Global Internal Gear Skiving Machine Market

Market Size in USD Million

CAGR :

%

USD

164.85 Million

USD

294.00 Million

2025

2033

USD

164.85 Million

USD

294.00 Million

2025

2033

| 2026 –2033 | |

| USD 164.85 Million | |

| USD 294.00 Million | |

|

|

|

|

Internal Gear Skiving Machine Market Size

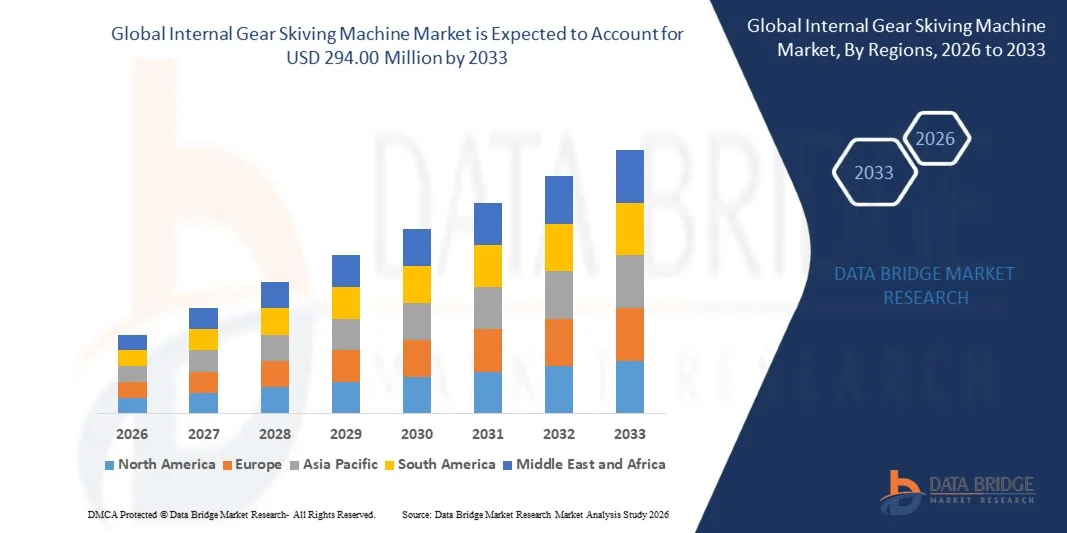

- The global internal gear skiving machine market size was valued at USD 164.85 million in 2025 and is expected to reach USD 294.00 million by 2033, at a CAGR of 7.50% during the forecast period

- The market growth is largely fuelled by rising demand for high-precision gear manufacturing across automotive, aerospace, and industrial machinery applications

- Increasing adoption of automation and CNC-based machining technologies, such as internal gear skiving, to enhance productivity and reduce cycle time is further supporting market expansion

Internal Gear Skiving Machine Market Analysis

- The market is witnessing steady growth due to the shift from traditional gear cutting methods to faster and more efficient skiving processes, enabling improved surface finish and dimensional accuracy

- In addition, technological advancements in cutting tools, machine rigidity, and software integration are improving operational efficiency, making internal gear skiving machines a preferred choice among manufacturers

- North America dominated the global internal gear skiving machine market with the largest revenue share of 38.75% in 2025, driven by high demand for precision gears in automotive, aerospace, and industrial machinery applications

- Asia-Pacific region is expected to witness the highest growth rate in the global internal gear skiving machine market, driven by expanding industrial production, rising demand for precision gears, government initiatives supporting manufacturing modernization, and increasing local manufacturing capabilities

- The standalone segment held the largest market revenue share in 2025, driven by its cost-effectiveness, operational simplicity, and suitability for small and mid-sized manufacturers. These machines are widely adopted for dedicated applications requiring high precision for specific gear types, helping manufacturers reduce capital investment while maintaining consistent quality

Report Scope and Internal Gear Skiving Machine Market Segmentation

|

Attributes |

Internal Gear Skiving Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Internal Gear Skiving Machine Market Trends

“Rising Adoption of High-Speed and Precision Gear Manufacturing Technologies”

• The increasing demand for high-speed and high-precision gear production is reshaping the internal gear skiving machine market, as manufacturers seek faster and more accurate machining solutions. Internal gear skiving enables simultaneous cutting and finishing, significantly reducing cycle times while maintaining superior surface quality. This capability is particularly critical in industries requiring tight tolerances, consistent output, and minimal post-processing to meet strict quality standards

• The growing focus on productivity enhancement in automotive, aerospace, and industrial equipment manufacturing is accelerating the adoption of advanced skiving machines. These machines support complex gear geometries, higher module ranges, and improved dimensional accuracy. In addition, their suitability for continuous and mass production environments helps manufacturers meet rising volume requirements without compromising precision or operational efficiency

• The integration of CNC controls, real-time monitoring, and advanced software in modern skiving machines is improving operational efficiency and repeatability. These features reduce dependency on manual intervention, minimize human error, and enable predictive maintenance through data-driven insights. As a result, manufacturers benefit from higher machine uptime, better process control, and improved flexibility in production planning

• For instance, in 2023, several global automotive component manufacturers reported reduced machining time and improved gear accuracy after upgrading to CNC-based internal gear skiving machines for transmission component production. This transition enabled faster ramp-up of production volumes and improved consistency across batches. In addition, lower rejection rates contributed to cost savings and improved overall equipment effectiveness

• While technological advancements are driving adoption, the long-term impact of this trend depends on continuous innovation, skilled workforce availability, and cost-effective machine deployment. Manufacturers must focus on enhancing machine versatility to handle diverse gear types and materials. In addition, simplifying machine operation and programming will be crucial to expand adoption across mid-sized and emerging-market manufacturers

Internal Gear Skiving Machine Market Dynamics

Driver

“Growing Demand for Gears in Automotive and Industrial Machinery Applications”

• The expanding automotive and industrial machinery sectors are driving strong demand for precision gears, directly supporting the growth of the internal gear skiving machine market. Applications such as transmissions, drivetrains, robotics, and heavy equipment require high-quality internal gears with consistent tolerances. This sustained demand is pushing manufacturers to adopt faster and more reliable gear cutting technologies

• Manufacturers are increasingly focused on reducing production lead times and operational costs while maintaining stringent quality standards. Internal gear skiving machines address these needs by offering faster machining and fewer processing steps compared to traditional shaping and broaching methods. In addition, reduced tool wear and improved surface finish contribute to lower long-term production costs

• Supportive investments in advanced manufacturing infrastructure and Industry 4.0 initiatives are further strengthening market demand. Companies are upgrading machining capabilities to remain competitive in global markets. The integration of skiving machines into automated production lines is improving consistency, traceability, and scalability of gear manufacturing operations

• For instance, in 2022, several European industrial equipment manufacturers expanded their gear production capacities by installing new internal gear skiving systems to meet rising demand from construction and material handling sectors. These investments improved throughput and reduced dependency on external gear suppliers. In addition, in-house production enhanced supply chain resilience

• While demand from core industries remains strong, sustaining growth will require continued alignment with evolving gear designs, material innovations, and production scalability requirements. Manufacturers must adapt skiving processes to lightweight materials and compact gear designs. In addition, flexibility to support customized and small-batch production will remain important

Restraint/Challenge

“High Capital Investment and Technical Complexity of Skiving Machines”

• The high initial cost of internal gear skiving machines presents a major challenge, particularly for small and mid-sized manufacturers. Advanced machines equipped with CNC controls, precision tooling, and automation features require significant upfront investment. This financial barrier often delays purchasing decisions and limits adoption among cost-sensitive manufacturers

• Operating internal gear skiving machines demands skilled operators and advanced programming expertise. In regions with limited access to trained personnel, manufacturers may struggle with efficient machine utilization and process optimization. In addition, inadequate training can lead to higher downtime, increased scrap rates, and suboptimal machine performance

• Market growth is also constrained by the complexity of tooling setup and process calibration, especially for manufacturers transitioning from conventional gear cutting methods. Initial implementation often involves trial-and-error adjustments and longer setup times. This complexity can discourage adoption among manufacturers seeking quick operational returns

• For instance, in 2023, several small gear manufacturers in emerging economies cited high machine costs and lack of skilled labor as key barriers to adopting internal gear skiving technology. These challenges limited their ability to upgrade from traditional machining methods. In addition, concerns over return on investment slowed modernization plans

• While advancements continue to simplify machine operation, addressing cost pressures and skill gaps remains essential. Industry stakeholders must focus on training programs, modular machine designs, and flexible financing models. In addition, partnerships between machine suppliers and end users can help improve knowledge transfer and long-term adoption outcomes

Internal Gear Skiving Machine Market Scope

The market is segmented on the basis of machine type, automation level, gear size, technology, and end use.

• By Machine Type

On the basis of machine type, the global internal gear skiving machine market is segmented into standalone and multi-functional machines. The standalone segment held the largest market revenue share in 2025, driven by its cost-effectiveness, operational simplicity, and suitability for small and mid-sized manufacturers. These machines are widely adopted for dedicated applications requiring high precision for specific gear types, helping manufacturers reduce capital investment while maintaining consistent quality.

The multi-functional segment is expected to witness steady growth from 2026 to 2033, supported by its ability to perform multiple gear machining operations such as skiving, chamfering, and finishing within a single setup. These machines help optimize floor space and setup time, making them increasingly attractive for high-volume production environments.

• By Automation Level

Based on automation level, the market is segmented into semi-automatic and fully automatic internal gear skiving machines. The fully automatic segment accounted for the largest revenue share in 2025, driven by increasing demand for high productivity, minimal human intervention, and consistent output quality. These systems are extensively used in large-scale production facilities where reduced labor dependency and higher throughput are critical.

The semi-automatic segment is expected to witness steady growth from 2026 to 2033, as it remains a preferred choice for manufacturers transitioning from manual processes. Semi-automatic machines offer flexibility, lower initial costs, and ease of operation, making them suitable for customized and low-to-medium volume production.

• By Gear Size

By gear size, the internal gear skiving machine market is segmented into small gears (upto 200 mm), medium gears (200–500 mm), and large gears (above 500 mm). The medium gears segment dominated the market in 2025, driven by its extensive use in automotive transmissions, industrial gearboxes, and robotics applications. Medium-sized gears offer a balance between load capacity and compact design, supporting widespread adoption.

The large gears segment is expected to witness significant growth from 2026 to 2033, supported by rising demand from wind energy, heavy machinery, and infrastructure equipment manufacturing. Increasing investments in renewable energy and large-scale industrial projects are contributing to higher adoption of skiving machines capable of handling larger gear diameters.

• By Technology

On the basis of technology, the market is segmented into conventional and CNC internal gear skiving machines. The CNC segment held the largest market share in 2025, driven by its superior precision, repeatability, and compatibility with automated production lines. CNC skiving machines enable complex gear geometries and support high-speed machining, making them the preferred choice for advanced manufacturing setups.

The conventional segment is expected to witness steady growth from 2026 to 2033, supported by its continued use in cost-sensitive markets and simpler gear manufacturing applications. These machines remain relevant in regions with limited access to advanced automation infrastructure.

• By End-use

By end use, the global internal gear skiving machine market is segmented into automotive, aerospace, industrial machinery, robotics, wind energy, and others. The automotive segment dominated the market in 2025, driven by high demand for precision gears used in transmissions, drivetrains, and powertrain systems. Continuous advancements in vehicle technology and production volumes are supporting sustained demand.

The wind energy segment is expected to witness steady growth from 2026 to 2033, driven by increasing installation of wind turbines and the need for large, high-precision gears. Growing investments in renewable energy infrastructure are further supporting adoption of internal gear skiving machines across this segment.

Internal Gear Skiving Machine Market Regional Analysis

• North America dominated the global internal gear skiving machine market with the largest revenue share of 38.75% in 2025, driven by high demand for precision gears in automotive, aerospace, and industrial machinery applications

• Manufacturers in the region are increasingly investing in high-speed, CNC-based skiving machines to enhance productivity, improve gear quality, and reduce production cycle times. The adoption of automation and integration with Industry 4.0 technologies is further boosting market growth

• This widespread adoption is supported by strong industrial infrastructure, high technological expertise, and the presence of leading gear and machine tool manufacturers, establishing North America as a key hub for advanced gear production

U.S. Internal Gear Skiving Machine Market Insight

The U.S. market captured the largest revenue share in North America in 2025, driven by rising automotive and industrial equipment production. The demand for high-precision gears in transmissions, drivetrains, and robotics is pushing manufacturers to adopt CNC-based internal gear skiving machines. In addition, the integration of automation, real-time monitoring, and advanced software solutions is further accelerating market growth. The presence of well-established machine tool companies and a technologically skilled workforce supports the rapid deployment of advanced skiving systems.

Europe Internal Gear Skiving Machine Market Insight

The Europe market is expected to witness the fastest growth rate from 2026 to 2033, fueled by increasing industrial automation and the demand for high-precision gears in aerospace and automotive sectors. The region’s emphasis on quality, sustainability, and advanced manufacturing practices is fostering adoption. European manufacturers are increasingly implementing CNC skiving machines to improve efficiency, reduce lead times, and meet stringent gear standards. The market is also supported by investments in advanced production infrastructure and R&D initiatives for gear manufacturing technologies.

U.K. Internal Gear Skiving Machine Market Insight

The U.K. market is expected to witness significant growth from 2026 to 2033, driven by the growing need for high-precision gears in industrial machinery, robotics, and automotive applications. Increased automation adoption and the push for efficient production processes are encouraging manufacturers to upgrade to CNC-based skiving machines. Moreover, supportive government initiatives promoting advanced manufacturing and the country’s robust engineering ecosystem are stimulating market growth.

Germany Internal Gear Skiving Machine Market Insight

The Germany market is expected to witness rapid growth from 2026 to 2033, fueled by rising demand for technologically advanced gear production in automotive and industrial machinery sectors. The country’s focus on innovation, precision engineering, and energy-efficient manufacturing supports the adoption of CNC and multi-functional skiving machines. Integration with Industry 4.0 technologies and automated production lines is becoming increasingly prevalent, enhancing operational efficiency and productivity.

Asia-Pacific Internal Gear Skiving Machine Market Insight

The Asia-Pacific market is expected to witness the fastest growth rate from 2026 to 2033, driven by increasing industrialization, urbanization, and manufacturing expansion in countries such as China, Japan, and India. Rising demand for precision gears in automotive, wind energy, and industrial machinery applications is boosting adoption of advanced skiving machines. Government initiatives supporting manufacturing modernization and the availability of cost-effective, locally produced machines are further contributing to market growth.

Japan Internal Gear Skiving Machine Market Insight

The Japan market is expected to witness strong growth from 2026 to 2033 due to the country’s advanced manufacturing sector, high technological adoption, and demand for efficient gear production. Japanese manufacturers are increasingly integrating CNC-based internal gear skiving machines with automated production lines to enhance precision, reduce cycle times, and improve output consistency. The focus on innovation and high-quality standards in automotive and industrial machinery sectors is driving market expansion.

China Internal Gear Skiving Machine Market Insight

The China market accounted for the largest revenue share in Asia-Pacific in 2025, attributed to the country’s rapid industrial growth, expanding automotive sector, and high adoption of advanced manufacturing technologies. China’s large-scale production of industrial machinery and automotive components is driving strong demand for CNC and multi-functional internal gear skiving machines. The push toward smart factories, coupled with local machine manufacturing capabilities and cost-effective solutions, is propelling market growth across the region.

Internal Gear Skiving Machine Market Share

The Internal Gear Skiving Machine industry is primarily led by well-established companies, including:

- Liebherr-Verzahntechnik GmbH (Germany)

- Gleason Corporation (U.S.)

- Mitsubishi Heavy Industries (Japan)

- EMAG GmbH & Co. KG (Germany)

- Klingelnberg AG (Switzerland)

- NIDE C Machine Tool Corporation (Japan)

- NACHI-FUJIKOSHI Corporation (Japan)

- JTEKT Corporation (Japan)

- FFG Werke (Austria)

- DMG Mori (Germany)

- DVS Technology Group (U.K.)

Latest Developments in Global Internal Gear Skiving Machine Market

- In July 2025, Klingelnberg AG announced its participation in the EMO/industry exhibition, focusing on precision gear systems and showcasing integrated measurement and process-controlled skiving workflows. These solutions are designed to enhance traceability and accuracy in internal gear production, particularly for aerospace and high-end automotive applications. The development is expected to streamline manufacturing processes, reduce errors, and support higher-quality gear outputs, reinforcing Klingelnberg’s position in the advanced gear machining market

- In September 2023, DMG MORI highlighted its gearSKIVING technology during Technology Days, demonstrating comprehensive gearSKIVING workflows, including process cycles and integration options for mill-turn centers. This initiative allows manufacturers to incorporate skiving capabilities without requiring separate dedicated production lines, improving operational flexibility and efficiency. The development is likely to accelerate adoption of internal gear skiving, reduce production costs, and enhance competitiveness in the gear manufacturing sector

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.