Global Hardware Independent Hmi Software Market

Market Size in USD Billion

CAGR :

%

USD

5.59 Billion

USD

11.40 Billion

2025

2033

USD

5.59 Billion

USD

11.40 Billion

2025

2033

| 2026 –2033 | |

| USD 5.59 Billion | |

| USD 11.40 Billion | |

|

|

|

|

Hardware Independent HMI Software Market Size

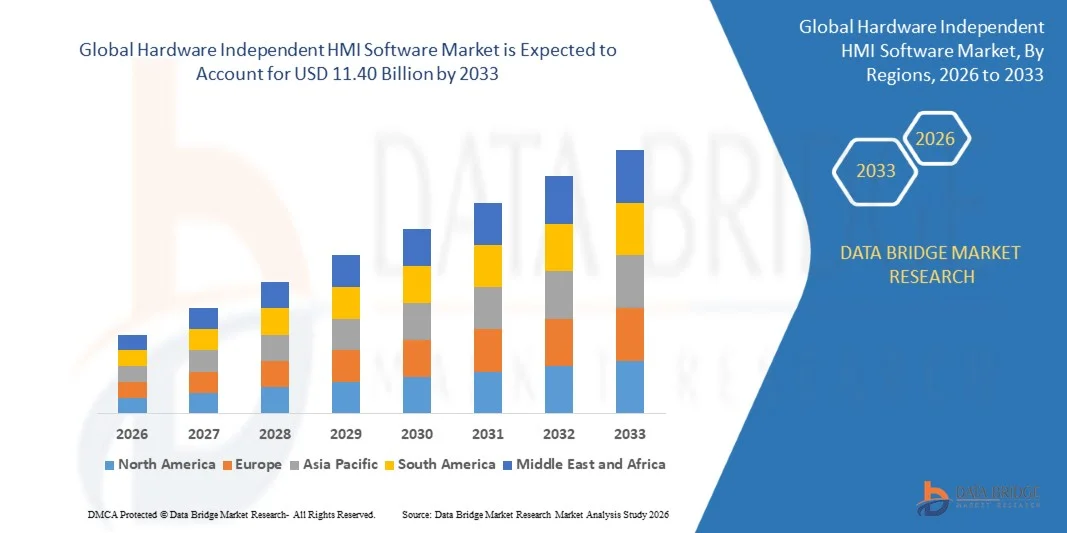

- The Hardware Independent HMI Software Market size was valued at USD 5.59 billion in 2025 and is expected to reach USD 11.40 billion by 2033, at a CAGR of 9.30% during the forecast period.

- The market growth is primarily driven by the increasing adoption of industrial automation and the rising demand for flexible, scalable, and platform-independent human-machine interface solutions across manufacturing, energy, and transportation sectors.

- Additionally, advancements in IoT integration, cloud connectivity, and AI-driven analytics are enhancing the efficiency and usability of HMI software, enabling real-time monitoring and control. These trends are fostering broader implementation of hardware-independent solutions, thereby significantly propelling the market’s expansion.

Hardware Independent HMI Software Market Analysis

- Hardware Independent HMI software, providing platform-agnostic interfaces for industrial machines and processes, is becoming increasingly critical in modern manufacturing, energy, and transportation sectors due to its flexibility, scalability, and compatibility with diverse hardware systems.

- The growing adoption of Industry 4.0 practices, rising demand for real-time monitoring and control, and the need for seamless integration of legacy and new automation systems are major factors driving the market for hardware-independent HMI solutions.

- North America dominated the Hardware Independent HMI Software Market with the largest revenue share of 33.2% in 2025, supported by early adoption of industrial automation, high investment in smart manufacturing, and the presence of leading software providers. The U.S. witnessed significant implementation of HMI solutions in automotive, energy, and food & beverage sectors, driven by innovations in cloud-based and AI-enabled HMI platforms.

- Asia-Pacific is expected to be the fastest-growing region in the Hardware Independent HMI Software Market during the forecast period, fueled by rapid industrialization, government initiatives supporting smart factories, and increasing demand for automation solutions in manufacturing hubs like China and India.

- The Motion HMI segment dominated the market with the largest revenue share of 41.8% in 2025, driven by its intuitive gesture-based control, enhanced user interaction, and applicability across automotive, manufacturing, and robotics sectors.

Report Scope and Hardware Independent HMI Software Market Segmentation

|

Attributes |

Hardware Independent HMI Software Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Hardware Independent HMI Software Market Trends

“Enhanced Efficiency Through AI and Predictive Analytics”

- A significant and accelerating trend in the Hardware Independent HMI Software Market is the increasing integration of artificial intelligence (AI) and predictive analytics into HMI platforms. This fusion of technologies is enhancing operational efficiency, real-time decision-making, and overall process optimization across industrial and manufacturing environments.

- For instance, Siemens’ WinCC and Rockwell Automation’s FactoryTalk View incorporate AI-driven analytics to monitor machine performance and predict maintenance requirements, allowing operators to prevent downtime and optimize production workflows. Similarly, Mitsubishi Electric’s HMI solutions leverage AI to provide adaptive visualization and context-aware alerts for complex industrial processes.

- AI integration in HMI software enables features such as anomaly detection, predictive maintenance, and real-time process optimization. Some platforms, like Inductive Automation’s Ignition, use machine learning to analyze historical production data, identify inefficiencies, and suggest operational improvements. Furthermore, voice-enabled interfaces allow operators to interact with machines hands-free, issuing commands or retrieving critical data verbally, which reduces response time and enhances safety.

- The seamless integration of HMI software with cloud platforms, IoT networks, and advanced analytics tools enables centralized monitoring and control of multiple industrial systems from a single interface. Operators can manage production lines, energy consumption, and process parameters in a unified environment, enhancing overall operational intelligence.

- This trend toward more intelligent, adaptive, and interconnected HMI systems is fundamentally transforming industrial automation, raising expectations for efficiency, usability, and predictive capabilities. Consequently, companies such as COPA-DATA and Beckhoff Automation are developing AI-enabled HMI platforms with features such as predictive alerts, automated workflow adjustments, and integration with voice-controlled industrial assistants.

- The demand for HMI software that incorporates AI and predictive analytics is growing rapidly across manufacturing, energy, and transportation sectors, as enterprises increasingly prioritize operational efficiency, reduced downtime, and data-driven decision-making.

Hardware Independent HMI Software Market Dynamics

Driver

“Growing Need Due to Increasing Industrial Automation and Operational Efficiency Demands”

- The rising adoption of industrial automation, coupled with the increasing need for flexible, platform-independent interfaces, is a key driver for the heightened demand for Hardware Independent HMI software.

- For instance, in 2025, Rockwell Automation launched new FactoryTalk HMI solutions with enhanced cloud connectivity and predictive analytics capabilities, enabling manufacturers to streamline production processes and reduce downtime. Such innovations by major players are expected to drive market growth during the forecast period.

- As industries face pressures to optimize operational efficiency, reduce manual intervention, and improve real-time monitoring, hardware-independent HMI software provides advanced features such as cross-platform compatibility, remote visualization, and integrated analytics, offering a significant upgrade over traditional HMI systems.

- Furthermore, the proliferation of Industry 4.0 initiatives and the demand for interconnected manufacturing environments are making HMI software an essential component of smart factories, allowing seamless integration with SCADA systems, PLCs, and IoT-enabled devices.

- The ability to monitor, control, and optimize multiple machines and processes from a unified interface, along with features like predictive alerts and AI-driven insights, are key factors propelling adoption across manufacturing, energy, and transportation sectors. The trend towards modular, scalable HMI solutions and increasing availability of user-friendly platforms further contributes to market growth.

Restraint/Challenge

“Concerns Regarding Cybersecurity and High Implementation Costs”

- Concerns surrounding cybersecurity vulnerabilities of connected industrial systems pose a significant challenge to broader adoption of hardware-independent HMI software. Since these platforms rely on network connectivity and data exchange, they are susceptible to cyberattacks, raising concerns among enterprises about operational disruptions and data breaches.

- For instance, reports of vulnerabilities in industrial IoT devices and SCADA systems have made some organizations cautious about implementing cloud-connected HMI solutions without robust security measures.

- Addressing these concerns through secure communication protocols, encryption, user authentication, and regular software updates is critical for building trust. Companies such as Siemens and Schneider Electric emphasize advanced security features in their HMI platforms to reassure clients. Additionally, the relatively high initial cost of implementing advanced HMI systems compared to traditional solutions can be a barrier for small and medium-sized enterprises or cost-sensitive markets.

- While modular and scalable solutions are making adoption more accessible, the perceived premium for sophisticated HMI platforms can still hinder widespread implementation, particularly in regions with lower industrial automation penetration.

- Overcoming these challenges through enhanced cybersecurity measures, staff training, and the development of more cost-effective HMI solutions will be essential for sustained market growth.

Hardware Independent HMI Software Market Scope

The hardware independent HMI software market is segmented on the basis of technology type, configuration, end-user industry and sales channel.

• By Technology Type

On the basis of technology type, the Hardware Independent HMI Software Market is segmented into Motion HMI, Bionic HMI, Tactile HMI, and Acoustic HMI. The Motion HMI segment dominated the market with the largest revenue share of 41.8% in 2025, driven by its intuitive gesture-based control, enhanced user interaction, and applicability across automotive, manufacturing, and robotics sectors. Motion HMI solutions enable operators to control machinery or processes with minimal physical contact, reducing operational errors and improving efficiency.

The Tactile HMI segment is anticipated to witness the fastest CAGR of 22.1% from 2026 to 2033, fueled by rising adoption in process automation and industrial applications requiring precise touch feedback. Tactile HMI interfaces offer superior accuracy and user-friendliness, making them increasingly preferred in sectors such as pharmaceuticals, electronics manufacturing, and food processing.

• By Configuration

On the basis of configuration, the Hardware Independent HMI Software Market is segmented into Embedded HMI and Stand-Alone HMI. The Embedded HMI segment held the largest market revenue share of 45.3% in 2025, owing to its seamless integration with PLCs, SCADA systems, and other industrial control hardware, enabling real-time monitoring and control in compact designs. Embedded HMI solutions are widely preferred in automation-intensive sectors for their reliability, stability, and reduced space requirements.

The Stand-Alone HMI segment is expected to witness the fastest CAGR of 21.5% from 2026 to 2033, driven by increasing demand for flexible, scalable, and cross-platform solutions that can operate independently across multiple industrial applications. Stand-alone HMIs provide easy installation, enhanced connectivity, and compatibility with diverse devices, making them highly versatile for retrofitting and modernization projects.

• By End-User Industry

On the basis of end-user industry, the Hardware Independent HMI Software Market is segmented into Process Industry and Discrete Industry. The Discrete Industry segment dominated the market with the largest revenue share of 48.7% in 2025, supported by high adoption in automotive, electronics, and consumer goods manufacturing, where real-time monitoring, production tracking, and predictive maintenance are critical. HMI solutions in discrete industries facilitate operator efficiency and improve machine-to-human interactions.

The Process Industry segment is expected to witness the fastest CAGR of 20.8% from 2026 to 2033, driven by increasing automation in chemical, pharmaceutical, and food processing plants. Process industry applications demand HMI software with robust data visualization, predictive analytics, and cross-platform integration to ensure process safety, efficiency, and regulatory compliance.

• By Sales Channel

On the basis of sales channel, the Hardware Independent HMI Software Market is segmented into Direct Sales Channel and Indirect Sales Channel. The Direct Sales Channel segment held the largest market revenue share of 52.1% in 2025, attributed to strong vendor-client relationships, customized solutions, and on-site implementation support offered by leading HMI providers. Direct sales enable manufacturers to deploy tailored HMI solutions while providing training and post-installation services, enhancing customer satisfaction and long-term retention.

The Indirect Sales Channel segment is expected to witness the fastest CAGR of 19.9% from 2026 to 2033, fueled by rising partnerships with distributors, resellers, and system integrators. Indirect channels facilitate broader market penetration, especially in emerging economies, by offering standardized solutions and after-sales support through established local networks.

Hardware Independent HMI Software Market Regional Analysis

- North America dominated the Hardware Independent HMI Software Market with the largest revenue share of 33.2% in 2025, driven by the early adoption of industrial automation, strong investment in smart manufacturing, and the presence of leading HMI software providers.

- Industries in the region highly prioritize operational efficiency, real-time monitoring, and predictive maintenance, which are facilitated by advanced hardware-independent HMI solutions compatible with diverse automation systems and platforms.

- This widespread adoption is further supported by high technological readiness, strong R&D infrastructure, and the growing focus on Industry 4.0 initiatives, establishing hardware-independent HMI software as a critical solution for manufacturing, energy, and process industries across North America.

U.S. Hardware Independent HMI Software Market Insight

The U.S. hardware-independent HMI software market captured the largest revenue share of 81% in 2025 within North America, driven by rapid adoption of industrial automation, Industry 4.0 initiatives, and increasing demand for flexible, cross-platform HMI solutions. Manufacturers are prioritizing real-time monitoring, predictive maintenance, and process optimization, which are efficiently enabled by hardware-independent HMI software. The growing trend of smart factories, coupled with the integration of IoT, cloud platforms, and AI analytics, is further propelling market growth. Additionally, the presence of leading HMI software providers, strong R&D infrastructure, and high technological readiness support widespread adoption across automotive, energy, and discrete manufacturing sectors.

Europe Hardware Independent HMI Software Market Insight

The Europe hardware-independent HMI software market is projected to expand at a substantial CAGR throughout the forecast period, fueled by increasing industrial automation, regulatory compliance requirements, and growing demand for advanced process monitoring. Countries such as Germany, France, and Italy are witnessing strong adoption due to their established manufacturing bases and emphasis on digitalization. The region is experiencing significant growth in discrete and process industries, with HMI solutions being integrated into both new plants and modernization projects to enhance operational efficiency, reduce downtime, and enable remote monitoring.

U.K. Hardware Independent HMI Software Market Insight

The U.K. hardware-independent HMI software market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by the rise in smart manufacturing initiatives, demand for operational efficiency, and digital transformation strategies across industrial sectors. Increasing concerns over process safety, the need for real-time control, and growing adoption of IoT-enabled HMI platforms are stimulating market growth. Additionally, the U.K.’s advanced industrial infrastructure, robust technology ecosystem, and strong support for automation solutions are expected to continue driving the adoption of hardware-independent HMI software.

Germany Hardware Independent HMI Software Market Insight

The Germany hardware-independent HMI software market is expected to expand at a considerable CAGR during the forecast period, driven by the country’s focus on Industry 4.0, digital factory implementations, and process optimization. Germany’s well-established industrial base, emphasis on high-quality manufacturing, and strong automation infrastructure promote the adoption of hardware-independent HMI solutions across automotive, electronics, and process industries. The integration of HMI platforms with predictive analytics, IoT devices, and SCADA systems is increasingly prevalent, with a strong preference for reliable, secure, and scalable solutions aligned with local industry standards.

Asia-Pacific Hardware Independent HMI Software Market Insight

The Asia-Pacific hardware-independent HMI software market is poised to grow at the fastest CAGR of 24% during the forecast period of 2026 to 2033, driven by rapid industrialization, increasing urbanization, and rising adoption of smart manufacturing technologies in countries such as China, Japan, and India. The region’s growing focus on Industry 4.0, government initiatives supporting digital factories, and increasing demand for flexible, cross-platform HMI solutions are key growth drivers. Additionally, APAC’s expanding manufacturing sector, coupled with cost-effective solutions from domestic HMI providers, is enabling broader adoption across process and discrete industries.

Japan Hardware Independent HMI Software Market Insight

The Japan hardware-independent HMI software market is gaining momentum due to the country’s advanced manufacturing culture, high technological adoption, and increasing focus on smart factory implementation. Japanese industries emphasize operational efficiency, safety, and predictive maintenance, which are enabled by AI-integrated and IoT-connected HMI solutions. The integration of HMI software with robotics, cloud analytics, and machine learning tools is fueling growth. Moreover, the country’s aging industrial workforce is driving the adoption of intuitive, user-friendly HMI systems that enhance operational productivity and reduce manual intervention.

China Hardware Independent HMI Software Market Insight

The China hardware-independent HMI software market accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to rapid industrial growth, urbanization, and widespread adoption of smart manufacturing technologies. China is emerging as a hub for automation and HMI software development, with strong domestic vendors offering cost-effective, scalable, and feature-rich solutions. The push toward smart factories, IoT-enabled industrial environments, and government initiatives supporting digital transformation are key factors propelling market growth. Hardware-independent HMI platforms are increasingly deployed across automotive, electronics, energy, and process industries to optimize efficiency and enhance real-time monitoring capabilities.

Hardware Independent HMI Software Market Share

The Hardware Independent HMI Software industry is primarily led by well-established companies, including:

- Siemens (Germany)

- Rockwell Automation (U.S.)

- Schneider Electric (France)

- Mitsubishi Electric (Japan)

- ABB (Switzerland)

- Honeywell (U.S.)

- Yokogawa Electric (Japan)

- Beckhoff Automation (Germany)

- GE Digital (U.S.)

- Inductive Automation (U.S.)

- Advantech (Taiwan)

- COPA-DATA (Austria)

- Iconics (U.S.)

- Emerson Electric (U.S.)

- Bosch Rexroth (Germany)

- Mitsubishi Electric Factory Automation (Japan)

- Weintek Labs (Taiwan)

- Red Lion Controls (U.S.)

- B&R Automation (Austria)

- Pro-face (Japan)

What are the Recent Developments in Hardware Independent HMI Software Market?

- In April 2024, Siemens AG, a global leader in industrial automation, launched a strategic initiative in South Africa to deploy its advanced hardware-independent HMI solutions across manufacturing and process industries. This initiative emphasizes Siemens’ commitment to enhancing operational efficiency, real-time monitoring, and process optimization tailored to the region’s industrial needs. By leveraging its global expertise and cutting-edge HMI platforms, Siemens is addressing local automation challenges while reinforcing its position in the rapidly growing Hardware Independent HMI Software Market.

- In March 2024, Rockwell Automation, headquartered in the U.S., introduced the latest FactoryTalk HMI platform, specifically designed for discrete and process manufacturing environments. The platform incorporates AI-driven predictive analytics, real-time visualization, and IoT integration to improve operational efficiency and reduce downtime. This advancement highlights Rockwell Automation’s dedication to delivering innovative solutions that empower industrial operators with smarter control and decision-making capabilities.

- In March 2024, Honeywell International Inc. successfully deployed an advanced HMI system as part of the Bengaluru Smart Factory Project, aimed at optimizing production processes and enhancing industrial safety. The implementation leverages state-of-the-art hardware-independent HMI solutions to provide real-time monitoring, predictive maintenance, and remote access, underscoring Honeywell’s commitment to enabling smarter, more resilient industrial operations.

- In February 2024, Advantech Co., Ltd., a leading provider of industrial automation solutions, announced a strategic partnership with several Southeast Asian manufacturing associations to implement standardized HMI platforms across multiple facilities. This collaboration is designed to streamline industrial operations, enhance interoperability, and improve productivity, demonstrating Advantech’s focus on fostering innovation and operational efficiency in regional industrial sectors.

- In January 2024, Schneider Electric unveiled its latest EcoStruxure HMI solution at the Hannover Messe 2024, equipped with cloud connectivity, AI-powered analytics, and modular design for both discrete and process industries. The new platform allows operators to monitor and control multiple systems remotely, offering enhanced usability, predictive insights, and robust security features. This release highlights Schneider Electric’s commitment to integrating advanced technology into industrial automation and strengthening operational intelligence for its global customer base.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.