating Market Segmentation

|

Attributes |

Epoxy Glass Flake Coating Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Epoxy Glass Flake Coating Market Trends

Rising Preference for Long-Lasting Anti-Corrosive Industrial Coatings

- The increasing demand for advanced anti-corrosion solutions is driving the popularity of epoxy glass flake coatings, especially in industries such as oil and gas, marine, and chemical processing. These coatings offer high chemical and abrasion resistance, which enhances the longevity of infrastructure exposed to harsh environments

- Companies are adopting epoxy glass flake coatings to reduce maintenance frequency and downtime. The cost efficiency of longer-lasting protection supports industrial productivity and reduces repair costs in offshore platforms, pipelines, and storage tanks

- Governments and industry bodies are mandating higher safety and durability standards for infrastructure assets, pushing firms to invest in premium coatings. Epoxy glass flake coatings meet these regulatory demands while delivering performance advantages over traditional systems

- For instance, in 2023, several petrochemical refineries in the Middle East upgraded their internal tank linings to glass flake epoxy systems, citing longer life cycles and improved corrosion resistance in high-temperature environments

- This trend is further supported by technological innovation in formulation chemistry, enabling thinner application layers, faster curing times, and better compatibility with various substrates—making these coatings ideal for both new builds and maintenance projects

Epoxy Glass Flake Coating Market Dynamics

Driver

Expanding Offshore and Marine Infrastructure Development

- Growing global investment in offshore energy infrastructure, including oil rigs, wind farms, and subsea pipelines, is significantly boosting the demand for epoxy glass flake coatings. These coatings are especially suited for extreme marine environments, offering long-term resistance against saltwater, chemicals, and temperature variations

- Emerging economies and energy-exporting nations are prioritizing offshore expansion as part of their energy security strategies. This requires robust corrosion protection systems that can withstand prolonged exposure to harsh marine conditions, where epoxy glass flake coatings outperform conventional alternatives

- Coatings manufacturers are forming partnerships with engineering and procurement contractors (EPCs) to supply customized protection systems tailored for complex offshore projects. The durability and efficiency of these coatings directly support reduced maintenance cycles and extended asset life

- For instance, in 2022, several offshore wind farm operators in Northern Europe standardized epoxy glass flake systems for their foundation structures to combat corrosion and biofouling, leading to improved asset performance and lower lifecycle costs

- As offshore activities continue to rise globally, epoxy glass flake coatings are becoming integral to project planning and execution. Their performance benefits and cost-effectiveness position them as essential components of long-term corrosion management strategies

Restraint/Challenge

High Cost and Technical Complexity of Application

- The application of epoxy glass flake coatings requires specialized surface preparation and skilled labor, which can increase operational costs and extend project timelines. This deters adoption among small-scale contractors and industries with limited budgets or technical capabilities

- Inadequate application can compromise coating effectiveness, leading to premature failure and costly rework. As a result, industries with insufficient access to skilled applicators often opt for simpler, lower-performance alternatives despite the long-term drawbacks

- The high viscosity and limited pot life of glass flake coatings demand precise environmental controls during application, which can be challenging in remote or unpredictable work environments. This adds complexity in sectors such as shipbuilding or field maintenance

- For instance, in 2023, construction firms in Southeast Asia reported delays and increased costs during port terminal upgrades due to the lack of certified coating specialists and humidity-controlled environments, affecting timely project delivery

- To overcome these challenges, manufacturers must focus on developing easier-to-apply formulations, invest in applicator training programs, and offer technical support throughout the coating lifecycle. These efforts are critical for improving user confidence and expanding market accessibility

Epoxy Glass Flake Coating Market Scope

The market is segmented on the basis of substrate, application method, and end-use industry.

• By Substrate

Based on substrate, the market is segmented into metal and concrete. The metal segment accounted for the largest revenue share in 2024, driven by the extensive use of epoxy glass flake coatings in protecting steel structures, tanks, and ship hulls from corrosion. Industries such as oil and gas, power generation, and shipping rely heavily on metal infrastructure, and the application of high-performance coatings on these surfaces is critical for asset longevity and operational efficiency.

The concrete segment is expected to witness the fastest growth rate from 2025 to 2032, due to rising usage in wastewater treatment facilities and industrial flooring. Epoxy glass flake coatings on concrete offer excellent chemical resistance and impermeability, making them ideal for environments with aggressive fluid exposure.

• By Application Method

On the basis of application method, the market is segmented into brush and airless spray. The airless spray segment held the largest share in 2024, largely due to its efficiency in covering large surface areas quickly and uniformly, which is essential in industrial-scale applications. Airless spray application also ensures consistent thickness and minimal waste, making it a preferred method for coatings on pipelines, storage tanks, and ship decks.

The brush segment is expected to witness the fastest growth rate from 2025 to 2032, particularly in maintenance and touch-up applications where precision and localized coating are required. It is also commonly used in small-scale projects and areas that are hard to reach with spraying equipment.

• By End-use Industry

By end-use industry, the epoxy glass flake coating market is segmented into oil and gas, marine, industrial, power generation, wastewater treatment, and others. The oil and gas segment led the market in 2024, as epoxy glass flake coatings are extensively employed to protect pipelines, offshore rigs, and storage units from corrosion and chemical attack. The extreme conditions faced in exploration and production activities necessitate robust protective coatings that can withstand long-term exposure to moisture and hydrocarbons.

The marine segment is expected to witness the fastest growth rate from 2025 to 2032, due to increasing investments in shipbuilding and the maintenance of existing fleets. Epoxy glass flake coatings are preferred for marine applications because they reduce water permeability and offer prolonged durability, reducing dry-docking frequency and maintenance costs.

Epoxy Glass Flake Coating Market Regional Analysis

- North America dominated the epoxy glass flake coating market with the largest revenue share of 38.44% in 2024, driven by the increasing demand for high-performance anti-corrosion coatings across industries such as oil and gas, power generation, and marine infrastructure

- The region benefits from a mature industrial base, strong regulatory standards, and a rising focus on asset durability and operational efficiency, all of which support sustained demand for epoxy glass flake coatings

- Moreover, investments in aging infrastructure rehabilitation and the growing need for long-term surface protection in critical facilities are accelerating market penetration across the United States and Canada

U.S. Epoxy Glass Flake Coating Market Insight

The U.S. epoxy glass flake coating market accounted for the largest revenue share in North America in 2024, supported by the country’s expansive oil and gas sector, stringent environmental standards, and emphasis on infrastructure protection. Key applications include pipelines, offshore platforms, and chemical processing units. The presence of leading coating manufacturers, combined with growing awareness regarding the lifecycle benefits of epoxy glass flake coatings, continues to drive market expansion across industrial and marine sectors.

Europe Epoxy Glass Flake Coating Market Insight

The Europe epoxy glass flake coating market is expected to witness the fastest growth rate from 2025 to 2032, driven by stringent corrosion protection regulations and the need for enhanced structural durability in offshore, energy, and public infrastructure applications. Countries such as Germany, Norway, and the U.K. are leading in the adoption of advanced protective coatings for marine assets and industrial equipment. In addition, growing emphasis on sustainability, coupled with retrofitting initiatives in aging infrastructure, is expected to support long-term market demand.

U.K. Epoxy Glass Flake Coating Market Insight

The U.K. epoxy glass flake coating market is expected to witness the fastest growth rate from 2025 to 2032, owing to the region’s heavy reliance on offshore energy infrastructure and increased spending on maintenance and corrosion protection. Rising demand for coatings with extended service life and reduced maintenance needs, especially in marine and industrial environments, is a key growth driver. Government regulations promoting asset integrity and environmental safety are further contributing to market development.

Asia-Pacific Epoxy Glass Flake Coating Market Insight

The Asia-Pacific epoxy glass flake coating market is expected to witness the fastest growth rate from 2025 to 2032, fuelled by rapid industrialization, urbanization, and expanding investments in sectors such as petrochemicals, marine, and wastewater treatment. The availability of low-cost raw materials and labor, coupled with rising demand for long-lasting protective solutions, is supporting adoption in countries such as China, India, and South Korea.

China Epoxy Glass Flake Coating Market Insight

The China epoxy glass flake coating market captured the largest revenue share in Asia-Pacific in 2024, driven by the country’s large-scale infrastructure projects and extensive industrial base. High demand for corrosion-resistant coatings in sectors such as offshore drilling, shipbuilding, and energy production is promoting the use of epoxy glass flake solutions. Furthermore, government investments in urban development and industrial safety are expected to sustain market growth over the coming years.

Japan Epoxy Glass Flake Coating Market Insight

The Japan epoxy glass flake coating market is expected to witness the fastest growth rate from 2025 to 2032, driven by the country’s high standards for infrastructure maintenance and preference for technologically advanced coating systems. With a focus on corrosion prevention in coastal structures, tunnels, and industrial facilities, the demand for epoxy glass flake coatings continues to rise. In addition, the integration of sustainable coating technologies and innovations in product formulation are further enhancing market attractiveness across both public and private sectors.

Epoxy Glass Flake Coating Market Share

The Epoxy Glass Flake Coating industry is primarily led by well-established companies, including:

- The Sherwin-Williams Company (U.S.)

- Axalta Coating Systems LLC (U.S.)

- Berger Paints India Limited (India)

- BASF SE (Germany)

- Valspar (U.S.)

- Nippon Paint Company Limited (Japan)

- Kansai Paint Co. (Japan)

- PPG Industries (U.S.)

- RPM International (U.S.)

- Tikkurila Oyj (Finland)

- SABIC (Saudi Arabia)

- Yokohama Tire Corporation (Japan)

- Crain (U.S.)

- Toyo Tire U.S.A. Corp. (U.S.)

- Balkrishna Industries Limited (India)

- KCC Corporation (South Korea)

- Chugoku Marine Paints (Japan)

- Kenda Tires (Taiwan)

- Pirelli & C. S.p.A. (Italy)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Epoxy Glass Flake Coating Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Epoxy Glass Flake Coating Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Epoxy Glass Flake Coating Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.