Global Glass Lined Equipment Market

Market Size in USD Billion

CAGR :

%

USD

2.13 Billion

USD

3.55 Billion

2024

2032

USD

2.13 Billion

USD

3.55 Billion

2024

2032

| 2025 –2032 | |

| USD 2.13 Billion | |

| USD 3.55 Billion | |

|

|

|

|

Glass Lined Equipment Market Size

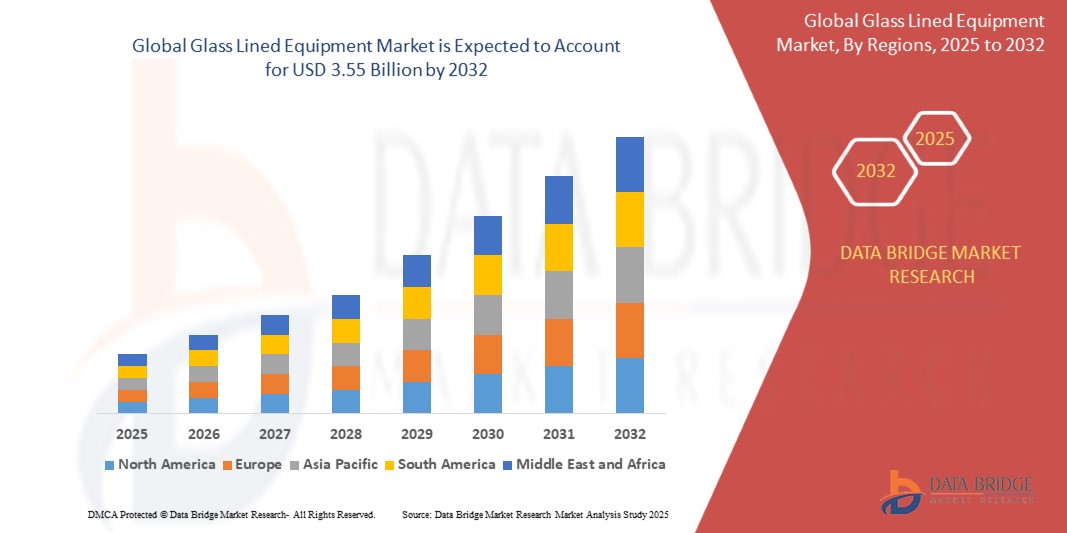

- The global glass lined equipment market was valued at USD 2.13 billion in 2024 and is expected to reach USD 3.55 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 6.6%, primarily driven by the expansion in chemical, pharmaceutical, and food processing industries

- This growth is fueled by factors such as the rising demand for corrosion-resistant and highly durable processing equipment, increased investment in industrial manufacturing infrastructure, and tightening regulatory standards for hygiene and chemical safety in processing industries

Glass Lined Equipment Market Analysis

- Glass lined equipment is essential in various industrial processes, especially in the chemical, pharmaceutical, and food processing sectors, due to its exceptional resistance to corrosion, thermal shock, and chemical reactions. It is widely used in reactors, storage tanks, and pipelines

- The demand for glass lined equipment is significantly driven by the increased use of aggressive chemicals, strict hygiene requirements, and regulatory pressure to adopt safer and more durable materials. Industries with high purity and safety requirements are among the key users of these systems

- The Asia-Pacific region stands out as one of the dominant regions for glass lined equipment, fueled by rapid industrialization, expanding pharmaceutical production, and significant investments in chemical manufacturing infrastructure

- For instance, countries such as China and India have been increasing their domestic manufacturing capacity for bulk drugs and chemicals, accelerating the demand for durable and compliant processing equipment such as glass lined reactors

- Globally, glass lined equipment is considered vital in processes involving corrosive substances, and it plays a crucial role in ensuring safety, durability, and product purity, especially where stainless steel or conventional materials fall short

Report Scope and Glass Lined Equipment Market Segmentation

|

Attributes |

Glass Lined Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Glass Lined Equipment Market Trends

“Growing Demand for Corrosion-Resistant and High-Purity Processing Solutions”

- One prominent trend in the global glass lined equipment market is the increased demand for corrosion-resistant and high-purity solutions across the chemical, pharmaceutical, and food industries

- These systems are gaining popularity due to their longer service life, ease of cleaning, and non-reactive surfaces, which are crucial for processing sensitive or hazardous materials

- For instance, in the pharmaceutical sector, the need for contamination-free production environments has led to the widespread adoption of glass lined reactors and storage tanks, ensuring compliance with GMP and FDA standards

- In addition, sustainability initiatives are prompting manufacturers to adopt equipment that minimizes maintenance and chemical waste

- This trend is reshaping equipment design preferences, with industries increasingly opting for glass lining over traditional metal alloys, ensuring better resistance to acids, solvents, and extreme temperatures, while enhancing process safety and reliability

Glass Lined Equipment Market Dynamics

Driver

“Rising Demand from Chemical and Pharmaceutical Industries”

- The increasing demand for safe and corrosion-resistant processing equipment is a major driver of the global glass lined equipment market, especially in sectors like chemicals, pharmaceuticals, and agrochemicals

- These industries require equipment capable of withstanding highly reactive, acidic, or caustic substances while maintaining purity, and glass lined vessels offer a superior solution due to their inert, smooth, and non-stick surfaces

- As regulatory frameworks become stricter regarding contamination, product consistency, and process safety, companies are turning to glass lined reactors, tanks, and pipes to ensure compliance with FDA, GMP, and other quality standards

- In addition, the growth of specialty chemicals and active pharmaceutical ingredients (APIs) is fueling demand for durable equipment that provides consistent thermal performance and chemical resistance

For instance,

- In October 2023, according to a report by Process Worldwide, the global pharmaceutical industry saw a 10% rise in demand for corrosion-resistant reactors, largely driven by the boom in biopharmaceutical manufacturing and clean-in-place (CIP) processing requirements

- In March 2024, data from Chemical Industry Digest revealed that India’s chemical processing sector is increasingly investing in glass lined equipment for greenfield and brownfield expansions, aiming to reduce operational downtime and contamination risks

- As a result of the expanding chemical and pharmaceutical industries and stricter compliance needs, glass lined equipment is becoming a critical investment for facilities requiring long-term reliability and chemical inertness

Opportunity

“Technological Advancements and Automation in Process Equipment”

- Technological innovations such as automated process control systems, advanced monitoring sensors, and integrated data analytics are opening new opportunities in the global glass lined equipment market

- Modern glass lined reactors and storage tanks are now being equipped with smart sensors and IoT capabilities to provide real-time data on pressure, temperature, pH, and chemical stability, ensuring optimal reaction conditions and predictive maintenance

- This level of integration enhances operational efficiency, reduces human error, and minimizes downtime, making them highly attractive to pharmaceutical, chemical, and biotech industries aiming for digitized manufacturing

For instance,

- In February 2024, according to an article published by Chemical Engineering News, companies in the U.S. and Germany have started deploying smart glass lined reactors integrated with AI-driven process monitoring systems to enable real-time optimization and fault detection during chemical synthesis

- In September 2023, a report from PharmaTech Europe highlighted that European API manufacturers are increasingly investing in automated, glass lined equipment for batch traceability and compliance with Industry 4.0 standards

- As demand grows for precision, safety, and sustainability in chemical processing, the integration of automation and smart technologies in glass lined equipment offers a significant opportunity for manufacturers to differentiate and boost market penetration in high-growth sectors

Restraint/Challenge

“High Capital Costs Hindering Market Penetration”

- The high initial cost of glass lined equipment poses a significant barrier to adoption, particularly in emerging economies and small-scale processing industries

- Glass lined reactors, storage tanks, and other related apparatus require specialized manufacturing, anti-corrosive linings, and customized installation, leading to equipment prices that can range from tens of thousands to several hundred thousand USD per unit

- This steep financial requirement often limits the ability of SMEs and local chemical manufacturers to upgrade from conventional steel equipment to glass lined alternatives, despite the long-term cost savings in maintenance and durability

For instance,

- In October 2024, according to a report by Process Engineering World, many Asian chemical processors continue to rely on stainless steel reactors due to the high capital investment required for transitioning to glass lined technology, especially when ROI takes several years to realize

- As a result, the high upfront cost of glass lined equipment remains a key challenge, limiting market penetration across price-sensitive regions and slowing the adoption rate despite its long-term advantages in chemical resistance and operational life

Glass Lined Equipment Market Scope

The market is segmented on the basis application, product type, technology, magnification type, end user, and distribution channel.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Application |

|

|

By End User |

|

|

By Product |

|

|

By Equipment Type |

|

|

By Capacity

|

|

|

By Pressure |

|

Glass Lined Equipment Market Regional Analysis

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- Asia-Pacific dominates the global glass lined equipment market, primarily due to the booming chemical and pharmaceutical manufacturing sectors, especially in countries like China, India, and Japan

- China holds a significant share of the market, driven by rapid industrialization, growing export capacity in chemicals and APIs, and increasing investments in production facility upgrades that demand corrosion-resistant, high-durability equipment

- In India, the presence of a large number of generic drug manufacturers and increasing government initiatives to boost domestic production capacity has spurred demand for glass lined reactors, columns, and storage tanks

- Furthermore, low manufacturing costs, coupled with an expanding base of process industries and foreign direct investment (FDI), have made Asia-Pacific a global hub for sourcing and utilizing glass lined equipment

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- The Asia-Pacific region is expected to witness the highest growth rate in the global glass lined equipment market, driven by rapid industrialization, expansion of chemical and pharmaceutical manufacturing, and increased capital investments in processing infrastructure

- Countries such as China, India, and South Korea are emerging as key markets due to rising production of active pharmaceutical ingredients (APIs), agrochemicals, and specialty chemicals—sectors that require corrosion-resistant and thermally stable equipment like glass lined reactors, tanks, and pipes

- China, being the world's largest producer of chemicals, is investing heavily in automated and compliant manufacturing systems, fueling high-volume demand for advanced glass lined process vessels

- India’s pharmaceutical and specialty chemical industries, supported by government initiatives such as "Make in India" and PLI schemes, are driving a surge in demand for durable, GMP-compliant glass lined reactors in both domestic and export-driven production

- Moreover, multinational chemical firms are establishing or expanding operations in Asia-Pacific, creating new opportunities for local and international equipment manufacturers to meet evolving safety and efficiency standards

Glass Lined Equipment Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Hengshui Jiangfeng Glasslined Equipment Co., Ltd (China)

- Pfaudler (U.S.)

- Euroglas S.p.A. (Italy)

- Heinkel Drying and Separation Group (Germany)

- Shandong Glass Lined Equipment Factory (China)

- LUOYANG HUIDA PHARMACEUTICAL EQUIPMENT CO., LTD (China)

- De Dietrich Process Systems (France)

- Hengshui Zhongyuan Pharmaceutical Equipment Co., Ltd (China)

- SIGMA Anlagenbau GmbH Co. KG (Germany)

- Alfa Laval AB (Sweden)

- B Process Equipment Systems, LLC. (U.S.)

- NIRO Process Technology (Denmark)

- Corning Incorporated (U.S.)

- Spirax Sarco Engineering plc (U.K.)

- SGT (Italy)

- 3V Tech (Italy)

Latest Developments in Global Glass Lined Equipment Market

- In September 2024, according to the India Chemical Council, India's specialty chemical sector grew by over 12%, with glass lined equipment being a key enabler of safe and efficient manufacturing, especially for acid-based reactions

- In September 2023, GMM Pfaudler Ltd, through its wholly-owned subsidiary GMM Pfaudler US Inc., announced that it had entered into an agreement to acquire 100% of the share capital of Professional Mixing Equipment Inc. The acquisition, valued at USD 7 million, is set to be funded through the company’s internal accruals

- In October 2023, according to ICIS China, more than USD 5 billion was allocated toward upgrading chemical plants in East China with glass lined and anti-corrosive systems, driven by stricter environmental regulations

- In December 2021, HLE Glascoat Limited successfully finalized the acquisition of the global operations of Thaletec GmbH, along with its wholly owned U.S. subsidiary, Thaletec Inc., after securing all regulatory approvals required to complete the transaction

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.