Global Grid Casting Machine Market

Market Size in USD Billion

CAGR :

%

USD

2.67 Billion

USD

4.07 Billion

2024

2032

USD

2.67 Billion

USD

4.07 Billion

2024

2032

| 2025 –2032 | |

| USD 2.67 Billion | |

| USD 4.07 Billion | |

|

|

|

|

Global Grid Casting Machine Market Analysis

The global grid casting machine market is witnessing significant growth, driven by the increasing demand for high-quality casting solutions in industries such as metal production, automotive, and construction. Grid casting machines, known for their precision in casting complex grids for various applications, have become integral in producing materials with enhanced strength, durability, and performance. As industries focus on improving production efficiency and reducing costs, the adoption of grid casting machines has surged, particularly in the steel and aluminium casting sectors. Innovations in automation, real-time monitoring systems, and the integration of Industry 4.0 technologies are further boosting the market, making these machines more efficient and cost-effective. Additionally, the emphasis on producing lightweight and high-performance materials for the automotive and aerospace sectors presents a strong growth opportunity for the grid casting machine market, fostering continuous advancements in both technology and market expansion.

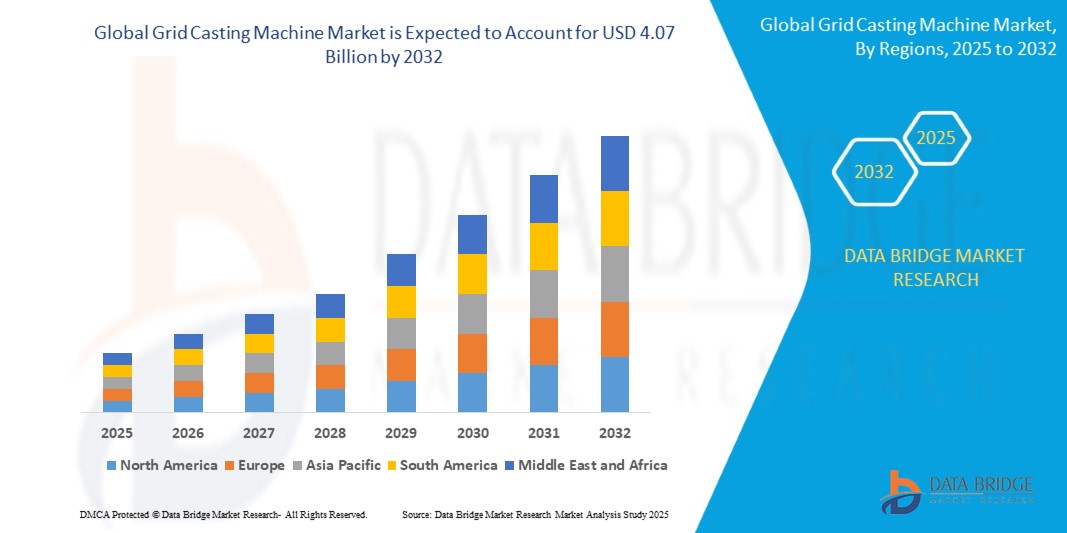

Grid Casting Machine Market Size

Global grid casting machine market size was valued at USD 2.67 billion in 2024 and is projected to reach USD 4.07 billion by 2032, with a CAGR of 5.42% during the forecast period of 2025 to 2032. In addition to the market insights such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Grid Casting Machine Market Trends

“Advancements in Automation and Material Efficiency for High-Performance Casting”

A significant trend in the global grid casting machine market is the growing adoption of automation and the focus on material efficiency. As industries such as automotive, aerospace, and heavy machinery manufacturing seek to improve production efficiency and product quality, grid casting machines are increasingly incorporating automated systems. These automated solutions enable faster production cycles, higher precision in grid formation, and reduced human error, which is crucial for industries requiring high-quality and durable metal components. Additionally, there is a trend toward material optimization, where manufacturers are designing machines that can cast grids with reduced material wastage while maintaining structural integrity. With the push for sustainability, manufacturers are also exploring the use of eco-friendly materials and energy-efficient processes to minimize the environmental impact of grid casting operations. This combination of automation, material efficiency, and eco-conscious innovations is driving growth in the market and positioning grid casting machines as an essential tool for industries aiming for both performance and sustainability.

Report Scope Grid Casting Machine Market Segmentation

|

Attributes |

Grid Casting Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada, Mexico, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa, Brazil, Argentina, Rest of South America |

|

Key Market Players |

WIRTZ Manufacturing Company (U.S), SoVema Group (Italy), MAC Engineering (U.S), HADI Manufacturing Company (U.S), AXFA Corporation (U.S), Borit NV (Belgium), EK Battemakina (Turkey), Kunshan Lead Power Equipment Co., Ltd. (China), CAM Elit Batarya (Turkey), Daramic, LLC (U.S) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Grid Casting Machine Market Definition

Grid casting machines are specialized equipment used in the manufacturing process of grids, which are critical components in industries such as automotive, aerospace, energy, and construction. These machines are designed to precisely cast metal grids that are used in batteries, energy storage systems, and other high-performance applications. The grid casting process involves the creation of grid structures with specific shapes and material properties to ensure maximum strength, conductivity, and durability. Grid casting machines are widely employed for producing grids in lead-acid batteries, electric vehicle (EV) power systems, and renewable energy storage systems. These machines play a crucial role in enabling high-quality, efficient, and scalable production of grid components required for energy storage, automotive, and industrial applications.

Grid Casting Machine Market Dynamics

Drivers

Increasing Demand for Advanced Energy Storage Solutions

The growing need for high-performance energy storage systems, particularly for renewable energy applications and electric vehicles (EVs), is a key driver for the grid casting machine market. These machines play a crucial role in producing high-quality grids for batteries used in energy storage systems and EVs. As the demand for efficient and durable energy storage solutions continues to rise, manufacturers are increasingly adopting grid casting machines to meet the precise requirements for grid components that ensure better performance and longevity of batteries.

Growth in the Automotive Industry

The automotive industry’s shift towards electric vehicles (EVs) is significantly driving the demand for grid casting machines. EVs require advanced battery technologies, and the grids produced by grid casting machines are essential components in lead-acid and lithium-ion batteries. As the adoption of EVs increases globally, the need for high-quality grid casting for batteries is expanding, thus providing substantial growth opportunities for the grid casting machine market.

Opportunities

Expansion in Renewable Energy and Electric Vehicle (EV) Industries

With the growing demand for renewable energy infrastructure and electric vehicles (EVs), there is a rising need for grid casting machines capable of producing high-quality components for energy storage systems, electric motors, and batteries. Grid casting machines are increasingly being used to manufacture high-performance components for energy storage solutions such as batteries and other power systems, contributing to the growth of green technologies. This expanding application base offers manufacturers new opportunities in the renewable energy and electric vehicle sectors.

Focus on Sustainability and Eco-friendly Manufacturing

The emphasis on sustainability and eco-friendly manufacturing processes is opening new opportunities in the grid casting machine market. Companies are looking for machines that not only produce high-quality components but also optimize material usage and energy consumption. The growing adoption of environmentally conscious practices in manufacturing presents a significant opportunity for grid casting machine suppliers to develop and market more energy-efficient and sustainable solutions that align with industry trends towards greener technologies.

Restraints/Challenges

High Initial Investment and Maintenance Costs

One of the significant challenges facing the grid casting machine market is the high initial investment required for purchasing and installing the machinery. These machines are often expensive, especially those designed for high-precision grid production used in industries such as automotive and energy storage. Additionally, the ongoing maintenance costs, including spare parts, skilled labor, and periodic servicing, can be a burden for small to medium-sized companies, which may limit their ability to adopt this technology, especially in cost-sensitive markets.

Limited Availability of Raw Materials

Another challenge in the grid casting machine market is the limited availability and rising costs of raw materials such as high-quality lead and other metals used in the production of battery grids. Fluctuations in the prices and supply of these materials can negatively impact the production of grid casting machines and their components, leading to price volatility and potential disruptions in manufacturing processes. This issue can constrain growth, particularly in markets where raw material sourcing is limited or expensive.

Grid Casting Machine Market Scope

The market is segmented on the basis of type and end-use industries. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Continuous Grid Casting Machines

- Semi-Continuous Grid Casting Machines

- Batch Grid Casting Machines

End-Use Industries

- Automotive

- Renewable Energy

- Aerospace

- Electronics

- Others

Global Grid Casting Machine Market Regional Analysis

The market is analyzed and market size insights and trends are provided by country, type, and end-use Industries as referenced above.

The countries covered in the market are U.S., Canada, Mexico, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, rest of Asia-Pacific, Saudi Arabia, U.A.E., South Africa, Egypt, Israel, rest of Middle East and Africa, Brazil, Argentina, and rest of South America.

The Asia Pacific region dominates the global grid casting machine market due to its robust manufacturing base and rapid industrial growth. Countries such as China and India are investing heavily in infrastructure projects and renewable energy solutions, which drives the demand for grid casting machines. The region's manufacturing capabilities and cost-effective production contribute significantly to the global supply. Additionally, government initiatives focused on energy efficiency and sustainable infrastructure further boost market growth.

North America is the fastest growing region in the grid casting machine market, driven by technological advancements and strong demand in the energy sector. The U.S. and Canada are at the forefront of renewable energy adoption and grid modernization, creating substantial demand for advanced grid casting solutions. Investments in sustainable energy infrastructure and smart grid technologies are propelling the growth of the market in this region. However, compared to Asia Pacific, North America faces higher production costs, impacting its competitive edge.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Global Grid Casting Machine Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Grid Casting Machine Market Leaders Operating in the Market Are:

- WIRTZ Manufacturing Company (U.S.)

- SoVema Group (Italy)

- MAC Engineering (U.S.)

- HADI Manufacturing Company (U.S.)

- AXFA Corporation (U.S.)

- Borit NV (Belgium)

- EK Battemakina (Turkey)

- Kunshan Lead Power Equipment Co., Ltd. (China)

- CAM Elit Batarya (Turkey)

- Daramic, LLC (U.S.)

Latest Developments in Grid Casting Machine Market

- In 2020 SoVema Group, is set to revolutionize the continuous strip casting process with its new flagship technology, further enhancing lead-acid battery production. Over the past three decades, the method of producing battery plate conducting grids has evolved from discrete to continuous processes, significantly improving production efficiency, material costs, and product uniformity. These advancements have led to better battery quality and performance, benefiting a wide range of lead-acid battery designs

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Grid Casting Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Grid Casting Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Grid Casting Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.