Global Industrial Maintenance Services In Operational Improvement And Operational Maintenance Market

Market Size in USD Billion

CAGR :

%

USD

51.77 Billion

USD

80.36 Billion

2022

2030

USD

51.77 Billion

USD

80.36 Billion

2022

2030

| 2023 –2030 | |

| USD 51.77 Billion | |

| USD 80.36 Billion | |

|

|

|

|

Industrial Maintenance Services in Operational Improvement and Operational Maintenance Market Analysis and Size

Manufacturing processes fall under the category of highly complex processes that make use of various machine types. The size of the facilities has greatly increased, and a variety of machinery is present. In addition, industries are always operating at the limit of their capacity due to rising end-user demand. These factors also make it extremely difficult to maintain and inspect the facilities. Furthermore the complexity of the machinery frequently calls for highly qualified professionals, which the company's staff frequently lacks. Consequently, there is a need for businesses that provide industrial maintenance services. Only experienced, highly qualified candidates who have received maintenance-specific training are employed by the company.

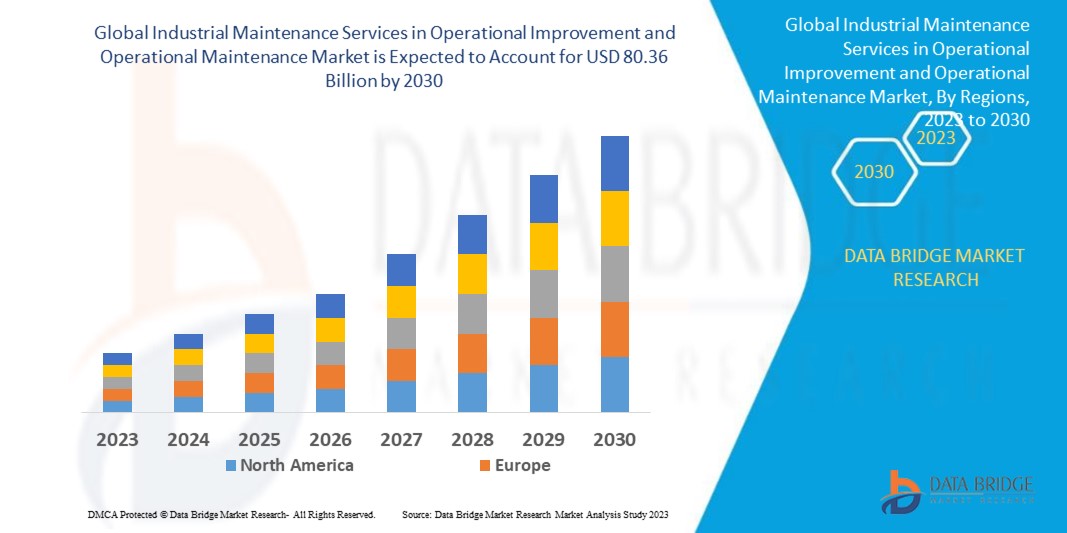

Data Bridge Market Research analyses that the industrial maintenance services in operational improvement and operational maintenance market valued at USD 51.77 billion in 2022, will reach USD 80.36 billion by 2030, growing at a CAGR of 5.65% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Industrial Maintenance Services in Operational Improvement and Operational Maintenance Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015 - 2020) |

|

Quantitative Units |

Revenue in USD Billion, Volumes in Units, Pricing in USD |

|

Segments Covered |

Services Type (Industrial Operational Maintenance, Industrial Operational Improvement), Application (Supervisory Control and Data Acquisition (SCADA), Electric Motors and Drives, Valves and Actuators, Distributed Control System (DCS), Human-Machine Interface (HMI), Manufacturing Execution System (MES), Safety System, Others), Industry (Automotive, Metals and Mining, Food and Beverages, Aerospace and Defense, Oil and Gas, Water and Wastewater, Energy and Power, Chemical, Pharmaceuticals, Others) |

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Market Players Covered |

ABB (Switzerland), Siemens (Germany), Schneider Electric (France), Honeywell International Inc. (U.S.), General Electric (U.S.), Emerson Electric Co. (U.S.), Rockwell Automation (U.S.), Johnson Controls. (Ireland), SKF (Sweden), Mitsubishi Electric Corporation (Japan), Yokogawa Electric Corporation (Japan), Danaher (U.S.), AECOM (U.S.), KBR, Inc. (U.S.), Veolia Environnement SA (France), Tetra Tech, Inc. (U.S.), John Wood Group PLC (U.K.), SNC-Lavalin Group. (Canada), Fluor Corporation (U.S.), Jacobs (U.S.), Worley (Australia), Bechtel Corporation (U.S.), Black & Veatch Holding Company (U.S.), CBRE (U.S.) |

|

Market Opportunities |

|

Market Definition

Operational maintenance and operational improvement are the two main components of industrial maintenance services. Operational improvement is concerned with raising overall effectiveness and productivity through process optimization, automation, and equipment upgrades. It seeks to increase productivity, decrease downtime, cut costs, and boost operational efficiency. Contrarily, operational maintenance entails routine and preventive maintenance procedures to guarantee efficient equipment operation, spot potential problems, and increase asset lifespan. Industrial maintenance services help businesses meet production goals, boost equipment dependability, cut downtime, and maximize resource use for increased operational effectiveness and cost savings.

Industrial Maintenance Services in Operational Improvement and Operational Maintenance Market Dynamics

Drivers

- Environmental stability drives the market growth

Environmental sustainability is a key driver for industrial maintenance services in operational improvement and operational maintenance. By optimizing energy consumption, maintenance services help organizations reduce their carbon footprint and mitigate environmental impact. They identify opportunities to minimize waste generation, promote recycling and responsible disposal practices, and implement eco-friendly solutions. This aligns with the growing emphasis on environmental sustainability and corporate social responsibility, as organizations strive to operate in a more sustainable manner. By integrating sustainable practices into maintenance operations, organizations can contribute to a greener future, meet regulatory requirements, enhance their reputation, and attract environmentally-conscious stakeholders.

- Improved safety drives the market

Improved safety is a crucial driver for industrial maintenance services in operational improvement and operational maintenance. By conducting regular inspections and preventive maintenance, these services help identify and rectify potential safety hazards in equipment and systems. Addressing issues such as faulty wiring, malfunctioning safety mechanisms, or worn-out components reduces the risk of accidents and injuries in the workplace. Maintenance services also ensure compliance with safety regulations and industry standards, creating a safer working environment for employees. By prioritizing safety, organizations can protect their workforce, minimize downtime due to accidents, and build a culture of safety consciousness, fostering employee well-being and productivity.

Opportunities

- Technological advancement surge in market expansion

Technological advancements create opportunities for industrial maintenance services in operational improvement and operational maintenance. These services leverage advanced tools and techniques, such as data analytics, Internet of Things (IoT), and predictive maintenance software, to enhance their effectiveness. By collecting and analyzing data from equipment sensors, maintenance services can identify patterns, predict failures, and schedule maintenance activities proactively. This enables organizations to make informed decisions, optimize resource allocation, and reduce unplanned downtime. The adoption of these technologies enhances efficiency, reduces costs, and improves overall asset performance, enabling organizations to achieve higher productivity and reliability while maximizing the lifespan of their industrial assets.

- Increase in relatability surge market opportunities

Increased reliability creates expansion in the industrial maintenance services in operational improvement and operational maintenance. These services focus on ensuring that industrial assets and equipment operate reliably, minimizing unexpected breakdowns and unplanned downtime. Through regular inspections, preventive maintenance measures, and timely repairs, maintenance services proactively address potential issues and keep critical systems in optimal condition. By maintaining the reliability of equipment, organizations can reduce the risk of costly interruptions to operations, maximize productivity, and meet production targets. Improved reliability also enhances customer satisfaction by ensuring consistent product quality and on-time delivery, thereby bolstering the reputation and competitiveness of the organization.

Restraints/Challenges

- Cost can act as a restraint to the market

Cost is a major restraint in industrial maintenance services for operational improvement and maintenance. Implementing improvement measures and conducting regular maintenance activities often require substantial investments in equipment upgrades, automation systems, and skilled labor. These expenses can strain the budgets of organizations, limiting the extent to which they can pursue these services. Budget constraints may force organizations to prioritize maintenance activities or defer certain improvement initiatives, potentially impacting the overall effectiveness and efficiency of their operations. Balancing the need for cost-effective solutions while ensuring the reliability and performance of industrial assets is a crucial challenge in industrial maintenance services

- Lack of skills and expertise can impede the market growth

Skill and expertise are significant restraints in industrial maintenance services for operational improvement and maintenance. The successful execution of improvement initiatives and complex maintenance tasks often demands specialized knowledge and skills. However, accessing qualified personnel or outsourcing services can be challenging, especially in remote locations or industries experiencing a shortage of skilled technicians. Limited availability of skilled professionals can result in delays, quality issues, and increased costs. It requires organizations to invest in training programs, attract and retain talent, or explore alternative solutions such as outsourcing or partnerships to overcome these skill-related restraints and ensure effective implementation of improvement and maintenance activities.

This industrial maintenance services in operational improvement and operational maintenance market, report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the industrial maintenance services in operational improvement and operational maintenance market, contact data bridge market research for an analyst brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Recent Developments

- In 2020, The augmented reality (AR) technology-based service was introduced by Emerson Electric Co. with improved customer support. The new Remote Assistance service capability aids in fixing industrial valve issues. The business improved their industrial maintenance market product portfolio as a result.

- In 2019, The Mindsphere app was developed by Siemens to improve the predictive service for drive systems. The new app provides effective services and maintenance for low voltage Simotics motors and Sinamics drive systems. company to increase its customer base and generate more revenue through effective maintenance solutions.

Global Industrial Maintenance Services in Operational Improvement and Operational Maintenance Market Scope

The industrial maintenance services in operational improvement and operational maintenance market, is segmented on the basis of service type, application and industry. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Service Type

- Industrial Operational Maintenance

- Industrial Operational Improvement

Application

- Supervisory Control and Data Acquisition (SCADA)

- Electric Motors and Drives

- Valves and Actuators

- Distributed Control System (DCS)

- Human-Machine Interface (HMI)

- Manufacturing Execution System (MES)

- Safety System

- Others

Industry

- Automotive

- Metals and Mining

- Food and Beverages

- Aerospace and Defense

- Oil and Gas

- Water and Wastewater

- Energy and Power

- Chemical

- Pharmaceuticals

- Others

Industrial Maintenance Services in Operational Improvement and Operational Maintenance Market Regional Analysis/Insights

The industrial maintenance services in operational improvement and operational maintenance market is analysed and market size insights and trends are provided by service type, application and industry as referenced above.

The countries covered in the industrial maintenance services in operational improvement and operational maintenance market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America

China accounted the largest market share for the industrial maintenance services in operational improvement and operational maintenance solution segment as the growing manufacturing hub and productions sites to support industrialisation. Germany accounted the largest market share owing to the demand for the preventive maintenance services to meet production target with efficiency. However, the U.S. accounted the largest market share for the solution due to the growing industrial automation and lack of skilled resources.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Industrial Maintenance Services in Operational Improvement and Operational Maintenance Market Share Analysis

The industrial maintenance services in operational improvement and operational maintenance market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to industrial maintenance services in operational improvement and operational maintenance market.

Some of the major players operating in the industrial maintenance services in operational improvement and operational maintenance market are:

- ABB (Switzerland)

- Siemens (Germany)

- Schneider Electric (France)

- Honeywell International Inc. (U.S.)

- General Electric (U.S.)

- Emerson Electric Co. (U.S.)

- Rockwell Automation (U.S.)

- Johnson Controls. (Ireland)

- SKF (Sweden)

- Mitsubishi Electric Corporation (Japan)

- Yokogawa Electric Corporation (Japan)

- Danaher (U.S.)

- AECOM (U.S.)

- KBR, Inc. (U.S.)

- Veolia Environnement SA (France)

- Tetra Tech, Inc. (U.S.)

- John Wood Group PLC (U.K.)

- SNC-Lavalin Group (Canada)

- Fluor Corporation (U.S.)

- Jacobs (U.S.)

- Worley (Australia)

- Bechtel Corporation (U.S.)

- Black & Veatch Holding Company (U.S.)

- CBRE (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET

2.2.1 VENDOR POSITIONING GRID

2.2.2 TECHNOLOGY LIFE LINE CURVE

2.2.3 MARKET GUIDE

2.2.4 COMPANY POSITIONING GRID

2.2.5 COMAPANY MARKET SHARE ANALYSIS

2.2.6 MULTIVARIATE MODELLING

2.2.7 TOP TO BOTTOM ANALYSIS

2.2.8 STANDARDS OF MEASUREMENT

2.2.9 VENDOR SHARE ANALYSIS

2.2.10 DATA POINTS FROM KEY PRIMARY INTERVIEWS

2.2.11 DATA POINTS FROM KEY SECONDARY DATABASES

2.3 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET : RESEARCH SNAPSHOT

2.4 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 PORTER’S FIVE FORCES

5.2 REGULATORY STANDARDS

5.3 TECHNOLOGICAL TRENDS

5.4 VALUE CHAIN ANALYSIS

5.5 COMPANY COMPARITIVE ANALYSIS

5.6 CASE STUDY

6 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET , BY SERVICES TYPE

6.1 OVERVIEW

6.2 INDUSTRIAL OPERATIONAL MAINTENANCE

6.2.1 PREDICTIVE MAINTENANCE

6.2.2 SCHEDULED MAINTENANCE

6.2.3 MECHANICAL

6.2.3.1. GENERAL LUBRICATION MAINTENANCE

6.2.3.2. PRODUCT RECTIFICATION MAINTENANCE

6.2.3.3. OTHERS

6.3 INDUSTRIAL OPERATIONAL IMPROVEMENT

6.3.1 COMPLAINCES

6.3.2 SYSTEM CONFIGURATION

6.3.3 RETROFIT & REPAIR

6.3.4 INFRASTRUCTURE AUDIT

6.3.5 INSTALLATION AND CONSULTING

7 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY APPLICATION

7.1 OVERVIEW

7.2 SUPERVISORY CONTROL AND DATA ACQUISITION (SCADA)

7.3 ELECTRIC MOTORS & DRIVES

7.4 MOTIONS CONTROLS

7.5 VALVES & ACTUATORS

7.6 DISTRIBUTED CONTROL SYSTEM (DCS)

7.7 HUMAN-MACHINE INTERFACE (HMI)

7.8 MANUFACTURING EXECUTION SYSTEM (MES)

7.9 SAFETY SYSTEM

7.9.1 EMERGENCY SHUTDOWN SYSTEM (ESD)

7.9.2 HIGH-INTEGRITY PRESSURE PROTECTION SYSTEMS (HIPPS)

7.9.3 FIRE & GAS MONITORING & CONTROL

7.9.4 TURBOMACHINERY CONTROL (TMC)

7.1 INDUSTRIAL ROBOTS

7.11 OTHERS

8 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY INDUSTRY

8.1 OVERVIEW

8.2 INTRALOGISTICS

8.2.1 BY SERVICES

8.2.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.2.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.3 AUTOMOTIVE

8.3.1 BY SERVICES

8.3.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.3.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.4 METALS & MINING

8.4.1 BY SERVICES

8.4.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.4.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.5 FOOD & BEVERAGES

8.5.1 BY SERVICES

8.5.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.5.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.6 AEROSPACE & DEFENSE

8.6.1 BY SERVICES

8.6.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.6.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.7 OIL & GAS

8.7.1 BY SERVICES

8.7.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.7.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.8 WATER AND WASTEWATER

8.8.1 BY SERVICES

8.8.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.8.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.9 ENERGY & POWER

8.9.1 BY SERVICES

8.9.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.9.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.1 CHEMICAL

8.10.1 BY SERVICES

8.10.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.10.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.11 PHARMACEUTICALS

8.11.1 BY SERVICES

8.11.1.1. INDUSTRIAL OPERATIONAL MAINTENANCE

8.11.1.2. INDUSTRIAL OPERATIONAL IMPROVEMENT

8.12 OTHERS

9 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, BY GEOGRAPHY

9.1 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

9.1.1 NORTH AMERICA

9.1.1.1. U.S.

9.1.1.2. CANADA

9.1.1.3. MEXICO

9.1.2 EUROPE

9.1.2.1. GERMANY

9.1.2.2. FRANCE

9.1.2.3. U.K.

9.1.2.4. ITALY

9.1.2.5. SPAIN

9.1.2.6. RUSSIA

9.1.2.7. TURKEY

9.1.2.8. BELGIUM

9.1.2.9. NETHERLANDS

9.1.2.10. SWITZERLAND

9.1.2.11. SWEDEN

9.1.2.12. DENMARK

9.1.2.13. POLAND

9.1.2.14. NORWAY

9.1.2.15. FINLAND

9.1.2.16. CZECH REPUBLIC

9.1.2.17. REST OF EUROPE

9.1.3 ASIA PACIFIC

9.1.3.1. JAPAN

9.1.3.2. CHINA

9.1.3.3. SOUTH KOREA

9.1.3.4. INDIA

9.1.3.5. AUSTRALIA AND NEW ZELAND

9.1.3.6. SINGAPORE

9.1.3.7. THAILAND

9.1.3.8. MALAYSIA

9.1.3.9. INDONESIA

9.1.3.10. PHILIPPINES

9.1.3.11. TAIWAN

9.1.3.12. VIETNAM

9.1.3.13. REST OF ASIA PACIFIC

9.1.4 SOUTH AMERICA

9.1.4.1. BRAZIL

9.1.4.2. ARGENTINA

9.1.4.3. REST OF SOUTH AMERICA

9.1.5 MIDDLE EAST AND AFRICA

9.1.5.1. SOUTH AFRICA

9.1.5.2. EGYPT

9.1.5.3. SAUDI ARABIA

9.1.5.4. U.A.E

9.1.5.5. ISRAEL

9.1.5.6. KUWAIT

9.1.5.7. QATAR

9.1.5.8. REST OF MIDDLE EAST AND AFRICA

9.1.6 KEY PRIMARY INSIGHTS: BY MAJOR COUNTRIES

10 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET,COMPANY LANDSCAPE

10.1 COMPANY SHARE ANALYSIS: GLOBAL

10.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

10.3 COMPANY SHARE ANALYSIS: EUROPE

10.4 COMPANY SHARE ANALYSIS: ASIA PACIFIC

10.5 MERGERS & ACQUISITIONS

10.6 NEW PRODUCT DEVELOPMENT AND APPROVALS

10.7 EXPANSIONS

10.8 REGULATORY CHANGES

10.9 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

11 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, SWOT & DBMR ANALYSIS

12 GLOBAL INDUSTRIAL MAINTENANCE SERVICES IN OPERATIONAL IMPROVEMENT AND OPERATIONAL MAINTENANCE MARKET, COMPANY PROFILE

12.1 SCHNEIDER ELECTRIC

12.1.1 COMPANY SNAPSHOT

12.1.2 REVENUE ANALYSIS

12.1.3 PRODUCT PORTFOLIO

12.1.4 RECENT DEVELOPMENTS

12.2 EMERSON ELECTRIC CO.

12.2.1 COMPANY SNAPSHOT

12.2.2 REVENUE ANALYSIS

12.2.3 PRODUCT PORTFOLIO

12.2.4 RECENT DEVELOPMENTS

12.3 ROCKWELL AUTOMATION, INC.

12.3.1 COMPANY SNAPSHOT

12.3.2 REVENUE ANALYSIS

12.3.3 PRODUCT PORTFOLIO

12.3.4 RECENT DEVELOPMENTS

12.4 SKF GROUP

12.4.1 COMPANY SNAPSHOT

12.4.2 REVENUE ANALYSIS

12.4.3 PRODUCT PORTFOLIO

12.4.4 RECENT DEVELOPMENTS

12.5 SIEMENS

12.5.1 COMPANY SNAPSHOT

12.5.2 REVENUE ANALYSIS

12.5.3 PRODUCT PORTFOLIO

12.5.4 RECENT DEVELOPMENTS

12.6 ADVANCED TECHNOLOGY SERVICES INC.

12.6.1 COMPANY SNAPSHOT

12.6.2 REVENUE ANALYSIS

12.6.3 PRODUCT PORTFOLIO

12.6.4 RECENT DEVELOPMENTS

12.7 SGS SA

12.7.1 COMPANY SNAPSHOT

12.7.2 REVENUE ANALYSIS

12.7.3 PRODUCT PORTFOLIO

12.7.4 RECENT DEVELOPMENTS

12.8 QUANT AB

12.8.1 COMPANY SNAPSHOT

12.8.2 REVENUE ANALYSIS

12.8.3 PRODUCT PORTFOLIO

12.8.4 RECENT DEVELOPMENTS

12.9 METSO

12.9.1 COMPANY SNAPSHOT

12.9.2 REVENUE ANALYSIS

12.9.3 PRODUCT PORTFOLIO

12.9.4 RECENT DEVELOPMENTS

12.1 ICONICS, INC.

12.10.1 COMPANY SNAPSHOT

12.10.2 REVENUE ANALYSIS

12.10.3 PRODUCT PORTFOLIO

12.10.4 RECENT DEVELOPMENTS

12.11 GENERAL ELECTRIC

12.11.1 COMPANY SNAPSHOT

12.11.2 REVENUE ANALYSIS

12.11.3 PRODUCT PORTFOLIO

12.11.4 RECENT DEVELOPMENTS

12.12 INTECH PROCESS AUTOMATION INC.

12.12.1 COMPANY SNAPSHOT

12.12.2 REVENUE ANALYSIS

12.12.3 PRODUCT PORTFOLIO

12.12.4 RECENT DEVELOPMENTS

12.13 DYNAMYSK AUTOMATION LTD.

12.13.1 COMPANY SNAPSHOT

12.13.2 REVENUE ANALYSIS

12.13.3 PRODUCT PORTFOLIO

12.13.4 RECENT DEVELOPMENTS

12.14 ABB

12.14.1 COMPANY SNAPSHOT

12.14.2 REVENUE ANALYSIS

12.14.3 PRODUCT PORTFOLIO

12.14.4 RECENT DEVELOPMENTS

12.15 ENDRESS +HAUSER GROUP SERVICES AG

12.15.1 COMPANY SNAPSHOT

12.15.2 REVENUE ANALYSIS

12.15.3 PRODUCT PORTFOLIO

12.15.4 RECENT DEVELOPMENTS

12.16 HONEYWELL INTERNATIONAL INC

12.16.1 COMPANY SNAPSHOT

12.16.2 REVENUE ANALYSIS

12.16.3 PRODUCT PORTFOLIO

12.16.4 RECENT DEVELOPMENTS

12.17 YASKAWA AMERICA, INC.

12.17.1 COMPANY SNAPSHOT

12.17.2 REVENUE ANALYSIS

12.17.3 PRODUCT PORTFOLIO

12.17.4 RECENT DEVELOPMENTS

12.18 ROHRER BETEILIGUNGS-UND VERWALTUNGS GMBH

12.18.1 COMPANY SNAPSHOT

12.18.2 REVENUE ANALYSIS

12.18.3 PRODUCT PORTFOLIO

12.18.4 RECENT DEVELOPMENTS

12.19 TIETOEVRY

12.19.1 COMPANY SNAPSHOT

12.19.2 REVENUE ANALYSIS

12.19.3 PRODUCT PORTFOLIO

12.19.4 RECENT DEVELOPMENTS

12.2 WUNDERLICH-MALEC ENGINEERING INC.

12.20.1 COMPANY SNAPSHOT

12.20.2 REVENUE ANALYSIS

12.20.3 PRODUCT PORTFOLIO

12.20.4 RECENT DEVELOPMENTS

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST

13 CONCLUSION

14 RELATED REPORTS

15 ABOUT DATA BRIDGE MARKET RESEARCH

Global Industrial Maintenance Services In Operational Improvement And Operational Maintenance Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Industrial Maintenance Services In Operational Improvement And Operational Maintenance Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Industrial Maintenance Services In Operational Improvement And Operational Maintenance Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.