Global Freeze Drying Market

Market Size in USD Billion

CAGR :

%

USD

2.10 Billion

USD

3.95 Billion

2024

2032

USD

2.10 Billion

USD

3.95 Billion

2024

2032

| 2025 –2032 | |

| USD 2.10 Billion | |

| USD 3.95 Billion | |

|

|

|

|

Freeze Drying Market Size

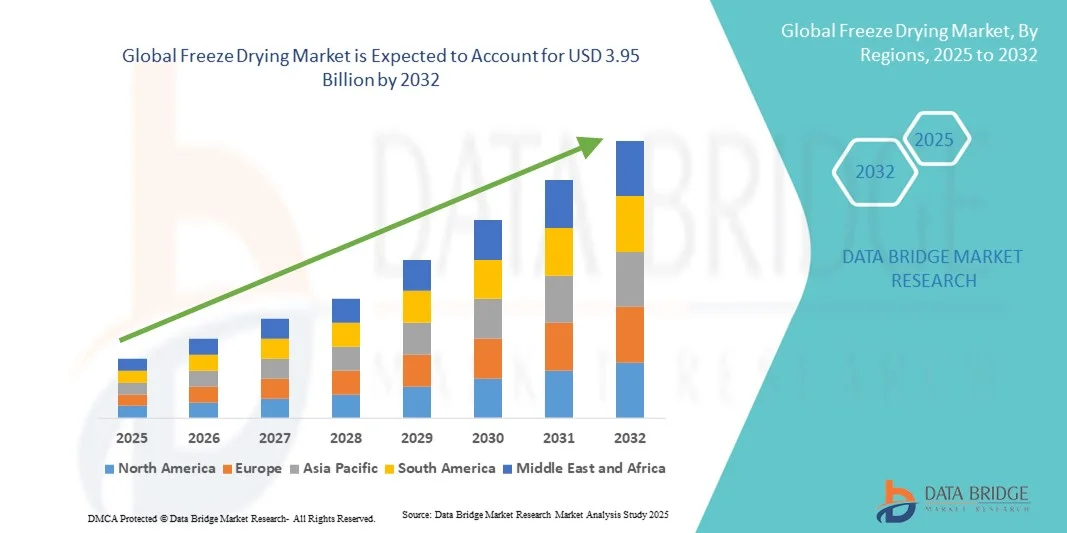

- The global freeze drying market size was valued at USD 2.10 billion in 2024 and is expected to reach USD 3.95 billion by 2032, at a CAGR of 8.20% during the forecast period

- The market growth is largely driven by the increasing demand for long-shelf-life products across pharmaceuticals, food & beverages, and biotechnology sectors, along with advancements in freeze drying technology enhancing product quality and efficiency

- Furthermore, rising consumer preference for preserved, high-nutrient, and easy-to-transport products is positioning freeze drying as a preferred preservation method in both industrial and research applications. These combined factors are accelerating the adoption of freeze drying solutions, thereby significantly propelling the market’s growth

Freeze Drying Market Analysis

- Freeze drying, a dehydration process that removes water from products while preserving their structure and bioactivity, is increasingly essential in pharmaceuticals, food & beverages, and biotechnology industries due to its ability to extend shelf life, maintain product quality, and enable convenient storage and transport

- The growing demand for freeze-dried products is primarily driven by the rising need for stable pharmaceuticals, high-nutrient food products, and biologics, along with technological advancements in freeze drying equipment enhancing efficiency and scalability

- North America dominated the freeze drying market with the largest revenue share of 38.4% in 2024, supported by a robust pharmaceutical and biotech industry, high adoption of advanced processing technologies, and strong investment in research & development, particularly in the U.S., where demand for freeze-dried biologics and specialty foods is rapidly increasing

- Asia-Pacific is expected to be the fastest growing region in the freeze drying market during the forecast period due to rising food processing activities, expanding pharmaceutical manufacturing, and increasing adoption of advanced preservation technologies in countries such as China and India

- Tray freeze dryers dominated the market by type with a share of 45.7% in 2024, driven by their widespread industrial use, scalability, and suitability for processing large volumes of products in pharmaceuticals, food, and biotech applications

Report Scope and Freeze Drying Market Segmentation

|

Attributes |

Freeze Drying Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Freeze Drying Market Trends

Increasing Adoption of Automation and Process Optimization

- A significant and accelerating trend in the global freeze drying market is the growing incorporation of automated control systems and advanced process monitoring technologies, which enhance operational efficiency and product quality

- For instance, modern freeze dryers from companies such as SP Scientific allow real-time monitoring of temperature, pressure, and moisture content, ensuring consistent product stability across batches

- Automation integration enables features such as pre-programmed drying cycles, predictive maintenance alerts, and optimized energy consumption, reducing manual intervention and operational errors

- Advanced software solutions facilitate centralized control over multiple freeze dryers, allowing operators to manage large-scale production in pharmaceuticals, biotech, and food industries from a single interface

- This trend towards intelligent, automated, and data-driven freeze drying systems is reshaping production standards, with companies developing solutions that combine automation, energy efficiency, and high throughput

- The demand for freeze drying systems with automated controls and process optimization is growing rapidly across pharmaceutical, biotech, and food sectors, as manufacturers increasingly prioritize efficiency, reproducibility, and product quality

Freeze Drying Market Dynamics

Driver

Rising Demand in Pharmaceuticals and Biologics

- The increasing need for stable, temperature-sensitive pharmaceuticals, vaccines, and biologics is a major driver for the growing adoption of freeze drying solutions

- For instance, in March 2024, Millrock Technology reported expansion of its freeze drying systems for monoclonal antibodies and vaccine formulations, addressing critical demand in biopharmaceutical production

- As the pharmaceutical industry focuses on long-term stability, shelf-life extension, and preservation of bioactive compounds, freeze drying offers an effective solution to maintain efficacy and safety

- Furthermore, the global rise in biologics manufacturing, coupled with increasing R&D investments, is propelling the demand for freeze drying equipment capable of large-scale, high-precision processing

- The ability to process complex formulations, reduce product degradation, and ensure regulatory compliance makes freeze drying indispensable in both pharmaceutical and biotech sectors

- The convergence of growing biologics production and stringent quality requirements is driving continuous adoption of advanced freeze drying technologies worldwide

Restraint/Challenge

High Capital Costs and Technical Complexity

- The substantial initial investment and operational complexity associated with freeze drying systems pose significant challenges to market growth, particularly for small and medium-scale enterprises

- For instance, high-end industrial freeze dryers from companies such as GEA Lyophil are capital-intensive and require skilled operators, making entry difficult for budget-conscious manufacturers

- Technical challenges such as precise control of temperature, vacuum, and drying cycles, along with maintenance of sterility and prevention of product collapse, increase operational risks

- In addition, prolonged processing times and energy-intensive operations contribute to higher production costs, affecting profitability in food, pharma, and biotech applications

- Overcoming these barriers requires investment in operator training, development of cost-efficient systems, and adoption of energy-optimized technologies to enhance accessibility and reduce operational complexity

- Addressing capital and technical hurdles is crucial for broader market penetration, particularly in emerging regions and smaller-scale manufacturing facilities

Freeze Drying Market Scope

The market is segmented on the basis of type, scale of operation, application, and accessories.

- By Type

On the basis of type, the freeze drying market is segmented into tray, shell, and manifold freeze dryers. The tray freeze dryer segment dominated the market with the largest revenue share of 45.7% in 2024, driven by its widespread industrial use, high processing capacity, and suitability for bulk production in pharmaceuticals, food, and biotech industries. Tray systems are preferred for their ability to provide uniform drying, maintain bioactive compound stability, and handle diverse product forms such as liquids, powders, and slurries. Manufacturers favor tray dryers for operational reliability, scalability, and automation capabilities. Advanced process controls in tray freeze dryers allow precise temperature, vacuum, and cycle management. Their capacity for large-scale batches makes them ideal for industrial applications requiring consistent product quality. The segment also benefits from strong adoption in North America and Europe due to established pharmaceutical and food processing industries.

The shell freeze dryer segment is anticipated to witness the fastest growth rate from 2025 to 2032 due to its increasing adoption in pilot-scale and specialized applications. Shell systems offer compact design, faster cycle times, and suitability for high-value biologics and pharmaceutical formulations. Their ability to reduce product handling and ensure uniform freeze drying makes them attractive for small-batch production. Rising R&D activities in pharmaceuticals and biotech labs are driving demand. These systems are also favored in emerging markets due to space efficiency and lower operational requirements. Shell freeze dryers are increasingly integrated with advanced monitoring systems, further enhancing their appeal.

- By Scale of Operation

On the basis of scale, the freeze drying market is segmented into industrial, lab, and pilot freeze dryers. The industrial segment dominated the market with the largest revenue share in 2024, owing to large-scale production requirements in pharmaceuticals, food processing, and biotechnology. Industrial freeze dryers support high throughput, continuous operation, and robust process control, meeting growing demand for long-shelf-life products. These systems are often integrated with automated loading/unloading, monitoring, and vacuum technologies to optimize efficiency. Industrial-scale freeze drying ensures consistent quality, regulatory compliance, and minimized product degradation. High adoption in North America and Europe is driven by established manufacturing infrastructures. The segment benefits from ongoing technological innovations that enhance productivity and energy efficiency.

The lab-scale segment is expected to witness the fastest CAGR from 2025 to 2032, fueled by increasing research and development activities in pharmaceuticals, biotech, and food sciences. Lab-scale freeze dryers allow precise control over experimental conditions, enabling development and optimization of new formulations. These systems are ideal for universities, research labs, and small biotech startups due to their affordability and versatility. Their small footprint and flexibility support pilot trials and quality testing. Growing focus on biologics and novel food products is driving adoption. Lab-scale freeze dryers are increasingly combined with digital monitoring solutions to enhance accuracy and reproducibility.

- By Application

On the basis of application, the market is segmented into food, pharma, and biotech. The pharmaceutical segment dominated the market in 2024 with the largest revenue share, driven by the critical need for freeze drying in vaccines, biologics, and temperature-sensitive drugs. Freeze drying ensures long-term stability, efficacy, and bioactivity, essential for regulatory compliance. Pharmaceutical manufacturers prioritize freeze drying to reduce degradation and extend shelf life. Integration with automated monitoring and control systems enhances product quality and operational efficiency. Industrial-scale pharmaceutical production relies heavily on freeze drying for high-value formulations. The segment benefits from continuous innovation in drying cycles, vacuum systems, and energy optimization technologies.

The food segment is anticipated to witness the fastest growth from 2025 to 2032 due to rising demand for nutrient-rich, ready-to-eat, and long-shelf-life products. Freeze drying preserves flavors, textures, and nutrients, making it ideal for fruits, vegetables, coffee, and specialty meals. Consumer preference for convenient, high-quality, and functional foods is accelerating adoption in the food industry. Technological improvements in energy efficiency and faster drying cycles support high-volume production. Small and medium-scale food manufacturers are increasingly investing in freeze drying solutions to diversify product portfolios. The growing trend of health-conscious and convenience-focused consumers is expected to drive market expansion.

- By Accessories

On the basis of accessories, the market is segmented into loading and unloading systems, monitoring systems, vacuum systems, and drying chambers. The monitoring systems segment dominated the market in 2024 due to the increasing importance of real-time process control and validation across pharmaceutical, biotech, and food industries. Monitoring systems allow precise tracking of temperature, pressure, and moisture content, ensuring consistent product quality. Adoption is critical for industrial operations that require compliance with regulatory standards. Advanced monitoring also enables predictive maintenance and reduces operational errors. Companies offering integrated monitoring solutions are witnessing higher adoption rates. The segment benefits from the growing focus on automation and quality assurance in freeze drying operations.

The vacuum systems segment is expected to witness the fastest growth from 2025 to 2032, driven by increasing adoption in lab and pilot-scale freeze drying applications. Vacuum systems are essential for maintaining low-pressure conditions that facilitate sublimation and uniform drying. Compact, energy-efficient, and high-performance vacuum solutions are in demand in research labs, small biotech setups, and emerging markets. The segment’s growth is further supported by technological advancements in vacuum pumps, energy optimization, and system integration. Increasing production of high-value biologics and specialty food products is accelerating demand. Vacuum systems are becoming indispensable for precise, efficient, and reproducible freeze drying processes.

Freeze Drying Market Regional Analysis

- North America dominated the freeze drying market with the largest revenue share of 38.4% in 2024, supported by a robust pharmaceutical and biotech industry, high adoption of advanced processing technologies, and strong investment in research & development

- Manufacturers in the region prioritize freeze drying for long-shelf-life products, temperature-sensitive biologics, and high-value specialty foods, ensuring consistent product quality and regulatory compliance

- The widespread adoption is further supported by strong R&D investments, technological advancements in automation and monitoring systems, and the availability of skilled labor, making North America a key hub for freeze drying operations

U.S. Freeze Drying Market Insight

The U.S. freeze drying market captured the largest revenue share of 42% in 2024 within North America, fueled by the country’s well-established pharmaceutical, biotech, and food processing industries. The growing demand for vaccines, biologics, and long-shelf-life food products is driving the adoption of advanced freeze drying technologies. Manufacturers are increasingly prioritizing automation, digital monitoring, and energy-efficient systems to ensure product quality and regulatory compliance. Furthermore, the expansion of R&D facilities and pilot-scale production units is accelerating the development of new formulations requiring precise freeze drying processes. The presence of leading freeze dryer manufacturers and continuous innovation in equipment design further strengthens market growth. The U.S. market benefits from strong government support and investment in healthcare and food technology sectors, promoting widespread adoption of freeze drying solutions.

Europe Freeze Drying Market Insight

The Europe freeze drying market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by the growing pharmaceutical and biotech sectors, along with the demand for high-quality processed foods. Strict regulatory standards for drug stability, biologics, and food safety are encouraging the adoption of advanced freeze drying systems. The increase in urbanization and industrial food processing activities is fostering market growth. European manufacturers are also focusing on energy-efficient and environmentally sustainable freeze drying technologies. The market is witnessing significant adoption across pharmaceutical, biotech, and food processing applications, with systems integrated into both large-scale industrial operations and research facilities. Consumer preference for high-nutrient, long-shelf-life products further supports market expansion.

U.K. Freeze Drying Market Insight

The U.K. freeze drying market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing demand for pharmaceuticals, nutraceuticals, and specialty foods. Rising awareness of product stability, extended shelf life, and bioactive compound preservation is encouraging manufacturers to invest in freeze drying solutions. The U.K.’s advanced R&D infrastructure and strong food and biotech industries support adoption across lab, pilot, and industrial scales. In addition, companies are emphasizing energy-efficient and automated systems to reduce operational costs. The demand for high-quality freeze-dried products in both residential and commercial food sectors contributes to market growth. Integration of freeze drying equipment into research laboratories for formulation development is also boosting the segment.

Germany Freeze Drying Market Insight

The Germany freeze drying market is expected to expand at a considerable CAGR during the forecast period, fueled by the country’s focus on technological innovation, sustainability, and quality standards in pharmaceuticals and food processing. Germany’s well-developed industrial infrastructure supports the adoption of high-capacity, automated freeze drying systems. The increasing demand for temperature-sensitive biologics, vaccines, and specialty foods drives market growth. Manufacturers are integrating advanced monitoring and vacuum systems to ensure product consistency and regulatory compliance. The preference for eco-friendly and energy-efficient technologies further strengthens the market. The adoption of freeze drying solutions in research labs, pilot projects, and industrial-scale production contributes to Germany’s leading position in Europe.

Asia-Pacific Freeze Drying Market Insight

The Asia-Pacific freeze drying market is poised to grow at the fastest CAGR of 25% during the forecast period of 2025 to 2032, driven by rising demand for processed foods, biologics, and pharmaceuticals in countries such as China, Japan, and India. Increasing urbanization, disposable incomes, and industrialization are boosting adoption across lab, pilot, and industrial scales. Government initiatives promoting pharmaceutical manufacturing, food processing, and biotech research are further accelerating market growth. The region is emerging as a manufacturing hub for freeze drying equipment, improving affordability and accessibility. Technological advancements in automation, monitoring, and energy efficiency are enhancing adoption. Growing awareness of product quality, stability, and long shelf life among consumers supports market expansion in APAC.

Japan Freeze Drying Market Insight

The Japan freeze drying market is gaining momentum due to high technological expertise, strong pharmaceutical and food industries, and increasing R&D activities. The country’s emphasis on high-quality, long-shelf-life food products and temperature-sensitive biologics is driving freeze dryer adoption. Integration of automated systems, digital monitoring, and energy-efficient technologies enhances operational efficiency. Japan’s aging population and preference for convenience foods and nutraceuticals further stimulate demand. Both industrial and lab-scale applications are expanding rapidly. The focus on innovation and precision in manufacturing supports growth in both residential and commercial food sectors, as well as pharmaceutical research.

India Freeze Drying Market Insight

The India freeze drying market accounted for the largest revenue share in Asia-Pacific in 2024, attributed to rapid industrialization, growing pharmaceutical and food processing sectors, and increasing R&D activities. India is witnessing rising demand for long-shelf-life foods, vaccines, biologics, and specialty formulations. Government initiatives supporting smart manufacturing, biotech, and nutraceutical production are accelerating adoption. Affordable and locally manufactured freeze drying equipment is enhancing accessibility for small and medium-scale manufacturers. Growing awareness of product quality, stability, and nutritional retention among consumers is driving demand. The expansion of industrial, pilot, and lab-scale freeze drying units is contributing to India’s leading position in the APAC region.

Freeze Drying Market Share

The Freeze Drying industry is primarily led by well-established companies, including:

- Harvest Right (U.S.)

- Millrock Technology, Inc. (U.S.)

- OFD, LLC. (U.S.)

- Labconco, (U.S.)

- GEA Group Aktiengesellschaft (Germany)

- Azbil Corporation (Japan)

- I.M.A. Industria Macchine Automatiche S.p.A. (Italy)

- ATS Automation Tooling Systems Inc (U.S.)

- Tofflon Science and Technology Co., Ltd. (China)

- OPTIMA (Germany)

- Martin Christ Gefriertrocknungsanlagen GmbH (Germany)

- MechaTech Systems Ltd. (U.K.)

- Cuddon Freeze Dry (New Zealand)

- Freezedry Specialties, Inc. (U.S.)

- Cryotec Fr (Germany)

- Freeze Drying Systems Pvt. Ltd. (India)

- HOF Sonderanlagenbau GmbH (Germany)

- Hitachi, Ltd. (Japan)

- BÜCHI Labortechnik AG (Switzerland)

- Scala Scientific (U.S.)

What are the Recent Developments in Global Freeze Drying Market?

- In June 2025, UAE-based company Red Planet unveiled a line of ready-to-eat meals with a shelf life of up to 25 years, utilizing advanced freeze-drying technology. These meals maintain taste, nutritional value, and safety without refrigeration or preservatives, marking a significant achievement in food security and emergency preparedness. The product line features a diverse, Halal-certified menu incorporating local flavors

- In March 2025, the U.S. Food and Drug Administration approved a freeze-dried formulation of Bavarian Nordic's Jynneos vaccine for mpox and smallpox. This new version offers improved transportation, storage, and shelf life, easing long-term stockpiling. Clinical data confirmed that the freeze-dried version provided comparable immune response and safety. Production began in 2024, with first deliveries expected in late 2025

- In July 2024, GEA, a leading supplier of systems and components for the food, beverage, and pharmaceutical industries, showcased significant advancements in pharmaceutical freeze-drying technology at ACHEMA 2024 in Frankfurt, Germany. GEA introduced the LYOAIR® cooling system, which utilizes 100% natural refrigerants and highly efficient compressors to reduce energy consumption compared to conventional systems

- In May 2024, high-tech startup LyoWave licensed Purdue University's microwave lyophilization technology and entered a joint development collaboration with Millrock Technology. This partnership aims to advance freeze-drying processes, enhancing efficiency and scalability in pharmaceutical and biotech applications

- In January 2023, Thrive Freeze Dry set up one of the largest freeze-drying facilities in North America to enhance its capabilities. This expansion aims to meet the growing demand for freeze-dried foods and improve production efficiency across various sectors

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.