Global Industrial Burner Market

Market Size in USD Billion

CAGR :

%

USD

6.24 Billion

USD

9.79 Billion

2025

2033

USD

6.24 Billion

USD

9.79 Billion

2025

2033

| 2026 –2033 | |

| USD 6.24 Billion | |

| USD 9.79 Billion | |

|

|

|

|

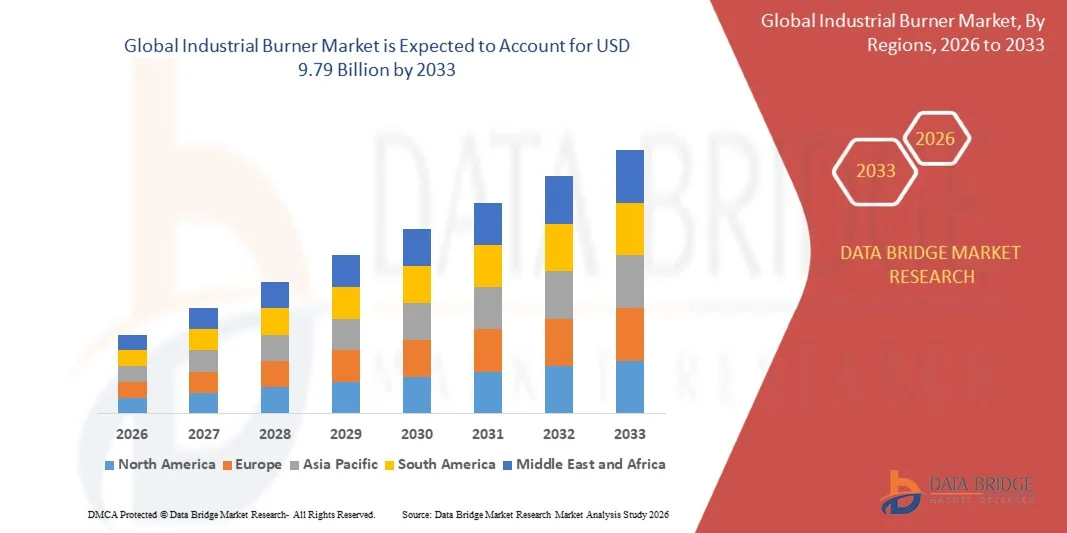

What is the Global Industrial Burner Market Size and Growth Rate?

- The global industrial burner market size was valued at USD 6.24 billion in 2025 and is expected to reach USD 9.79 billion by 2033, at a CAGR of 5.80% during the forecast period

- Increasing demand from industries such as power generation, chemical processing, and metal fabrication, driven by the need for energy-efficient, high-performance combustion solutions, is a major factor supporting market growth. Rising focus on reducing greenhouse gas emissions and improving fuel efficiency further fuels adoption of advanced industrial burners globally

- Growing awareness of sustainable energy practices, government initiatives to promote energy-efficient industrial equipment, and technological innovations in burner design, automation, and control systems are further boosting market expansion

What are the Major Takeaways of Industrial Burner Market?

- Rising awareness of energy efficiency benefits, stricter emission regulations, and adoption of automated and smart burners positively influence the market. Product innovations in low-NOx and dual-fuel burners provide additional growth opportunities

- High initial investment costs, complex installation requirements, and competition from alternative heating technologies are expected to restrain market expansion. Limited awareness in small-scale industrial setups about advanced burner solutions may further challenge growth

- Asia-Pacific dominated the industrial burner market with a 42.5% revenue share in 2025, driven by strong industrial growth, rising energy demand, and increasing adoption of high-efficiency burners across manufacturing, metals, chemicals, and food processing sectors

- North America is projected to register the fastest CAGR of 7.9% from 2026 to 2033, driven by growing demand for high-efficiency and low-emission burners in the U.S. and Canada

- The Regenerative Burner segment dominated the market with a revenue share of 35.7% in 2025, owing to its superior energy efficiency, low emission capabilities, and widespread use in high-temperature industrial applications

Report Scope and Industrial Burner Market Segmentation

|

Attributes |

Industrial Burner Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Industrial Burner Market?

“Rising Demand for Energy-Efficient and Low-Emission Industrial Burners”

- The industrial burner market is witnessing strong growth toward energy-efficient, low-emission, and multi-fuel burner solutions, driven by stricter environmental regulations, sustainability goals, and the need for cost-effective operations

- Manufacturers are introducing burners with advanced combustion technology, precise flame control, and integrated monitoring systems that support fuel savings, reduced NOx/SOx emissions, and optimized thermal efficiency across industrial applications such as steel, cement, chemical, and food processing

- End-users are increasingly prioritizing environmentally friendly and high-performance burners to meet regulatory compliance, reduce operational costs, and enhance production efficiency

- For instance, companies such as Honeywell, Ariston Group, Baltur S.P.A., Fives, and Riello are launching advanced low-emission and smart burners to cater to industrial heating needs across multiple sectors

- Growing emphasis on sustainability, operational efficiency, and reduced carbon footprint is accelerating market adoption globally

- As industries continue to prioritize energy optimization and emissions reduction, Industrial Burners are expected to remain central to technological innovation within global industrial heating solutions

What are the Key Drivers of Industrial Burner Market?

- Rising demand for energy-efficient, low-emission, and multi-fuel burners is driving strong adoption of Industrial Burners globally

- For instance, in 2025, Honeywell, Baltur S.P.A., and Fives introduced advanced burners with integrated automation and real-time monitoring to improve efficiency and lower emissions

- Increasing regulatory pressures in North America, Europe, and Asia-Pacific on industrial emissions, coupled with sustainability initiatives, are boosting demand across cement, metal, chemical, and food processing industries

- Technological advancements such as digital flame control, fuel flexibility, and predictive maintenance are enhancing burner performance, safety, and energy savings

- Rising adoption of smart industrial systems and industrial IoT integration further contributes to market expansion by enabling remote monitoring, diagnostics, and reduced downtime

- With ongoing R&D investments, product innovations, and partnerships, the Industrial Burner market is expected to maintain robust growth in the coming years

Which Factor is Challenging the Growth of the Industrial Burner Market?

- High initial investment costs for advanced low-emission and energy-efficient burners limit adoption in price-sensitive industrial segments

- For instance, during 2024–2025, fluctuating steel, cement, and chemical sector budgets impacted procurement of premium burners with automation and emission control features

- Complex installation, maintenance requirements, and need for skilled labor increase operational challenges

- Limited awareness in emerging markets about benefits of energy-efficient and low-emission burners restricts adoption

- Strong competition from conventional burner technologies and low-cost alternatives creates pricing pressure and differentiation challenges

- To overcome these challenges, companies are focusing on cost-effective solutions, financing models, training programs, and regulatory compliance support to expand global adoption of high-performance Industrial Burners

How is the Industrial Burner Market Segmented?

The market is segmented on the basis of type, fuel type, automation, operating temperature, application, and end-use industry.

• By Type

On the basis of type, the industrial burner market is segmented into Regenerative Burner, High-Velocity Burner, Thermal Radiation, Radiant Burner, Customized (Burner Boiler), Flat Flame Burner, Line Burner, and Others. The Regenerative Burner segment dominated the market with a revenue share of 35.7% in 2025, owing to its superior energy efficiency, low emission capabilities, and widespread use in high-temperature industrial applications. Regenerative burners are preferred in metals, cement, and ceramics due to their ability to recover heat, reduce fuel consumption, and lower operational costs.

The High-Velocity Burner segment is projected to grow at the fastest CAGR from 2026 to 2033, supported by rising demand for rapid heating, compact designs, and versatile fuel compatibility across industries. Increasing industrial automation and stringent emission standards are driving adoption of advanced burner types globally.

• By Fuel Type

On the basis of fuel type, the Industrial Burner market is segmented into Oil-based, Gas-based, and Dual Fuel. The Gas-based segment dominated the market with a revenue share of 52.3% in 2025, driven by cleaner combustion, lower operational costs, and easier integration with modern industrial processes. Gas burners are widely used in chemicals, food processing, and power generation due to reduced pollutant emissions and higher thermal efficiency.

The Dual Fuel segment is projected to grow at the fastest CAGR from 2026 to 2033, supported by flexibility in fuel switching, reliability during supply fluctuations, and increasing adoption in emerging markets. Rising emphasis on energy security and emission compliance is expected to accelerate the demand for dual-fuel solutions globally.

• By Automation

On the basis of automation, the Industrial Burner market is segmented into Monoblock and Duoblock. The Duoblock segment dominated the market with a revenue share of 57.8% in 2025, owing to its higher performance, precise flame control, and suitability for large-scale industrial operations. Duoblock burners are widely preferred in cement, metals, and chemical industries for their ability to integrate with process automation systems.

The Monoblock segment is projected to grow at the fastest CAGR from 2026 to 2033, fueled by demand for compact, low-maintenance, and cost-effective burner systems in small-to-medium-sized industrial applications. Digital controls, IoT-enabled monitoring, and enhanced operational safety are further boosting adoption.

• By Operating Temperature

On the basis of operating temperature, the Industrial Burner market is segmented into High Temperature (>1,400°F) and Low Temperature (<1,400°F). The High-Temperature segment dominated the market with a revenue share of 61.2% in 2025, driven by the need for efficient heat generation in metals, glass, ceramics, and power generation. High-temperature burners offer consistent thermal output, reduced fuel consumption, and emission compliance.

The Low-Temperature segment is projected to grow at the fastest CAGR from 2026 to 2033, supported by increasing adoption in food processing, drying, and HVAC applications. Rising awareness of energy efficiency, thermal process optimization, and sustainable operations is accelerating growth globally.

• By Application

On the basis of application, the Industrial Burner market is segmented into Boilers, Furnace/Ovens/Kiln, Air Heating/Drying, and Others. The Boilers segment dominated the market with a revenue share of 54.6% in 2025, owing to high industrial demand for steam and process heat across power generation, chemical, and food processing sectors. Industrial burners in boilers provide precise heat control, efficiency, and emission management.

The Furnace/Ovens/Kiln segment is projected to grow at the fastest CAGR from 2026 to 2033, driven by increasing industrial heating applications, technological upgrades, and the need for energy-efficient solutions in metals, ceramics, and glass manufacturing.

• By End-Use Industry

On the basis of end-use industry, the Industrial Burner market is segmented into Food and Beverages, Power Generation, Chemicals, Petrochemicals, Metals and Mining, Automotive, and Others. The Metals and Mining segment dominated the market with a revenue share of 32.4% in 2025, supported by high thermal energy requirements, large-scale operations, and adoption of regenerative and high-velocity burners.

The Food and Beverages segment is projected to grow at the fastest CAGR from 2026 to 2033, fueled by increasing processed food production, stringent hygiene standards, and demand for precise temperature-controlled heating solutions. Rising automation, sustainability mandates, and energy efficiency are key factors driving global adoption.

Which Region Holds the Largest Share of the Industrial Burner Market?

- Asia-Pacific dominated the industrial burner market with a 42.5% revenue share in 2025, driven by strong industrial growth, rising energy demand, and increasing adoption of high-efficiency burners across manufacturing, metals, chemicals, and food processing sectors. Rapid urbanization, industrialization, and supportive government policies for energy-efficient technologies further strengthen regional leadership

- Leading players are investing in R&D, advanced burner technologies, and eco-friendly fuel systems to improve operational efficiency, reduce emissions, and comply with environmental regulations. Strong industrial infrastructure and expanding manufacturing capacities enhance the region’s market dominance

- High consumption of processed foods, expanding power generation, and growing demand in metals and chemical industries also fuel the adoption of Industrial Burners across Asia-Pacific

China Industrial Burner Market Insight

China is the largest contributor in Asia-Pacific, supported by a robust industrial base, growing demand in metals, chemicals, and food processing, and increasing adoption of regenerative and high-velocity burners. Manufacturers are focusing on energy-efficient and emission-compliant technologies. Strong government initiatives for industrial energy efficiency further strengthen domestic consumption and export potential.

Japan Industrial Burner Market Insight

Japan shows steady growth, driven by high industrial automation, strict emission regulations, and adoption of advanced burner technologies in food processing, metals, and chemicals. Investments in R&D for energy-efficient solutions and precision temperature control are boosting market expansion.

India Industrial Burner Market Insight

India is emerging as a key growth market, fueled by rapid industrialization, growing power generation capacity, and rising demand from food processing and metal industries. Increasing adoption of energy-efficient and dual-fuel burners, along with expansion of manufacturing facilities, supports rapid market penetration.

South Korea Industrial Burner Market Insight

South Korea contributes significantly due to industrial modernization, strong automotive and electronics manufacturing sectors, and growing emphasis on emission reduction. Advanced burner solutions for furnaces, boilers, and kilns are driving adoption.

North America Industrial Burner Market Insight

North America is projected to register the fastest CAGR of 7.9% from 2026 to 2033, driven by growing demand for high-efficiency and low-emission burners in the U.S. and Canada. Industrial upgrades in metals, chemicals, and power generation, combined with regulatory support for cleaner combustion technologies, accelerate market growth.

U.S. Industrial Burner Market Insight

The U.S. is the largest contributor in North America, driven by modernization of industrial plants, rising focus on energy efficiency, and adoption of advanced automation in burners. Investment in research and integration with IoT-enabled monitoring systems supports market expansion.

Canada Industrial Burner Market Insight

Canada contributes significantly to regional growth, supported by energy-efficient industrial heating solutions, strict environmental regulations, and rising demand in metals, food processing, and chemical sectors. Expansion of sustainable burner systems and digital control technologies is boosting adoption.

Which are the Top Companies in Industrial Burner Market?

The industrial burner industry is primarily led by well-established companies, including:

- Ariston Group N.V. (Netherlands)

- Alzeta Corporation (U.S.)

- Andritz Group (Austria)

- Selas Heat Technology Company (U.S.)

- Baltur S.P.A. (Italy)

- Bloom Engineering (U.S.)

- Fives (France)

- Honeywell International Inc. (U.S.)

- Nibe Group (Sweden)

- Oilon Group OY (Finland)

- Oxilon Pvt Ltd (India)

- Riello S.P.A. (Italy)

- Weishaupt (Germany)

- Ebico (U.K.)

- Zeeco (U.S.)

What are the Recent Developments in Global Industrial Burner Market?

- In January 2025, Red Bull unveiled its “Red Bull Zero” energy drink in the U.S., incorporating monk fruit extract along with other sweeteners to create a completely zero-sugar formulation, strengthening the brand’s presence in the health-focused beverage category

- In January 2024, Elo Life Systems secured USD 20.5 Mn in Series A2 funding, led by Novo Holdings and DCVC Bio, to accelerate the planned 2026 launch of a natural, plant-based monk fruit-derived sweetener, marking a major step in expanding clean-label ingredient innovation

- In October 2023, Lakanto introduced a new addition to its Industrial Burner range, the Monkfruit Sweetener with Allulose, blending monk fruit’s natural sweetness with the unique characteristics of allulose to broaden consumer choices for natural sugar alternatives, reinforcing the company’s product diversification strategy.

- In April 2023, SweetLeaf partnered with the American Diabetes Association to promote its natural, sugar-free Industrial Burner as a diabetes-friendly option, participating in ADA programs such as the Tour de Cure event in Arizona, enhancing the brand’s credibility within the diabetic and wellness community

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.