Global Food Processing Seals Market

Market Size in USD Billion

CAGR :

%

USD

3.12 Billion

USD

4.68 Billion

2024

2032

USD

3.12 Billion

USD

4.68 Billion

2024

2032

| 2025 –2032 | |

| USD 3.12 Billion | |

| USD 4.68 Billion | |

|

|

|

|

Food Processing Seals Market Size

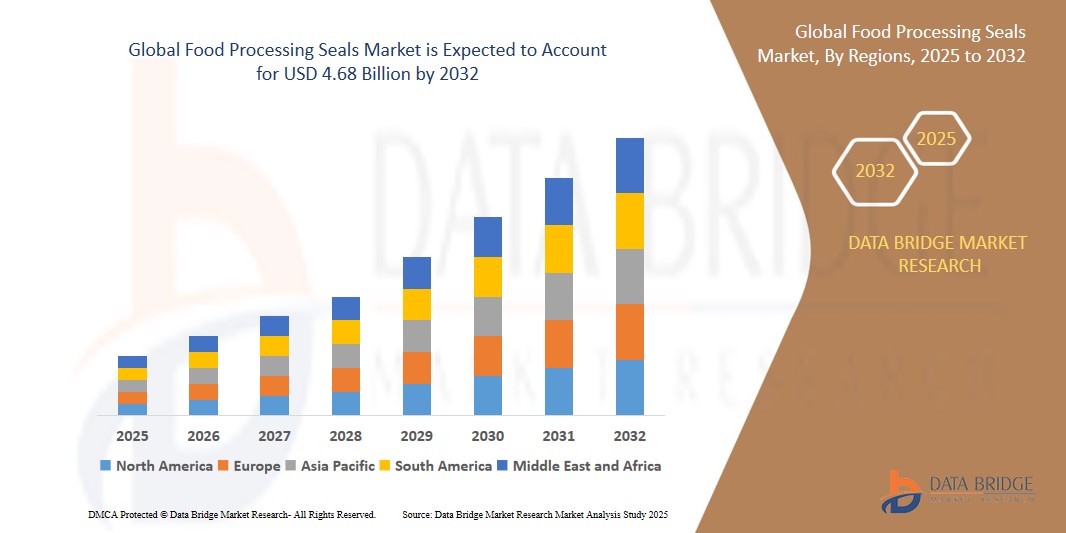

- The Global Food Processing Seals Market size was valued at USD 3.12 billion in 2024 and is expected to reach USD 4.68 billion by 2032, at a CAGR of 4.6% during the forecast period

- The market growth is largely fueled by growth of packaged food in the developed and developing countries

- Furthermore, the growing demand for dairy, bakery, confectionery and meat products and increase in the purchasing power of consumers is further anticipated to propel the growth of the food processing seals market

Food Processing Seals Market Analysis

- Food processing seals are the materials that act as covers to seal the food items and protect their edibility. They are demanded to cover the beverages and protect them from spilling.

- Seals protect the food items from getting contaminated. Thus, the seals provide safety and keep the hygiene of the food items intact. The seals are used in chemical industries where they don’t allow the chemicals to evaporate or react with the oxygen present in the air.

- The seals are also capable of withstanding temperature pressures and provide solid support to the container

- North America dominates the Food Processing Seals Market with the largest revenue share of 38.25% in 2025, characterized by stringent food safety standards and increasing automation in food manufacturing processes.

- Asia-Pacific is expected to be the fastest growing region in the Food Processing Seals Market during the forecast period due to rising food demand from growing populations and increased adoption of automated food processing equipment

- Elastomers segment is expected to dominate the Food Processing Seals Market with a market share of 42.6% in 2025, driven by their superior flexibility, chemical resistance, and sealing effectiveness across a wide range of temperatures

Report Scope and Food Processing Seals Market Segmentation

|

Attributes |

Food Processing Seals Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Food Processing Seals Market Trends

“Integration of AI and Smart Technologies in Sealing Solutions”

- A significant and accelerating trend in the global food processing seals market is the integration of artificial intelligence (AI) and smart technologies into sealing solutions. This advancement enhances real-time monitoring, predictive maintenance, and quality control in food processing operations.

- For instance, AI-powered systems are being utilized for real-time defect detection, contamination identification, and ensuring uniform product quality during processing. These systems can identify anomalies like cracks, discoloration, or foreign objects, thereby improving product safety and consistency.

- Additionally, smart seals equipped with sensors and RFID technology enable real-time tracking of product freshness and integrity throughout the supply chain, facilitating better inventory management and reducing food waste.

- The adoption of these intelligent sealing solutions is driven by the need for enhanced food safety, regulatory compliance, and operational efficiency in the food processing industry.

Food Processing Seals Market Dynamics

Driver

“Rising Demand for Packaged and Processed Foods”

- The increasing global demand for packaged and processed foods is a primary driver of the food processing seals market. Urbanization, changing lifestyles, and rising disposable incomes have led consumers to prefer convenient food options, thereby boosting the need for effective sealing solutions to ensure product safety and longevity.

- Food processing seals are critical in maintaining hygienic conditions during processing and packaging, preventing contamination, and preserving the freshness of food products.

- Moreover, stringent food safety regulations and standards imposed by authorities worldwide compel manufacturers to adopt high-quality seals that comply with these regulations, further propelling market growth.

Restraint/Challenge

“High Initial Investment and Regulatory Compliance Costs”

- One of the significant challenges in the food processing seals market is the high initial investment required for advanced sealing technologies and the costs associated with regulatory compliance.

- Small and medium-sized enterprises (SMEs) may find it financially burdensome to invest in state-of-the-art sealing equipment and materials that meet stringent food safety standards.

- Moreover, navigating the complex regulatory landscape requires continuous monitoring and testing to ensure compliance, which can strain resources and impact profitability.

- Addressing these challenges necessitates collaborative efforts between industry stakeholders and regulatory bodies to develop cost-effective solutions and provide support for SMEs in adopting compliant sealing technologies.

Food Processing Seals Market Scope

The market is segmented on the basis of material and application.

- By Material

On the basis of material, the Food Processing Seals Market is segmented into elastomers, metals, face materials, and others. The elastomers segment dominates the largest market revenue share of 42.6% in 2025, attributed to their superior flexibility, chemical resistance, and sealing effectiveness across a wide range of temperatures. Elastomer seals are widely used in hygienic food processing applications due to their compatibility with cleaning agents and ability to maintain a tight seal in dynamic equipment conditions. Their adaptability to various equipment types makes them the preferred choice in many food production settings.

The metals segment is anticipated to witness the fastest growth rate of 20.9% from 2025 to 2032, fueled by increasing demand in high-pressure and high-temperature applications such as meat and seafood processing. Metal seals offer excellent durability and strength under extreme conditions, and their compatibility with aggressive cleaning procedures adds to their value in heavily sanitized environments. Advancements in stainless steel and other food-grade alloys are also supporting market expansion.

- By Application

On the basis of application, the food processing seals market is segmented into dairy products, bakery & confectionery, meat, poultry and seafood, beverages, and others. The dairy products segment held the largest market revenue share in 2025, driven by the need for high-performance seals in pasteurization, homogenization, and packaging machinery. Dairy processing requires frequent cleaning and temperature variation handling, which elastomer and face material seals effectively accommodate. Regulatory pressure for contamination control also supports segment dominance.

The meat, poultry and seafood segment is expected to witness the fastest CAGR from 2025 to 2032, driven by increasing global consumption and the need for robust sealing solutions in harsh processing environments. This segment demands seals with excellent abrasion resistance, high-pressure tolerance, and hygiene compliance. Technological innovations in seal materials and designs are enhancing their reliability, thereby boosting adoption in automated meat processing lines.

Food Processing Seals Market Regional Analysis

- North America dominates the Food Processing Seals Market with the largest revenue share of 38.25% in 2024, driven by stringent food safety standards and increasing automation in food manufacturing processes.

- High consumer demand for processed and packaged foods supports adoption. The need for contamination prevention in food processing drives use of high-performance sealing solutions in machinery.

- Additionally, widespread modernization of processing plants, high regulatory compliance, and strong focus on product quality and hygiene contribute to regional dominance. These factors position North America as a leader in seal technology for food-grade applications.

U.S. Food Processing Seals Market Insight

The U.S. Food Processing Seals Market captured the largest revenue share of 81.04% within North America in 2025, fueled by regulatory emphasis on hygiene and equipment safety. Food producers are upgrading equipment to reduce contamination risks, supporting advanced seal adoption. Increasing processed food consumption, driven by convenience and changing lifestyles, also fuels growth. Moreover, investments in plant automation, the rise of ready-to-eat food categories, and strict FDA regulations further boost market expansion for sealing technologies tailored for food safety.

Europe Food Processing Seals Market Insight

The European Food Processing Seals Market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by the growing health awareness and demand for compliant, hygienic processing systems. EU regulations require safe contact materials in food handling, boosting use of certified sealants and gaskets. Sustainable and recyclable materials are gaining attention among European producers. Increased focus on vegan and allergen-free products is driving the need for cross-contamination-resistant sealing systems.

U.K. Food Processing Seals Market Insight

The U.K. Food Processing Seals Market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by the expanding frozen and ready-meal segments. The growing trend of local sourcing and small-batch production requires adaptable sealing technologies that preserve freshness and comply with food-grade regulations. Increasing demand for energy-efficient equipment and safety compliance also supports market growth across SMEs and large manufacturers in the U.K.

Germany Food Processing Seals Market Insight

The German Food Processing Seals Market is expected to expand at a considerable CAGR during the forecast period, fueled by the country’s engineering excellence and focus on advanced industrial automation. Germany's meat, dairy, and bakery sectors drive strong demand for hygienic seals in rotary and linear equipment. Sustainability initiatives are encouraging the use of long-lasting, recyclable seal components, aligning with both performance and ecological goals in the German food processing sector.

Asia-Pacific Food Processing Seals Market Insight

The Asia-Pacific Food Processing Seals Market is poised to grow at the fastest CAGR of over 24.35% in 2025, driven by rising food demand from growing populations and increased adoption of automated food processing equipment. China, India, and Southeast Asian nations are prioritizing modernization of food facilities, boosting seal use. Rising health awareness, government hygiene mandates, and expanding food export activities are also propelling the market across the region.

Japan Food Processing Seals Market Insight

The Japan food processing seals market is gaining momentum due to precision manufacturing and rising demand for high-quality food products. Aging population and preference for convenience food are supporting the rise in automated food processing, increasing the need for sanitary seals. Japan’s strict hygiene laws and cultural emphasis on food purity are pushing seal innovation and localized production for quality assurance.

China Food Processing Seals Market Insight

The China Food Processing Seals Market accounted for the largest market revenue share in Asia Pacific in 2025, driven by rapid urbanization, changing dietary habits, and significant food export volume. Government support for food safety reforms and expansion of cold-chain logistics are key contributors. Local manufacturing hubs and increased investment in food-grade sealing technologies are ensuring widespread availability of reliable and cost-effective sealing solutions.

Food Processing Seals Market Share

The Food Processing Seals industry is primarily led by well-established companies, including:

- AESSEAL plc (U.K.)

- Smiths Group Plc (U.K.)

- Flowserve Corporation (U.S.)

- A.W. Chesterton Company (U.S.)

- SKF (Sweden)

- PARKER HANNIFIN CORP (U.S.)

- Trelleborg AB (publ) (Sweden)

- IDEX (U.S.)

- EnPro Industries (U.S.)

- James Walker (U.K.)

- Meccanotecnica Umbra S.p.A. (Italy)

- Freudenberg Sealing Technologies GmbH & Co. KG (Germany)

- GARLOCK FAMILY OF COMPANIES (U.S.)

- Precision Associates, Inc. (U.S.)

- CinchSeal (U.S.)

- Kismet Rubber Products (U.S.)

- KLINGER Limited. (U.K.)

- Spareage Sealing Solutions (India)

- Rex Sealing & Packing Industries Private Limited (India)

- Aries India Earthmovers Private Limited (India)

Latest Developments in Global Food Processing Seals Market

- In February 2024, Ampack, a Syntegon company, introduced the FBL filling machine for liquid food products packaged in HDPE, PP, and PET bottles. This addition strengthens Ampack’s global reputation as a key provider of aseptic filling solutions. The FBL is capable of processing a wide range of products, including baby food, medical nutrition, dairy and plant-based beverages, milk, and soups. It emphasizes production flexibility and hygienic design, featuring a neck-handling system that allows quick bottle design changes and an innovative approach to sanitation and maintenance. Ampack plans to showcase this technology at Anuga FoodTec in Cologne from March 19–22, continuing its momentum in filling and sealing systems for preformed cups.

- In January 2024, more international brands entered the Indian market, with major players like Reliance and Aditya Birla expressing interest in new collaborations. Reliance Brands partnered with Sandro and Maje, while Aditya Birla Fashion and Retail teamed up with Galeries Lafayette, and Metro Brands allied with Foot Locker. Sandro and Maje will launch at Jio World Plaza in BKC, Pull and Bear at Phoenix Palladium in Lower Parel, and Galeries Lafayette will soon open its doors in Fort, Mumbai.

- In March 2024, Amcor, a global leader in packaging, joined forces with Stonyfield Organic, a leading organic yogurt brand, and Cheer Pack North America, a prominent manufacturer of spouted pouch packaging, to unveil the first-ever all-polyethylene (PE) spouted pouch. This partnership brings together three sustainability leaders to deliver a groundbreaking, more environmentally friendly packaging solution without compromising on performance.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Food Processing Seals Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Food Processing Seals Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Food Processing Seals Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.