Global Laser Marking Market

Market Size in USD Billion

CAGR :

%

USD

5.02 Billion

USD

8.06 Billion

2024

2032

USD

5.02 Billion

USD

8.06 Billion

2024

2032

| 2025 –2032 | |

| USD 5.02 Billion | |

| USD 8.06 Billion | |

|

|

|

|

Laser Marking Market Size

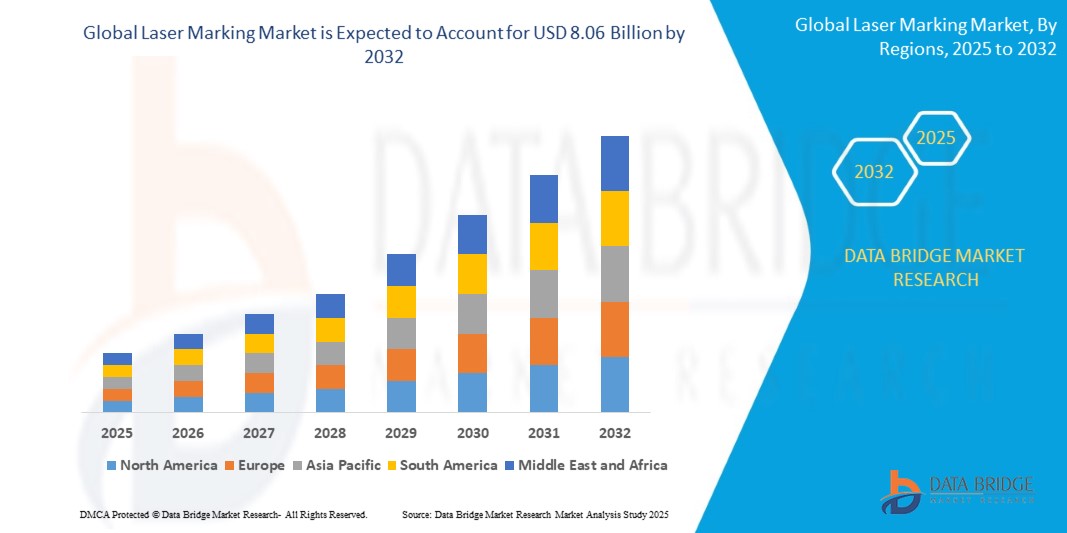

- The Laser Marking Market was valued at USD 5.02 billion in 2025 and is projected to reach USD 8.06 billion by 2032, growing at a CAGR of 7.1% during the forecast period.

- Growth is primarily driven by increasing adoption of laser-based marking systems across manufacturing, automotive, medical devices, and packaging industries due to their precision, permanence, speed, and non-contact nature. The rising demand for traceability, anti-counterfeiting, and regulatory compliance is further accelerating market expansion globally.

Laser Marking Market Analysis

- The Laser Marking Market is experiencing significant growth driven by the rising demand for permanent, high-resolution marking across various materials such as metals, plastics, ceramics, and glass. Laser marking technologies—including fiber lasers, CO₂ lasers, and UV lasers—are increasingly favored due to their precision, speed, low maintenance, and eco-friendliness compared to traditional ink-based methods.

- Industries such as automotive, electronics, aerospace, medical devices, packaging, and machine tools rely heavily on laser marking for serial numbers, barcodes, QR codes, logos, date codes, and traceability marks that are resistant to wear, heat, and chemical exposure. The integration of laser marking systems in automated production lines is accelerating adoption, particularly with the growth of Industry 4.0.

- Moreover, stringent regulatory requirements around product traceability, counterfeit prevention, and safety labeling—especially in healthcare, electronics, and defense—are fueling market demand. The rise of portable and compact laser marking machines is also opening opportunities in small-scale manufacturing and field-based applications.

- The market is further supported by advancements in 3D laser marking, software integration, and AI-based pattern recognition, which enhance marking precision on complex surfaces and curved components. However, high initial capital investment and safety compliance requirements may limit adoption among small and medium enterprises in price-sensitive markets.

Report Scope and Laser Marking Market Segmentation

|

Attributes |

Laser Marking Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Laser Marking Market Trends

Automation, Miniaturization, and Eco-Friendly Marking Driving Innovation

- Fiber lasers are gaining rapid adoption due to their longer operational life, lower maintenance, and higher precision on metal and hard materials. They offer faster marking speeds and lower operating costs, making them ideal for industrial applications.

- With the miniaturization of components in electronics, medical devices, and aerospace, there is a growing need for high-resolution and micro-scale laser marking systems capable of permanent, legible marks on small surfaces.

- The market is witnessing a shift toward compact, mobile laser marking devices for on-site, flexible applications—particularly in construction, automotive repair, and inventory management.

- Laser marking machines are increasingly being embedded into automated production lines with features like machine vision, AI-assisted quality checks, and real-time data logging to support smart manufacturing.

- The move away from chemical etching and ink-based marking toward clean, non-contact laser marking aligns with global environmental sustainability efforts and regulations.

Laser Marking Market Dynamics

Driver

Rising Demand for Traceability and Product Authentication Across Industries

- The growing need for permanent, tamper-proof marking for parts and components is driving the adoption of laser marking across sectors such as automotive, aerospace, electronics, and medical devices. Laser marking ensures traceability for regulatory compliance, warranty validation, and supply chain transparency.

- Government regulations and industry standards, such as UDI (Unique Device Identification) for medical equipment, VIN marking in automobiles, and anti-counterfeiting mandates in electronics and luxury goods, are pushing manufacturers to integrate laser marking into production lines.

- With increasing industrial automation, manufacturers are opting for laser marking due to its speed, accuracy, and ability to integrate seamlessly with robotics and vision systems for high-volume, real-time production environments.

- Sustainability initiatives are promoting laser marking as an eco-friendly alternative to chemical etching, inkjet printing, and labeling—helping companies reduce consumables, waste, and VOC emissions.

Restraint/Challenge

High Capital Investment and System Complexity

- The initial setup cost of laser marking systems, especially those using fiber or UV lasers, remains high compared to traditional marking methods. This can limit adoption among small and medium-sized enterprises (SMEs).

- System complexity and integration challenges arise when embedding laser markers into existing production lines, especially in multi-line factories or legacy infrastructure.

- Safety concerns related to laser emissions require protective shielding, trained operators, and compliance with international laser safety standards (e.g., ISO 11553), increasing the total cost of ownership.

- The limited marking efficiency on some materials like certain plastics, glass, or heat-sensitive substrates may necessitate pre-treatment or multiple passes—impacting throughput and consistency in high-speed operations.

Laser Marking Market Scope

The market is segmented on the basis of by offering, by material, by laser type, by application, by industry.

- By Offering

The market is categorized into Hardware, Software, and Services. Hardware dominates the segment in 2025, driven by the extensive deployment of high-speed fiber and CO₂ laser systems in industrial environments. Software solutions are gaining momentum with the need for precision control, real-time diagnostics, and CAD/CAM compatibility. Services such as installation, calibration, and maintenance are growing steadily with increasing demand for system customization and lifecycle support.

- By Material

The Laser Marking Market includes marking on Metals, Plastics, Glass, Paper, Ceramics, and Others. Metals hold the largest market share owing to widespread application in automotive parts, aerospace components, and machine tools. Plastics follow closely, especially in electronics and packaging sectors. Glass and ceramics are niche segments but growing in the healthcare and luxury goods industries due to demand for permanent, non-invasive markings.

- By Laser Type

Laser types include Fiber Laser, Diode Laser, Solid-State Laser, CO₂ Laser, UV Laser, and Others. Fiber lasers dominate due to their superior speed, precision, and compatibility with metal surfaces. CO₂ lasers are preferred for non-metallic materials such as plastics, glass, and ceramics. UV lasers are gaining traction for micro-marking and applications requiring low thermal impact, such as semiconductor and medical device marking.

- By Application

Applications span Bar Codes, Logos, Date Codes, Part Numbers, QR Codes, and Others.

Bar codes and QR codes are widely used across packaging, logistics, and electronics for traceability. Logos and part numbers are common in automotive and machine tool components for brand identification and warranty tracking. Date codes dominate in food, beverage, and pharmaceutical industries due to regulatory labelling mandates.

- By Industry

End-user industries include Machine Tools, Automotive, Semiconductor & Electronics, Aerospace & Defense, Healthcare, Packaging, and Others.

The automotive sector leads the market in 2025, using laser marking for VIN numbers, component traceability, and logo engraving. Packaging is growing rapidly due to demand for clean, high-speed, ink-free coding. Semiconductor & electronics sectors are adopting laser systems for micro-scale component marking and anti-counterfeiting. Healthcare and aerospace use laser marking for compliance with strict safety and traceability regulations

Laser Marking Market Regional Analysis

North America

North America dominates the laser marking market with the largest revenue share in 2025, driven by rising demand for product traceability, permanent marking, and anti-counterfeiting solutions across key sectors such as automotive, aerospace, electronics, and healthcare. The region benefits from strong industrial automation, early adoption of fiber and UV laser systems, and strict regulatory mandates requiring high-quality and durable marking.

Additionally, the increasing need for serialization in pharmaceuticals, compliance with FDA and UDI standards, and the shift toward sustainable and non-contact marking technologies are accelerating market growth. The presence of major laser equipment manufacturers and system integrators in the U.S. and Canada further supports technological advancements and large-scale deployments.

U.S.

The U.S. laser marking market captured the largest share in North America in 2025. Growth is propelled by stringent regulations for product identification, anti-counterfeiting, and traceability, particularly in healthcare, defense, and consumer electronics. The automotive sector also contributes significantly, using laser marking for VINs, components, and branding. The increasing trend of reshoring and Industry 4.0 initiatives further enhances demand for integrated laser systems in smart factories.

Europe

Europe is projected to grow steadily during the forecast period, fueled by industrial automation, regulatory compliance, and sustainability goals. Laser marking is increasingly replacing ink-based systems due to its eco-friendly and maintenance-free advantages. Demand is particularly strong in automotive, aerospace, and machine tool manufacturing sectors. The EU’s focus on digital manufacturing and traceability in pharmaceuticals and food packaging also supports market expansion.

Germany

Germany leads the European market due to its dominance in precision engineering and machine tool industries. High adoption of laser technology in automotive manufacturing, electronics, and medical equipment production drives growth. Industry 4.0 initiatives and smart factory developments further encourage integration of laser marking systems with MES/ERP platforms for real-time control and traceability.

France

France’s laser marking market is expanding as industrial sectors modernize to meet sustainability and digital transformation targets. The aerospace and healthcare industries are adopting laser systems for permanent, high-resolution, and non-contact marking. Government incentives for automation and strong packaging exports also contribute to market expansion.

Asia-Pacific

Asia-Pacific is expected to grow at the fastest CAGR through 2032, driven by rapid industrialization, large-scale manufacturing, and growing electronics exports. Countries like China, Japan, South Korea, and India are investing in laser marking for electronics labeling, automotive part serialization, and anti-counterfeit solutions. Rising labor costs and environmental regulations are accelerating the shift from traditional marking to automated laser technologies.

Japan

Japan’s market is driven by innovation in electronics and miniaturized manufacturing. Laser marking is widely used in semiconductor devices, precision tools, and consumer electronics. The demand for high-speed, high-precision, and low-damage marking techniques is boosting the adoption of UV and fiber laser technologies.

China

China dominates the Asia-Pacific laser marking market in 2025 due to mass manufacturing of automotive parts, smartphones, and medical devices. Government policies supporting industrial automation and domestic high-tech production, along with growing export requirements for traceability and quality control, are driving strong adoption of laser marking systems in both SMEs and large enterprises.

Laser Marking Market Share

The laser marking market is primarily led by a combination of global laser equipment manufacturers and industrial automation solution providers. These companies are investing in high-speed, precision marking systems, integration with Industry 4.0 technologies, and development of eco-friendly and non-contact marking solutions to meet regulatory compliance and traceability requirements across industries:

- Han's Laser Technology Industry Group Co., Ltd. (China)

- Telesis Technologies, Inc. (U.S.)

- Videojet Technologies Inc. (U.S.)

- Trotec Laser GmbH (Austria)

- Epilog Laser (U.S.)

- TYKMA Electrox (U.S.)

- MECCO (U.S.)

- LaserStar Technologies Corporation (U.S.)

- Gravotech Engineering Pvt. Ltd. (India)

- Sea Force Co., Ltd. (Japan)

Latest Developments in Laser Marking Market

- In May 2025, Han's Laser Technology announced the development of a next-generation fiber laser marking system with integrated AI-assisted vision recognition, enabling real-time barcode verification and part positioning for improved marking accuracy and speed in industrial automation lines.

- In April 2025, Telesis Technologies, Inc. launched a high-speed UV laser marker tailored for micro-marking on sensitive materials such as medical plastics and semiconductors. The system offers enhanced energy efficiency and low thermal impact.

- In March 2025, Videojet Technologies introduced the 7810 Series, a new CO₂ laser marking solution optimized for high-speed packaging lines. It features advanced cooling systems and a compact footprint, catering to the food, beverage, and pharma industries.

- In February 2025, Trotec Laser GmbH unveiled a dual-source laser marker combining fiber and CO₂ lasers in a single unit, designed for flexible marking across diverse materials such as metals, plastics, and glass—ideal for small-batch manufacturers.

- In January 2025, Gravotech Engineering Pvt. Ltd. enhanced its LS900 industrial laser engraver with RFID-based job automation and IoT connectivity for remote monitoring and preventive maintenance in marking operations.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Laser Marking Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Laser Marking Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Laser Marking Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.