Global Food Powder Packing Machines Market

Market Size in USD Billion

CAGR :

%

USD

3.60 Billion

USD

4.72 Billion

2025

2033

USD

3.60 Billion

USD

4.72 Billion

2025

2033

| 2026 –2033 | |

| USD 3.60 Billion | |

| USD 4.72 Billion | |

|

|

|

|

Food Powder Packing Machines Market Size

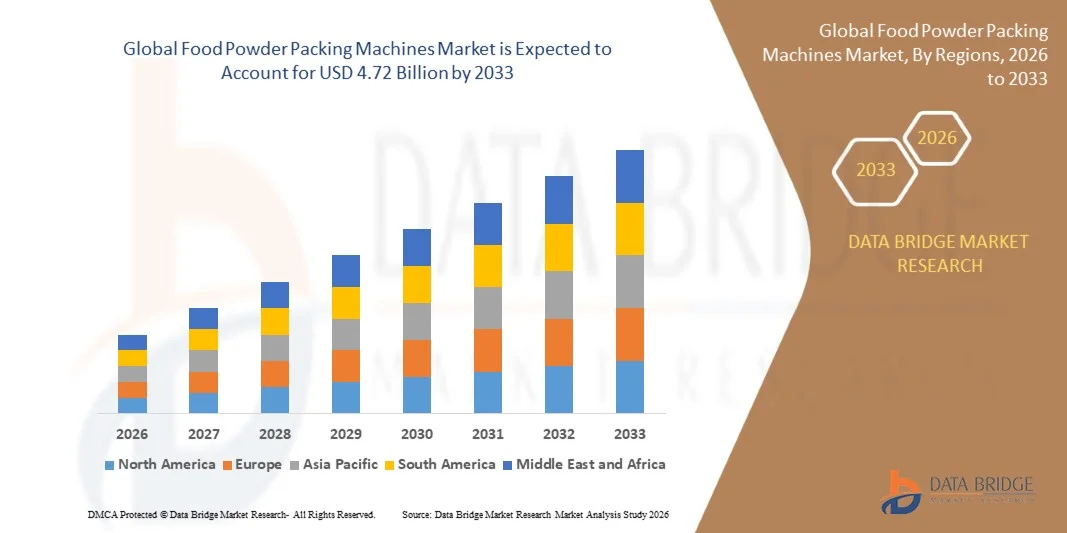

- The global food powder packing machines market size was valued at USD 3.6 billion in 2025 and is expected to reach USD 4.72 billion by 2033, at a CAGR of 3.47% during the forecast period

- The market growth is largely fueled by the increasing adoption of automated and high-speed packing solutions across the food and beverage industry, driven by rising demand for packaged powders such as milk powder, protein supplements, and infant formulas

- Furthermore, growing emphasis on hygiene, precision, and efficiency in powder packaging is pushing manufacturers to invest in advanced machinery with integrated weighing, dosing, and sealing systems. These converging factors are accelerating the adoption of food powder packing machines, thereby significantly boosting the industry's growth

Food Powder Packing Machines Market Analysis

- Food powder packing machines, designed for automated handling, weighing, filling, and sealing of powdered products, are becoming essential components in modern food processing lines due to their ability to enhance production efficiency, maintain product quality, and reduce manual intervention

- The escalating demand for these machines is primarily fueled by the global growth of the dairy, nutrition, and powdered beverage sectors, increasing focus on food safety and hygiene standards, and rising adoption of automation and smart packaging technologies among manufacturers

- North America dominated the food powder packing machines market with a share of 33.3% in 2025, due to expanding food and beverage manufacturing, increasing demand for packaged and processed powders, and a strong presence of machinery manufacturing hubs

- Asia-Pacific is expected to be the fastest growing region in the food powder packing machines market during the forecast period due to robust demand for packaged powders in dairy, coffee, and nutritional supplements

- Vertical segment dominated the market with a market share of 57.9% in 2025, due to its versatility in handling a wide range of powder products and efficient use of floor space. Vertical packing machines are preferred by manufacturers for their faster operation, reduced manual intervention, and capability to handle small to medium-sized packaging formats. The market demand is further strengthened by their compatibility with automated feeding and weighing systems, which enhances production efficiency and reduces product wastage. These machines are commonly adopted across dairy, coffee, and nutritional powder production lines due to their reliability and ease of integration

Report Scope and Food Powder Packing Machines Market Segmentation

|

Attributes |

Food Powder Packing Machines Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Food Powder Packing Machines Market Trends

“Growing Adoption of Automated Powder Packaging”

- A significant trend in the food powder packing machines market is the increasing adoption of automated and high-speed packaging systems across food processing industries, driven by the rising demand for packaged powders such as milk powder, protein supplements, and infant formulas. This trend is elevating the role of advanced packing machines as essential components for efficient, hygienic, and high-precision production lines

- For instance, Optima Packaging Group and Syntegon Technology offer high-speed powder packing machines with integrated weighing and sealing systems, widely adopted in dairy, nutrition, and powdered beverage production lines. These machines enhance production efficiency, reduce manual labor, and ensure consistent packaging quality across high-volume operations

- The demand for smart and automated packing solutions is particularly growing in emerging markets where rapid expansion of the food processing industry requires scalable, reliable, and hygienic packaging solutions. This is positioning food powder packing machines as critical enablers of productivity improvements and operational cost reduction

- Industries producing nutritional powders and infant formulas are increasingly integrating high-precision packaging lines to maintain product integrity and meet strict safety standards. This trend supports manufacturers’ efforts to comply with hygiene regulations while improving throughput and reducing wastage

- Manufacturers are also seeking multi-functional machines capable of handling various powder types with minimal changeover time. The rising focus on flexibility and adaptability in production lines is further strengthening the adoption of advanced automated packing machines

- The market is witnessing robust growth as food producers emphasize automation, speed, and precision in powder packaging. This rising incorporation of automated systems is reinforcing the overall transition toward highly efficient, hygienic, and technologically advanced food powder production operations

Food Powder Packing Machines Market Dynamics

Driver

“Rising Demand for Packaged Dairy and Nutrition Powders”

- The growing consumption of packaged dairy, nutritional supplements, and infant formulas is driving the demand for automated powder packing machines. These machines enable precise filling, accurate weighing, and secure sealing, ensuring product quality and hygiene across high-volume production lines

- For instance, GEA Group and Robert Bosch GmbH supply advanced powder packing machines that cater to the high precision and efficiency requirements of dairy and nutritional product manufacturers. Their adoption helps companies meet consumer expectations for consistent quality and safe packaging

- Rising health awareness and changing dietary habits are fueling the expansion of protein supplements and fortified powders, further accelerating the need for automated packing solutions

- The integration of automated systems also reduces dependency on manual labor, lowers operational costs, and improves production speed, making these machines attractive for both large-scale and small-scale manufacturers

- Increasing regulatory standards for food safety and hygiene are encouraging manufacturers to invest in precision packing machines that minimize contamination risks while enhancing throughput

Restraint/Challenge

“High Cost of Advanced Packing Machines”

- The food powder packing machines market faces challenges due to the high initial investment and maintenance costs associated with advanced automated systems. These costs can be prohibitive for small-scale producers, limiting widespread adoption

- For instance, high-speed multi-functional machines from companies such as Syntegon and Optima require significant capital outlay and specialized technical support for installation and operation

- Complex machine configurations and integration with existing production lines increase setup time and require skilled personnel, adding to operational expenses

- The cost of spare parts and regular maintenance further contributes to the total ownership cost, making budgeting and cost management critical for manufacturers

- These financial barriers continue to restrict adoption among emerging and small-scale food processing enterprises, despite growing demand for efficiency and automation

Food Powder Packing Machines Market Scope

The market is segmented on the basis of machine type, channel type, and end user.

• By Machine Type

On the basis of machine type, the Food Powder Packing Machines market is segmented into vertical and horizontal machines. The vertical segment dominated the market with the largest revenue share of 57.9% in 2025, driven by its versatility in handling a wide range of powder products and efficient use of floor space. Vertical packing machines are preferred by manufacturers for their faster operation, reduced manual intervention, and capability to handle small to medium-sized packaging formats. The market demand is further strengthened by their compatibility with automated feeding and weighing systems, which enhances production efficiency and reduces product wastage. These machines are commonly adopted across dairy, coffee, and nutritional powder production lines due to their reliability and ease of integration.

The horizontal segment is anticipated to witness the fastest growth from 2026 to 2033, fueled by increasing adoption in high-capacity industrial operations. Horizontal packing machines offer advantages in handling larger packaging volumes and complex multi-lane filling processes, which suits large-scale production of powders such as infant formulas and protein supplements. For instance, Bosch Packaging Technology has introduced advanced horizontal machines capable of high-speed, multi-lane filling, which is attracting significant interest from large-scale manufacturers. The growing demand for customized and flexible packaging solutions in the food industry further supports the adoption of horizontal machines, particularly in automated production facilities.

• By Channel Type

On the basis of channel type, the Food Powder Packing Machines market is segmented into Business to Business (B2B) and Business to Consumer (B2C). The B2B segment dominated the market with the largest revenue share in 2025, driven by widespread procurement by large-scale food manufacturers and contract packing companies. B2B sales often involve bulk orders of sophisticated machinery integrated into complete production lines, ensuring efficiency and reduced downtime. Manufacturers prioritize B2B channels for technical support, after-sales service, and access to customized solutions tailored for their specific powder handling requirements. The demand is particularly high from sectors producing milk powder, coffee, and nutritional powders due to the need for high precision and speed in packaging.

The B2C segment is expected to witness the fastest growth from 2026 to 2033, driven by increasing interest from small-scale enterprises, startups, and specialty food brands. For instance, companies such as Packit Solutions are offering compact and semi-automatic machines for direct consumer purchase, enabling small producers to package their products independently. Rising e-commerce penetration and growth in home-based or artisanal powder production further boost the demand for B2C-oriented packing machines. These machines appeal to businesses seeking flexible, easy-to-operate solutions for niche markets, personalized packaging, and smaller production runs.

• By End User

On the basis of end user, the Food Powder Packing Machines market is segmented into milk powder, tea powder, cocoa powder, coffee powder, wheat/soybean flour, specialty dairy powder, nutritionals/protein supplements, whey powder, infant formulas, and others. The milk powder segment dominated the market with the largest revenue share in 2025, driven by the global demand for packaged milk powder products and infant nutrition. Milk powder production lines require high-precision packaging machines to maintain hygiene, ensure accurate weight, and reduce wastage during filling. Manufacturers prefer machines that integrate automated weighing, sealing, and labeling to enhance productivity and maintain product quality standards. The strong presence of dairy manufacturing hubs worldwide and growing consumption in developing regions further sustains the dominance of this segment.

The nutritionals/protein supplements segment is anticipated to witness the fastest growth from 2026 to 2033, fueled by rising health consciousness and demand for dietary supplements. For instance, Tetra Pak and GEA Group have launched advanced powder packing machines capable of handling protein supplements and nutritional powders with precision and minimal contamination. The growth is also supported by expanding fitness, sports nutrition, and wellness industries, which require packaging machines capable of managing small-batch production with flexible packaging formats. Rising popularity of protein shakes, plant-based supplements, and functional nutrition powders among consumers drives the rapid adoption of specialized packing machinery in this segment.

Food Powder Packing Machines Market Regional Analysis

- North America dominated the food powder packing machines market with the largest revenue share of 33.3% in 2025, driven by expanding food and beverage manufacturing, increasing demand for packaged and processed powders, and a strong presence of machinery manufacturing hubs

- The region’s cost-effective manufacturing landscape, rising investments in automated packaging solutions, and growing exports of food powders are accelerating market expansion

- The availability of skilled labor, favorable government policies, and rapid industrialization across developing economies are contributing to increased adoption of food powder packing machines across both large-scale and small-scale production facilities

China Food Powder Packing Machines Market Insight

China held the largest share in the Asia-Pacific Food Powder Packing Machines market in 2025, owing to its status as a global leader in food processing equipment manufacturing and dairy and nutrition powder production. The country's strong industrial base, favorable government policies supporting automation and machinery sector expansion, and extensive export capabilities are major growth drivers. Demand is further bolstered by ongoing investments in smart packing technologies and automated production lines for milk, coffee, and nutritional powders.

India Food Powder Packing Machines Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by rapidly expanding dairy and nutrition supplement industries, increasing small- and medium-scale food enterprises, and rising investments in automated machinery. Government initiatives promoting food processing and manufacturing, coupled with a shift toward mechanized and hygienic packaging solutions, are strengthening demand. In addition, growing exports of milk powder, protein supplements, and other packaged powders are contributing to robust market expansion.

Europe Food Powder Packing Machines Market Insight

The Europe Food Powder Packing Machines market is expanding steadily, supported by high demand for high-quality packaged powders, stringent food safety regulations, and growing investments in sustainable and automated machinery solutions. The region emphasizes hygiene, precision, and advanced technology integration, particularly in dairy, coffee, and nutritional powder production. Rising adoption of smart packaging lines and multi-functional machines is further enhancing market growth.

Germany Food Powder Packing Machines Market Insight

Germany’s market is driven by its leadership in high-precision food machinery manufacturing, strong engineering expertise, and export-oriented production model. The country has well-established R&D networks and partnerships between academic institutions and equipment manufacturers, fostering continuous innovation in packing technology. Demand is particularly strong for automated solutions used in milk powder, infant formulas, and protein supplements.

U.K. Food Powder Packing Machines Market Insight

The U.K. market is supported by a mature food and beverage processing industry, growing focus on mechanized and hygienic powder packaging, and rising adoption of automated machinery in small- and medium-scale enterprises. With increasing emphasis on R&D, technological upgrades, and integration of smart packing solutions, the U.K. continues to play a significant role in high-value food machinery markets.

North America Food Powder Packing Machines Market Insight

North America is projected to grow at the fastest CAGR from 2026 to 2033, driven by robust demand for packaged powders in dairy, coffee, and nutritional supplements. A strong focus on automation, precision machinery, and smart packaging technology is boosting adoption. In addition, rising reshoring of food machinery manufacturing and increasing collaboration between food producers and equipment manufacturers are supporting market expansion.

U.S. Food Powder Packing Machines Market Insight

The U.S. accounted for the largest share in the North America market in 2025, underpinned by its expansive food processing industry, strong R&D infrastructure, and significant investment in advanced packing machinery. The country’s focus on efficiency, hygiene, and innovation is encouraging the use of automated and high-precision food powder packing machines. Presence of key players and a mature distribution network further solidify the U.S.'s leading position in the region.

Food Powder Packing Machines Market Share

The food powder packing machines industry is primarily led by well-established companies, including:

- GEA Group Aktiengesellschaft (Germany)

- OPTIMA Packaging Group GmbH (Germany)

- Robert Bosch GmbH (Germany)

- UFlex Limited (India)

- HAVER & BOECKER OHG (Germany)

- ROVEMA GmbH (Germany)

- Tokyo Automatic Machinery Works, Ltd. (Japan)

- FUJI MACHINERY CO., LTD. (Japan)

- Premier Tech Ltd. (Canada)

- SAPLI Solutions S.L. (Spain)

- Turpack Packaging Machinery (Spain)

- Bossar Packaging SA (Spain)

- Berry Global Inc. (U.S.)

- Glenroy, Inc. (U.S.)

- Nichrome Packaging Solutions (India)

- Sunfood Nutraceuticals (U.S.)

- IPK Packaging (India) Private Limited (India)

- Shivalaya Machinery Mfg. Co. (India)

- Viking Masek Global Packaging (U.K.)

Latest Developments in Global Food Powder Packing Machines Market

- In August 2025, XyloTech Industries unveiled a proprietary laser‑guided sorting system designed to significantly enhance throughput and reduce powder loss by over 25 percent. This development allows manufacturers to operate high-speed packing lines with improved efficiency, minimizing waste and operational costs. By addressing a critical bottleneck in automated powder packing, the technology enables businesses to scale production rapidly while maintaining consistent quality, thereby strengthening competitiveness in both domestic and export markets

- In July 2025, Optima Packaging Group launched a new high‑speed powder packaging system with advanced dosing technology tailored for food and pharmaceutical applications. The system enhances packing accuracy and accelerates cycle times, enabling manufacturers to meet growing demand for powdered products such as milk powder, protein supplements, and infant formulas. This product launch reinforces the trend toward automation and smart packaging solutions, helping companies improve productivity, reduce manual intervention, and maintain strict hygiene standards

- In July 2025, Ishida announced a strategic partnership with a powder packaging systems integrator to expand global service coverage and jointly develop enhanced dosing solutions. The collaboration strengthens Ishida’s market position by providing access to improved technical support and innovative machinery tailored for complex powders. This partnership accelerates adoption of high-precision packing equipment, allowing manufacturers to achieve better operational efficiency, maintain consistent quality, and reduce downtime across diverse powder applications

- In June 2024, WeighPack Systems introduced a new bulk weigh filling machine with an integrated in‑line metal detector positioned between the filling process and weigh bucket. This innovation enhances food safety by detecting and isolating contaminated batches before packaging, reducing risk to consumers and avoiding costly recalls. The machine also improves overall packing efficiency and accuracy, meeting stringent quality regulations and enabling manufacturers to adopt advanced, reliable solutions for high-volume powder packaging lines

- In March 2025, Syntegon Technology introduced a high-speed powder bagging system optimized for fine powders, featuring enhanced dust control and digital quality assurance integration. This development improves operational safety and hygiene, reduces product loss, and allows manufacturers to achieve faster, more precise packaging for sensitive powders such as nutritional supplements and specialty dairy products. The innovation supports the growing demand for automated, high-capacity packaging solutions, making production lines more efficient and adaptable to evolving market requirements

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Food Powder Packing Machines Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Food Powder Packing Machines Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Food Powder Packing Machines Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.