Global Industrial Metaverse Market

Market Size in USD Billion

CAGR :

%

USD

958.16 Billion

USD

1,474.94 Billion

2020

2028

USD

958.16 Billion

USD

1,474.94 Billion

2020

2028

| 2021 –2028 | |

| USD 958.16 Billion | |

| USD 1,474.94 Billion | |

|

|

|

|

Industrial Metaverse Market Size

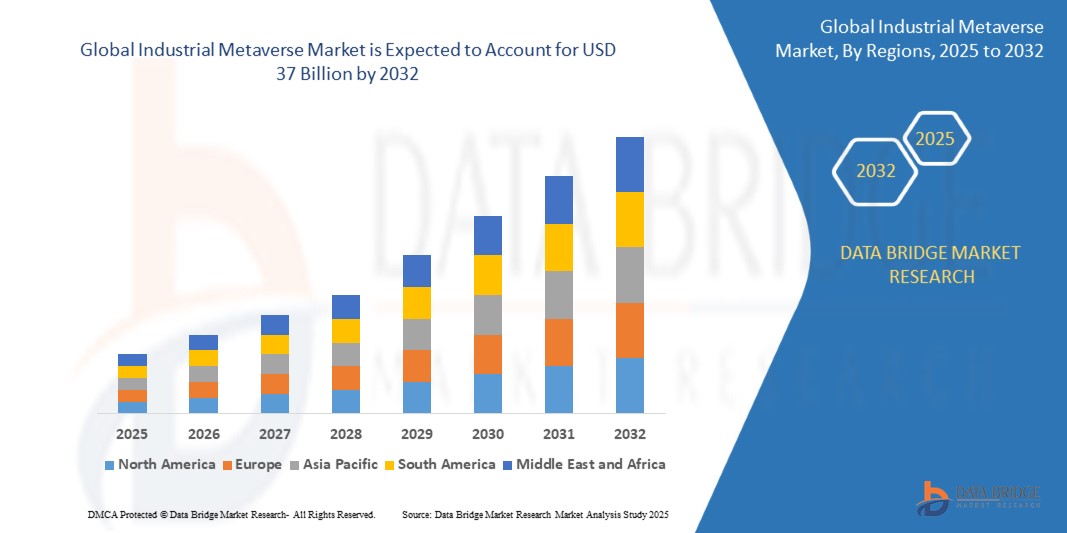

- The Global Industrial Metaverse market was valued at USD 26.62 billion in 2024 and is expected to reach USD 37 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 39.2%, primarily driven by the high research optimization and growth in emerging sectors.

- The Global Industrial Metaverse Market is being driven by the rapid adoption of digital twin technology, augmented and virtual reality (AR/VR), and AI-powered simulations to optimize industrial operations.

Industrial Metaverse Market Analysis

- The Industrial Metaverse refers to the integration of digital and physical environments in industrial settings, leveraging technologies like virtual reality (VR), augmented reality (AR), mixed reality (MR), digital twins, AI, and IoT to create immersive, collaborative, and optimized virtual ecosystems for manufacturing, training, and operations.

- The demand for the Industrial Metaverse is significantly driven by the need for operational efficiency, with digital twins reducing downtime by up to 20% in manufacturing, and the rise of remote work, with 70% of industrial firms adopting virtual collaboration tools post-COVID-19.

- North America is expected to dominate the industrial metaverse market with a largest market share of 32.2% in 2025 due to its robust technological infrastructure and investments from tech giants like NVIDIA and Microsoft

- Asia-Pacific is expected to be the fastest-growing region during the forecast period due to rapid industrialization, Industry 4.0 initiatives, and technological advancements in countries like China and Japan.

Report Scope and Industrial Metaverse Market Segmentation

|

Attributes |

Industrial Metaverse Market Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada, Mexico, Germany, U.K., France, Italy, Spain, Russia, Turkey, Netherlands, Norway, Finland, Denmark, Sweden, Poland, Switzerland, Belgium, Rest of Europe, China, Japan, India, South Korea, Australia, Indonesia, Thailand, Malaysia, Singapore, Philippines, Rest of Asia-Pacific, Brazil, Argentina, Rest of South America, U.A.E., Saudi Arabia, South Africa, Egypt, Israel, and Rest of Middle East & Africa |

|

Key Market Players |

|

|

Market Opportunities |

Growing demand for immersive workforce training tools Expansion of digital twin applications in manufacturing. |

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, PORTER analysis, and PESTLE analysis. |

Industrial Metaverse Market Trends

“Rising integration of AI with digital twins”

- The integration of AI with digital twins is transforming industries by enabling real-time monitoring and optimization of physical assets. AI enhances digital twins by predicting maintenance needs, simulating scenarios, and optimizing processes, resulting in more efficient operations.

- In sectors like manufacturing and energy, AI-powered digital twins help reduce downtime and operational costs by providing predictive insights. They analyze vast amounts of data to anticipate potential issues before they occur, improving productivity.

- The trend is also spreading to industries like smart cities and agriculture, where virtual simulations aid in planning and resource management. This creates new opportunities for innovation and better decision-making.

- For instance, in March 2025, Siemens AG unveiled groundbreaking partnerships and AI advancements to propel the industrial metaverse forward. Leveraging its Siemens Xcelerator platform, the company introduced an innovative immersive engineering solution in collaboration with Sony, integrating Sony's head-mounted displays with Xcelerator software. This initiative aims to empower global innovators and revolutionize industrial design and manufacturing processes.

- In conclusion, combining AI with digital twins is revolutionizing industries by improving efficiency, reducing costs, and enabling smarter, data-driven decisions in the Industrial Metaverse.

Industrial Metaverse Market Dynamics

Driver

“Increased demand for real-time data-driven industrial optimization solutions”

- The increased demand for real-time data-driven industrial optimization solutions is a key driver of the Industrial Metaverse market. Industries are increasingly looking for ways to streamline operations and enhance efficiency.

- This demand is particularly strong in manufacturing, energy, and logistics sectors, where real-time data can help predict maintenance needs, avoid downtimes, and enhance supply chain visibility. With the ability to gather and process data instantaneously, companies are gaining valuable insights that support more agile and responsive operations.

- For instance, in November 2022, Renault Group launched the first industrial Metaverse as part of its digital transformation. This Metaverse leverages mass data collection, digital twins, and real-time Supply Chain monitoring to enhance production and operational efficiency. By 2025, it aims to generate significant savings, reduce vehicle delivery time, lower carbon footprint, and contribute to lower warranty costs.

- The push toward digital transformation is also contributing to this trend, as businesses invest in technologies that enable real-time monitoring, predictive maintenance, and operational optimization. AI, IoT, and digital twin technology are central to this evolution, providing a connected and data-driven environment that enhances decision-making and performance.

Opportunity

“Leveraging real-time data for enhanced operational efficiency”

- Leveraging real-time data allows industries to optimize operations by providing instant insights into processes, machinery, and supply chains.

- With advanced technologies like AI, digital twins, and IoT, businesses can monitor and adjust their workflows dynamically, leading to greater efficiency and reduced downtime.

- This data-driven approach enables faster decision-making, predictive maintenance, and real-time issue resolution, which directly impacts productivity and cost savings.

- It also supports a more responsive and adaptable operational environment, allowing companies to stay competitive and resilient in an ever-evolving market.

- For instance, in November 2024, Cintoo launched the Cintoo Metaverse, featuring the Cintoo VR Experience app, which leverages real-time 3D data streaming to enhance collaboration and decision-making in industries like construction and manufacturing. By allowing users to navigate and compare reality models at a 1:1 scale, the platform enables real-time issue identification, cost reductions, and workflow optimization.

- Cintoo Metaverse aligns with the growing demand for real-time data-driven optimization solutions. It not only enhances operational efficiency but also drives smarter decision-making, leading to cost reductions and better overall performance.

Restraint/Challenge

“Integration complexity across diverse platforms and technologies”

- Integration complexity across diverse platforms and technologies is a significant challenge in the Industrial Metaverse market. As companies adopt new technologies like AI, digital twins, and VR, the need for seamless integration between these systems becomes crucial. Ensuring compatibility across various platforms, software, and hardware is often complex and resource-intensive.

- Moreover, different industries may use varying data formats, protocols, and standards, making it difficult to create a unified ecosystem.

- This lack of standardization can lead to issues with data sharing, system performance, and overall efficiency. It also increases the time and cost required for implementation and maintenance.

- For instance, in November 2024, Siemens announced a USD 500 million investment in a new technology campus in Erlangen, Germany, aiming to advance the development of an industrial metaverse—a virtual representation of manufacturing processes powered by AI.

- Overcoming integration complexity is key to the success of the Industrial Metaverse. Companies must invest in robust integration frameworks and standardization efforts to ensure smooth interoperability. Streamlined integration will enable better collaboration and maximize the benefits of digital transformation.

Industrial Metaverse Market Scope

The market is segmented into five notable segments based on components, technology, application, organization size and End-User

|

Segmentation |

Sub-Segmentation |

|

By Component |

|

|

By Technology |

|

|

By Application |

|

|

By Organization Size |

|

|

By End User |

|

In 2025, the Hardware segment is projected to dominate the market with the largest share in the component segment.

The Hardware segment is expected to dominate the Industrial Metaverse market with the largest share of 41.0% in 2025 due to the essential role of VR/AR headsets, sensors, and high-performance computing systems in enabling immersive industrial applications.

Industrial Metaverse Market Country Analysis

“North America is a Dominant Region in the Global Industrial Metaverse market”

- North America dominates the Industrial Metaverse market due to its early adoption of advanced technologies such as AI, IoT, and AR/VR. The region's strong technological infrastructure and high investment in research and development have positioned it as a leader in digital transformation across industries.

- Additionally, North America is home to some of the largest companies in sectors like manufacturing, oil and gas, and automotive, which are actively investing in the Industrial Metaverse to optimize operations, reduce costs, and enhance productivity.

- Furthermore, government support for digital initiatives and the presence of numerous tech startups focused on industrial applications contribute to North America's leadership. The region's robust ecosystem of technology providers, software developers, and industrial players creates a favorable environment for the rapid adoption of Industrial Metaverse technologies.

“Asia-Pacific is Projected to Register the Highest CAGR in the Industrial Metaverse Market”

- The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, Industry 4.0 initiatives, and technological advancements in countries like China, Japan, and South Korea.

- China, with a projected market value of USD 10 billion by 2032, remains a key market due to its focus on smart manufacturing and digital transformation.

- Japan is projected to grow at a CAGR of 35.5% due to its leadership in robotics and IoT integration.

- The expanding presence of global tech vendors and government support for 5G infrastructure further contribute to market growth.

Industrial Metaverse Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- ABB (Switzerland)

- Alphabet (U.S.)

- Amazon Web Services (U.S.)

- GE Vernova (U.S.)

- HTC (Taiwan)

- IBM (U.S.)

- Meta (U.S.)

- Microsoft (U.S.)

- NVIDIA (U.S.)

- Siemens AG (Germany)

Latest Developments in Industrial Metaverse Market

- In November 2024, Siemens Innovation Day highlighted advancements in AI, the Industrial Metaverse, and sustainable technology solutions aimed at improving productivity, quality, and energy efficiency in industries like manufacturing and infrastructure. The event showcased how combining technologies like digital twins and generative AI can enhance factory productivity, optimize energy systems, and support sustainable urban infrastructure.

- In September 2022, NVIDIA launched its first software- and infrastructure-as-a-service offering, Omniverse Cloud, a suite of cloud services designed for building and operating industrial metaverse applications. The platform enabled users to design, collaborate, and operate 3D workflows without local compute power. It was particularly useful for industries like robotics, autonomous vehicles, and automotive design, offering scalable, AI-driven simulations and sensor data generation.

- In January 2024, Siemens and Sony launched a new industrial metaverse system at CES 2024, combining Siemens' Xcelerator software with Sony’s spatial content creation system. The system features a VR headset with 4K OLED displays, spatial recognition, and video see-through functionality, enabling designers and engineers to collaborate in a "borderless immersive workspace." This immersive platform, using Siemens’ software and Sony’s hardware, allows for sophisticated 3D content creation and real-time collaboration, enhancing design processes.

- In June 2022, Siemens and NVIDIA expanded their partnership to enable the industrial metaverse by connecting Siemens Xcelerator with NVIDIA Omniverse. This collaboration aimed to integrate physics-based digital twins and AI-driven systems, enhancing decision-making and productivity across the entire lifecycle from design to operation.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.