Global Industrial Cleaning Market

Market Size in USD Billion

CAGR :

%

USD

45.30 Billion

USD

55.70 Billion

2024

2032

USD

45.30 Billion

USD

55.70 Billion

2024

2032

| 2025 –2032 | |

| USD 45.30 Billion | |

| USD 55.70 Billion | |

|

|

|

|

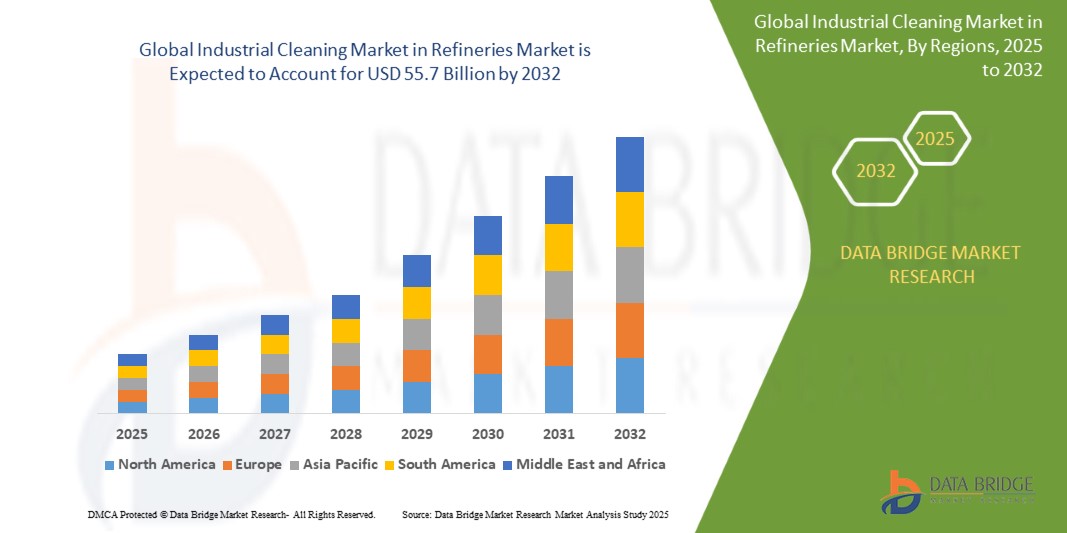

Industrial Cleaning Market in Refineries Market Size

- The global industrial cleaning market in refineries market was valued at USD 45.3 billion in 2024 and is expected to reach USD 55.7 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 5.04%, primarily driven by the increasing adoption of environmentally sustainable and closed-loop cleaning technologies to meet regulatory standards and reduce hazardous waste.

- This growth is driven by factors such as stringent environmental and occupational safety regulations boosting demand for specialized cleaning solutions and technological advancements in cleaning solutions.

Industrial Cleaning Market in Refineries Market Analysis

- The surfactants market is driven by increasing demand across various industries, including personal care, household cleaning, agriculture, and oil & gas. The need for effective cleaning solutions, emulsification, and enhanced product performance is driving growth in this sector.

- Anionic surfactants continue to dominate the market due to their superior cleaning properties and widespread use in detergents, soaps, and industrial cleaning products. However, non-ionic and amphoteric surfactants are gaining traction due to their mildness, making them ideal for use in personal care and specialty applications.

- North America remain dominant markets, with strong demand from personal care and industrial sectors, while Asia-Pacific is experiencing rapid growth, driven by expanding manufacturing, urbanization, and increasing consumer demand for personal care and cleaning products.

- The surfactants segment (by type) is expected to dominate the market, accounting for approximately 40% of the global revenue share in 2025, as they are crucial in formulating cleaning agents, cosmetics, and agricultural chemicals.

Report Scope and Industrial Cleaning Market in Refineries Market Segmentation

|

Attributes |

Industrial Cleaning Market in Refineries Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Info sets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Industrial Cleaning Market in Refineries Market Trends

Shift Toward Eco-Friendly and Closed-Loop Cleaning Technologies

- A significant trend in the industrial cleaning market for refineries is the increasing adoption of environmentally sustainable and closed-loop cleaning technologies to meet regulatory standards and reduce hazardous waste.

- Traditional cleaning methods in refineries often involve large volumes of water and chemicals, generating contaminated effluents. Companies are transitioning to closed-loop systems that recycle cleaning solvents and minimize discharge.

- These systems also enhance worker safety, reduce turnaround time, and improve the cleaning efficiency of equipment like heat exchangers, pipelines, and reactors.

- The demand for non-invasive and automated cleaning techniques, such as online chemical cleaning and hydroblasting, is rising due to their minimal disruption to refinery operations.

- For instance, Shell has implemented closed-loop chemical cleaning technology at its Pernis refinery in the Netherlands to reduce environmental impact and improve operational efficiency. The solution allows for the cleaning of heat exchangers without disassembly, saving time, reducing solvent usage, and avoiding hydrocarbon emissions during maintenance.

Industrial Cleaning Market in Refineries Market Dynamics

Driver

Stringent Environmental and Occupational Safety Regulations Boosting Demand for Specialized Cleaning Solutions

- Refineries operate under tight regulations related to emissions, hazardous waste handling, and workplace safety. Compliance with standards such as the U.S. Environmental Protection Agency (EPA), OSHA (Occupational Safety and Health Administration), and the EU Industrial Emissions Directive drives the demand for effective industrial cleaning.

- Industrial cleaning solutions are essential for maintaining heat exchangers, pipelines, distillation units, and tanks—where residue buildup can severely reduce efficiency, create safety hazards, and violate regulatory thresholds.

- The growing focus on reducing VOC (volatile organic compounds) emissions and ensuring worker safety is accelerating the adoption of biodegradable, non-toxic, and non-flammable cleaning agents in refinery operations.

- Automation and robotics are increasingly being used for high-risk cleaning tasks, especially in confined or toxic environments, further fueling demand for advanced cleaning technologies in refinery settings.

For instance,

- Ecolab, a major player in industrial cleaning, has expanded its 3D TRASAR TM Technology to monitor and optimize cleaning operations in refining and petrochemical plants. This smart system helps reduce downtime and chemical waste while enhancing heat exchanger efficiency. This system has been adopted by several global oil refineries, especially in North America and Europe, to lower maintenance costs and increase energy efficiency.

- As the global refining sector continues to evolve with stricter environmental regulations, efficiency goals, and safety standards, the demand for advanced industrial cleaning solutions is poised to grow significantly.

Opportunity

Adoption of Eco-friendly Cleaning Agents and Technologies

- The increasing focus on sustainability is driving the demand for environmentally friendly and non-toxic cleaning agents in refineries.

- The transition to greener solutions is particularly relevant in refining processes that deal with hazardous chemicals and solvents, where eco-friendly alternatives can reduce environmental impact and improve worker safety.

- Refineries are adopting biodegradable chemicals and surfactants that provide effective cleaning performance while reducing the carbon footprint of their operations.

For instance,

- APT Commercial Chemicals offers a range of sustainable cleaning and water treatment products designed for the oil and gas industry. Their eco-friendly cleaning agents help refineries meet environmental regulations while maintaining cleaning performance.

- As refineries face increasing pressure to meet environmental regulations and adopt sustainable practices, the shift toward eco-friendly cleaning agents and technologies presents a significant opportunity for growth.

Restraint/Challenge

Operational Challenges in Cleaning Complex Refinery Equipment and Systems

- Industrial cleaning in refineries involves intricate processes across a wide range of equipment, including heat exchangers, reactors, distillation columns, and pipelines—each with unique cleaning needs and access limitations.

- Residual fouling, high operating temperatures, pressure conditions, and diverse material types complicate the cleaning procedures and require highly customized solutions.

- Shutting down units for manual or chemical cleaning leads to production losses and unplanned downtime, negatively impacting overall operational efficiency and profitability.

- Refineries are under constant pressure to balance thorough cleaning with minimal disruption, especially in high-throughput plants operating close to capacity limits.

For instance,

- A U.S. refinery faced challenges with heat exchanger E-126, which suffered a 60% decline in heat recovery. Despite multiple cleanings, performance issues persisted. Investigation revealed that high staff turnover among hydroblasting contractors led to inadequate cleaning, leaving residual fouling. This case underscores the importance of skilled personnel in maintenance operations.

Industrial Cleaning Market in Refineries Market Scope

The market is segmented on the basis of type, product type, and application.

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Product Type |

|

|

By Application |

|

In 2025, the Manufacturing & Commercial Offices segment is projected to dominate the market with the largest share in the application segment

The Manufacturing & Commercial Offices segment is expected to hold the largest share, accounting for approximately 45% of the global market in 2025. This growth is driven by increasing demand for industrial cleaning solutions to maintain cleanliness, hygiene, and safety standards in factories, warehouses, and commercial spaces, as well as to meet regulatory requirements in various industries.

In 2025, the Surfactant segment is expected to account for the largest share during the forecast period in the type segment

The Surfactant segment is expected to dominate the market by type, accounting for approximately 55% of global revenue share in 2025. This dominance is driven by the widespread use of surfactants in cleaning agents, detergents, and industrial applications, where they play a crucial role in emulsifying oils, removing dirt, and improving product performance across various industries, including manufacturing, cleaning, and personal care.

Industrial Cleaning Market in Refineries Market Regional Analysis

North America is the Dominant Region in the Industrial Cleaning Market in Refineries

- North America is projected to hold a leading position in the global industrial cleaning market in refineries, accounting for approximately 41% of the global market share in 2025. This dominance is fueled by the region’s extensive refining capacity, stringent environmental regulations, and continuous investments in advanced cleaning technologies.

- The U.S., home to some of the world’s largest and most complex refineries, is driving demand for high-performance, eco-friendly cleaning solutions to ensure compliance with EPA standards and optimize plant safety and operational efficiency.

- In Canada, investments in upgrading oil sands refineries and petrochemical facilities are boosting demand for industrial cleaning services, particularly those designed for heavy-duty residue removal and waste management.

- Mexico’s energy reforms and foreign investments in refinery modernization, including projects to improve downstream capabilities and reduce reliance on fuel imports, are further strengthening the region’s industrial cleaning market.

Asia-Pacific is Projected to Register the Highest Growth Rate

- Asia-Pacific is expected to witness the fastest growth in the refinery cleaning market, backed by ongoing capacity expansions, stricter environmental compliance mandates, and the rise of digital plant maintenance solutions.

- China’s push for energy security and green refinery practices is prompting refiners to adopt closed-loop cleaning systems and zero-waste water solutions, enhancing the need for advanced cleaning technologies.

- Indian Oil, Reliance Industries, and Bharat Petroleum are investing in smart refinery initiatives and sustainability, further increasing the demand for customized cleaning solutions and periodic shutdown cleaning services.

- The region's fast-paced industrialization, increasing crude processing throughput, and emphasis on reducing operational costs and emissions continue to make Asia-Pacific a hub for future growth in refinery cleaning services.

Industrial Cleaning Market in Refineries Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Diversey, Inc (U.S.)

- Evonik Industries (Germany)

- Dow (U.S.)

- BASF SE (Germany)

- Clariant (Switzerland)

- Stepan Company (U.S.)

- Spartan Chemical Company, Inc (U.S.)

- Ecolab (U.S.)

- Solvay (Belgium)

- Croda International Plc (U.K.)

- 3M (U.S.)

- NEOS COMPANY LIMITED (Japan)

- Kao Corporation (Japan)

- WVT Industries NV (Belgium)

- Mitsubishi Chemical Holdings Corporation (Japan)

Latest Developments in Global Industrial Cleaning Market in Refineries Market

- In December 2022, Clariant AG announced a USD 87.5 million investment to expand its ethoxylation plant in China, aiming to increase capacity for existing products and support the development of new ones by the end of 2024.

- In November 2022, BASF SE entered into a collaboration with Inditex to develop the first detergent specifically designed to minimize microfiber release from textiles during washing.

- In June 2022, Evonik Industries AG marked the beginning of construction on the world’s first commercial rhamnolipid production facility with a groundbreaking ceremony. The biosurfactant plant represents a triple-digit million-euro investment at the company’s biotech hub in Slovakia.

- In April 2022, Solvay SA announced it would begin producing its biodegradable solvent, Rhodiasolv IRIS, at its Melle site in France. The solvent was previously manufactured in China.

- In January 2022, Dow Inc. signed an exclusive agreement with Locus Performance Ingredients to expand its biosurfactant portfolio for the global home care and personal care markets.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Industrial Cleaning Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Industrial Cleaning Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Industrial Cleaning Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.