Global High Performance Additives Market

Market Size in USD Billion

CAGR :

%

USD

14.42 Billion

USD

18.26 Billion

2025

2033

USD

14.42 Billion

USD

18.26 Billion

2025

2033

| 2026 –2033 | |

| USD 14.42 Billion | |

| USD 18.26 Billion | |

|

|

|

|

What is the Global High Performance Additives Market Size and Growth Rate?

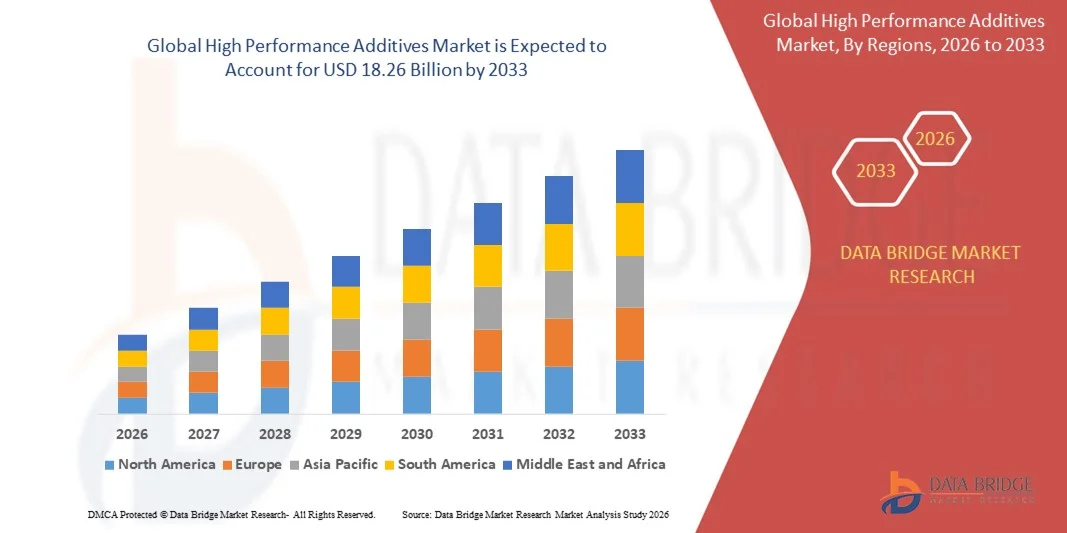

- The global high performance additives market size was valued at USD 14.42 billion in 2025 and is expected to reach USD 18.26 billion by 2033, at a CAGR of 3.00% during the forecast period

- Rise in the disposable income is leading to the hike in infrastructural activities which acts as the vital factor escalating the market growth, also rising development of multipurpose additives, growing demand from industries, such as paints and coatings, adhesives and sealants, plastic, packaging, and automotive, and growing investments into the residential and commercial construction in the countries are the major factors among others driving the high performance additives market

What are the Major Takeaways of High Performance Additives Market?

- Rising packaging applications in emerging markets, rising research and development activities in the market and increasing technological advancements and modernization in the production techniques will further create new opportunities for the high performance additives

- However, rising volatility in the prices of raw materials and stringent environmental regulations are the major factors among others acting as restraints, while increasing labor cost in developed countries will further challenge the growth of high performance additives market

- Asia-Pacific dominated the high performance additives market with a 39.4% revenue share in 2025, driven by rapid expansion of manufacturing, automotive, packaging, electronics, and construction industries across China, India, Japan, and Southeast Asia

- North America is projected to register the fastest CAGR of 8.12% from 2026 to 2033, driven by increasing adoption of high-performance additives across automotive, medical, aerospace, packaging, and construction industries

- The Solvent-Based segment dominated the market with a 42.6% revenue share in 2025, driven by its superior adhesion, faster drying characteristics, and compatibility with industrial coatings, plastics, and automotive applications

Report Scope and High Performance Additives Market Segmentation

|

Attributes |

High Performance Additives Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the High Performance Additives Market?

Rising Demand for Sustainable and High-Performance High Performance Additives

- The high performance additives market is experiencing a strong shift toward eco-friendly, energy-efficient, and high-performance additive solutions that enhance durability, stability, and functionality across industrial applications. Manufacturers are prioritizing materials that deliver better processing efficiency while meeting sustainability standards

- For instance, companies such as BASF, Evonik, and Clariant are expanding portfolios featuring bio-based additives, multifunctional formulations, and low-VOC technologies to support greener production across automotive, construction, packaging, and electronics industries

- Stricter environmental regulations, emission control policies, and rising preference for recyclable and sustainable materials are accelerating demand for advanced additives

- Producers are adopting nanostructured materials, high-stability polymers, and surface-engineered additives to improve performance, longevity, and compatibility with modern manufacturing processes

- Increased R&D in high-temperature stability, green chemistry, and multifunctional additive design is encouraging continuous innovation

- As industries transition toward lightweight materials, energy-efficient processes, and sustainable formulations, High Performance Additives are expected to remain essential to global material enhancement and product innovation

What are the Key Drivers of High Performance Additives Market?

- Rising demand for high-performance materials that improve product durability, energy efficiency, and processing quality is driving adoption across automotive, aerospace, construction, and packaging sectors

- For instance, in 2025, companies such as 3M and Dow expanded production of bio-based and multifunctional High Performance Additives to support sustainable, high-strength industrial manufacturing

- Increasing demand for advanced additives in polymer modification, adhesives, coatings, and composites is boosting market penetration across North America, Europe, and Asia-Pacific

- Technological advancements in additive chemistry—such as improved dispersants, stabilizers, flame retardants, and nanomaterials—are enhancing performance, compatibility, and durability

- Rising focus on green chemistry, lightweight material development, and emission control is strengthening global market growth

- With continuous investments in R&D, material innovation, and environmentally compliant manufacturing, the High Performance Additives market is projected to witness sustained and robust expansion in the coming years

Which Factor is Challenging the Growth of the High Performance Additives Market?

- High production costs associated with advanced additive chemistries, specialty polymers, and nanomaterials limit adoption in cost-sensitive regions

- For instance, from 2024 to 2025, volatility in raw material prices—such as specialty chemicals, rare additives, and polymer precursors—affected production costs for leading manufacturers

- Regulatory compliance related to VOC emissions, chemical safety, and waste management increases operational complexity and raises manufacturing expenses

- Limited awareness among small-scale manufacturers regarding the performance, sustainability benefits, and long-term value of advanced additives restricts large-scale adoption

- Competition from low-cost conventional additives and alternative material enhancement technologies creates pricing pressure in the industry

- To address these challenges, companies are prioritizing cost-efficient raw material sourcing, scalable production, recycled material integration, and formulation optimization to deliver high-quality, sustainable, and competitive High Performance Additive solutions

How is the High Performance Additives Market Segmented?

The market is segmented on the basis of technology, type, and end-user.

- By Technology

On the basis of technology, the high performance additives market is segmented into Solvent-Based, Water-Based, Hot-Melt, and Other technologies. The Solvent-Based segment dominated the market with a 42.6% revenue share in 2025, driven by its superior adhesion, faster drying characteristics, and compatibility with industrial coatings, plastics, and automotive applications. These additives deliver high durability, chemical resistance, and performance stability, making them essential for heavy-duty environments.

The Water-Based segment is projected to grow at the fastest CAGR between 2026 and 2033, supported by rising demand for low-VOC, environmentally friendly formulations across packaging, construction, and electronics industries. Increasing regulatory pressure toward sustainable chemistry and expanding adoption of green coating technologies further strengthen this shift. Continuous advancements in polymer dispersions, bio-based solvents, and high-performance waterborne systems are expected to enhance efficiency, making water-based additives a key growth engine for the global High Performance Additives market.

- By Type

By type, the high performance additives market is segmented into Plastic Additives, Rubber Additives, Paints & Coatings Additives, Fuel Additives, Ink Additives, Leather Additives, Lubricant Additives, and Adhesives & Sealants Additives. The Plastic Additives segment dominated the market with a 34.9% revenue share in 2025, supported by rising consumption of polymers in packaging, transportation, electronics, and construction. These additives enhance material strength, stability, UV resistance, flame retardancy, and processing efficiency, making them essential for high-performance polymer applications.

The Lubricant Additives segment is expected to grow at the fastest CAGR from 2026 to 2033, driven by increasing adoption in automotive, industrial machinery, and heavy equipment to improve wear resistance, oxidation stability, friction reduction, and energy efficiency. Ongoing innovation in anti-wear agents, dispersants, VI improvers, and eco-friendly lubricant chemistries is accelerating growth. Rising demand for lightweight materials and high-efficiency industrial operations continues to support long-term market expansion.

- By End-User

On the basis of end-user, the high performance additives market is segmented into Transportation, Packaging, Electronics, Construction, Medical, and Other end-use industries. The Transportation segment dominated the market with a 31.4% revenue share in 2025, driven by strong demand for high-performance additives in automotive components, coatings, lubricants, polymer enhancements, and lightweight material applications. These additives improve durability, fuel efficiency, heat resistance, and mechanical performance across vehicles and aircraft.

The Electronics segment is projected to grow at the fastest CAGR between 2026 and 2033, fueled by the rapid expansion of advanced consumer electronics, EV batteries, semiconductors, and circuit board manufacturing. Increasing demand for thermal stabilizers, conductive additives, flame retardants, and precision coating materials is further accelerating adoption. Rising industrial modernization, electrification, and technological advancements are expected to sustain growth across both established and emerging electronic applications globally.

Which Region Holds the Largest Share of the High Performance Additives Market?

- Asia-Pacific dominated the high performance additives market with a 39.4% revenue share in 2025, driven by rapid expansion of manufacturing, automotive, packaging, electronics, and construction industries across China, India, Japan, and Southeast Asia. Strong industrialization, rising consumption of plastics and advanced materials, and increasing adoption of high-performance and sustainable additives strengthen regional leadership.

- Manufacturers in the region are investing in innovative additive technologies, improved polymer formulations, and energy-efficient production systems to meet rising industrial demand

- Government initiatives to develop eco-friendly, high-durability materials further enhance market dominance. Growing urbanization, rising exports, and expanding chemical production continue boosting adoption of High Performance Additives across Asia-Pacific industries

China High Performance Additives Market Insight

China leads the Asia-Pacific market, fueled by expanding plastics manufacturing, automotive production, electronics fabrication, and construction activities. High Performance Additives are widely used to improve material durability, heat resistance, processing efficiency, and sustainability. Strong government support for advanced materials, large-scale manufacturing capabilities, and rapid expansion of infrastructure projects significantly enhance market penetration. Continuous innovation in polymer stabilizers, flame retardants, lubricant additives, and performance enhancers is strengthening China’s leadership position.

India High Performance Additives Market Insight

India is emerging as a major contributor, supported by rapid industrialization, growth in packaging and automotive sectors, and rising focus on sustainable materials. Increasing investments in chemical manufacturing, polymer processing, and electronics assembly are driving demand for High Performance Additives. As companies shift toward high-efficiency, eco-friendly formulations, adoption continues to accelerate. Government initiatives promoting domestic manufacturing and clean technologies are expected to support strong long-term growth.

Japan High Performance Additives Market Insight

Japan contributes significantly due to advanced technological capabilities, strong automotive and electronics industries, and high adoption of premium additive formulations. Focus on precision manufacturing, high-performance polymers, and sustainability supports continuous demand. Investments in lightweight materials, advanced coatings, and energy-efficient systems further strengthen market growth. Japan remains a key innovator within the Asia-Pacific High Performance Additives sector.

North America High Performance Additives Market Insight (Fastest-Growing Region)

North America is projected to register the fastest CAGR of 8.12% from 2026 to 2033, driven by increasing adoption of high-performance additives across automotive, medical, aerospace, packaging, and construction industries. Rising demand for lightweight materials, sustainable polymers, high-durability coatings, and advanced lubricants is fueling rapid market expansion. Strong R&D capabilities, technological innovation, and stringent environmental regulations are encouraging manufacturers to develop advanced, eco-friendly additive solutions. Energy-efficient production processes and digital manufacturing systems are further accelerating adoption across the U.S. and Canada.

U.S. High Performance Additives Market Insight

The U.S. is the largest contributor in North America, supported by strong demand for high-performance additives in automotive, aerospace, medical devices, packaging, and industrial manufacturing. Companies are investing in polymer innovation, high-end coatings, advanced lubricant technologies, and sustainable materials. Regulatory pressure for low-VOC, environmentally friendly additives continues to drive R&D advancements and market penetration.

Canada High Performance Additives Market Insight

Canada contributes steadily, supported by growing adoption of high-performance additive technologies in packaging, construction, and industrial manufacturing. Rising demand for eco-friendly polymers, advanced coatings, and high-efficiency lubricants is broadening market presence. Industry collaborations and government initiatives promoting sustainable material development further support market growth.

Europe High Performance Additives Market Insight

Europe holds a substantial share, driven by increasing emphasis on sustainability, energy efficiency, and high-performance materials across Germany, the U.K., France, and Italy. The region is a leader in regulatory compliance, prompting greater adoption of low-VOC, recyclable, and advanced additive solutions. Continuous innovation in specialty polymers, protective coatings, and high-end industrial materials is strengthening regional momentum.

Germany High Performance Additives Market Insight

Germany dominates the European market, driven by strong demand across automotive, industrial machinery, and chemical manufacturing. High-quality engineering standards, R&D investments, and advanced material technologies support widespread adoption of high-performance additives. Focus on lightweight materials and sustainability initiatives continues to enhance market growth.

U.K. High Performance Additives Market Insight

The U.K. market is expanding steadily due to rising adoption of high-performance additive solutions across packaging, construction, automotive coatings, and electronics. Regulatory support for eco-friendly materials, along with increased R&D collaboration, contributes to ongoing market expansion. Emphasis on modernization and production optimization strengthens future growth prospects.

Which are the Top Companies in High Performance Additives Market?

The high performance additives industry is primarily led by well-established companies, including:

- 3M (U.S.)

- Sika AG (Switzerland)

- H.B. Fuller Company (U.S.)

- Pidilite Industries Limited (India)

- Henkel (Germany)

- Huntsman International LLC. (U.S.)

- Bostik (France)

- Engineered Bonding Solutions (U.S.)

- Anabond (India)

- Ashland (U.S.)

- Delo Industrial Adhesives, LLC (U.S.)

- Gougeon Brothers (U.S.)

- WEICON GmbH & Co. KG (Germany)

- Olympus Corporation (Japan)

- Royal Adhesives & Sealants, LLC (U.S.)

- Permabond LLC. (U.S.)

- Hernon Manufacturing, Inc. (U.S.)

- Master Bond Inc., LLC (U.S.)

- Dymax Corporation (U.S.)

- Uniseal Inc. (U.S.)

- Parson Adhesives, Inc. (U.S.)

- Loxeal S.r.l. (Italy)

- MAPEI (Italy)

- Gurit (Switzerland)

- Parker Hannifin Corp (U.S.)

What are the Recent Developments in Global High Performance Additives Market?

- In February 2025, LANXESS introduced Vulkanox HS Scopeblue, a next-generation rubber additive designed to enhance tire sustainability and extend product lifespan. The formulation contains 55% sustainable raw materials and offers a greener alternative to the traditional Vulkanox HS (TMQ), delivering over 30% lower carbon footprint through the use of biocircular acetone and green energy. This launch highlights LANXESS’s commitment to eco-efficient rubber additive solutions

- In January 2025, Solvay and Hankook entered into a strategic collaboration by signing an MoU to develop circular silica derived from waste and bio-based resources for tire manufacturing. The partnership leverages Solvay’s silica innovation and sustainability expertise combined with Hankook’s advanced production capabilities and global reach. This initiative reinforces efforts toward circularity and environmentally responsible tire production

- In January 2024, BASF released an upgraded version of its Keropur gasoline additive bottle in Taiwan’s automotive aftermarket, offering a refined formula for modern DISI engines while retaining strong performance for traditional PFI engines. This new-generation formulation is engineered to improve engine efficiency and reliability across diverse vehicle types. The launch strengthens BASF’s presence in high-performance fuel additive solutions

- In November 2022, Evonik Industries AG collaborated with Biesterfeld Performance Rubber GmbH to strengthen distribution of its premium rubber additive VESTENAMER across the EMEA region excluding Italy. The alliance aims to ensure a stable and responsive supply chain, improving access for industries such as rubber recycling. This move supports enhanced market availability and supply resilience for high-quality rubber additives

- In November 2022, Evonik Industries AG partnered with Biesterfeld Performance Rubber GmbH to broaden the reach of its VESTENAMER high-performance rubber additive throughout the EMEA region except Italy. The partnership focuses on creating a flexible and secure value chain to support key industrial markets including rubber recycling. This expansion emphasizes Evonik’s focus on sustainability and improved material circulation

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global High Performance Additives Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global High Performance Additives Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global High Performance Additives Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.