Global Implant Grade Peek Polymer Machining Services Market

Market Size in USD Million

CAGR :

%

USD

420.00 Million

USD

1,042.13 Million

2024

2032

USD

420.00 Million

USD

1,042.13 Million

2024

2032

| 2025 –2032 | |

| USD 420.00 Million | |

| USD 1,042.13 Million | |

|

|

|

|

Implant-Grade PEEK Polymer Machining Services Market Size

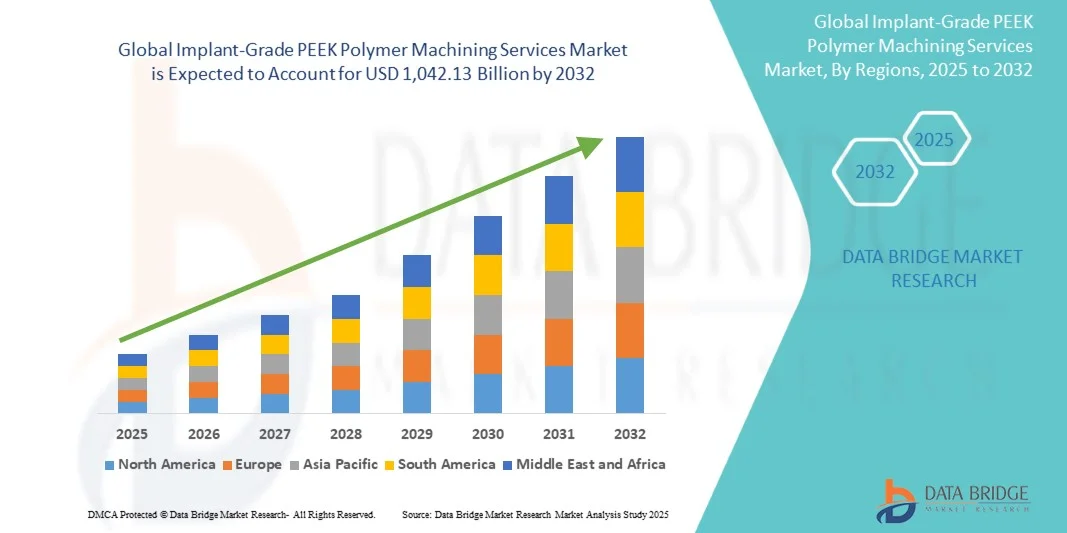

- The global implant-grade PEEK polymer machining services market size was valued at USD 420 Million in 2024 and is expected to reach USD 1,042.13 Million by 2032, at a CAGR of 12.03% during the forecast period

- The market growth is largely fueled by the increasing adoption of advanced materials and precision manufacturing technologies, driving demand for high-performance Implant-Grade PEEK polymer machining solutions in medical, aerospace, and industrial applications

- Furthermore, rising consumer and industry demand for biocompatible, durable, and lightweight materials is creating significant opportunities for Implant-Grade PEEK Polymer Machining Services providers, thereby accelerating the growth of the global market

Implant-Grade PEEK Polymer Machining Services Market Analysis

- Implant-Grade PEEK Polymer Machining Services, offering precision machining of high-performance polyether ether ketone (PEEK) components, are increasingly vital for medical implants, orthopedic devices, and dental applications due to their biocompatibility, strength, and thermal stability

- The escalating demand for implant-grade PEEK polymer machining services is primarily fueled by the growing adoption of PEEK in implantable medical devices, increasing orthopedic and dental surgeries, and the rising need for lightweight and durable biomaterials

- North America dominated the implant-grade PEEK polymer machining services market with the largest revenue share of 39.5% in 2024, characterized by advanced healthcare infrastructure, high R&D investment, and a strong presence of key industry players, with the U.S. experiencing substantial growth in PEEK machining services installations, particularly in orthopedic and spinal implant applications, driven by innovations from both established medical device companies and startups focusing on precision manufacturing

- Asia-Pacific is expected to be the fastest-growing region in the implant-grade PEEK polymer Machining Services market during the forecast period due to increasing urbanization, rising healthcare expenditure, expanding medical infrastructure, and growing adoption of advanced biomaterials in countries such as China, India, and Japan

- The Medical-Grade PEEK segment dominated the market with a revenue share of 47.2% in 2024, attributed to its superior biocompatibility, chemical resistance, and proven track record in orthopedic and spinal implants. Medical-grade PEEK meets stringent FDA and ISO standards, ensuring safe application in critical healthcare procedures

Report Scope and Implant-Grade PEEK Polymer Machining Services Market Segmentation

|

Attributes |

Implant-Grade PEEK Polymer Machining Services Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Implant-Grade PEEK Polymer Machining Services Market Trends

“Enhanced Convenience Through Advanced Manufacturing Technologies”

- A significant and accelerating trend in the global implant-grade PEEK polymer machining services market is the increasing adoption of advanced manufacturing technologies such as CNC machining, additive manufacturing, and automation systems. These technologies are significantly enhancing precision, consistency, and efficiency in machining high-performance PEEK components used in medical implants, dental applications, and orthopedic devices

- For instance, several leading service providers have implemented automated CNC lines capable of producing complex PEEK components with tight tolerances, reducing human error and increasing production throughput. Similarly, the integration of real-time monitoring systems ensures high-quality outputs and minimizes waste, offering a more reliable and cost-efficient machining process

- Advanced software solutions and simulation tools are being used to optimize machining parameters, predict material behavior, and enhance process efficiency. These tools help manufacturers reduce production time, minimize defects, and improve overall component quality

- The trend towards the adoption of automated and digitally integrated machining processes is reshaping industry expectations, with manufacturers increasingly focusing on delivering high-precision, consistent, and scalable PEEK components

- Companies such as Evonik, Solvay, and RTP Company are investing in state-of-the-art machining technologies and digital monitoring systems to improve operational efficiency, reduce lead times, and ensure compliance with stringent medical device standards

- The demand for high-precision Implant-Grade PEEK machining services is growing rapidly across the medical, dental, and orthopedic sectors, driven by the need for reliable, durable, and biocompatible components

Implant-Grade PEEK Polymer Machining Services Market Dynamics

Driver

“Rising Demand for High-Performance Biocompatible Materials”

- The increasing prevalence of orthopedic, spinal, and dental procedures, coupled with the rising need for lightweight, durable, and biocompatible implant materials, is a significant driver for the growth of Implant-Grade PEEK Polymer Machining Services

- For instance: In March 2023, Solvay announced the expansion of its PEEK-based materials portfolio for medical devices, enabling manufacturers to produce more complex and high-performance implants. Such developments are expected to drive market growth in the forecast period

- The trend of personalized and patient-specific implants, facilitated by advancements in 3D printing and CNC machining of PEEK, further propels market demand

- High-performance PEEK components offer advantages such as radiolucency, chemical resistance, and mechanical strength, making them increasingly preferred for critical medical applications

- Moreover, regulatory approvals and quality certifications are encouraging healthcare providers and manufacturers to adopt PEEK machining services for implantable devices

- The aging global population and rising cases of degenerative bone and joint disorders are further fueling demand for advanced implant-grade PEEK solutions

- Continuous research into PEEK modifications, such as carbon-fiber-reinforced and bioactive PEEK composites, is opening new opportunities for machining services, driving innovation and adoption in both developed and emerging markets

- Strategic collaborations between material suppliers, machining service providers, and medical device manufacturers are creating integrated value chains, helping accelerate innovation and reduce time-to-market

Restraint/Challenge

“High Costs and Technical Complexity”

- The relatively high cost of implant-grade PEEK materials and machining services can pose a challenge to broader adoption, particularly among small-scale medical device manufacturers or in cost-sensitive markets

- Precision machining of PEEK requires advanced equipment, skilled labor, and strict quality controls, which increases operational costs and limits entry for smaller players.

- In addition, maintaining consistency and compliance with medical device standards is technically challenging, requiring continuous investment in training, calibration, and quality assurance processes

- Manufacturers also face supply chain constraints for high-purity PEEK resins, which can impact production timelines and scalability

- The limited availability of skilled professionals with expertise in machining high-performance polymers adds to the challenge, often slowing down innovation and capacity expansion

- Regulatory barriers, including the long approval timelines for new medical devices, can delay commercialization and increase costs for companies operating in this space

- Competition from alternative biomaterials, such as titanium, stainless steel, and bioresorbable polymers, may hinder growth if PEEK solutions are perceived as costlier or less accessible

- Overcoming these challenges through process optimization, automation, strategic sourcing of materials, partnerships with academic/research institutions, and the development of cost-effective machining methods will be vital for sustained market growth

Implant-Grade PEEK Polymer Machining Services Market Scope

The market is segmented on the basis of service type, material grade, and end-use application.

• By Service Type

On the basis of service type, the Implant-Grade PEEK Polymer Machining Services market is segmented into CNC Machining, Turning, Milling, Drilling, and Others. The CNC Machining segment dominated the largest market revenue share of 41.5% in 2024, driven by its high precision, repeatability, and suitability for complex geometries required in medical implants. CNC machining allows manufacturers to maintain tight tolerances, ensuring reliability and safety in orthopedic, dental, and spinal implants. The segment’s growth is supported by hospitals and medical device manufacturers seeking quality and consistency in PEEK components while reducing production time and material waste. Technological advancements, including multi-axis CNC machines and computer-aided programming, further enhance the efficiency and capabilities of CNC machining. The segment also benefits from stringent regulatory compliance in medical device manufacturing, which favors highly controlled machining processes. Demand is particularly strong in developed regions such as North America and Europe due to established healthcare infrastructure and rising adoption of minimally invasive procedures. Additionally, the ability to produce patient-specific implants with CNC machining reinforces its dominance in the market. The increasing need for lightweight, durable, and biocompatible implants further supports the segment. Overall, CNC machining continues to be the preferred method for precision PEEK component manufacturing in the medical sector.

The Milling segment is expected to witness the fastest CAGR of 20.8% from 2025 to 2032, driven by its versatility in shaping complex implant geometries and its cost-effectiveness compared to other machining methods. Milling allows rapid prototyping and small-batch production, catering to both established medical device manufacturers and emerging startups. The segment growth is also fueled by increasing demand for customized orthopedic and dental implants, where precise contouring and surface finishing are critical. Technological upgrades, such as automated milling and adaptive control systems, improve production efficiency and reduce the risk of errors. The expansion of hospitals and specialty clinics in emerging economies further supports adoption. Integration with computer-aided design (CAD) systems ensures seamless transfer of patient-specific implant designs to the milling machines. Additionally, milling enables modifications and adjustments during production without major disruptions, making it highly suitable for iterative design processes. Partnerships between material suppliers and machining service providers strengthen reliability and availability. The combination of speed, precision, and flexibility positions milling as the fastest-growing service segment.

• By Material Grade

On the basis of material grade, the Implant-Grade PEEK Polymer Machining Services market is segmented into Medical-Grade PEEK, Reinforced PEEK, and Bio-Compatible PEEK. The Medical-Grade PEEK segment dominated the market with a revenue share of 47.2% in 2024, attributed to its superior biocompatibility, chemical resistance, and proven track record in orthopedic and spinal implants. Medical-grade PEEK meets stringent FDA and ISO standards, ensuring safe application in critical healthcare procedures. The segment is widely adopted by implant manufacturers for load-bearing applications, where mechanical strength and fatigue resistance are crucial. Rising prevalence of orthopedic conditions, spinal disorders, and dental reconstruction procedures further drives demand. Continuous innovations in sterilization and surface modification techniques enhance implant integration with human tissues. North America and Europe lead in market share due to early adoption of advanced medical technologies, well-established regulatory frameworks, and high healthcare expenditure. OEM-certified PEEK polymers guarantee consistency and performance in critical medical applications. Hospitals and clinics prefer medical-grade PEEK implants for durability, reduced risk of complications, and long-term reliability. The segment also benefits from collaborative research programs between academic institutions and medical device companies, fostering innovation. Overall, medical-grade PEEK remains the benchmark for high-quality implants.

The Reinforced PEEK segment is expected to witness the fastest CAGR of 19.7% from 2025 to 2032, driven by the addition of carbon fibers or glass fibers that enhance mechanical strength and stiffness. Reinforced PEEK is increasingly used in load-bearing orthopedic and spinal implants where additional strength is required without adding significant weight. The segment benefits from technological advancements in fiber orientation and processing techniques, which improve implant performance. Hospitals and specialty clinics in emerging economies are adopting reinforced PEEK implants as cost-effective alternatives to metal implants. Growing awareness about minimally invasive surgeries and patient-specific implants supports adoption. Reinforced PEEK’s compatibility with CNC machining and milling further strengthens its market presence. Additionally, government initiatives promoting affordable healthcare infrastructure encourage the use of durable, high-performance implant materials. The flexibility in design, combined with excellent biocompatibility, positions reinforced PEEK as the fastest-growing material segment.

• By End-Use Application

On the basis of end-use application, the Implant-Grade PEEK Polymer Machining Services market is segmented into Orthopedic Implants, Dental Implants, Spinal Implants, Cardiovascular Implants, and Others. The Orthopedic Implants segment dominated the market with a revenue share of 44.6% in 2024, fueled by rising prevalence of fractures, joint disorders, and age-related bone conditions. Hospitals and orthopedic centers increasingly rely on PEEK implants due to their lightweight, radiolucent, and biocompatible properties. High adoption of minimally invasive surgical procedures and patient-specific implants further drives demand. Continuous technological innovations, including surface texturing and coating, enhance osseointegration and long-term implant stability. North America and Europe lead the segment due to advanced healthcare infrastructure, high disposable incomes, and regulatory support. OEM-certified implant manufacturers provide reliable solutions, ensuring safety and consistency. The segment also benefits from collaborations between hospitals and machining service providers for customized implant designs. Rising orthopedic surgeries and the aging population continue to reinforce the segment’s dominance.

The Dental Implants segment is expected to witness the fastest CAGR of 21.5% from 2025 to 2032, driven by increasing dental disorders, rising oral healthcare awareness, and the demand for biocompatible and durable materials. Customized PEEK dental implants allow precise fitting and improved patient outcomes, reducing post-operative complications. Technological advancements, such as CAD/CAM integration, enhance production efficiency and accuracy. Growing adoption of dental implants in emerging regions, where cost-effective yet high-quality solutions are required, supports segment growth. Dental clinics and specialized implant centers are increasingly relying on PEEK machining services to provide patient-specific restorations. The lightweight, radiolucent nature of PEEK materials further improves clinical outcomes. Expansion of dental services, government healthcare initiatives, and insurance coverage for implant procedures also contribute to growth. Overall, the segment represents the fastest-growing end-use category in the market.

Implant-Grade PEEK Polymer Machining Services Market Regional Analysis

- North America dominated the implant-grade PEEK polymer machining services market with the largest revenue share of 39.5% in 2024, characterized by advanced healthcare infrastructure, high R&D investment, and a strong presence of key industry players

- The market captured nearly 81% of the regional share, driven by substantial growth in PEEK machining services installations, particularly in orthopedic and spinal implant applications

- Continuous innovations from both established medical device companies and startups focusing on precision manufacturing are further accelerating adoption. The demand is also supported by favorable reimbursement policies and the presence of leading academic and research institutions promoting biomaterials innovation

U.S. Implant-Grade PEEK Polymer Machining Services Market Insight

The U.S. implant-grade PEEK polymer machining services market dominated North America with an revenue share in 2024, fueled by increasing demand for orthopedic, spinal, and dental implants requiring high-precision PEEK machining. Strong adoption is attributed to the country’s well-established healthcare infrastructure, robust clinical trials pipeline, and leading role in advanced biomaterials research. Additionally, collaborations between medical device manufacturers and machining service providers are enhancing technology integration, driving efficiency, and reducing time-to-market for implantable devices.

Europe Implant-Grade PEEK Polymer Machining Services Market Insight

The Europe implant-grade PEEK polymer machining services market is projected to expand at a substantial CAGR during the forecast period, primarily driven by stringent medical device regulations, growing focus on patient safety, and increasing adoption of advanced biomaterials. Countries such as Germany, the U.K., and France are at the forefront of PEEK machining adoption due to strong healthcare systems and emphasis on innovation in precision implants. Expansion of minimally invasive surgeries and a growing preference for bio-compatible materials further boost demand across orthopedic and cardiovascular applications.

U.K. Implant-Grade PEEK Polymer Machining Services Market Insight

The U.K. implant-grade PEEK polymer machining services market is expected to grow at a notable CAGR, supported by its rising focus on personalized medicine and increasing investment in orthopedic and dental implant solutions. Strong regulatory oversight ensures high-quality manufacturing, while government-backed healthcare initiatives are promoting adoption of bio-compatible materials such as PEEK. Additionally, rising demand for advanced surgical implants and collaborations between machining companies and hospitals are contributing to market growth.

Germany Implant-Grade PEEK Polymer Machining Services Market Insight

The Germany implant-grade PEEK polymer machining services market is anticipated to register considerable CAGR growth, underpinned by its advanced manufacturing infrastructure and focus on innovation. The country is a leader in precision engineering, making it a hub for implant-grade PEEK machining services. Growing demand for spinal implants, along with strong partnerships between research institutions and medical device companies, supports expansion. Germany’s emphasis on eco-friendly and sustainable manufacturing also aligns with the broader healthcare sector’s goals.

Asia Pacific Implant-Grade PEEK Polymer Machining Services Market Insight

The Asia-Pacific implant-grade PEEK polymer machining services market is expected to be the fastest-growing region in the Implant-Grade PEEK Polymer Machining Services market, registering a CAGR from 2025 to 2032, driven by increasing urbanization, rising healthcare expenditure, expanding medical infrastructure, and growing adoption of advanced biomaterials in countries such as China, India, and Japan. The region benefits from the presence of emerging local manufacturers, government support for healthcare modernization, and growing medical tourism, particularly in orthopedic and dental treatments.

Japan Implant-Grade PEEK Polymer Machining Services Market Insight

The Japan implant-grade PEEK polymer machining services market is witnessing strong growth due to its high-tech healthcare ecosystem and demand for advanced biomaterials. The country’s aging population drives demand for orthopedic, spinal, and dental implants requiring precision machining services. Integration of PEEK components into advanced minimally invasive surgical procedures, along with collaborations between hospitals and biomaterial companies, is fueling rapid adoption.

China Implant-Grade PEEK Polymer Machining Services Market Insight

The China implant-grade PEEK polymer machining services market accounted for the largest revenue share in Asia-Pacific in 2024, attributed to its expanding middle class, rapid healthcare infrastructure development, and strong domestic manufacturing base. The country is emerging as a hub for affordable yet advanced machining services, making PEEK implants more accessible. Government initiatives supporting innovation in medical devices, alongside a growing emphasis on spinal and orthopedic implant adoption, are key drivers.

India Implant-Grade PEEK Polymer Machining Services Market Insight

The India implant-grade PEEK polymer machining services market is projected to witness one of the fastest growth rates in the region, fueled by rising healthcare investments, increasing demand for cost-effective implant solutions, and expanding private healthcare infrastructure. The growing prevalence of orthopedic disorders and dental treatments is creating strong demand for PEEK machining services. Furthermore, collaborations with international medical device manufacturers are enhancing technology transfer and boosting local production capabilities.

Implant-Grade PEEK Polymer Machining Services Market Share

The Implant-Grade PEEK Polymer Machining Services industry is primarily led by well-established companies, including:

- Evonik Industries AG (Germany)

- Quadrant AG (Switzerland)

- Ensinger GmbH (Germany)

- Solvay S.A. (Belgium)

- Victrex plc (U.K.)

- Arkema Group (France)

- Saint-Gobain (France)

- Celanese Corporation (U.S.)

- SABIC (Saudi Arabia)

- Mitsubishi Chemical Holdings Corporation (Japan)

Latest Developments in Implant-Grade PEEK Polymer Machining Services Market

- In March 2023, Invibio, a subsidiary of Victrex plc, announced the launch of PEEK-OPTIMA™ AM filament, an implant-grade PEEK material designed for additive manufacturing (3D printing) of long-term medical implants, expanding options for customized implant production

- In February 2023, Victrex invested in a new medical R&D and manufacturing centre in Leeds, U.K., to strengthen Invibio’s capabilities in implant-grade PEEK innovation and scale-up for orthopedic, spine, and dental applications

- In June 2023, Invibio partnered with Paragon Medical to expand manufacturing of trauma devices using implant-grade PEEK, including establishing new composite trauma device production capacity in China

- In October 2023, Evonik introduced a new implant-grade VESTAKEEP® PEEK filament for long-term medical use, including carbon-fiber reinforced grades, enabling high-performance machining and 3D-printing of orthopedic and spinal implant

- In September 2024, Nvision Biomedical Technologies, in collaboration with Invibio, received FDA clearance for the first 3D-printed porous PEEK interbody spinal system made with PEEK-OPTIMA, marking a major milestone in regulatory approval for additively manufactured PEEK implants

- In September 2024, Maxx Orthopedics and Invibio (Victrex) received FDA Investigational Device Exemption (IDE) approval for a staged clinical study evaluating a PEEK-OPTIMA femoral knee component in the Freedom Total Knee System against traditional metal implants

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.