Market Analysis and Insights of Factory Automation Market

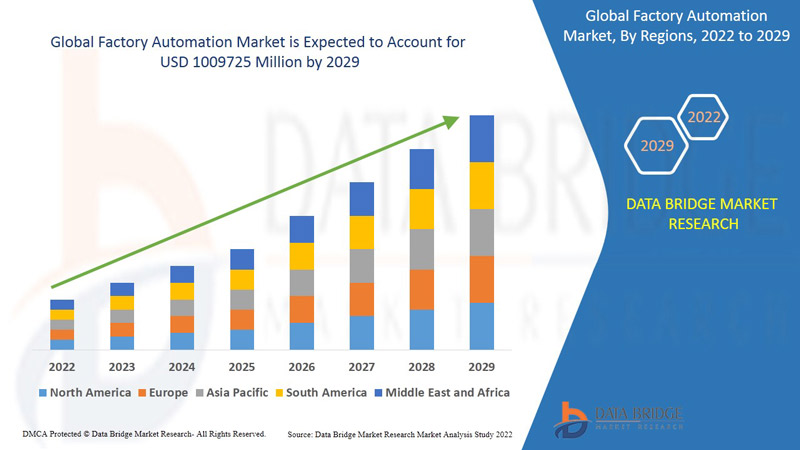

Factory automation market is expected to gain market growth in the forecast period of 2022 to 2029. Data Bridge Market Research analyses the market to rise up to the USD 1009725 million by 2029 and to grow at a CAGR of 9.60% in the above-mentioned forecast period.

Image processing is a basically a procedure that is utilized to get an enhanced image by performing some operation on the image as it is advanced and rapidly growing technology. Generally, it includes three steps such as importing the image, analyses and manipulating the image and provides report based on image analysis. They are widely used for various end-users such as camera device, AR/VR devices, mobile phones, smart phones, tablets and others.

The factors such increasing adoption of industry 4.0 and rising demand for automation for qualitative and reliable manufacturing are expected to emerge as the significant factors accelerating the growth of factory automation market in the forecast period of 2022 to 2029. In addition to this, rising government initiatives to enhance the adoption of industrial automation, rising usage of enabling technologies in manufacturing and growing need for mass production with decreased operation cost will further aggravate the growth of the factory automation market in the above-mentioned forecast period. The government initiatives to advance industrial automation and the endorsement of new technologies such as the internet of things (IOT) and artificial intelligence (AI) in automation environments are estimated to boost the overall growth of the market within the forecasted period. However, the dearth of skilled and trained professionals along with the high investment cost of the factory automation systems are projected to result as a growth restraint for the market which will further hamper the market’s overall growth.

The advent of cloud systems, smart sensors and other advanced technologies are also anticipated to generate lucrative opportunities for the factory automation market in the forecast period of 2022 to 2029. On the slip side, the increasing awareness regarding security will pose as a challenge for the factory automation market.

This factory automation market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on Factory automation market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Global Factory Automation Market Scope and Market Size

The factory automation market is segmented on the basis of control systems, component, and end- user. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target market.

- On the basis of control systems, the factory automation market is segmented into distributed control systems, supervisory control and data acquisition system, manufacturing execution system, safety instrumented system, programmable logic controller and human machine interface.

- The component segment of the factory automation market is divided into sensors, controller, switches and relays, industrial robots, drives and others.

- The end- user segment of the factory automation market is divided into automotive manufacturing, food and beverage, oil and gas processing, mining and others.

Factory Automation Market Country Level Analysis

The factory automation market is analyzed and market size, volume information is provided by control systems, component, and end- user as referenced above.

The countries covered in the factory automation market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the factory automation market during the forecast period owing to the increasing number of factory automation companies in the region and rising industry 4.0 initiatives to enhance the manufacturing productivity in the forecast period of 2022 to 2029. Asia-Pacific, on the other hand, is expected to show a lucrative growth due to technological advancement, rising demand for automation and various other factors.

The country section of the factory automation market report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Factory Automation Market Share Analysis

The factory automation market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to Factory automation market.

Some of the major players operating in the factory automation market report are ABB, Emerson Electric Co., Mitsubishi Electric Corporation, GENERAL ELECTRIC, Texas Instruments Incorporated, Honeywell International Inc., Rockwell Automation, Inc., OMRON Corporation, Rockwell Automation, Inc., Schneider Electric, Siemens, Yokogawa India Ltd., SD3D Printing., Dwyer Instruments, Ltd., WIKA Instruments India Pvt. Ltd., FANUC INDIA Private Limited.., Hitachi, Ltd., and VEGA India Level and Pressure Measurement Pvt. Ltd., among others.

Recent Developments

In April 2021, the Mitsubishi Electric Corporation released a seven new X-Series products, including two HVIGBTs and five HVDIODEs, for a total of 24 X-Series power semiconductor modules. These modules are intended for high-voltage, large-current equipment such as traction motors, DC-power transmitters, large industrial machines, and other high-voltage, small-size inverters.

In March 2021, the GE DIGITAL has launched enhancements to its CIMPLICITY and Tracker software, which give important decision support for operators and help them become more efficient. Client-server visualisation is provided by CIMPLICITY HMI/SCADA to precisely monitor and control activities. Tracker, part of GE Digital's Proficy Manufacturing Execution Systems (MES) product, automates routing and sequencing to decrease warranty and recall risk and promote lean operations.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL FACTORY AUTOMATION MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL FACTORY AUTOMATION MARKET

2.2.1 VENDOR POSITIONING GRID

2.2.2 TECHNOLOGY LIFE LINE CURVE

2.2.3 MARKET GUIDE

2.2.4 COMAPANY MARKET SHARE ANALYSIS

2.2.5 MULTIVARIATE MODELLING

2.2.6 TOP TO BOTTOM ANALYSIS

2.2.7 STANDARDS OF MEASUREMENT

2.2.8 VENDOR SHARE ANALYSIS

2.2.9 DATA POINTS FROM KEY PRIMARY INTERVIEWS

2.2.10 DATA POINTS FROM KEY SECONDARY DATABASES

2.3 GLOBAL FACTORY AUTOMATION MARKET: RESEARCH SNAPSHOT

2.4 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHT

5.1 PORTERS FIVE FORCES

5.2 REGULATORY STANDARDS

5.3 TECHNOLOGICAL TRENDS

5.4 PATENT ANALYSIS

5.5 CASE STUDY

5.6 VALUE CHAIN ANALYSIS

5.7 COMPANY COMPARITIVE ANALYSIS

6 GLOBAL FACTORY AUTOMATION MARKET, BY COMPONENTS

6.1 OVERVIEW

6.2 HARDWARE

6.2.1 MACHINE VISION

6.2.1.1. CAMERAS

6.2.1.1.1. DIGITAL CAMERAS

6.2.1.1.2. SMART CAMERAS

6.2.1.1.3. ANALOG CAMERAS

6.2.1.2. FRAME GRABBERS

6.2.1.3. LED LIGHTING

6.2.1.4. OPTICS

6.2.1.5. PROCESSOR

6.2.1.5.1. FPGA

6.2.1.5.2. MICROCONTROLLER AND MICROPROCESSOR

6.2.1.5.3. DSP

6.2.1.5.4. VPU

6.2.1.6. OTHERS

6.2.2 ROBOTICS

6.2.2.1. TRADITIONAL ROBOTS

6.2.2.1.1. CARTESIAN ROBOTS

6.2.2.1.2. PARALLEL ROBOTS

6.2.2.1.3. ARTICULATED ROBOTS

6.2.2.1.4. SELECTIVE COMPLIANCE ASSEMBLY ROBOT ARMS (SCARA)

6.2.2.1.5. OTHERS

6.2.2.2. COLLABORATIVE ROBOTS

6.2.3 INDUSTRIAL PC

6.2.3.1. PANEL IPC

6.2.3.2. BOX IPC

6.2.3.3. RACK MOUNT IPC

6.2.3.4. EMBEDDED BOX IPC

6.2.3.5. DIN RAIL IPC

6.2.4 SENSORS

6.2.5 HUMAN–MACHINE INTERFACE (HMI)

6.2.5.1. BY CONFIGURATION

6.2.5.1.1. EMBEDDED HMI

6.2.5.1.2. STAND-ALONE HMI

6.2.6 3D PRINTING

6.2.6.1. BY PROCESS

6.2.6.1.1. DIRECTED ENERGY DEPOSITION

6.2.6.1.2. BINDER JETTING

6.2.6.1.3. MATERIAL JETTING

6.2.6.1.4. VAT PHOTOPOLYMERIZATION

6.2.6.1.5. MATERIAL EXTRUSION

6.2.6.1.6. POWDER BED FUSION

6.2.6.1.7. SHEET LAMINATION

6.2.7 FIELD INSTRUMENTS

6.2.7.1. TRANSMITTERS

6.2.7.1.1. TEMPERATURE TRANSMITTERS

6.2.7.1.2. LEVEL TRANSMITTERS

6.2.7.1.3. PRESSURE TRANSMITTERS

6.2.7.2. FLOWMETERS

6.2.8 CONTROL VALVES

6.2.8.1. ROTARY VALVES

6.2.8.2. LINEAR VALVES

6.2.9 AC & DC MOTORS AND DRIVES

6.2.10 SWITCHES AND RELAYS

6.3 SOFTWARE

6.3.1 PROGRAMMING SOFTWARE

6.3.2 ANALYSIS SOFTWARE

6.3.3 DESIGN SOFTWARE

6.3.4 OFFICE SOFTWARE

6.3.5 OTHERS

6.4 SERVICES

6.4.1 INSTALLATION

6.4.2 ENGINEERING

6.4.3 TRAINING

6.4.4 SUPPORT AND MAINTAINENCE

7 GLOBAL FACTORY AUTOMATION MARKET, BY SOLUTION

7.1 OVERVIEW

7.2 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

7.3 MANUFACTURING EXECUTION SYSTEMS (MES)

7.4 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

7.5 DISTRIBUTED CONTROL SYSTEMS (DCS)

7.6 HUMAN MACHINE INTERFACE (HMI)

7.7 PLANT ASSET MANAGEMENT (PAM)

7.8 PRODUCT LIFECYCLE MANAGEMENT (PLM)

7.9 ENTERPRISE RESOURCE PLANNING (ERP)

7.1 ELECTRONIC CONTROL UNITS (ECU)

7.11 SAFETY INSTRUMENTED SYSTEM

7.12 OTHERS

8 GLOBAL FACTORY AUTOMATION MARKET, BY AUTOMATION LEVEL

8.1 OVERVIEW

8.2 MANUAL / MINIMAL AUTOMATION

8.3 SINGLE AUTOMATED MACHINES

8.4 AUTOMATED PRODUCTION LINES

8.5 FULLY AUTOMATED (END-TO-END)

9 GLOBAL FACTORY AUTOMATION MARKET, BY END USER

9.1 OVERVIEW

9.2 PROCESS INDUSTRY

9.2.1 PROCESS INDUSTRY, BY TYPE

9.2.1.1. FOOD AND BEVERAGES

9.2.1.1.1. BY SOLUTION

9.2.1.1.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.1.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.1.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.1.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.1.1.5 HUMAN MACHINE INTERFACE (HMI)

9.2.1.1.1.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.1.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.1.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.1.1.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.1.1.10 OTHERS

9.2.1.2. OIL AND GAS

9.2.1.2.1. BY TYPE

9.2.1.2.1.1 UPSTREAM

9.2.1.2.1.2 DOWNSTREAM

9.2.1.2.1.3 MIDSTREAM

9.2.1.2.2. BY SOLUTION

9.2.1.2.2.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.2.2.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.2.2.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.2.2.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.2.2.5 HUMAN MACHINE INTERFACE (HMI)

9.2.1.2.2.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.2.2.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.2.2.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.2.2.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.2.2.10 OTHERS

9.2.1.3. POWER

9.2.1.3.1. BY SOLUTION

9.2.1.3.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.3.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.3.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.3.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.3.1.5 8.2.1.3.1.5. HUMAN MACHINE INTERFACE (HMI)

9.2.1.3.1.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.3.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.3.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.3.1.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.3.1.10 OTHERS

9.2.1.4. CHEMICAL

9.2.1.4.1. BY SOLUTION

9.2.1.4.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.4.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.4.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.4.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.4.1.5 HUMAN MACHINE INTERFACE (HMI)

9.2.1.4.1.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.4.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.4.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.4.1.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.4.1.10 OTHERS

9.2.1.5. PHARMACEUTICALS

9.2.1.5.1. BY SOLUTION

9.2.1.5.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.5.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.5.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.5.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.5.1.5 HUMAN MACHINE INTERFACE (HMI)

9.2.1.5.1.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.5.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.5.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.5.1.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.5.1.10 OTHERS

9.2.1.6. METAL AND MINING

9.2.1.6.1. BY SOLUTION

9.2.1.6.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.6.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.6.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.6.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.6.1.5 HUMAN MACHINE INTERFACE (HMI)

9.2.1.6.1.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.6.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.6.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.6.1.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.6.1.10 OTHERS

9.2.1.7. PULP AND PAPER

9.2.1.7.1. BY SOLUTION

9.2.1.7.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.2.1.7.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.2.1.7.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.2.1.7.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.2.1.7.1.5 HUMAN MACHINE INTERFACE (HMI)

9.2.1.7.1.6 PLANT ASSET MANAGEMENT (PAM)

9.2.1.7.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.2.1.7.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.2.1.7.1.9 SAFETY INSTRUMENTED SYSTEM

9.2.1.7.1.10 OTHERS

9.2.1.8. OTHERS

9.3 DISCRETE INDUSTRY

9.3.1 BY TYPE

9.3.1.1. AUTOMOTIVE

9.3.1.1.1. BY SOLUTION

9.3.1.1.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.3.1.1.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.3.1.1.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.3.1.1.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.3.1.1.1.5 HUMAN MACHINE INTERFACE (HMI)

9.3.1.1.1.6 PLANT ASSET MANAGEMENT (PAM)

9.3.1.1.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.3.1.1.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.3.1.1.1.9 SAFETY INSTRUMENTED SYSTEM

9.3.1.1.1.10 OTHERS

9.3.1.2. AEROSPACE AND DEFENSE

9.3.1.2.1. BY SOLUTION

9.3.1.2.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.3.1.2.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.3.1.2.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.3.1.2.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.3.1.2.1.5 HUMAN MACHINE INTERFACE (HMI)

9.3.1.2.1.6 PLANT ASSET MANAGEMENT (PAM)

9.3.1.2.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.3.1.2.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.3.1.2.1.9 SAFETY INSTRUMENTED SYSTEM

9.3.1.2.1.10 OTHERS

9.3.1.3. SEMICONDUCTORS AND ELECTRONICS

9.3.1.3.1. BY SOLUTION

9.3.1.3.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.3.1.3.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.3.1.3.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.3.1.3.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.3.1.3.1.5 HUMAN MACHINE INTERFACE (HMI)

9.3.1.3.1.6 PLANT ASSET MANAGEMENT (PAM)

9.3.1.3.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.3.1.3.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.3.1.3.1.9 SAFETY INSTRUMENTED SYSTEM

9.3.1.3.1.10 OTHERS

9.3.1.4. MEDICAL DEVICES

9.3.1.4.1. BY SOLUTION

9.3.1.4.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.3.1.4.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.3.1.4.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.3.1.4.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.3.1.4.1.5 HUMAN MACHINE INTERFACE (HMI)

9.3.1.4.1.6 PLANT ASSET MANAGEMENT (PAM)

9.3.1.4.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.3.1.4.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.3.1.4.1.9 SAFETY INSTRUMENTED SYSTEM

9.3.1.4.1.10 OTHERS

9.3.1.5. MACHINE MANUFACTURING

9.3.1.5.1. BY SOLUTION

9.3.1.5.1.1 PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.3.1.5.1.2 MANUFACTURING EXECUTION SYSTEMS (MES)

9.3.1.5.1.3 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.3.1.5.1.4 DISTRIBUTED CONTROL SYSTEMS (DCS)

9.3.1.5.1.5 HUMAN MACHINE INTERFACE (HMI)

9.3.1.5.1.6 PLANT ASSET MANAGEMENT (PAM)

9.3.1.5.1.7 ENTERPRISE RESOURCE PLANNING (ERP)

9.3.1.5.1.8 ELECTRONIC CONTROL UNITS (ECU)

9.3.1.5.1.9 SAFETY INSTRUMENTED SYSTEM

9.3.1.5.1.10 OTHERS

9.3.1.6. OTHERS

9.4 MILITARY

9.4.1 BY SOLUTION

9.4.1.1. PROGRAMMABLE LOGIC CONTROLLERS (PLC)

9.4.1.2. MANUFACTURING EXECUTION SYSTEMS (MES)

9.4.1.3. SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

9.4.1.4. HUMAN MACHINE INTERFACE (HMI)

9.4.1.5. ENTERPRISE RESOURCE PLANNING (ERP)

9.4.1.6. OTHERS

10 GLOBAL FACTORY AUTOMATION MARKET, BY GEOGRAPHY

GLOBAL FACTORY AUTOMATION MARKET, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

10.1 NORTH AMERICA

10.1.1 U.S.

10.1.2 CANADA

10.1.3 MEXICO

10.2 EUROPE

10.2.1 GERMANY

10.2.2 FRANCE

10.2.3 U.K.

10.2.4 ITALY

10.2.5 SPAIN

10.2.6 RUSSIA

10.2.7 TURKEY

10.2.8 BELGIUM

10.2.9 NETHERLANDS

10.2.10 NORWAY

10.2.11 FINLAND

10.2.12 SWITZERLAND

10.2.13 DENMARK

10.2.14 SWEDEN

10.2.15 POLAND

10.2.16 REST OF EUROPE

10.3 ASIA PACIFIC

10.3.1 JAPAN

10.3.2 CHINA

10.3.3 SOUTH KOREA

10.3.4 INDIA

10.3.5 AUSTRALIA

10.3.6 NEW ZEALAND

10.3.7 SINGAPORE

10.3.8 THAILAND

10.3.9 MALAYSIA

10.3.10 INDONESIA

10.3.11 PHILIPPINES

10.3.12 TAIWAN

10.3.13 VIETNAM

10.3.14 REST OF ASIA PACIFIC

10.4 SOUTH AMERICA

10.4.1 BRAZIL

10.4.2 ARGENTINA

10.4.3 REST OF SOUTH AMERICA

10.5 MIDDLE EAST AND AFRICA

10.5.1 SOUTH AFRICA

10.5.2 EGYPT

10.5.3 SAUDI ARABIA

10.5.4 U.A.E

10.5.5 OMAN

10.5.6 BAHRAIN

10.5.7 ISRAEL

10.5.8 KUWAIT

10.5.9 QATAR

10.5.10 REST OF MIDDLE EAST AND AFRICA

10.6 KEY PRIMARY INSIGHTS: BY MAJOR COUNTRIES

11 GLOBAL FACTORY AUTOMATION MARKET,COMPANY LANDSCAPE

11.1 COMPANY SHARE ANALYSIS: GLOBAL

11.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

11.3 COMPANY SHARE ANALYSIS: EUROPE

11.4 COMPANY SHARE ANALYSIS: ASIA PACIFIC

11.5 MERGERS & ACQUISITIONS

11.6 NEW PRODUCT DEVELOPMENT AND APPROVALS

11.7 EXPANSIONS

11.8 REGULATORY CHANGES

11.9 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

12 GLOBAL FACTORY AUTOMATION MARKET, SWOT & DBMR ANALYSIS

13 GLOBAL FACTORY AUTOMATION MARKET, COMPANY PROFILE

13.1 SCHNEIDER ELECTRIC

13.1.1 COMPANY SNAPSHOT

13.1.2 REVENUE ANALYSIS

13.1.3 GEOGRAPHIC PRESENCE

13.1.4 PRODUCT PORTFOLIO

13.1.5 RECENT DEVELOPMENT

13.2 ROCKWELL AUTOMATION, INC.

13.2.1 COMPANY SNAPSHOT

13.2.2 REVENUE ANALYSIS

13.2.3 GEOGRAPHIC PRESENCE

13.2.4 PRODUCT PORTFOLIO

13.2.5 RECENT DEVELOPMENT

13.3 CAPULA LTD

13.3.1 COMPANY SNAPSHOT

13.3.2 REVENUE ANALYSIS

13.3.3 GEOGRAPHIC PRESENCE

13.3.4 PRODUCT PORTFOLIO

13.3.5 RECENT DEVELOPMENT

13.4 ABB

13.4.1 COMPANY SNAPSHOT

13.4.2 REVENUE ANALYSIS

13.4.3 GEOGRAPHIC PRESENCE

13.4.4 PRODUCT PORTFOLIO

13.4.5 RECENT DEVELOPMENT

13.5 SIEMENS

13.5.1 COMPANY SNAPSHOT

13.5.2 REVENUE ANALYSIS

13.5.3 GEOGRAPHIC PRESENCE

13.5.4 PRODUCT PORTFOLIO

13.5.5 RECENT DEVELOPMENT

13.6 OMRON CORPORATION

13.6.1 COMPANY SNAPSHOT

13.6.2 REVENUE ANALYSIS

13.6.3 GEOGRAPHIC PRESENCE

13.6.4 PRODUCT PORTFOLIO

13.6.5 RECENT DEVELOPMENT

13.7 HONEYWELL INTERNATIONAL INC.

13.7.1 COMPANY SNAPSHOT

13.7.2 REVENUE ANALYSIS

13.7.3 GEOGRAPHIC PRESENCE

13.7.4 PRODUCT PORTFOLIO

13.7.5 RECENT DEVELOPMENT

13.8 MITSUBISHI ELECTRIC CORPORATION

13.8.1 COMPANY SNAPSHOT

13.8.2 REVENUE ANALYSIS

13.8.3 GEOGRAPHIC PRESENCE

13.8.4 PRODUCT PORTFOLIO

13.8.5 RECENT DEVELOPMENT

13.9 TE CONNECTIVITY

13.9.1 COMPANY SNAPSHOT

13.9.2 REVENUE ANALYSIS

13.9.3 GEOGRAPHIC PRESENCE

13.9.4 PRODUCT PORTFOLIO

13.9.5 RECENT DEVELOPMENT

13.1 ENDRESS+HAUSER

13.10.1 COMPANY SNAPSHOT

13.10.2 REVENUE ANALYSIS

13.10.3 GEOGRAPHIC PRESENCE

13.10.4 PRODUCT PORTFOLIO

13.10.5 RECENT DEVELOPMENT

13.11 GENERAL ELECTRIC

13.11.1 COMPANY SNAPSHOT

13.11.2 REVENUE ANALYSIS

13.11.3 GEOGRAPHIC PRESENCE

13.11.4 PRODUCT PORTFOLIO

13.11.5 RECENT DEVELOPMENT

13.12 YOKOGAWA ELECTRIC CORPORATION

13.12.1 COMPANY SNAPSHOT

13.12.2 REVENUE ANALYSIS

13.12.3 GEOGRAPHIC PRESENCE

13.12.4 PRODUCT PORTFOLIO

13.12.5 RECENT DEVELOPMENT

13.13 AZBIL CORPORATION

13.13.1 COMPANY SNAPSHOT

13.13.2 REVENUE ANALYSIS

13.13.3 GEOGRAPHIC PRESENCE

13.13.4 PRODUCT PORTFOLIO

13.13.5 RECENT DEVELOPMENT

13.14 WIKA

13.14.1 COMPANY SNAPSHOT

13.14.2 REVENUE ANALYSIS

13.14.3 GEOGRAPHIC PRESENCE

13.14.4 PRODUCT PORTFOLIO

13.14.5 RECENT DEVELOPMENT

13.15 HITACHI, LTD.

13.15.1 COMPANY SNAPSHOT

13.15.2 REVENUE ANALYSIS

13.15.3 GEOGRAPHIC PRESENCE

13.15.4 PRODUCT PORTFOLIO

13.15.5 RECENT DEVELOPMENT

13.16 BOSCH REXROTH AG

13.16.1 COMPANY SNAPSHOT

13.16.2 REVENUE ANALYSIS

13.16.3 GEOGRAPHIC PRESENCE

13.16.4 PRODUCT PORTFOLIO

13.16.5 RECENT DEVELOPMENT

13.17 FUJI ELECTRIC

13.17.1 COMPANY SNAPSHOT

13.17.2 REVENUE ANALYSIS

13.17.3 GEOGRAPHIC PRESENCE

13.17.4 PRODUCT PORTFOLIO

13.17.5 RECENT DEVELOPMENT

13.18 VALMET

13.18.1 COMPANY SNAPSHOT

13.18.2 REVENUE ANALYSIS

13.18.3 GEOGRAPHIC PRESENCE

13.18.4 PRODUCT PORTFOLIO

13.18.5 RECENT DEVELOPMENT

13.19 EMERSON ELECTRIC CO.

13.19.1 COMPANY SNAPSHOT

13.19.2 REVENUE ANALYSIS

13.19.3 GEOGRAPHIC PRESENCE

13.19.4 PRODUCT PORTFOLIO

13.19.5 RECENT DEVELOPMENT

13.2 KROHNE

13.20.1 COMPANY SNAPSHOT

13.20.2 REVENUE ANALYSIS

13.20.3 GEOGRAPHIC PRESENCE

13.20.4 PRODUCT PORTFOLIO

13.20.5 RECENT DEVELOPMENT

13.21 DANFOSS

13.21.1 COMPANY SNAPSHOT

13.21.2 REVENUE ANALYSIS

13.21.3 GEOGRAPHIC PRESENCE

13.21.4 PRODUCT PORTFOLIO

13.21.5 RECENT DEVELOPMENT

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST

14 CONCLUSION

15 QUESTIONNAIRE

16 RELATED REPORTS

17 ABOUT DATA BRIDGE MARKET RESEARCH

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.