Global Flame Retardant Masterbatch Market

Market Size in USD Billion

CAGR :

%

USD

2.60 Billion

USD

5.45 Billion

2024

2032

USD

2.60 Billion

USD

5.45 Billion

2024

2032

| 2025 –2032 | |

| USD 2.60 Billion | |

| USD 5.45 Billion | |

|

|

|

|

Flame Retardant Masterbatch Market Size

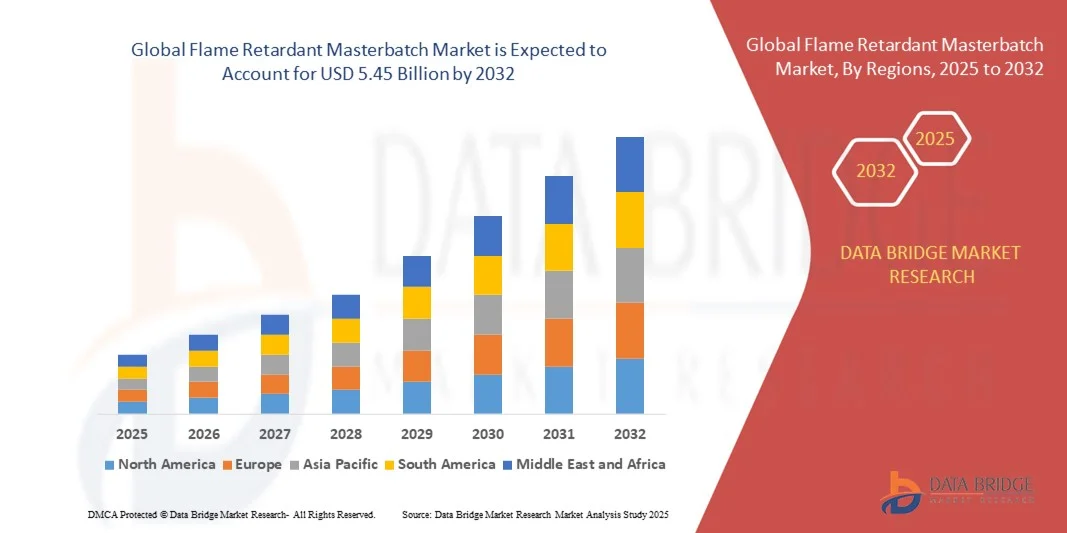

- The global flame retardant masterbatch market size was valued at USD 2.60 billion in 2024 and is expected to reach USD 5.45 billion by 2032, at a CAGR of 9.70% during the forecast period

- The market growth is largely fuelled by the increasing demand for fire-resistant plastics across industries such as automotive, construction, and electronics

- Rising safety regulations and the growing use of lightweight polymer materials in manufacturing applications are further supporting market expansion

Flame Retardant Masterbatch Market Analysis

- The market is witnessing strong growth due to advancements in polymer compounding technologies and increasing emphasis on product safety standards

- The rising adoption of flame retardant masterbatches in electrical and electronic applications for insulation and casing materials is boosting market demand

- Asia-Pacific dominated the flame retardant masterbatch market with the largest revenue share of 43.12% in 2024, driven by rapid industrialization, expansion of the manufacturing sector, and increasing demand from the construction and automotive industries

- North America region is expected to witness the highest growth rate in the global flame retardant masterbatch market, driven by technological advancements, stringent safety standards, and expanding demand from automotive and consumer electronics industries

- The Brominated Chlorinated segment held the largest market revenue share in 2024, driven by its superior flame resistance and wide usage in electrical, electronics, and construction applications. These compounds are preferred for their cost efficiency and effectiveness at low loadings, making them ideal for high-performance plastics and polymer systems

Report Scope and Flame Retardant Masterbatch Market Segmentation

|

Attributes |

Flame Retardant Masterbatch Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Flame Retardant Masterbatch Market Trends

Growing Demand For Environmentally Friendly And Halogen-Free Flame Retardants

- The global market is witnessing a strong shift toward halogen-free flame retardant masterbatches, driven by rising environmental regulations and the need for safer materials in end-use applications. These formulations reduce toxic emissions during combustion and comply with international safety standards, making them ideal for sustainable manufacturing practices across industries. Increasing sustainability commitments among manufacturers are further accelerating investments in greener additive technologies

- Growing awareness about the health hazards associated with halogenated compounds is encouraging manufacturers to invest in phosphorus- and mineral-based alternatives. These eco-friendly solutions are being rapidly adopted in automotive, construction, and electronics applications to meet green compliance requirements. The growing demand for recyclable and non-toxic materials is also propelling partnerships between additive producers and polymer compounders to develop customized halogen-free solutions

- The transition toward halogen-free solutions is further supported by innovation in polymer compatibility and thermal stability. This enables improved flame resistance without compromising material performance, supporting their integration into advanced plastic systems. R&D efforts are increasingly focused on developing multifunctional masterbatches that enhance both safety and material durability, promoting their usage in next-generation engineering plastics

- For instance, in 2023, several European polymer companies introduced halogen-free flame retardant masterbatches tailored for automotive interiors and electronic housings, enhancing fire safety and recyclability. These innovations align with the EU’s Green Deal objectives and circular economy initiatives, encouraging OEMs to adopt eco-friendly components. The resulting shift has strengthened Europe’s leadership position in sustainable polymer innovation

- While eco-friendly alternatives are gaining traction, their relatively high cost and formulation complexity continue to challenge widespread adoption. Ongoing R&D and process optimization are expected to lower production costs and enhance global market penetration. The establishment of collaborative research centers and government-funded sustainability programs is expected to drive large-scale commercialization in the coming years

Flame Retardant Masterbatch Market Dynamics

Driver

Increasing Safety Regulations Across Construction, Automotive, And Electrical Industries

- The rising stringency of fire safety regulations in industries such as construction, automotive, and electronics is a major factor driving market growth. Governments worldwide are mandating the use of flame retardant materials to enhance product safety and minimize fire-related risks. This trend is strengthening global demand for compliant and high-performance flame retardant solutions that ensure safety without compromising quality

- Manufacturers are incorporating flame retardant masterbatches into polymers used for building materials, vehicle components, and consumer electronics to comply with global standards such as UL 94 and REACH. This regulatory push has significantly expanded product adoption in both developed and emerging markets. Furthermore, partnerships with certification agencies are helping producers streamline compliance and expand their product portfolios globally

- The growing demand for lightweight, durable, and flame-resistant plastics in electric vehicles and infrastructure projects further stimulates the market. Flame retardant masterbatches ensure compliance while maintaining mechanical integrity and design flexibility. As the EV industry grows, the use of fire-safe polymer systems in batteries, charging units, and interiors is creating new growth avenues for manufacturers

- For instance, in 2023, automakers in the U.S. and Europe adopted advanced flame retardant masterbatches in EV battery housings and wire coatings to meet enhanced safety norms. These developments highlight the increasing alignment between safety standards and material innovation in the mobility sector. The initiative also sets a benchmark for future integration of sustainable fire-retardant solutions in electric vehicles

- While regulations are propelling demand, continuous material innovation and testing are essential to balance flame resistance, mechanical performance, and environmental safety. Collaborative R&D programs between industry leaders and academic institutions are playing a crucial role in enhancing material functionality. As global safety benchmarks evolve, these initiatives will help sustain long-term industry growth and standardization

Restraint/Challenge

High Production Costs And Compatibility Issues With Polymers

- The development of high-performance flame retardant masterbatches requires costly additives, specialized equipment, and complex compounding processes. This results in higher production expenses, limiting adoption among price-sensitive manufacturers, particularly in developing economies. Moreover, fluctuating raw material prices further impact production margins and supply consistency across markets

- Compatibility challenges between flame retardant additives and various polymer matrices can lead to reduced mechanical strength, color instability, and processing difficulties. These technical limitations often restrict product use in specific applications. Addressing these issues requires advanced formulation engineering and testing, which increases development time and cost for manufacturers

- Smaller manufacturers face barriers due to the lack of access to advanced formulations and testing infrastructure, which hinders innovation and scalability in the global market. Limited R&D funding also restricts experimentation with novel additive chemistries, slowing down the commercialization of next-generation masterbatches. Strategic collaborations and government grants are therefore vital to bridge this technological gap

- For instance, in 2023, several Asian compounders reported increased production costs after transitioning to non-halogenated formulations, citing additive price volatility and blending challenges. The lack of uniform standards and technical expertise further delayed product certification and large-scale adoption. These challenges underscore the need for standardized testing and regional knowledge-sharing initiatives

- Addressing cost efficiency through raw material optimization and enhanced additive dispersion technologies will be crucial for overcoming these challenges and sustaining market growth. The expansion of localized manufacturing facilities and investment in automation can further reduce operational costs. This, coupled with stronger supply chain integration, will enable manufacturers to deliver high-performance, cost-effective flame retardant solutions globally

Flame Retardant Masterbatch Market Scope

The flame retardant masterbatch market is segmented on the basis of product, resin, and end users.

- By Product

On the basis of product, the flame retardant masterbatch market is segmented into Brominated Chlorinated, Organophosphorus, Antimony Oxides, Alumina Trihydrate, and Others. The Brominated Chlorinated segment held the largest market revenue share in 2024, driven by its superior flame resistance and wide usage in electrical, electronics, and construction applications. These compounds are preferred for their cost efficiency and effectiveness at low loadings, making them ideal for high-performance plastics and polymer systems.

The Organophosphorus segment is expected to witness the fastest growth rate from 2025 to 2032, fuelled by increasing demand for halogen-free solutions and growing regulatory restrictions on brominated additives. These compounds offer excellent thermal stability and low toxicity, aligning with global sustainability standards and driving their adoption across automotive and consumer goods industries.

- By Resin

On the basis of resin, the market is segmented into PE, PP, ABS, PS, PC, and Others. The PP segment held the largest revenue share in 2024, attributed to its extensive use in automotive parts, electrical housings, and packaging applications due to its durability and processability. Flame retardant masterbatches in PP provide an optimal balance of fire safety and mechanical strength, making it a preferred material for diverse industrial uses.

The PC segment is expected to register the fastest growth rate from 2025 to 2032, driven by its high heat resistance and transparency, which make it suitable for electronic components, lighting, and optical applications. The rising use of PC in lightweight and high-strength electrical devices is further boosting demand for flame retardant masterbatches compatible with this resin type.

- By End Users

On the basis of end users, the market is segmented into Automotive, Agriculture, Building and Construction, Electrical and Electronics, Consumer Products, Packaging, and Others. The Electrical and Electronics segment held the largest market revenue share in 2024, supported by stringent safety regulations and the need for fire-safe materials in wiring, circuit boards, and casings. Manufacturers are increasingly integrating flame retardant masterbatches to meet compliance standards and enhance product reliability.

The Automotive segment is expected to register the fastest growth rate from 2025 to 2032, driven by the rising adoption of lightweight, flame-resistant polymers in electric vehicle components and interior systems. The ongoing electrification trend and focus on passenger safety are further stimulating product demand across global automotive manufacturing hubs.

Flame Retardant Masterbatch Market Regional Analysis

- Asia-Pacific dominated the flame retardant masterbatch market with the largest revenue share of 43.12% in 2024, driven by rapid industrialization, expansion of the manufacturing sector, and increasing demand from the construction and automotive industries

- The region’s strong presence of plastic and polymer manufacturers, coupled with rising safety regulations and government emphasis on fire protection standards, supports large-scale product adoption

- Moreover, the availability of low-cost raw materials, expanding production capacities, and growing investments in sustainable flame-retardant technologies further strengthen Asia-Pacific’s market leadership

China Flame Retardant Masterbatch Market Insight

The China flame retardant masterbatch market captured the largest revenue share in 2024 within the Asia-Pacific region, driven by robust demand from the electrical, construction, and automotive industries. The country’s strong manufacturing base and emphasis on safety compliance across consumer products have accelerated product adoption. In addition, China’s growing investments in halogen-free and eco-friendly formulations are reinforcing its dominance, supported by ongoing technological innovation and favorable government initiatives promoting sustainable production practices.

Japan Flame Retardant Masterbatch Market Insight

The Japan flame retardant masterbatch market is expected to witness a notable growth rate from 2025 to 2032, driven by the country’s strong technological foundation and emphasis on product safety. Japan’s well-established automotive and electronics industries are key consumers, adopting advanced flame retardant solutions that comply with stringent fire safety and environmental regulations. In addition, the growing demand for lightweight, high-performance materials in electric vehicles and smart devices is promoting the use of halogen-free masterbatches. Continuous innovation in material science and the focus on sustainable manufacturing practices further support market growth in Japan.

North America Flame Retardant Masterbatch Market Insight

The North America flame retardant masterbatch market is projected to experience steady growth from 2025 to 2032, fuelled by stringent fire safety regulations and growing awareness regarding material safety in critical industries. The widespread use of flame-retardant materials in electronics, automotive interiors, and building applications continues to support steady demand. The presence of key players focusing on product innovation, sustainability, and compliance with environmental standards further enhances market growth across the region.

U.S. Flame Retardant Masterbatch Market Insight

The U.S. flame retardant masterbatch market is projected to experience steady growth from 2025 to 2032, supported by increasing application in the construction and transportation sectors. Rising demand for lightweight yet fire-safe materials, particularly in electric vehicles and infrastructure projects, has spurred adoption. Furthermore, the push toward halogen-free, recyclable, and high-performance masterbatches aligns with the country’s growing emphasis on sustainability and regulatory compliance. Continuous innovation in polymer compatibility and additive dispersion is also contributing to market expansion.

Europe Flame Retardant Masterbatch Market Insight

The Europe flame retardant masterbatch market is projected to witness considerable growth from 2025 to 2032, driven by strict environmental regulations and safety standards. Countries across the region are transitioning toward halogen-free and eco-friendly alternatives in response to REACH and RoHS directives. The growing adoption of sustainable plastic materials in construction, automotive, and electronics sectors underpins steady market expansion. Furthermore, technological advancements in polymer formulations and recycling-friendly flame retardant systems are enhancing product adoption across European industries.

Germany Flame Retardant Masterbatch Market Insight

The Germany flame retardant masterbatch market is expected to witness the fastest growth rate in Europe from 2025 to 2032, fuelled by its robust industrial base and strong focus on innovation and environmental safety. The country’s automotive and electrical sectors are major contributors to market demand, emphasizing non-toxic, high-performance materials. In addition, the growing integration of flame retardant solutions into recyclable and sustainable polymers supports Germany’s broader commitment to green manufacturing practices, reinforcing its position as a key European market.

U.K. Flame Retardant Masterbatch Market Insight

The U.K. flame retardant masterbatch market is projected to experience steady growth from 2025 to 2032, fuelled by rising fire safety awareness and the implementation of strict regulatory standards in construction and consumer goods. The expanding adoption of eco-friendly and recyclable materials across the country’s packaging, automotive, and electronics sectors is driving demand for halogen-free and low-smoke formulations. Furthermore, the U.K.’s growing focus on sustainability, coupled with government initiatives to promote green manufacturing, is encouraging domestic producers to develop innovative flame retardant masterbatches that align with environmental goals.

Flame Retardant Masterbatch Market Share

The Flame Retardant Masterbatch industry is primarily led by well-established companies, including:

• BASF SE (Germany)

• Ampacet Corporation (U.S.)

• Clariant (Switzerland)

• Cromex S/A (Brazil)

• DIC Corporation (Japan)

• Dongguan GreenTech Plastics Co., Ltd. (China)

• Dover Chemical Corporation (U.S.)

• Ferroplast (Italy)

• LANXESS (Germany)

• Nouryon - Chamber of Commerce (Netherlands)

• PPM, Tous droits réservés (France)

• Tosaf (Israel)

• Americhem (U.S.)

• Polytechs (France)

• Albemarle Corporation (U.S.)

• Akzo Nobel N.V. (Netherlands)

• Dow-DuPont (U.S.)

Latest Developments in Global Flame Retardant Masterbatch Market

- In August 2025, BASF SE (Germany) introduced a new range of bio-based flame retardant masterbatches targeted at the automotive industry. This product development focuses on integrating sustainable materials to reduce environmental impact while maintaining high performance standards. The initiative strengthens BASF’s commitment to eco-friendly innovation and positions the company to meet rising global demand for greener manufacturing solutions. This launch is expected to enhance BASF’s market presence and influence the industry’s transition toward sustainable flame retardant technologies

- In July 2025, Clariant AG (Switzerland) expanded its manufacturing footprint in Asia with the establishment of a new production facility for flame retardant masterbatches. The expansion aims to meet growing regional demand for advanced fire safety materials and improve operational efficiency. This move allows Clariant to reduce lead times, enhance supply chain reliability, and strengthen its competitive position in key Asian markets. The facility’s operation is anticipated to boost production capacity and support the company’s long-term growth strategy

- In September 2025, SABIC (Saudi Arabia) entered a strategic partnership with a technology firm to co-develop AI-enhanced flame retardant materials. The collaboration focuses on leveraging artificial intelligence to accelerate product innovation, optimize formulations, and tailor performance to industry-specific needs. This partnership is set to improve R&D efficiency and responsiveness to market trends, enabling SABIC to gain a technological edge. The initiative reinforces SABIC’s role as a leader in advanced material solutions within the global flame retardant market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Flame Retardant Masterbatch Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Flame Retardant Masterbatch Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Flame Retardant Masterbatch Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.