Global Food And Beverage Mechanical Seals Market

Market Size in USD Billion

CAGR :

%

USD

1.34 Billion

USD

2.11 Billion

2024

2032

USD

1.34 Billion

USD

2.11 Billion

2024

2032

| 2025 –2032 | |

| USD 1.34 Billion | |

| USD 2.11 Billion | |

|

|

|

|

Global Food and Beverage Mechanical Seals Market Size

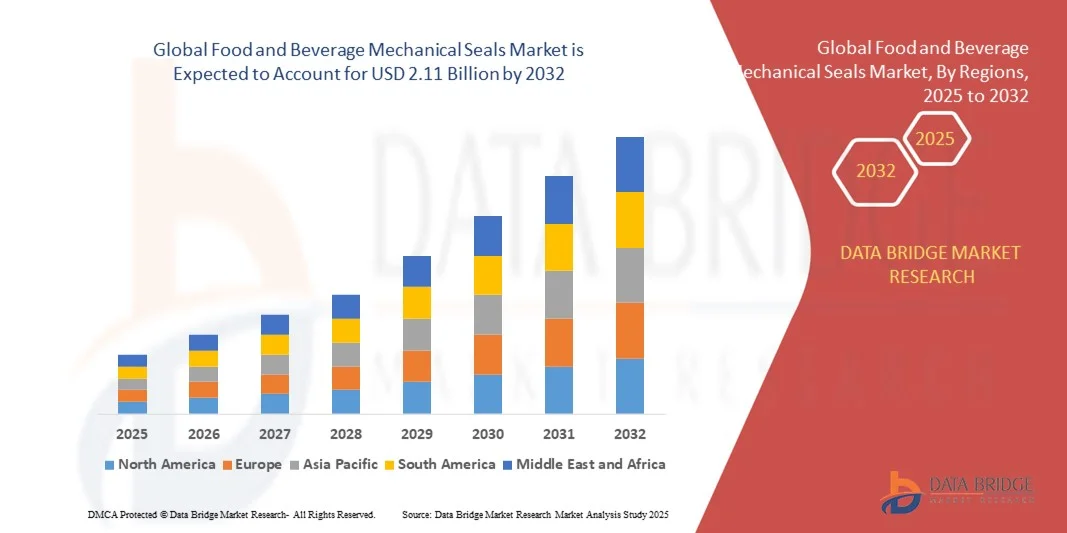

- The global Food and Beverage Mechanical Seals Market size was valued at USD 1.34 billion in 2024 and is expected to reach USD 2.11 billion by 2032, at a CAGR of 5.80% during the forecast period.

- The market growth is primarily driven by the increasing demand for durable and reliable sealing solutions in the food and beverage industry, coupled with technological advancements in mechanical seal designs that enhance efficiency, hygiene, and safety.

- Additionally, stringent regulatory standards for food safety, along with rising consumer demand for high-quality and contamination-free products, are pushing manufacturers to adopt advanced sealing solutions. These factors are collectively accelerating the adoption of mechanical seals, thereby significantly boosting the market’s growth.

Global Food and Beverage Mechanical Seals Market Analysis

- Mechanical seals, used to prevent leakage in pumps and rotating equipment, are increasingly vital components in the food and beverage industry due to their ability to ensure product safety, maintain hygiene standards, and improve operational efficiency in both processing and packaging operations.

- The rising demand for mechanical seals is primarily driven by stringent food safety regulations, the need for contamination-free production, and the growing adoption of automated and high-capacity processing equipment.

- Europe dominated the Global Food and Beverage Mechanical Seals Market with the largest revenue share of 34.5% in 2024, characterized by early adoption of advanced manufacturing technologies, strong regulatory frameworks for food safety, and the presence of key industry players, with the U.S. experiencing substantial growth in mechanical seal installations across dairy, beverage, and processed food facilities, driven by innovations in durable, corrosion-resistant, and hygienic seal designs.

- Asia-Pacific is expected to be the fastest-growing region in the Global Food and Beverage Mechanical Seals Market during the forecast period due to increasing industrialization, expanding food processing capacities, and rising demand for packaged and processed food products.

- The Face Materials segment dominated the market with the largest revenue share of 45.6% in 2024, driven by its critical role in providing wear resistance, chemical compatibility, and hygienic sealing in food and beverage processing applications.

Report Scope and Global Food and Beverage Mechanical Seals Market Segmentation

|

Attributes |

Food and Beverage Mechanical Seals Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Food and Beverage Mechanical Seals Market Trends

Enhanced Efficiency Through Smart and Automated Sealing Solutions

- A significant and accelerating trend in the global Food and Beverage Mechanical Seals Market is the increasing integration of smart and automated monitoring technologies, including sensors and predictive maintenance systems. These innovations are significantly enhancing operational efficiency, reducing downtime, and ensuring consistent product quality.

- For instance, advanced mechanical seals equipped with real-time monitoring sensors can detect leakage, vibration, or temperature fluctuations, allowing maintenance teams to intervene before critical failures occur. Similarly, some high-end cartridge seals feature automated lubrication and condition monitoring, optimizing performance in continuous production environments.

- AI and predictive analytics integration in mechanical seals enables features such as anticipating wear patterns, suggesting preventive maintenance schedules, and generating alerts for abnormal operating conditions. For example, smart seals from John Crane and Flowserve can monitor shaft conditions and alert operators to potential seal degradation, preventing contamination or costly downtime. Furthermore, automated adjustments improve reliability and reduce the need for manual inspection.

- The seamless integration of mechanical seals with broader process automation systems facilitates centralized monitoring and control of pumps, mixers, and other rotating equipment. Through a single interface, operators can track seal health alongside production parameters, energy consumption, and product quality metrics, creating a more efficient and automated manufacturing environment.

- This trend toward more intelligent, connected, and self-monitoring sealing solutions is fundamentally reshaping expectations for operational reliability in the food and beverage industry. Consequently, companies such as EagleBurgmann and AESSEAL are developing smart mechanical seals with predictive maintenance features, automated lubrication systems, and compatibility with industrial IoT platforms.

- The demand for mechanical seals offering integrated monitoring, AI-driven predictive maintenance, and automated functionality is growing rapidly across both food and beverage processing and packaging sectors, as manufacturers increasingly prioritize efficiency, hygiene, and uninterrupted production.

Global Food and Beverage Mechanical Seals Market Dynamics

Driver

Growing Need Due to Stringent Food Safety Standards and Process Reliability

- The increasing demand for contamination-free production and adherence to stringent food safety regulations, coupled with the growing adoption of automated and high-capacity processing equipment, is a significant driver for the heightened demand for advanced mechanical seals.

- For instance, in 2024, John Crane launched next-generation mechanical seals with integrated real-time monitoring sensors, designed to detect leaks and abnormal operating conditions in food and beverage plants. Such innovations by key companies are expected to drive the mechanical seals market growth during the forecast period.

- As manufacturers become more aware of the risks of product contamination, spoilage, and production downtime, mechanical seals offer advanced features such as hygienic designs, wear-resistant materials, and real-time condition monitoring, providing a compelling upgrade over conventional sealing solutions.

- Furthermore, the increasing automation of food and beverage processing lines and the growing focus on operational efficiency are making advanced mechanical seals an integral component of modern processing systems, ensuring seamless integration with pumps, mixers, and other critical equipment.

- The reliability of high-performance seals, reduced maintenance requirements, and the ability to maintain continuous production with minimal risk of leakage or contamination are key factors propelling the adoption of mechanical seals across both small-scale and large-scale food and beverage facilities. The trend towards predictive maintenance and smart factory implementations further contributes to market growth.

Restraint/Challenge

Concerns Regarding Equipment Downtime and High Initial Costs

- Concerns surrounding equipment downtime, maintenance complexity, and high initial investment costs pose significant challenges to broader market penetration for advanced mechanical seals. As high-performance seals often require specialized installation and monitoring, some manufacturers are hesitant to adopt them.

- For instance, reports of production stoppages due to improper seal installation or failure in high-pressure processing environments have made some companies cautious about upgrading from conventional sealing solutions.

- Addressing these challenges through robust training programs, simplified installation designs, and predictive maintenance technologies is crucial for building manufacturer confidence. Companies such as Flowserve and AESSEAL emphasize ease of integration, durability, and condition monitoring features to reassure potential buyers.

- Additionally, the relatively high initial cost of premium mechanical seals compared to standard seals can be a barrier to adoption for cost-sensitive producers, particularly in emerging markets or small-scale operations. While modular and cartridge seal designs have become more accessible, advanced features such as smart monitoring or corrosion-resistant coatings often come at a premium.

- Overcoming these challenges through enhanced operator training, cost-effective design innovations, and scalable seal solutions will be vital for sustained market growth in the global food and beverage mechanical seals industry.

Global Food and Beverage Mechanical Seals Market Scope

Food and beverage mechanical seals market is segmented on the basis of type, application, design, product..

- By Type

On the basis of type, the Global Food and Beverage Mechanical Seals Market is segmented into Metals, Face Materials, Elastomers, and Other Types. The Face Materials segment dominated the market with the largest revenue share of 45.6% in 2024, driven by its critical role in providing wear resistance, chemical compatibility, and hygienic sealing in food and beverage processing applications. Face materials such as carbon, ceramic, and silicon carbide are preferred for their durability and ability to maintain seal integrity under high temperatures and pressures.

The Elastomers segment is anticipated to witness the fastest growth rate of 22.1% from 2025 to 2032, fueled by increasing demand for flexible, leak-proof sealing solutions compatible with diverse process fluids. Elastomer seals provide excellent elasticity and adaptability, making them suitable for pumps, mixers, and valves across bakery, dairy, and beverage production lines. The combination of durability and adaptability positions these materials as key enablers for modern, hygienic food processing.

- By Application

On the basis of application, the Global Food and Beverage Mechanical Seals Market is segmented into Bakery and Confectionery, Meat, Poultry, and Seafood, Dairy Products, Alcoholic Beverages, Non-Alcoholic Beverages, and Others. The Dairy Products segment dominated the market with the largest revenue share of 38.4% in 2024, driven by the stringent hygiene and contamination-free requirements in milk, yogurt, and cheese processing. Mechanical seals in dairy applications are critical to preventing leakage, ensuring food safety, and maintaining continuous production.

The Non-Alcoholic Beverages segment is expected to witness the fastest CAGR of 23.0% from 2025 to 2032, fueled by the booming demand for bottled water, juices, and soft drinks in emerging markets. The growth is supported by increasing automation, higher production capacity, and the need for reliable sealing solutions that maintain product integrity and extend shelf life.

- By Design

On the basis of design, the Global Food and Beverage Mechanical Seals Market is segmented into Balanced and Unbalanced Mechanical Seals, Single Spring and Multiple Spring Mechanical Seals, and Pusher and Non-Pusher Type Mechanical Seals. The Balanced Mechanical Seals segment dominated the market with the largest revenue share of 42.7% in 2024, owing to their ability to handle higher pressures and reduce face wear, making them ideal for heavy-duty food processing equipment.

The Multiple Spring Mechanical Seals segment is projected to witness the fastest CAGR of 21.8% from 2025 to 2032, driven by growing demand for robust, reliable sealing solutions that maintain consistent performance under varying operational conditions. These designs allow for better load distribution and durability, especially in pumps and mixers handling viscous or abrasive food products, ensuring minimal maintenance and enhanced operational efficiency in high-volume production facilities.

- By Product

On the basis of product, the Global Food and Beverage Mechanical Seals Market is segmented into Axial Seal, Bi-Directional Seal, Diaphragm, Dynamic Seal, Excluder, Gasket, Hydrodynamic Seal, O-Ring, Radial Seal, Rotary Seal, and Static Seal. The Rotary Seal segment dominated the market with the largest revenue share of 40.3% in 2024, due to its critical role in preventing leakage in rotating equipment such as pumps, agitators, and mixers in food and beverage processing. Rotary seals provide consistent performance, durability, and compliance with sanitary standards, making them essential for large-scale production.

The Dynamic Seal segment is expected to witness the fastest CAGR of 22.5% from 2025 to 2032, fueled by rising demand for seals capable of handling variable motion and pressure in automated processing systems. Dynamic seals offer flexibility and improved reliability, making them highly suitable for modern, high-speed, and high-efficiency food and beverage operations.

Global Food and Beverage Mechanical Seals Market Regional Analysis

- Europe dominated the Global Food and Beverage Mechanical Seals Market with the largest revenue share of 34.5% in 2024, driven by the presence of a highly developed food processing industry, stringent hygiene regulations, and widespread adoption of advanced manufacturing technologies.

- Manufacturers in the region prioritize high-quality, durable, and hygienic sealing solutions to ensure product safety, maintain operational efficiency, and comply with FDA and other regulatory standards.

- This strong market position is further supported by established industrial infrastructure, high investment in automation, and the presence of key global mechanical seal manufacturers. The adoption of predictive maintenance and smart sealing technologies is accelerating, enhancing operational reliability and reducing downtime. North America’s robust demand for technologically advanced, high-performance seals positions the region as a global leader in the food and beverage mechanical seals market.

U.S. Food and Beverage Mechanical Seals Market Insight

The U.S. Food and Beverage Mechanical Seals Market captured the largest revenue share of 82% in North America in 2024, driven by a highly developed food and beverage processing industry and stringent regulatory requirements from the FDA. Manufacturers increasingly prioritize durable, hygienic, and high-performance sealing solutions to maintain product safety and operational efficiency. The adoption of automated production lines, predictive maintenance practices, and technologically advanced mechanical seals further propels market growth. Additionally, the integration of mechanical seals with smart monitoring systems and IoT-enabled equipment is enhancing reliability and reducing downtime across dairy, bakery, and beverage processing plants.

Europe Food and Beverage Mechanical Seals Market Insight

The Europe Food and Beverage Mechanical Seals Market is projected to expand at a substantial CAGR during the forecast period, primarily driven by strict hygiene regulations, increasing automation in food processing, and rising consumer demand for high-quality packaged food and beverages. Countries such as Germany, France, and Italy are witnessing strong adoption of advanced mechanical seal technologies in dairy, meat, and beverage production lines. Additionally, the need for energy-efficient, low-maintenance sealing solutions and the trend of retrofitting existing plants with reliable sealing systems are supporting market growth across residential, commercial, and industrial food processing sectors.

U.K. Food and Beverage Mechanical Seals Market Insight

The U.K. Food and Beverage Mechanical Seals Market is expected to grow at a noteworthy CAGR during the forecast period, driven by the modernization of food processing facilities and increasing demand for high-quality, safe, and long-shelf-life products. The growing emphasis on automated production lines and the adoption of hygienic sealing technologies in dairy, bakery, and beverage industries further stimulate market growth. Additionally, the U.K.’s strong food export industry and regulatory focus on contamination prevention encourage the use of durable and efficient mechanical seals in commercial and industrial applications.

Germany Food and Beverage Mechanical Seals Market Insight

The Germany Food and Beverage Mechanical Seals Market is anticipated to expand at a considerable CAGR during the forecast period, fueled by the country’s advanced food processing sector and focus on technological innovation. Germany’s emphasis on sustainability, energy efficiency, and hygienic production practices drives the adoption of high-performance mechanical seals in dairy, meat, and beverage processing plants. The growing integration of predictive maintenance, IoT-enabled equipment, and automated production lines ensures operational reliability and reduces downtime, promoting market expansion. Germany’s strong industrial infrastructure and skilled workforce support the adoption of innovative sealing solutions across the food and beverage industry.

Asia-Pacific Food and Beverage Mechanical Seals Market Insight

The Asia-Pacific Food and Beverage Mechanical Seals Market is poised to grow at the fastest CAGR of 24% from 2025 to 2032, driven by increasing urbanization, rising disposable incomes, and rapid industrialization in countries such as China, Japan, and India. The region’s expanding food and beverage manufacturing base, supported by government initiatives promoting modern food safety standards and automation, is fueling the demand for durable and hygienic sealing solutions. Growing investments in dairy, bakery, and beverage production facilities, alongside increasing adoption of high-performance mechanical seals in automated lines, are key growth factors.

Japan Food and Beverage Mechanical Seals Market Insight

The Japan Food and Beverage Mechanical Seals Market is witnessing steady growth due to the country’s advanced manufacturing sector, high-tech culture, and stringent food safety standards. The rising adoption of automated food processing lines, smart monitoring systems, and hygienic sealing solutions is driving market demand. Additionally, Japan’s aging population and increasing focus on efficient, low-maintenance equipment boost the need for reliable mechanical seals in both residential-scale and commercial food processing operations.

China Food and Beverage Mechanical Seals Market Insight

The China Food and Beverage Mechanical Seals Market accounted for the largest market revenue share in Asia-Pacific in 2024, attributed to rapid industrialization, expanding middle-class consumption, and large-scale food and beverage production. The country’s focus on food safety, increasing adoption of automated processing lines, and availability of affordable, high-quality mechanical seals are major growth drivers. China’s strong domestic manufacturing base, combined with investments in smart production facilities and the push for modern food processing standards, supports the rising demand for mechanical seals across dairy, beverage, and packaged food industries.

Global Food and Beverage Mechanical Seals Market Share

The Food and Beverage Mechanical Seals industry is primarily led by well-established companies, including:

• John Crane (U.S.)

• Flowserve (U.S.)

• AESSEAL (U.K.)

• EagleBurgmann (Germany)

• Chesterton (U.S.)

• KSB Seals (Germany)

• Siemens Mechanical Seals (Germany)

• Trelleborg Sealing Solutions (Sweden)

• Roten (U.S.)

• Garlock (U.S.)

• DSS Seals (U.S.)

• Technetics Group (U.S.)

• Freudenberg Sealing Technologies (Germany)

• NOK Corporation (Japan)

• Fox Seals (U.K.)

• John Crane India (India)

• SKF Seals (Sweden)

• Parker Hannifin (U.S.)

• Reliance Seals (U.S.)

• Flowserve India (India)

What are the Recent Developments in Global Food and Beverage Mechanical Seals Market?

- In April 2023, John Crane (U.S.), a global leader in sealing solutions, launched a new range of high-performance mechanical seals specifically designed for the dairy and beverage processing industries. The initiative aims to improve equipment reliability, reduce downtime, and enhance food safety standards across commercial production facilities. By leveraging its global expertise in advanced sealing technologies, John Crane strengthens its position in the rapidly expanding Food and Beverage Mechanical Seals Market.

- In March 2023, Flowserve Corporation (U.S.) introduced its next-generation elastomer-based mechanical seals for high-speed bottling and packaging lines. Engineered for both beverage and confectionery applications, the seals offer superior durability and reduced maintenance requirements, highlighting Flowserve’s commitment to innovation and operational efficiency in the food and beverage sector.

- In March 2023, EagleBurgmann (Germany) successfully deployed advanced mechanical seals in a large-scale brewery automation project in Bengaluru, India. The project focused on minimizing product contamination and improving plant uptime, reflecting EagleBurgmann’s dedication to providing reliable, high-quality sealing solutions for industrial food and beverage processes.

- In February 2023, Siemens Energy (Germany) partnered with a leading meat processing group to integrate smart monitoring systems with mechanical seals in processing lines. This collaboration enables predictive maintenance, real-time performance tracking, and enhanced hygiene compliance, emphasizing Siemens Energy’s commitment to technological innovation and operational excellence in food manufacturing.

- In January 2023, Graham Corporation (U.S.) unveiled its latest rotary and axial seals for high-pressure beverage and dairy applications at the International Food Processing Expo 2023. The new product line offers enhanced durability, precision sealing, and energy efficiency, reinforcing Graham Corporation’s focus on delivering advanced mechanical seal solutions for modern food and beverage production environments.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Food And Beverage Mechanical Seals Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Food And Beverage Mechanical Seals Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Food And Beverage Mechanical Seals Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.