Global Heat Resistant Polymers Market

Market Size in USD Million

CAGR :

%

USD

20.22 Million

USD

44.09 Million

2024

2032

USD

20.22 Million

USD

44.09 Million

2024

2032

| 2025 –2032 | |

| USD 20.22 Million | |

| USD 44.09 Million | |

|

|

|

|

Heat Resistant Polymers Market Size

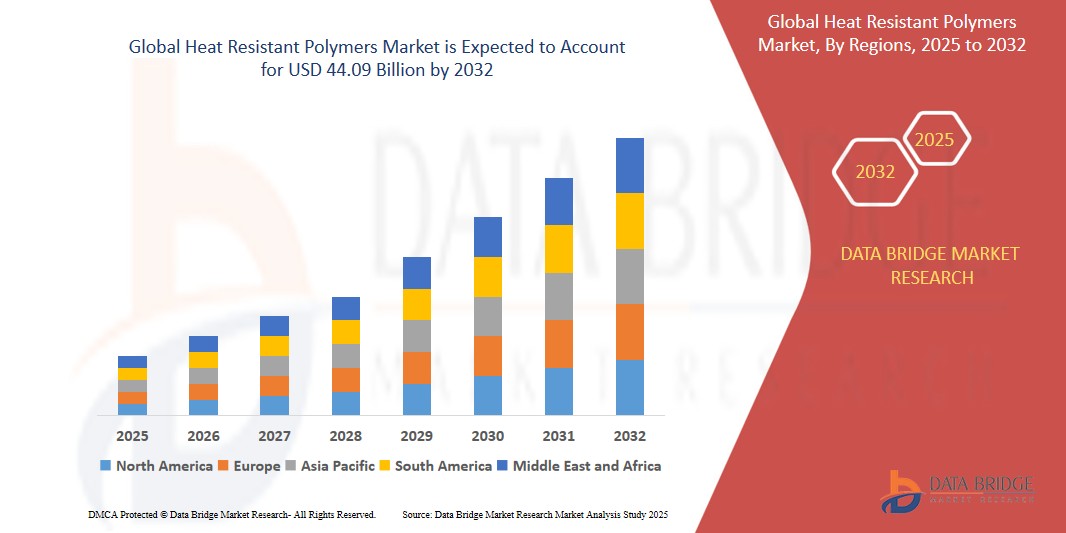

- The global Heat Resistant Polymers market was valued at USD 20.22 billion in 2024 and is expected to reach USD 44.09 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 10.25%, primarily driven by the increasing demand from high-temperature applications across various industries

- This growth is driven by factors such as exceptional thermal stability, mechanical strength, and chemical resistance, making them indispensable in environments where materials are exposed to elevated temperatures

Heat Resistant Polymers Market Analysis

- The market is driven by increasing usage in aerospace, automotive, and electronics industries where materials must withstand high thermal stress without degrading mechanical properties.

- The trend towards lightweight, high-performance components is pushing adoption of heat-resistant polymers like polyimides, PEEK, and PPS.

- Despite strong performance attributes, heat-resistant polymers are significantly more expensive than conventional polymers, and their complex processing requirements pose challenges for mass production.

- This limits their adoption mainly to high-value or specialized applications rather than commodity uses.

Report Scope and Heat Resistant Polymers Market Segmentation

|

Attributes |

Heat Resistant Polymers Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Heat Resistant Polymers Market Trends

“Increasing Demand from the Automotive Industry”

- The automotive sector is increasingly adopting HRPs to replace traditional metal components. This transition is motivated by the need to reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. HRPs offer the necessary thermal stability and mechanical strength required for under-the-hood applications.

- Governments worldwide are implementing stringent emission regulations, compelling automakers to innovate. Incorporating HRPs allows manufacturers to meet these standards by enabling the production of lighter vehicles without compromising safety or performance.

- Technological innovations have led to the development of advanced HRPs like polyphenylene sulfide (PPS) and polyether ether ketone (PEEK), which offer superior heat resistance and durability. These materials are increasingly used in high-performance automotive applications.

- For instance, as vehicle technology advances, the need for high-performance materials that can withstand extreme temperatures and provide durability is expected to increase, solidifying the role of heat-resistant polymers (HRPs) in automotive manufacturing. HRPs are increasingly being used for various vehicle components, including engine parts, exhaust systems, and even body panels, due to their ability to withstand high heat and maintain structural integrity, especially in high-performance vehicles

- As vehicles become more advanced, the reliance on materials that can withstand higher temperatures and offer durability will continue to grow, solidifying heat resistant polymers role in the future of automotive manufacturing.

Heat Resistant Polymers Market Dynamics

Driver

“The Increasing Demand from High-Temperature Applications Across Various Industries”

- The automotive sector is a significant driver of the heat-resistant polymers market. With the push towards electric vehicles (EVs) and the need for lightweight components, manufacturers are turning to materials that can withstand high temperatures while maintaining structural integrity.

- The aerospace industry demands materials that can perform reliably under extreme conditions, including high temperatures, pressure, and exposure to aggressive chemicals. Heat-resistant polymers are used in various aerospace applications, such as wire insulation, fuel system components, and structural parts, where their exceptional thermal and mechanical properties are critical.

- The defense sector also relies on these polymers for military vehicles, aircraft, and protective gear applications, where durability and performance are paramount.

- The electronics industry is experiencing rapid growth, driven by the demand for smaller, faster, and more efficient devices. Heat-resistant polymers are essential in the production of circuit boards, connectors, and other electronic components that must withstand the heat generated during operation.

For instance,

- Toyota and Ford have incorporated Polyphenylene Sulfide (PPS) parts to reduce metal usage and vehicle weight while maintaining heat resistance. PPS is a high-performance polymer known for its excellent thermal stability and mechanical properties, making it a suitable alternative to metal in certain automotive applications

- In conclusion, the increasing demand from high-temperature applications across various industries is a significant driver of the global heat-resistant polymers market.

Opportunity

“Expansion of Heat-Resistant Polymers in Aerospace and Defense Applications”

- The aerospace industry requires materials that maintain structural integrity under high temperatures and stress. Heat-resistant polymers like polyetheretherketone (PEEK) and polybenzimidazole (PBI) offer exceptional thermal stability and mechanical strength, making them ideal for components such as engine parts, insulation, and structural elements.

- Reducing the weight of aircraft is crucial for improving fuel efficiency and reducing emissions. Heat-resistant polymers are significantly lighter than traditional metals and can replace metal components without compromising strength or durability. This substitution contributes to overall weight reduction and operational cost savings.

- In the defense sector, heat-resistant polymers are utilized in military vehicles, aircraft, and protective gear, where durability and performance under extreme conditions are paramount. The materials' resistance to high temperatures and harsh environments makes them suitable for various defense applications, including components exposed to combustion or high friction.

- The aerospace and defense industries' ongoing pursuit of materials that offer high thermal stability, strength, and weight reduction positions heat-resistant polymers as a critical component in future developments. Companies investing in the research and production of these polymers are likely to benefit from the growing demand in these sectors.

Restraint/Challenge

“High Cost of Production”

- Producing heat-resistant polymers involves intricate processes and specialized equipment. These polymers require precise chemical compositions and controlled processing conditions, leading to increased production costs.

- The raw materials used in heat-resistant polymers, such as high-performance resins and specific chemical precursors, are often costly and have limited availability. This scarcity drives up material costs, impacting the overall expense of polymer production.

- The manufacturing of these polymers is energy-intensive, requiring high temperatures and pressures. This not only increases operational costs but also raises environmental concerns due to higher energy consumption.

- The elevated costs associated with heat-resistant polymers can deter their adoption, especially in cost-sensitive industries or regions. This financial barrier limits their widespread use despite their superior performance characteristics.

- The high production costs of heat-resistant polymers, driven by complex manufacturing, expensive raw materials, and energy demands, pose a significant challenge to their market growth. Addressing these cost factors is crucial for broader adoption and competitiveness in various industries.

Heat Resistant Polymers Market Scope

The market is segmented on the basis of type and application.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Application |

|

Heat Resistant Polymers Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Heat Resistant Polymers Market”

- Asia-Pacific dominates the Heat Resistant Polymers market, due to strong economic growth and increase in the demand for high temperature plastics from automotive, electronics, and aerospace industries in this region

- The China holds a significant share due to its large manufacturing base, growing automotive and electronics industries, and government support for high-performance materials.

- Its cost-effective production, expanding R&D capabilities, and rising demand for lightweight, durable polymers in industrial applications further drive its market leadership.

“Europe is Projected to Register the Highest Growth Rate”

- Europe region is expected to witness the highest growth rate in the heat resistant polymers market, driven by rise in the production of automobiles and investments in defense & aerospace in this region

- Germany is expected to lead the growth due to its strong automotive, aerospace, and electrical industries.

- Increasing demand for lightweight, high-performance materials in manufacturing, coupled with robust R&D investments and sustainability initiatives, further fuels market expansion in the country.

Heat Resistant Polymers Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- BASF SE (Germany)

- Arkema Group (France)

- Evonik Industries AG (Germany)

- DAIKIN INDUSTRIES, Ltd. (Japan)

- Celanese Corporation (U.S.)

- Solvay (Belgium)

- KURARAY CO., LTD. (Japan)

- Victrex plc. (U.K.)

- Dongyue Group (China)

- DIC CORPORATION (Japan)

- Honeywell International Inc. (U.S.)

- Covestro AG (Germany)

- Parkway Products, LLC (U.S.)

- A. Schulman, Inc. (U.S.)

- Caledonian Industries Ltd (U.K.)

- Quadrant Epp Surlon India Limited (India)

- Tri-Mack Plastics Manufacturing Corporation (U.S.)

- Dow (U.S.)

- Huntsman International LLC (U.S.)

- PolyOne Corporation (U.S.)

- RTP Company (U.S.)

- Ensinger (Germany)

Latest Developments in Global Heat Resistant Polymers Market

- In May 2023, Solvay launched a new flame-retardant polymer under the brand name, Xydar LCP G-330 HH, which is designed specifically for electric vehicle (EV) battery module insulation to enhance passenger safety during battery thermal runaway events. This addition is expected to keep the company’s commitment to deliver safer, high-performance materials in the e-mobility sector.

- In January 2022, Junkosha, a Japanese manufacturer of fluoropolymers, revealed plans to expand its production capacity for polytetrafluoroethylene liners and peelable fluorinated ethylene propylene heat-shrink materials by 100%.

- In October 2021, HDC Hyundai Engineering Plastics Co. acquired SK Chemicals Co.'s polyphenylene sulfide business for US$32.8 million.

- In August 2019, Zeus Industrial Products, a leading provider of polymer solutions and material science innovations, announced the launch of a new range of polyimide products.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Heat Resistant Polymers Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Heat Resistant Polymers Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Heat Resistant Polymers Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.