Global Fiber Reinforced Composites Market

Market Size in USD Billion

CAGR :

%

USD

114.28 Billion

USD

183.53 Billion

2025

2033

USD

114.28 Billion

USD

183.53 Billion

2025

2033

| 2026 –2033 | |

| USD 114.28 Billion | |

| USD 183.53 Billion | |

|

|

|

|

What is the Global Fiber-Reinforced Composites Market Size and Growth Rate?

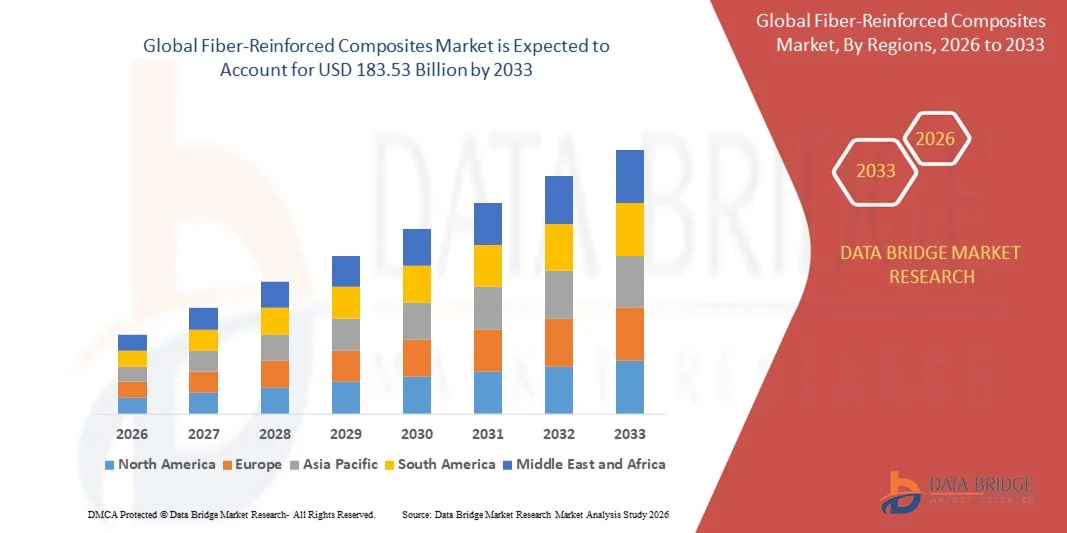

- The global fiber-reinforced composites market size was valued at USD 114.28 billion in 2025 and is expected to reach USD 183.53 billion by 2033, at a CAGR of6.1% during the forecast period

- The rise in the demand for the composites from the transportation, electrical & electronics, wind energy and pipes & tanks industries acts as one of the major factors driving the growth of fiber-reinforced composites market

- The increase in the number of wind energy capacity installations and growing usage of composite pipes in sewage & water management and oil & gas industry accelerate the fiber-reinforced composites market growth

What are the Major Takeaways of Fiber-Reinforced Composites Market?

- The rise in the rate of fiber-reinforced composites adoption in the transportation industry, and the recovery of the U.S. marine industry further influences the fiber-reinforced composites market

- In addition, growing use of composites in the construction & infrastructure industry, expansion of end user industries, rapid industrialization and surge in investment positively affect the fiber-reinforced composites market. Furthermore, increase in demand for these composites from emerging economies extends profitable opportunities to the fiber-reinforced composites market players

- North America dominated the fiber-reinforced composites market with a 39.8% revenue share in 2025, driven by strong demand from aerospace, wind energy, EV manufacturing, marine structures, and large-scale construction activities across the U.S. and Canada

- Asia-Pacific is projected to register the fastest CAGR of 11.2% from 2026 to 2033, driven by rapid industrialization, strong automotive production, expanding wind energy installations, and large-scale construction activities across China, Japan, India, South Korea, and Southeast Asia

- The Polyester segment dominated the market with a 41.2% share in 2025, supported by its low cost, ease of processing, strong mechanical compatibility with glass fibers, and widespread use in construction, marine components, and industrial applications

Report Scope and Fiber-Reinforced Composites Market Segmentation

|

Attributes |

Fiber-Reinforced Composites Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Fiber-Reinforced Composites Market?

Increasing Shift Toward High-Performance, Lightweight, and Multi-Functional Composite Materials

- The fiber-reinforced composites market is witnessing rapid adoption of lightweight, corrosion-resistant, and high-strength composite materials driven by automotive lightweighting, aerospace modernization, and renewable energy projects

- Manufacturers are introducing high-modulus fibers, hybrid composites, and thermoplastic composites that deliver improved durability, recyclability, and faster processing cycles

- Growing demand for energy-efficient, sustainable, and multi-functional materials is accelerating usage across wind turbines, EV components, construction, marine structures, and industrial equipment

- For instance, companies such as PPG Industries, Owens Corning, Jushi Group, Saint-Gobain, and AGY have advanced their composite portfolios with high-strength glass fibers, carbon-glass hybrids, and performance-enhanced resins to support next-generation industrial applications

- Rising need for lightweight structural components, higher fatigue resistance, and improved thermal stability is fueling the shift toward advanced fiber-reinforced composites

- As industries transition toward sustainable and efficient materials, Fiber-Reinforced Composites will remain critical for high-performance engineering, design flexibility, and next-gen manufacturing

What are the Key Drivers of Fiber-Reinforced Composites Market?

- Increasing demand for lightweight, strong, and durable materials to support automotive, aerospace, electronics, construction, and energy sector expansion

- For instance, in 2025, companies such as Saint-Gobain, Celanese, Owens Corning, and Jiangsu Jiuding expanded their composite offerings with high-tensile fibers, thermoplastic matrices, and improved resin systems to enhance strength-to-weight ratios

- Growing adoption of EVs, wind energy installations, modular construction, and industrial automation is pushing demand for fiber-reinforced composite components across the U.S., Europe, and Asia-Pacific

- Advancements in fiber manufacturing, resin chemistry, compression molding, pultrusion, and automated lay-up technologies have improved productivity and material performance

- Rising use of high-modulus fibers, impact-resistant laminates, and corrosion-proof solutions is creating demand for engineered composite systems

- Supported by increasing investments in sustainable materials, lightweight manufacturing, and structural innovation, the Fiber-Reinforced Composites market is expected to experience strong long-term growth

Which Factor is Challenging the Growth of the Fiber-Reinforced Composites Market?

- High costs associated with premium fibers (carbon, aramid), advanced resin systems, and automated production equipment limit adoption among small manufacturers and price-sensitive end-users

- For instance, during 2024–2025, fluctuations in raw material prices (resins, fibers), supply-chain disruptions, and higher energy costs increased manufacturing expenses for several global composite producers

- Complexity in design optimization, structural analysis, and multi-material integration increases the need for skilled engineers and specialized manufacturing expertise

- Limited awareness in emerging markets regarding composite processing technologies, performance benefits, and life-cycle advantages slows adoption

- Competition from metals, low-cost plastics, and hybrid material alternatives creates price pressure and challenges differentiation

- To address these issues, companies are focusing on cost-optimized fiber systems, recyclable composites, automated production, and enhanced R&D to increase global adoption of Fiber-Reinforced Composites

How is the Fiber-Reinforced Composites Market Segmented?

The market is segmented on the basis of resin type, manufacturing process, and end-use industry.

- By Resin Type

The fiber-reinforced composites market is segmented into Polyester, Vinyl Ester, Epoxy, Polyurethane, Thermoplastic, and Others. The Polyester segment dominated the market with a 41.2% share in 2025, supported by its low cost, ease of processing, strong mechanical compatibility with glass fibers, and widespread use in construction, marine components, and industrial applications. Polyester resins offer excellent corrosion resistance, making them ideal for pipes, tanks, panels, and infrastructure parts.

The Thermoplastic segment is expected to grow at the fastest CAGR from 2026 to 2033, driven by rising demand for recyclable, impact-resistant, and high-toughness composite materials. Thermoplastic composites support rapid manufacturing cycles, lightweighting, and high structural performance, fueling adoption in automotive, aerospace, and consumer electronics. Increasing focus on sustainability, high-volume production, and improved energy absorption capabilities further accelerates thermoplastic penetration across global composite manufacturing.

- By Manufacturing Process

The market is segmented into Compression & Injection Molding, Layup, Filament Winding, Pultrusion, Resin Transfer Molding (RTM), and Others. The Compression & Injection Molding segment dominated the market with a 33.7% share in 2025, driven by its suitability for mass production of lightweight, high-strength composite parts used in automotive, electronics housings, consumer goods, and industrial components. The process offers high repeatability, shorter cycle times, and strong compatibility with both thermoset and thermoplastic resins.

The Resin Transfer Molding (RTM) segment is projected to grow at the fastest CAGR from 2026 to 2033, supported by increasing demand for precision-engineered, high-quality parts in aerospace, EVs, and industrial equipment. RTM enables tighter dimensional control, smoother surface finishes, and reduced waste, making it ideal for producing complex structural components. Growing deployment of automated RTM systems further enhances scalability and performance across advanced composite manufacturing.

- By End-Use Industry

The fiber-reinforced composites market is segmented into Wind Energy, Electrical & Electronics, Transportation, Pipes & Tanks, Construction & Infrastructure, Marine, Aerospace & Defense, and Others. The Transportation segment dominated the market with a 29.8% share in 2025, driven by rising demand for lightweight materials in EVs, rail components, commercial vehicles, and structural automotive parts. Fiber composites help improve fuel efficiency, enhance crash performance, and reduce lifecycle maintenance.

The Wind Energy segment is expected to grow at the fastest CAGR from 2026 to 2033, supported by global expansion of wind turbine installations and increasing rotor blade length requirements. Fiber-reinforced composites—especially glass and carbon fiber-based systems—offer exceptional fatigue resistance, stiffness, and weather durability essential for next-generation turbine blades. Increasing renewable energy investments across the U.S., Europe, China, and India further accelerate composite adoption in wind energy infrastructure.

Which Region Holds the Largest Share of the Fiber-Reinforced Composites Market?

- North America dominated the fiber-reinforced composites market with a 39.8% revenue share in 2025, driven by strong demand from aerospace, wind energy, EV manufacturing, marine structures, and large-scale construction activities across the U.S. and Canada. The region’s focus on lightweight materials, corrosion-resistant composites, and high-performance fiber systems supports widespread adoption across both industrial and defence applications

- Leading companies in North America are investing in advanced glass and carbon fiber technologies, high-modulus composites, and automated molding processes to support next-generation aircraft, automotive platforms, renewable energy systems, and infrastructure. Growing investments in sustainability, composite recycling, and high-strength thermoplastic systems further strengthen regional dominance

- High engineering capabilities, mature manufacturing infrastructure, and strong aerospace and automotive clusters reinforce North America’s leadership position in the global Fiber-Reinforced Composites market

U.S. Fiber-Reinforced Composites Market Insight

The U.S. is the largest contributor to the North American market, supported by extensive adoption of fiber-reinforced composites in aerospace, defense, EV manufacturing, wind turbine production, and high-performance industrial applications. Advanced material research programs, strong OEM presence, and growing investments in lightweight structural components accelerate composite usage across aircraft parts, automotive body panels, blades, pipes, tanks, and marine systems. Increasing demand for energy-efficient materials, high-strength laminates, and durable corrosion-resistant solutions further strengthens the U.S. market outlook.

Canada Fiber-Reinforced Composites Market Insight

Canada contributes significantly to regional demand due to its expanding wind energy sector, rising construction activities, and growing use of composite materials in transportation, marine components, and industrial infrastructure. Universities, R&D centers, and manufacturing clusters are increasingly adopting fiber-reinforced composites for advanced structural applications. Government-supported clean energy programs, aerospace investments, and focus on sustainable materials continue to enhance composite adoption across the country.

Asia-Pacific Fiber-Reinforced Composites Market

Asia-Pacific is projected to register the fastest CAGR of 11.2% from 2026 to 2033, driven by rapid industrialization, strong automotive production, expanding wind energy installations, and large-scale construction activities across China, Japan, India, South Korea, and Southeast Asia. High-volume manufacturing of composite parts, rising demand for lightweight vehicles, and strong growth in marine, electronics, and renewable energy sectors are driving regional market expansion. Increasing investments in carbon fiber production, advanced molding processes, and large composite facilities further accelerate market adoption.

China Fiber-Reinforced Composites Market Insight

China is the largest contributor to the Asia-Pacific region, supported by massive manufacturing capacity, rapid expansion of wind energy projects, and strong demand for composites in automotive, electronics, marine, and industrial applications. Government-backed infrastructure programs and large composite blade manufacturing operations drive significant consumption of glass and carbon fibers. Competitive costs and advanced production capabilities further strengthen China’s position as a global composite leader.

Japan Fiber-Reinforced Composites Market Insight

Japan shows steady growth driven by advanced automotive engineering, aerospace materials development, and strong emphasis on high-quality composite components. The country’s leadership in precision manufacturing, robotics, and high-performance industrial equipment drives demand for reliable, lightweight, and high-modulus fiber-reinforced materials. Continuous R&D in carbon fiber technologies further enhances Japan’s market footprint.

India Fiber-Reinforced Composites Market Insight

India is emerging as a rapidly growing market, supported by infrastructure development, renewable energy expansions, rising automotive production, and government-backed manufacturing initiatives. Increasing adoption of fiber composites in wind blades, railway components, pipes, tanks, and lightweight automotive parts is strengthening market penetration. Growing industrialization and investments in material innovation further boost demand.

South Korea Fiber-Reinforced Composites Market Insight

South Korea contributes strongly through its advanced automotive, electronics, defense, and shipbuilding industries. Increasing development of high-performance vehicles, marine vessels, and renewable energy systems drives demand for high-strength, lightweight, and corrosion-resistant composites. Continuous investments in automation, carbon fiber production, and advanced molding technologies support long-term industry expansion.

Which are the Top Companies in Fiber-Reinforced Composites Market?

The fiber-reinforced composites industry is primarily led by well-established companies, including:

- PPG Industries Inc. (U.S.)

- Owens Corning (U.S.)

- Johns Manville (U.S.)

- Yuntianhua Group Co. Ltd. (China)

- Jushi Group (China)

- Saint-Gobain (France)

- ASAHI FIBER GLASS Co. Ltd. (Japan)

- Nippon Sheet Glass Co. Ltd. (Japan)

- AGY (U.S.)

- CTG Group (China)

- Nitto Boseki Co. Ltd. (Japan)

- Braj Binani Group (India)

- China Beihai Fiberglass Co. Ltd. (China)

- BGF Industries Inc. (U.S.)

- SAERTEX GmbH & Co. KG (Germany)

- Jiangsu Jiuding New Materials Co. Ltd. (China)

- Celanese Corporation (U.S.)

- Quantum Composites (U.S.)

- Reliance Industries Limited (India)

- PFG FIBER GLASS CORPORATION (Taiwan)

- Advanced Composites Inc. (U.S.)

What are the Recent Developments in Global Fiber-Reinforced Composites Market?

- In May 2025, Hexcel and Specialty Materials jointly developed a next-generation carbon-fiber composite that integrates boron and carbon fibers using Hexcel’s advanced resin technology, enhancing overall structural performance. This innovation strengthens both companies’ portfolios in high-strength composite materials

- In May 2024, Hexcel Corporation entered a 10-year sustainability-focused agreement with Fairmat to recycle carbon fiber composite materials, supported by Fairmat’s newly opened large-scale recycling facility near Hexcel’s Salt Lake City operations. This long-term collaboration reinforces their commitment to circular composite material management

- In December 2024, Toray Advanced Composites acquired the assets of Gordon Plastics to expand its production capacity for continuous fiber-reinforced thermoplastic tapes, improving manufacturing efficiency and output. This acquisition supports Toray’s strategic goal of strengthening its global thermoplastic composites capabilities

- In October 2023, Mitsubishi Chemical Group Corporation completed the acquisition of CPC, an Italian manufacturer specializing in carbon fiber reinforced plastic (CFRP) automotive components, broadening its capabilities within the composite supply chain. This strategic move enhances Mitsubishi Chemical’s competitive presence in advanced carbon fiber automotive applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Fiber Reinforced Composites Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Fiber Reinforced Composites Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Fiber Reinforced Composites Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.