Global Lined Valve Market

Market Size in USD Billion

CAGR :

%

USD

3.73 Billion

USD

5.56 Billion

2025

2033

USD

3.73 Billion

USD

5.56 Billion

2025

2033

| 2026 –2033 | |

| USD 3.73 Billion | |

| USD 5.56 Billion | |

|

|

|

|

Lined Valve Market Size

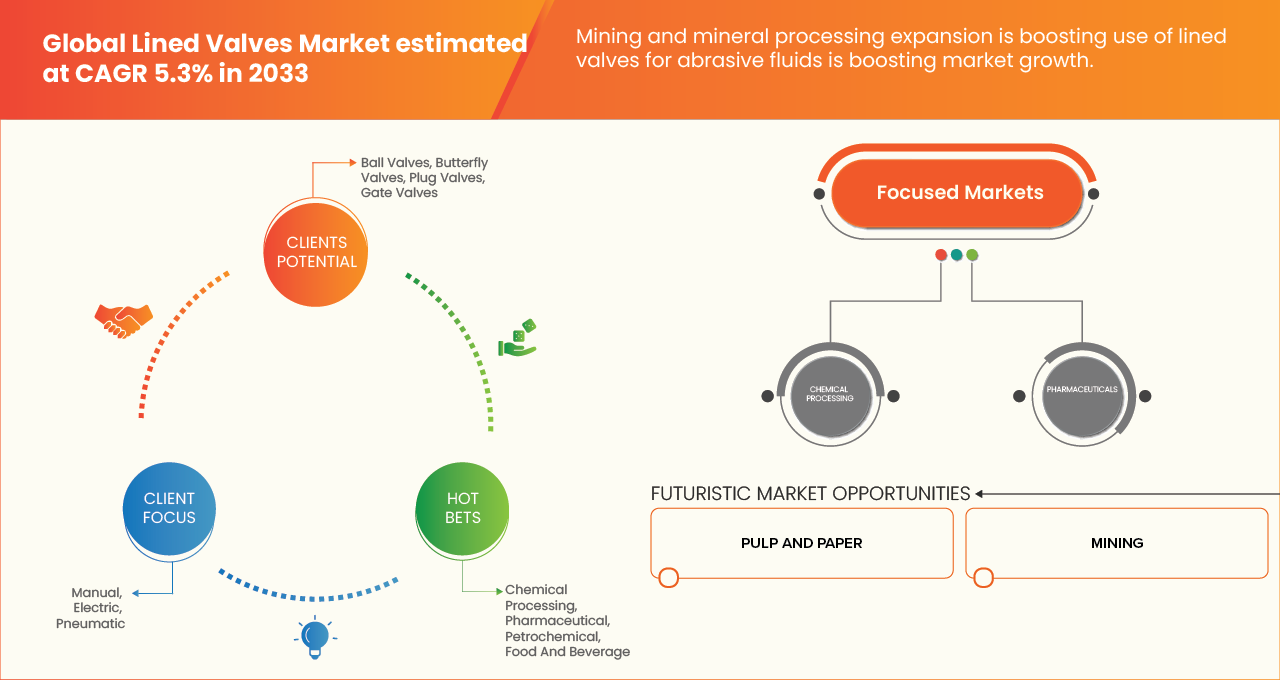

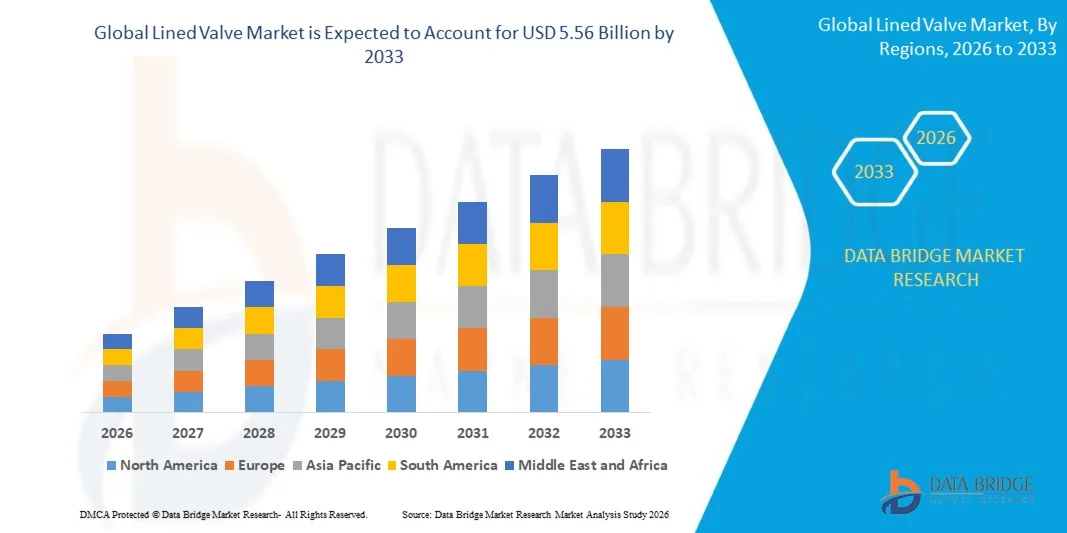

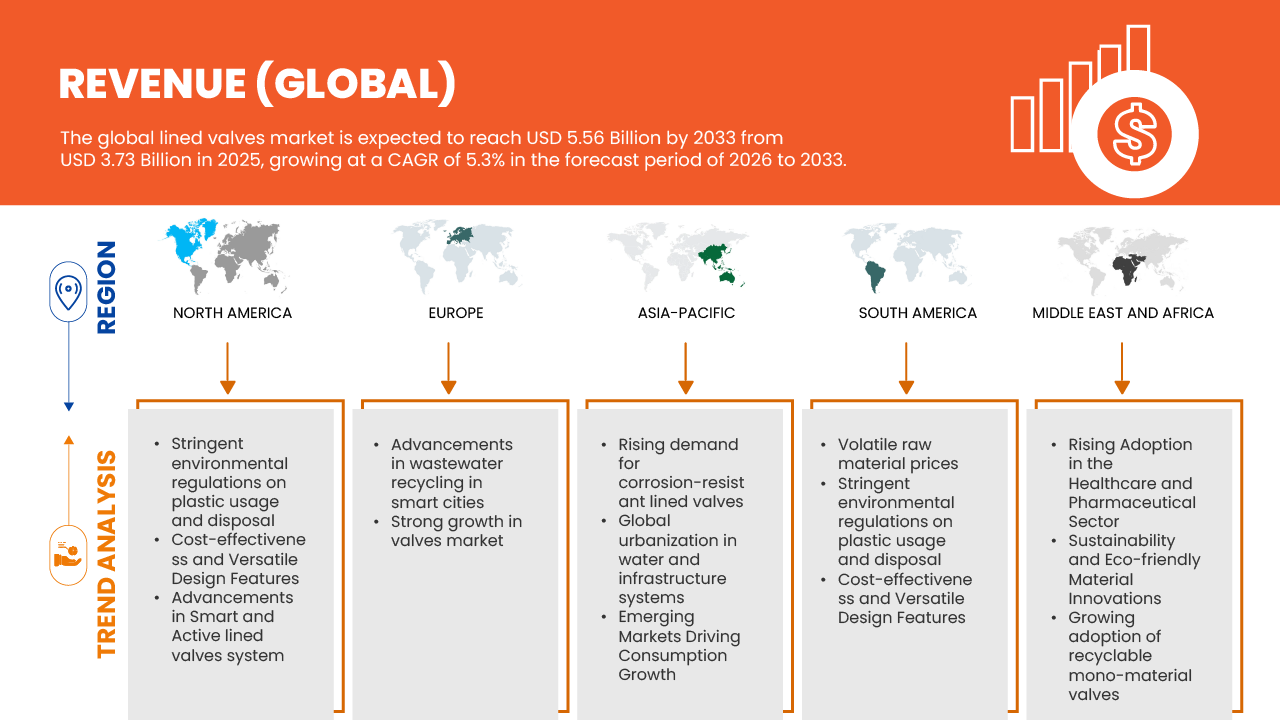

- The Global lined valve market size was valued at USD 3.73 Billion in 2025 and is expected to reach USD 5.56 Billion by 2033, at a CAGR of 5.3% during the forecast period

- The global Lined Valve market is witnessing steady growth, driven by increasing demand for corrosion-resistant flow control solutions across industries handling aggressive, toxic, and high-purity fluids. Market expansion is primarily supported by the rapid growth of the chemical, petrochemical, pharmaceutical, water & wastewater treatment, and specialty manufacturing sectors, where operational safety, regulatory compliance, and equipment longevity are critical. The rising need to minimize leakage, reduce unplanned downtime, and extend valve service life in harsh operating environments continues to accelerate adoption.

- Technological advancements in lining materials, precision manufacturing, CNC machining, and quality assurance processes are enhancing valve performance, dimensional accuracy, and reliability. Additionally, the integration of advanced actuation systems, automation, and digital monitoring technologies is improving process control, predictive maintenance, and plant efficiency, further strengthening market penetration.

Lined Valve Market Analysis

- The market serves diverse end-use industries, including chemical processing, petrochemicals, pharmaceuticals, oil & gas, water and wastewater treatment, power generation, mining, pulp & paper, and specialty industrial manufacturing. Lined valves play a critical role in fluid isolation, flow regulation, backflow prevention, safety protection, and corrosion-resistant fluid transfer, supporting operational efficiency, regulatory compliance, and plant safety.

- Asia-Pacific is expected to dominate the Global Lined Valve Market with the largest market share of 42.59% in 2026 and is also projected to record the CAGR 5.7%. This dominance is supported by its robust industrial expansion and strategic investments. The kingdom's oil and gas sector leads demand, fueled by massive infrastructure projects, refinery upgrades, and unconventional gas production initiatives under Vision 2030, which prioritize reliable valves for high-pressure handling in petrochemical and energy operations.

- In 2026, the ball valves segment is expected to dominate the market with an 25.27% market share, growing at the highest CAGR of 5.9% during the forecast period of 2026 to 2033in the Global Lined Valve packaging market, driven by surging demand in oil & gas, petrochemicals, and water infrastructure.

Report Scope and Lined Valve Market Segmentation

|

Attributes |

Lined Valve Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Lined Valve Market Trends

“Rapid Integration of Automation And IoT Technologies Into Lined Valves”

- Predictive analytics via IoT sensors analyze vibration, pressure, and temperature data continuously, forecasting potential failures before they disrupt operations in extreme desert heat or corrosive flows common in Saudi refineries.

- Remote monitoring eliminates frequent manual inspections across vast oil fields like Ghawar, slashing labor and travel expenses while enabling centralized control from Riyadh hubs. Data-driven insights optimize maintenance schedules, reducing overall ownership costs by integrating with SCADA systems for seamless fleet management.

- Automated shutoffs trigger instantly on anomaly detection, preventing leaks of hazardous substances and aligning with strict Saudi Aramco and GCC regulations like API 6D standards. IoT logging provides audit trails for environmental compliance, crucial amid rising ESG mandates in desalination and LNG facilities. Enhanced traceability also supports insurance reductions through proven reliability records.

Lined Valve Market Dynamics

Driver

“Pharmaceutical Sector Growth is Increasing Demand for Corrosion-Resistant Lined Valves”

- The growth of the pharmaceutical sector is significantly increasing demand for corrosion-resistant lined valves due to the industry’s strict requirements for purity, safety, and process reliability.

- Pharmaceutical manufacturing involves the handling of highly aggressive chemicals, solvents, acids, and active pharmaceutical ingredients that rapidly degrade conventional metal valves. Lined valves, typically coated with materials such as PTFE or PFA, provide strong resistance to corrosion while preventing product contamination, making them well-suited for sensitive drug production processes.

- As pharmaceutical companies expand manufacturing capacities and invest in new facilities to meet rising healthcare needs, the installation of hygienic and durable flow control equipment becomes a priority.

- Additionally, increased adoption of advanced drug formulations and complex chemical synthesis processes requires valves that can withstand frequent cleaning, sterilization, and exposure to harsh media without compromising performance. Regulatory pressure to maintain consistent product quality and comply with stringent validation standards further encourages the use of lined valves that offer long service life and stable operation.

- The sector’s shift toward continuous processing and higher automation levels also supports demand for reliable valves that minimize downtime and maintenance risks. Collectively, these factors make corrosion-resistant lined valves a critical component in supporting the pharmaceutical industry’s ongoing expansion and operational excellence.

Restraint/Challenge

“Volatile Raw Material Prices are Increasing Cost Pressures for Lined Valve Manufacturers”

- Volatile raw material prices are creating significant cost pressures for lined valve manufacturers and are hindering overall market growth. Lined valves rely heavily on specialized materials such as fluoropolymers, elastomers, and high-grade metals such as nickel alloys, stainless steel, titanium and others, which are often subject to price fluctuations driven by supply chain disruptions, energy cost changes, and geopolitical uncertainties.

- When the prices of these inputs rise unpredictably, manufacturers face difficulty in accurately forecasting production costs and setting stable pricing strategies. This uncertainty compresses profit margins, especially for companies operating under long-term supply contracts or fixed-price agreements.

- Smaller and mid-sized manufacturers are particularly vulnerable, as they have limited bargaining power with suppliers and less flexibility to absorb sudden cost increases. To protect margins, manufacturers may pass higher costs on to customers, making lined valves less price-competitive compared to alternative valve solutions. This can delay purchasing decisions or push end users to seek lower-cost substitutes, slowing demand growth.

- Additionally, volatile input costs can disrupt procurement planning and inventory management, leading to inefficiencies and longer lead times. The resulting financial strain often limits manufacturers’ ability to invest in product innovation, capacity expansion, and quality improvements. Collectively, these factors reduce market momentum and create barriers to sustained growth in the lined valve industry.

Lined Valve Market Scope

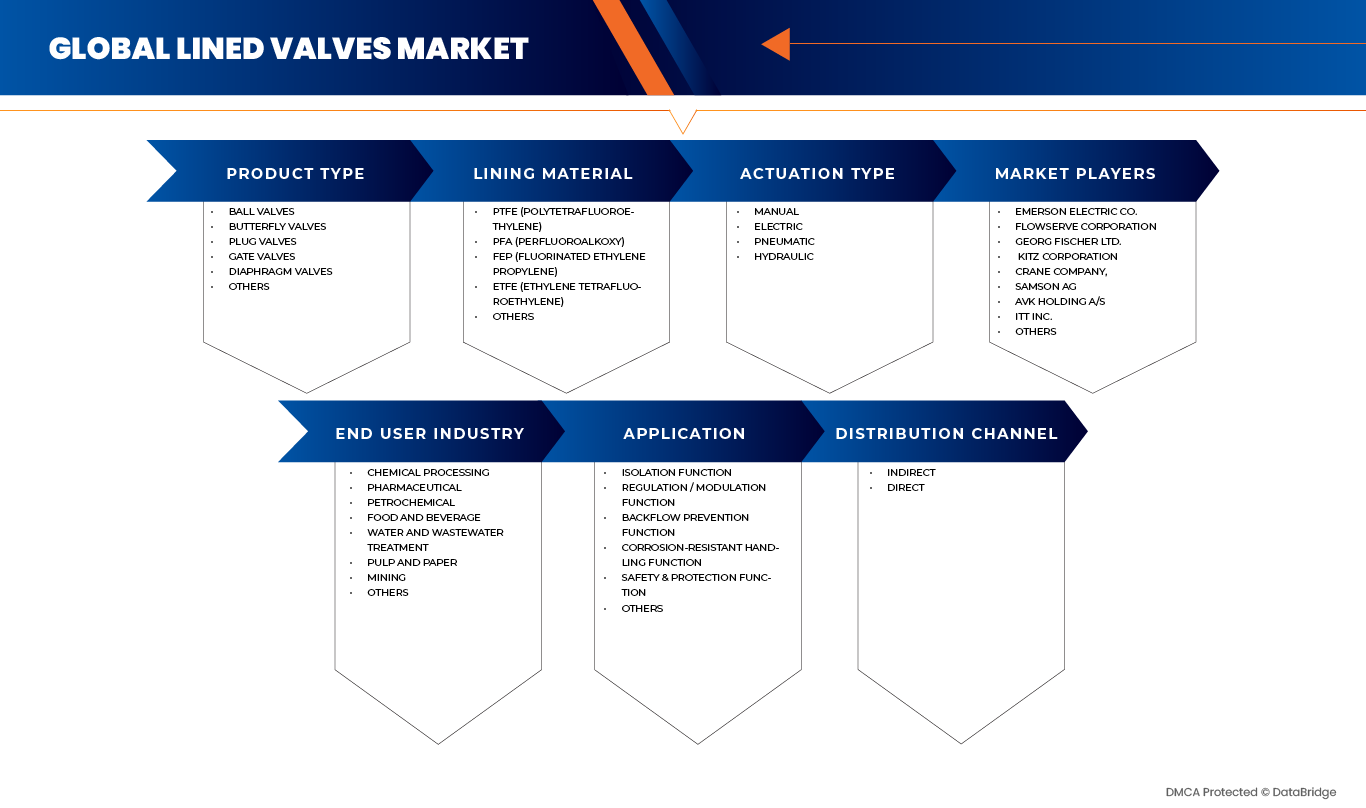

The global lined valve market segmented into Six notable segments which are based on six notable segments which are based on product type, lining material, actuation type, end user industry, application, and distribution channel.

By Product Type

On the basis of product, the global lined valve market is segmented into ball valves, butterfly valves, check valves, gate valves, globe valves, plug valves, diaphragm valves, and others. In 2026, the ball valves segment is expected to dominate the global lined valve market , accounting for the highest share of 25.27% due to its unmatched suitability for high-pressure hydrocarbon flows in oil & gas operations, where quick quarter-turn operation ensures rapid shutoff and minimal leakage in corrosive environments.

Ball valves segment is projected to grow with the highest CAGR of 6.1% owing to surging infrastructure investments and technological advancements tailored to oil & gas dominance.

By Lining Material

On the basis of Lining Material, the global lined valve market is segmented into PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), FEP (Fluorinated Ethylene Propylene), ETFE (Ethylene Tetrafluoroethylene), and Others. In 2026, the PTFE (Polytetrafluoroethylene) segment is expected to dominate the global lined valve market , accounting for the highest share of 40.69%, due to its unparalleled chemical inertness and broad compatibility with aggressive media in oil & gas and petrochemical sectors.

PFA (Perfluoroalkoxy) segment is projected to grow with the highest CAGR of 5.6% owing to its superior mechanical strength and flexibility over PTFE, enabling thinner linings for larger diameters in high-pressure petrochemical applications.

By Actuation Type

On the basis of actuation type, the global lined valve market is segmented into manual, electric, pneumatic, and hydraulic. In 2026, the manual segment is expected to dominate the global lined valve market , accounting for the highest share of 46.94%, due to its proven reliability, simplicity, and cost-effectiveness in routine operations across oil & gas and water treatment facilities.

Pneumatic segment is projected to grow with the highest CAGR of 5.9% owing to its seamless integration with automated process control systems in expanding oil & gas refineries and chemical plants, where compressed air availability drives rapid actuation.

By End User Industry

On the basis of End User Industry, the global lined valve market is segmented into chemical processing, petrochemical, water and wastewater treatment, pharmaceutical, food and beverage, pulp and paper, mining, and others. In 2026, the chemical processing segment is projected to lead the global lined valve market , capturing the largest share of 30.43%, due to its intensive handling of corrosive acids, alkalis, and solvents in expanding petrochemical complexes, where lined valves prevent contamination and ensure process integrity.

Water and Wastewater Treatment segment is projected to grow with the highest CAGR of 5.8% owing to acute water scarcity driving massive desalination and recycling investments across GCC nations.

By Application

On the basis of application, the global lined valve market is segmented into Corrosion-Resistant Handling Function, Isolation Function, Regulation / Modulation Function, Backflow Prevention Function, Safety & Protection Function, and Others. In 2026, the Corrosion-Resistant Handling Function segment is expected to dominate the global lined valve market , accounting for the highest share of 37.46%, due to the prevalence of aggressive chemicals, acids, and high-salinity brines in oil & gas refineries and petrochemical plants, where standard metal valves rapidly degrade.

Regulation /Modulation Function segment is projected to grow with the highest CAGR of 5.8% owing to escalating demand for precise flow and pressure control in automated chemical processing and water treatment systems amid Vision 2030 infrastructure upgrades.

By Distribution Channel

On the basis of distribution channel, the global lined valve market is segmented into direct and indirect. In 2026, the direct segment is expected to dominate the global lined valve market , accounting for the highest share of 63.53%, due to its straightforward design that enables immediate, reliable operation in critical isolation applications across oil & gas pipelines and chemical plants, where simplicity trumps complexity.

Direct segment is projected to grow with the highest CAGR of 5.4% owing to surging infrastructure projects and the need for reliable, low-maintenance shut-off solutions in remote oil & gas fields and expanding chemical facilities.

Lined Valve Market Regional Analysis

- The Asia-Pacific represents one of the most mature and high-volume Lined Valve markets in Global, driven by its dominant oil & gas sector, massive Vision 2030 infrastructure projects, and strategic economic diversification efforts.

- South Africa is witnessing sustained demand for advanced Lined Valve solutions, supported by its thriving oil & gas sector, ambitious desalination expansions, and rapid infrastructure diversification under national visions like Brazil Energy Strategy 2050.

- North America emerging Lined Valve ecosystem is contributing steadily to regional market growth due to its robust mining sector, expanding water treatment infrastructure, and strategic investments in industrial diversification.

China Lined Valve Market Insight

China lined valve market is experiencing consistent growth, driven by nation's expansive oil and gas sector, which demands corrosion-resistant valves for handling aggressive chemicals in refineries and petrochemical plants. Vision 2030 initiatives accelerate this trend through massive infrastructure projects like NEOM, desalination expansions, and renewable energy developments, necessitating durable lined valves for water treatment and power generation. Rapid industrialization, urbanization, and investments in LNG/hydrogen infrastructure further boost demand.

North America Lined Valve Market Insight

The North American lined valve market is projected to grow steadily, driven by for advanced Lined Valve solutions, supported by its thriving oil & gas sector, ambitious desalination expansions, and rapid infrastructure diversification under national visions. Strong regulatory support for sustainable materials, recyclability, and reduced plastic waste is encouraging the development of bio-based and downgauged cast films across U.S., Canada and Mexico.

U.S. Lined Valve Market Insight

The U.S. lined valve market holds the largest share in North America in 2026, which demands corrosion-resistant valves for handling aggressive chemicals in refineries and petrochemical plants. The country’s emphasis on recyclable materials, smart packaging, and high-speed packaging lines is accelerating adoption of advanced cast film solutions

Europe lined valve market Insight

The European lined valve market is projected to grow steadily, driven by for advanced Lined Valve solutions, supported by its thriving oil & gas sector, ambitious desalination expansions, and rapid infrastructure diversification under national visions. Strong regulatory support for sustainable materials, recyclability, and reduced plastic waste is encouraging the development of bio-based and downgauged cast films across Germany, Italy, France and U.K.

Germany lined valve market Insight

The German lined valve market is growing at a stable pace due to robust demand from premium corrosion-resistant valves for handling aggressive chemicals in refineries and petrochemical plants. The country’s emphasis on recyclable materials, smart packaging, and high-speed packaging lines is accelerating adoption of advanced cast film solutions.

Lined Valve Market Share

The lined valve industry is primarily led by well-established companies, including:

- Emerson Electric Co. (U.S.)

- Flowserve Corporation (U.S.)

- Georg Fischer Ltd. (Switzerland)

- KITZ Corporation (Japan)

- Crane Company (U.S.)

- SAMSON AG (Germany)

- AVK Holding A/S (Denmark)

- ITT Inc. (U.S.)

- Bray International (U.S.)

- Richter Chemie-technik Gmbh (Idex Corporation) (Germany)

- Chemvalve-schmid Ag (Switzerland)

- Asahi Yukizai Corporation / Asahi/America (Japan)

- Unp Polyvalves (India) Pvt. Ltd. (India)

- Nivz Valves & Automation (India)

- Frenstar Valves Ltd (India)

- Aira Euro Automation Pvt. Ltd. (India)

- ICON Valves & Engineering Pvt. Ltd. (India)

- Andronaco Industries (Chemtite) (U.S.)

- Chemtech Polyplast Private Limited (India)

- Bflon (India)

- Zhejiang Youfumi Valve Co., Ltd. (China)

- Lianke Valve Co., Ltd. (China)

- Mvs Valves Pvt. Ltd. (India)

- Galaxy Thermoplast Pvt. Ltd. (India)

- Flow Line Valve Pvt. Ltd. (India)

- Polycoat Flowchem Pvt. Ltd (India)

Latest Developments in Lined Valve Market

- In January 2026, Crane Company Completes Acquisition of Precision Sensors & Instrumentation. Crane Company (NYSE: CR) announced it has finalized the acquisition of Precision Sensors & Instrumentation (PSI) from Baker Hughes (NASDAQ: BKR). PSI specializes in sensor-based technologies for aerospace, nuclear, and process industries. Crane will discuss the acquisition during its fourth quarter 2025 earnings call, with the release scheduled for January 26, 2026, and a teleconference on January 27, 2026. Investors can access the call and slides via the company’s website. The acquisition strengthens Crane’s technology portfolio, enhancing its capabilities in advanced sensor solutions across critical industrial markets.

- In January 2026, Emerson (NYSE: EMR) has been honored as the ‘2026 Industrial IoT Company of the Year’ by the IoT Breakthrough Awards for its innovation and technology leadership. Following its 2025 acquisition of Aspen Technology, Emerson offers a comprehensive industrial IoT technology stack, supporting industries like energy, life sciences, aerospace, and semiconductors with AI-enabled autonomous operations. The company’s software-defined, data-centric automation platform enables faster deployment, seamless modernization, and optimized performance across mission-critical operations. Strengthens Emerson’s position as a global automation leader, driving digital transformation and operational excellence for industrial customers worldwide.

- In November 2025, Emerson (NYSE: EMR) has been selected by global mining company South32 to provide advanced automation solutions for its Hermosa mine in Arizona, the company’s first ‘next generation mine.’ Emerson’s software portfolio, including the DeltaV platform, will enable a centralized remote operations center, optimizing safety, efficiency, and environmental performance. The project aims to produce critical metals like zinc, silver, and lead to support renewable energy, transportation, and low-carbon infrastructure. Emerson’s automation technology helps South32 improve operational efficiency while minimizing environmental impact at its Hermosa mine.

- In November 2025, Flowserve to Participate in Investor Conferences. Flowserve Corporation (NYSE: FLS), a global leader in flow control products and services, announced its participation in several upcoming investor conferences. CEO Scott Rowe and CFO Amy Schwetz will attend the Baird Global Industrial Conference on November 12, with Rowe also joining a fireside chat. The company will engage in meetings at the UBS Global Industrials and Transportation Conference on December 2, and Schwetz will participate in the Goldman Sachs Industrials and Materials Conference on December 3, including a fireside chat. Webcasts and replays will be available via Flowserve’s Investor Relations website. Enhances transparency and engagement with investors worldwide.

- In March 2025,Flowserve has launched the INNOMAG TB-MAG Dual Drive Pump, the world’s first sealless pump with true secondary containment, setting a new safety standard. The pump features double hermetic sealing and an independent containment system, preventing leaks and protecting the motor even if a failure occurs. Designed for hazardous chemicals, it includes a corrosion-resistant non-metallic liner and supports solids handling up to 30% concentration. The modular design allows upgrading standard INNOMAG TB-MAG pumps to Dual Drive or purchasing it as a complete unit. This innovation aligns with Flowserve’s strategy of diversification, decarbonization, and digitization.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL LINED VALVE MARKET

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 CURRENCY AND PRICING

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 MULTIVARIATE MODELLING

2.7 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.8 DBMR MARKET POSITION GRID

2.9 MARKET APPLICATION COVERAGE GRID

2.1 VENDOR SHARE ANALYSIS

2.11 SECONDARY SOURCES

2.12 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTERS FIVE FORCES ANALYSIS

4.2 BRAND OUTLOOK

4.2.1 EXPLANATION:

4.2.1.1 BRAND-LEVEL INSIGHTS:

4.2.1.2 COMPANY-LEVEL INSIGHTS:

4.2.1.3 APPLICATION-SPECIFIC TRENDS:

4.3 TECHNOLOGICAL ADVANCEMENTS

4.3.1 OVERVIEW

4.3.2 ADVANCED MATERIALS: EXPANDING PERFORMANCE FRONTIERS

4.3.2.1 HIGH-PERFORMANCE POLYMERS

4.3.2.2 COMPOSITE AND HYBRID LININGS

4.3.3 PRECISION MANUFACTURING AND ADDITIVE TECHNOLOGIES

4.3.3.1 3D PRINTING AND ADDITIVE MANUFACTURING

4.3.3.2 ADVANCED CNC MACHINING

4.3.4 INTELLIGENT VALVE SYSTEMS AND AUTOMATION INTEGRATION

4.3.4.1 IOT ENABLED VALVES

4.3.4.2 ACTUATION AND CONTROL SYSTEMS

4.3.5 ENHANCED SEALING TECHNOLOGIES

4.3.5.1 NEXT GENERATION SEALS

4.3.5.2 SELF ADJUSTING AND ADAPTIVE SEALS

4.3.6 COMPUTATIONAL DESIGN AND SIMULATION TOOLS

4.3.6.1 CFD AND FEA SIMULATIONS

4.3.6.2 DIGITAL TWIN TECHNOLOGY

4.3.7 SUSTAINABILITY AND LIFECYCLE CONSIDERATIONS

4.3.7.1 ECO‑FRIENDLY MATERIALS

4.3.7.2 LIFECYCLE COST OPTIMIZATION

4.3.8 INDUSTRY 4.0 AND DATA ANALYTICS

4.3.9 MARKET IMPACT AND INDUSTRY ADOPTION

4.3.10 CONCLUSION

4.4 VENDOR SELECTION CRITERIA

4.4.1 TECHNICAL CAPABILITY AND PRODUCT PERFORMANCE

4.4.2 QUALITY ASSURANCE AND REGULATORY COMPLIANCE

4.4.3 INDUSTRY EXPERIENCE AND APPLICATION REFERENCES

4.4.4 LIFECYCLE COST AND VALUE PROPOSITION

4.4.5 CUSTOMIZATION AND ENGINEERING SUPPORT

4.4.6 DELIVERY CAPABILITY AND SUPPLY CHAIN RELIABILITY

4.4.7 AFTER-SALES SERVICE AND TECHNICAL SUPPORT

4.4.8 PRICING TRANSPARENCY AND COMMERCIAL TERMS

4.4.9 DIGITAL CAPABILITIES AND DOCUMENTATION ACCESS

4.4.10 CONCLUSION

4.5 CONSUMER BUYING BEHAVIOR

4.5.1 INTRODUCTION

4.5.2 APPLICATION-DRIVEN PURCHASING DECISIONS

4.5.3 TECHNICAL SPECIFICATIONS AND ENGINEERING EVALUATION

4.5.4 QUALITY ASSURANCE, COMPLIANCE, AND SAFETY CONSIDERATIONS

4.5.5 LIFECYCLE COST AND VALUE-BASED BUYING BEHAVIOUR

4.5.6 MULTI-STAKEHOLDER DECISION-MAKING PROCESS

4.5.7 REGIONAL VARIATIONS IN BUYING BEHAVIOUR

4.5.8 INFLUENCE OF DIGITALIZATION AND INFORMATION ACCESS

4.5.9 CONCLUSION

4.6 INNOVATION TRACKER AND STRATEGIC ANALYSIS

4.6.1 MAJOR DEALS AND STRATEGIC ALLIANCES ANALYSIS

4.6.1.1 JOINT VENTURES

4.6.1.2 MERGERS AND ACQUISITIONS

4.6.1.3 LICENSING AND PARTNERSHIP

4.6.1.4 TECHNOLOGY COLLABORATIONS

4.6.1.5 STRATEGIC DIVESTMENTS

4.6.2 NUMBER OF PRODUCTS IN DEVELOPMENT

4.6.3 STAGE OF DEVELOPMENT

4.6.4 TIMELINES AND MILESTONES

4.6.5 INNOVATION STRATEGIES AND METHODOLOGIES

4.6.6 RISK ASSESSMENT AND MITIGATION

4.6.7 FUTURE OUTLOOK

4.7 VALUE CHAIN ANALYSIS

4.7.1 INBOUND LOGISTICS

4.7.2 OPERATIONS

4.7.3 OUTBOUND LOGISTICS

4.7.4 MARKETING AND SALES

4.7.5 SERVICE

5 TARIFFS & IMPACT ON THE MARKET

5.1 CURRENT TARIFF RATE (S) IN TOP-5 COUNTRY MARKETS

5.2 OUTLOOK: LOCAL PRODUCTION V/S IMPORT RELIANCE

5.3 VENDOR SELECTION CRITERIA

5.4 IMPACT ON SUPPLY CHAIN

5.4.1 RAW MATERIAL PROCUREMENT

5.4.2 MANUFACTURING AND PRODUCTION

5.4.3 LOGISTICS AND DISTRIBUTION

5.4.4 PRICE PITCHING AND POSITION OF MARKET

5.5 INDUSTRY PARTICIPANTS: PROACTIVE MOVES

5.5.1 SUPPLY CHAIN OPTIMIZATION

5.5.2 JOINT VENTURE ESTABLISHMENTS

5.6 IMPACT ON PRICES

5.7 REGULATORY INCLINATION

5.7.1 GEOPOLITICAL SITUATION

5.7.2 TRADE PARTNERSHIPS BETWEEN THE COUNTRIES

5.7.2.1 FREE TRADE AGREEMENTS

5.7.2.2 ALLIANCES ESTABLISHMENTS

5.7.3 STATUS ACCREDITATION (INCLUDING MFTN)

5.7.4 DOMESTIC COURSE OF CORRECTION

5.7.4.1 INCENTIVE SCHEMES TO BOOST PRODUCTION OUTPUTS

5.7.4.2 ESTABLISHMENT OF SEZS/INDUSTRIAL PARKS

6 REGULATION COVERAGE

6.1 PRODUCT CODES

6.2 CERTIFIED STANDARDS

6.3 SAFETY STANDARDS

6.3.1 MATERIAL HANDLING & STORAGE

6.3.2 TRANSPORT & PRECAUTIONS

6.3.3 HAZARD IDENTIFICATION

7 MARKET OVERVIEW

7.1 DRIVERS

7.1.1 PHARMACEUTICAL SECTOR GROWTH IS INCREASING DEMAND FOR CORROSION-RESISTANT LINED VALVES

7.1.2 MINING AND MINERAL PROCESSING EXPANSION IS BOOSTING USE OF LINED VALVES FOR ABRASIVE FLUIDS

7.1.3 GLOBAL URBANIZATION IS DRIVING DEMAND FOR DURABLE LINED VALVES IN WATER AND INFRASTRUCTURE SYSTEMS

7.1.4 CHEMICAL INDUSTRY GROWTH IS FUELING ADOPTION OF LINED VALVES FOR HANDLING AGGRESSIVE CHEMICALS

7.2 RESTRAINTS

7.2.1 VOLATILE RAW MATERIAL PRICES ARE INCREASING COST PRESSURES FOR LINED VALVE MANUFACTURERS

7.2.2 HIGH UPFRONT COSTS ARE LIMITING ADOPTION COMPARED TO CONVENTIONAL VALVES

7.3 OPPORTUNITIES

7.3.1 INCREASING INVESTMENT IN LITHIUM-ION BATTERY MANUFACTURING

7.3.2 RISING DEMAND FOR WASTEWATER RECYCLING IN SMART CITIES

7.3.3 IMPROVED FLUOROPOLYMER LININGS ARE ENHANCING VALVE EFFICIENCY AND SERVICE LIFE

7.4 CHALLENGES

7.4.1 GLOBAL SUPPLY CHAIN DISRUPTIONS ARE AFFECTING TIMELY PRODUCTION AND DELIVERY

7.4.2 VARYING INTERNATIONAL CERTIFICATION STANDARDS ARE COMPLICATING MARKET ENTRY AND COMPLIANCE

8 GLOBAL LINED VALVE MARKET, BY PRODUCT TYPE

8.1 OVERVIEW

8.2 BALL VALVES

8.3 BUTTERFLY VALVES

8.4 CHECK VALVES

8.5 GATE VALVES

8.6 GLOBE VALVES

8.7 PLUG VALVES

8.8 DIAPHRAGM VALVES

8.9 OTHERS

8.1 GLOBAL BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

8.10.1 PTFE LINED BALL VALVES

8.10.2 PFA LINED BALL VALVES

8.10.3 FEP LINED BALL VALVES

8.10.4 ETFE LINED BALL VALVES

8.11 GLOBAL BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

8.11.1 FLOATING BALL

8.11.2 TRUNNION MOUNTED BALL

8.12 BALL VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.12.1 ASIA-PACIFIC

8.12.2 NORTH AMERICA

8.12.3 EUROPE

8.12.4 SOUTH AMERICA

8.12.5 MIDDLE EAST & AFRICA

8.13 GLOBAL BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

8.13.1 PTFE LINED BUTTERFLY VALVES

8.13.2 PFA LINED BUTTERFLY VALVES

8.14 GLOBAL BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

8.14.1 WAFER TYPE

8.14.2 LUG TYPE

8.15 BUTTERFLY VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.15.1 ASIA-PACIFIC

8.15.2 NORTH AMERICA

8.15.3 EUROPE

8.15.4 SOUTH AMERICA

8.15.5 MIDDLE EAST & AFRICA

8.16 GLOBAL CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

8.16.1 MANUAL

8.16.2 ELECTRIC

8.16.3 PNEUMATIC

8.16.4 HYDRAULIC

8.17 GLOBAL CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

8.17.1 SWING TYPE

8.17.2 WAFER TYPE

8.17.3 LIFT CHECK

8.17.4 DUAL PLATE CHECK

8.17.5 BALL CHECK

8.18 CHECK VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.18.1 ASIA-PACIFIC

8.18.2 NORTH AMERICA

8.18.3 EUROPE

8.18.4 SOUTH AMERICA

8.18.5 MIDDLE EAST & AFRICA

8.19 GLOBAL GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

8.19.1 MANUAL

8.19.2 ELECTRIC

8.19.3 PNEUMATIC

8.19.4 HYDRAULIC

8.2 GLOBAL GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

8.20.1 WEDGE GATE

8.20.2 KNIFE GATE

8.20.3 PARALLEL SLIDE GATE

8.21 GATE VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.21.1 ASIA-PACIFIC

8.21.2 NORTH AMERICA

8.21.3 EUROPE

8.21.4 SOUTH AMERICA

8.21.5 MIDDLE EAST & AFRICA

8.22 GLOBAL GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

8.22.1 MANUAL

8.22.2 ELECTRIC

8.22.3 PNEUMATIC

8.22.4 HYDRAULIC

8.23 GLOBAL GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

8.23.1 STRAIGHT PATTERN

8.23.2 ANGLE PATTERN

8.23.3 Y-PATTERN

8.24 GLOBE VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.24.1 ASIA-PACIFIC

8.24.2 NORTH AMERICA

8.24.3 EUROPE

8.24.4 SOUTH AMERICA

8.24.5 MIDDLE EAST & AFRICA

8.25 GLOBAL PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

8.25.1 PTFE LINED PLUG VALVES

8.25.2 PFALINED PLUG VALVES

8.26 GLOBAL PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

8.26.1 STANDARD PLUG

8.26.2 LUBRICATED PLUG

8.27 GLOBAL PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

8.27.1 MANUAL

8.27.2 PNEUMATIC

8.27.3 ELECTRIC

8.27.4 HYDRAULIC

8.28 PLUG VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.28.1 ASIA-PACIFIC

8.28.2 NORTH AMERICA

8.28.3 EUROPE

8.28.4 SOUTH AMERICA

8.28.5 MIDDLE EAST & AFRICA

8.29 GLOBAL DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

8.29.1 MANUAL

8.29.2 PNEUMATIC

8.29.3 ELECTRIC

8.29.4 HYDRAULIC

8.3 DIAPHRAGM VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.30.1 ASIA-PACIFIC

8.30.2 NORTH AMERICA

8.30.3 EUROPE

8.30.4 SOUTH AMERICA

8.30.5 MIDDLE EAST & AFRICA

8.31 OTHER VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

8.31.1 ASIA-PACIFIC

8.31.2 NORTH AMERICA

8.31.3 EUROPE

8.31.4 SOUTH AMERICA

8.31.5 MIDDLE EAST & AFRICA

9 GLOBAL LINED VALVE MARKET, BY LINING MATERIAL

9.1 OVERVIEW

9.2 PTFE (POLYTETRAFLUOROETHYLENE)

9.3 PFA (PERFLUOROALKOXY)

9.4 FEP (FLUORINATED ETHYLENE PROPYLENE)

9.5 ETFE (ETHYLENE TETRAFLUOROETHYLENE)

9.6 OTHERS

9.7 GLOBAL PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

9.7.1 MOLDING

9.7.2 EXTRUSION

9.7.3 LINING TECHNOLOGY

9.8 PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

9.8.1 ASIA-PACIFIC

9.8.2 NORTH AMERICA

9.8.3 EUROPE

9.8.4 SOUTH AMERICA

9.8.5 MIDDLE EAST & AFRICA

9.9 GLOBAL PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

9.9.1 MOLDING

9.9.2 INJECTION MOULDING

9.1 PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

9.10.1 ASIA-PACIFIC

9.10.2 NORTH AMERICA

9.10.3 EUROPE

9.10.4 SOUTH AMERICA

9.10.5 MIDDLE EAST & AFRICA

10 GLOBAL LINED VALVE MARKET, BY ACTUATION TYPE

10.1 OVERVIEW

10.2 MANUAL

10.3 ELECTRIC

10.4 PNEUMATIC

10.5 HYDRAULIC

10.6 MANUAL IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

10.6.1 ASIA-PACIFIC

10.6.2 NORTH AMERICA

10.6.3 EUROPE

10.6.4 SOUTH AMERICA

10.6.5 MIDDLE EAST & AFRICA

10.7 ELECTRIC IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

10.7.1 ASIA-PACIFIC

10.7.2 NORTH AMERICA

10.7.3 EUROPE

10.7.4 SOUTH AMERICA

10.7.5 MIDDLE EAST & AFRICA

10.8 PNEUMATIC IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

10.8.1 ASIA-PACIFIC

10.8.2 NORTH AMERICA

10.8.3 EUROPE

10.8.4 SOUTH AMERICA

10.8.5 MIDDLE EAST & AFRICA

10.9 HYDRAULIC IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

10.9.1 ASIA-PACIFIC

10.9.2 NORTH AMERICA

10.9.3 EUROPE

10.9.4 SOUTH AMERICA

10.9.5 MIDDLE EAST & AFRICA

11 GLOBAL LINED VALVE MARKET, BY END-USER INDUSTRY

11.1 OVERVIEW

11.2 CHEMICAL PROCESSING

11.3 PETROCHEMICAL

11.4 WATER AND WASTEWATER TREATMENT

11.5 PHARMACEUTICAL

11.6 FOOD AND BEVERAGE

11.7 PULP AND PAPER

11.8 MINING

11.9 OTHERS

11.1 GLOBAL CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.10.1 ACID TRANSPORT

11.10.2 CAUSTIC FLUIDS HANDLING

11.11 CHEMICAL PROCESSING IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.11.1 ASIA-PACIFIC

11.11.2 NORTH AMERICA

11.11.3 EUROPE

11.11.4 SOUTH AMERICA

11.11.5 MIDDLE EAST & AFRICA

11.12 GLOBAL PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.12.1 REFINERIES

11.12.2 POLYMER PRODUCTION

11.13 PETROCHEMICAL IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.13.1 ASIA-PACIFIC

11.13.2 NORTH AMERICA

11.13.3 EUROPE

11.13.4 SOUTH AMERICA

11.13.5 MIDDLE EAST & AFRICA

11.14 GLOBAL WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.14.1 CORROSIVE WASTEWATER HANDLING

11.14.2 CHEMICAL DOSING SYSTEMS

11.14.3 DESALINATION PLANTS

11.14.4 SLUDGE & SLURRY FLOW MANAGEMENT

11.14.5 DISINFECTION SYSTEM CONTROL

11.15 WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.15.1 ASIA-PACIFIC

11.15.2 NORTH AMERICA

11.15.3 EUROPE

11.15.4 SOUTH AMERICA

11.15.5 MIDDLE EAST & AFRICA

11.16 GLOBAL PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.16.1 BULK DRUG PRODUCTION

11.16.2 CLEAN-IN-PLACE SYSTEMS

11.17 PHARMACEUTICAL IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.17.1 ASIA-PACIFIC

11.17.2 NORTH AMERICA

11.17.3 EUROPE

11.17.4 SOUTH AMERICA

11.17.5 MIDDLE EAST & AFRICA

11.18 GLOBAL FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.18.1 LIQUID PROCESSING

11.18.2 WASHING LINES

11.19 FOOD AND BEVERAGE IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.19.1 ASIA-PACIFIC

11.19.2 NORTH AMERICA

11.19.3 EUROPE

11.19.4 SOUTH AMERICA

11.19.5 MIDDLE EAST & AFRICA

11.2 GLOBAL PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.20.1 BLACK LIQUOR & WHITE LIQUOR HANDLING

11.20.2 BLEACHING CHEMICALS

11.20.3 ACID/ALKALI RECOVERY SYSTEMS

11.20.4 OTHERS

11.21 PULP AND PAPER IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.21.1 ASIA-PACIFIC

11.21.2 NORTH AMERICA

11.21.3 EUROPE

11.21.4 SOUTH AMERICA

11.21.5 MIDDLE EAST & AFRICA

11.22 GLOBAL MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

11.22.1 SLURRY HANDLING SYSTEMS

11.22.2 CHEMICAL LEACHING PROCESSES

11.22.3 MINERAL PROCESSING ACID LINES

11.22.4 WASTEWATER & TAILING FLOWS

11.22.5 FLOTATION REAGENT DISTRIBUTION

11.23 MINING IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.23.1 ASIA-PACIFIC

11.23.2 NORTH AMERICA

11.23.3 EUROPE

11.23.4 SOUTH AMERICA

11.23.5 MIDDLE EAST & AFRICA

11.24 OTHERS IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

11.24.1 ASIA-PACIFIC

11.24.2 NORTH AMERICA

11.24.3 EUROPE

11.24.4 SOUTH AMERICA

11.24.5 MIDDLE EAST & AFRICA

12 GLOBAL LINED VALVE MARKET, BY APPLICATION

12.1 OVERVIEW

12.2 CORROSION-RESISTANT HANDLING FUNCTION

12.3 ISOLATION FUNCTION

12.4 REGULATION / MODULATION FUNCTION

12.5 BACKFLOW PREVENTION FUNCTION

12.6 SAFETY & PROTECTION FUNCTION

12.7 OTHERS

12.8 GLOBAL CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

12.8.1 CHEMICAL-RESISTANT FLOW CONTROL

12.8.2 ACID & ALKALI HANDLING

12.8.3 OTHERS

12.9 CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

12.9.1 ASIA-PACIFIC

12.9.2 NORTH AMERICA

12.9.3 EUROPE

12.9.4 SOUTH AMERICA

12.9.5 MIDDLE EAST & AFRICA

12.1 GLOBAL ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

12.10.1 CHEMICAL-RESISTANT FLOW CONTROL

12.10.2 ACID & ALKALI HANDLING

12.10.3 OTHERS

12.11 ISOLATION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

12.11.1 ASIA-PACIFIC

12.11.2 NORTH AMERICA

12.11.3 EUROPE

12.11.4 SOUTH AMERICA

12.11.5 MIDDLE EAST & AFRICA

12.12 GLOBAL REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

12.12.1 CORROSIVE WASTEWATER HANDLING

12.12.2 CHEMICAL DOSING SYSTEMS

12.12.3 DESALINATION PLANTS

12.13 REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

12.13.1 ASIA-PACIFIC

12.13.2 NORTH AMERICA

12.13.3 EUROPE

12.13.4 SOUTH AMERICA

12.13.5 MIDDLE EAST & AFRICA

12.14 GLOBAL BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

12.14.1 NON-RETURN / CHECK PROTECTION

12.14.2 REVERSE FLOW PROTECTION IN CORROSIVE MEDIA

12.15 GLOBAL BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

12.15.1 ASIA-PACIFIC

12.15.2 NORTH AMERICA

12.15.3 EUROPE

12.15.4 SOUTH AMERICA

12.15.5 MIDDLE EAST & AFRICA

12.16 GLOBAL SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

12.16.1 LIQUID PROCESSING

12.16.2 WASHING LINES

12.17 SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

12.17.1 ASIA-PACIFIC

12.17.2 NORTH AMERICA

12.17.3 EUROPE

12.17.4 SOUTH AMERICA

12.17.5 MIDDLE EAST & AFRICA

12.18 OTHERS IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

12.18.1 ASIA-PACIFIC

12.18.2 NORTH AMERICA

12.18.3 EUROPE

12.18.4 SOUTH AMERICA

12.18.5 MIDDLE EAST & AFRICA

13 GLOBAL LINED VALVE MARKET, BY DISTRIBUTION CHANNEL

13.1 OVERVIEW

13.2 DIRECT

13.3 INDIRECT

13.4 DIRECT IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

13.4.1 ASIA-PACIFIC

13.4.2 NORTH AMERICA

13.4.3 EUROPE

13.4.4 SOUTH AMERICA

13.4.5 MIDDLE EAST & AFRICA

13.5 GLOBAL INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

13.5.1 DISTRIBUTORS

13.5.2 SYSTEM INTEGRATORS

13.5.3 THIRD-PARTY ONLINE MARKETPLACES

13.5.4 OTHERS

13.6 INDIRECT IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

13.6.1 ASIA-PACIFIC

13.6.2 NORTH AMERICA

13.6.3 EUROPE

13.6.4 SOUTH AMERICA

13.6.5 MIDDLE EAST & AFRICA

14 GLOBAL LINED VALVES MARKET, BY REGION

14.1 OVERVIEW

14.2 ASIA PACIFIC

14.2.1 CHINA

14.2.2 INDIA

14.2.3 JAPAN

14.2.4 SOUTH KOREA

14.2.5 INDONESIA

14.2.6 THAILAND

14.2.7 MALAYSIA

14.2.8 PHILIPPINES

14.2.9 AUSTRALIA

14.2.10 TAIWAN

14.2.11 SINAGPORE

14.2.12 HONG KONG

14.2.13 NEW ZEALAND

14.2.14 REST OF ASIA PACIFIC

14.3 NORTH AMERICA

14.3.1 U.S.

14.3.2 CANADA

14.3.3 MEXICO

14.4 EUROPE

14.4.1 GERMANY

14.4.2 U.K.

14.4.3 ITALY

14.4.4 FRANCE

14.4.5 SPAIN

14.4.6 SWITZERLAND

14.4.7 RUSSIA

14.4.8 TURKEY

14.4.9 BELGIUM

14.4.10 NETHERLANDS

14.4.11 DENMARK

14.4.12 NORWAY

14.4.13 FINLAND

14.4.14 SWEDEN

14.4.15 REST 0F EUROPE

14.5 SOUTH AMERICA

14.5.1 BRAZIL

14.5.2 CHILE

14.5.3 ARGENTINA

14.5.4 PERU

14.5.5 COLOMBIA

14.5.6 VENEZUELA

14.5.7 ECUADOR

14.5.8 BOLIVIA

14.5.9 PARAGUAY

14.5.10 URUGUAY

14.5.11 REST OF SOUTH AMERICA

14.6 MIDDLE EAST AND AFRICA

14.6.1 SAUDI ARABIA

14.6.2 UNITED ARAB EMIRATES

14.6.3 SOUTH AFRICA

14.6.4 EGYPT

14.6.5 QATAR

14.6.6 KUWAIT

14.6.7 OMAN

14.6.8 ISRAEL

14.6.9 BAHRAIN

14.6.10 REST OF MIDDLE EAST AND AFRICA

15 GLOBAL LINED VALVE MARKET: COMPANY LANDSCAPE

15.1 MANUFACTURER COMPANY SHARE ANALYSIS: GLOBAL

15.2 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

15.3 COMPANY SHARE ANALYSIS: NORTH AMERICA

15.4 COMPANY SHARE ANALYSIS: EUROPE

16 SWOT ANALYSIS

17 COMPANY PROFILES

17.1 CRANE CO.

17.1.1 COMPANY SNAPSHOT

17.1.2 REVENUE ANALYSIS

17.1.3 COMPANY SHARE ANALYSIS

17.1.4 PRODUCT PORTFOLIO

17.1.5 RECENT DEVELOPMENT

17.2 EMERSON ELECTRIC CO

17.2.1 COMPANY SNAPSHOT

17.2.2 REVENUE ANALYSIS

17.2.3 COMPANY SHARE ANALYSIS

17.2.4 PRODUCT PORTFOLIO

17.2.5 RECENT DEVELOPMENT

17.3 FLOWSERVE CORPORATION

17.3.1 COMPANY SNAPSHOT

17.3.2 REVENUE ANALYSIS

17.3.3 COMPANY SHARE ANALYSIS

17.3.4 PRODUCT PORTFOLIO

17.3.5 RECENT DEVELOPMENT

17.4 KITZ CORPORATION.

17.4.1 COMPANY SNAPSHOT

17.4.2 REVENUE ANALYSIS

17.4.3 COMPANY SHARE ANALYSIS

17.4.4 PRODUCT PORTFOLIO

17.4.5 RECENT DEVELOPMENT

17.5 GEORG FISCHER PIPING SYSTEMS (GEORG FISCHER AG)

17.5.1 COMPANY SNAPSHOT

17.5.2 REVENUE ANALYSIS

17.5.3 COMPANY SHARE ANALYSIS

17.5.4 PRODUCT PORTFOLIO

17.5.5 RECENT DEVELOPMENT

17.6 AIRA EURO AUTOMATION PVT. LTD

17.6.1 COMPANY SNAPSHOT

17.6.2 PRODUCT/SERVICE PORTFOLIO

17.6.3 RECENT DEVELOPMENT

17.7 ANDRONACO INDUSTRIES

17.7.1 COMPANY SNAPSHOT

17.7.2 PRODUCT PORTFOLIO

17.7.3 RECENT DEVELOPMENT

17.8 ASAHI YUKIZAI CORPORATION / ASAHI/AMERICA

17.8.1 COMPANY SNAPSHOT

17.8.2 REVENUE ANALYSIS

17.8.3 PRODUCT PORTFOLIO

17.8.4 RECENT DEVELOPMENT

17.9 AVK HOLDING A/S

17.9.1 COMPANY SNAPSHOT

17.9.2 REVENUE ANALYSIS

17.9.3 PRODUCT PORTFOLIO

17.9.4 RECENT DEVELOPMENT

17.1 BFLON

17.10.1 COMPANY SNAPSHOT

17.10.2 PRODUCT PORTFOLIO

17.10.3 RECENT DEVELOPMENT

17.11 BRAY INTERNATIONAL, INC.

17.11.1 COMPANY SNAPSHOT

17.11.2 PRODUCT PORTFOLIO

17.11.3 RECENT DEVELOPMENT

17.12 CHEMTECH POLYPLAST PRIVATE LIMITED

17.12.1 COMPANY SNAPSHOT

17.12.2 PRODUCT/SERVICE PORTFOLIO

17.12.3 RECENT DEVELOPMENT

17.13 CHEMVALVE-SCHMID AG

17.13.1 COMPANY SNAPSHOT

17.13.2 PRODUCT PORTFOLIO

17.13.3 RECENT DEVELOPMENT

17.14 FLOW LINE VALVES

17.14.1 COMPANY SNAPSHOT

17.14.2 PRODUCT PORTFOLIO

17.14.3 RECENT DEVELOPMENT

17.15 FRENSTAR

17.15.1 COMPANY SNAPSHOT

17.15.2 PRODUCT PORTFOLIO

17.15.3 RECENT DEVELOPMENT

17.16 GALAXY THERMOPLAST PVT. LTD.

17.16.1 COMPANY SNAPSHOT

17.16.2 PRODUCT PORTFOLIO

17.16.3 RECENT DEVELOPMENT

17.17 ICON VALVES & ENGINEERING PVT.

17.17.1 COMPANY SNAPSHOT

17.17.2 PRODUCT/SERVICE PORTFOLIO

17.17.3 RECENT DEVELOPMENT

17.18 ITT INC.

17.18.1 COMPANY SNAPSHOT

17.18.2 REVENUE ANALYSIS

17.18.3 SOLUTION PORTFOLIO

17.18.4 RECENT DEVELOPMENT/NEWS

17.19 LIANKE VALVE CO., LTD.

17.19.1 COMPANY SNAPSHOT

17.19.2 PRODUCT PORTFOLIO

17.19.3 RECENT DEVELOPMENT

17.2 MAYUR (VALVES) SYSTME PRIVATE LIMITED

17.20.1 COMPANY SNAPSHOT

17.20.2 PRODUCT PORTFOLIO

17.20.3 RECENT DEVELOPMENT

17.21 NIVZ VALVES & AUTOMATION

17.21.1 COMPANY SNAPSHOT

17.21.2 PRODUCT/SERVICE PORTFOLIO

17.21.3 RECENT DEVELOPMENT

17.22 POLYCOAT FLOWCHEM PVT. LTD.

17.22.1 COMPANY SNAPSHOT

17.22.2 PRODUCT PORTFOLIO

17.22.3 RECENT DEVELOPMENT

17.23 RICHTER CHEMIE-TECHNIK GMBH (IDEX CORPORATION)

17.23.1 COMPANY SNAPSHOT

17.23.2 PRODUCT PORTFOLIO

17.23.3 RECENT DEVELOPMENT

17.24 SAMSON AG

17.24.1 COMPANY SNAPSHOT

17.24.2 PRODUCT PORTFOLIO

17.24.3 RECENT DEVELOPMENT

17.25 UNP POLYVALVES (INDIA) PVT. LTD.

17.25.1 COMPANY SNAPSHOT

17.25.2 PRODUCT PORTFOLIO

17.25.3 RECENT DEVELOPMENT

17.26 ZHEJIANG YOUFUMI VALVE CO., LTD.

17.26.1 COMPANY SNAPSHOT

17.26.2 PRODUCT PORTFOLIO

17.26.3 RECENT DEVELOPMENT

18 QUESTIONNAIRE

19 RELATED REPORTS

List of Table

TABLE 1 BRAND COMPARATIVE ANALYSIS

TABLE 2 COMPANY VS BRAND OVERVIEW

TABLE 3 CONSUMER PREFERENCE MATRIX

TABLE 4 GLOBAL LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 5 GLOBAL BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 6 GLOBAL BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 7 BALL VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 8 GLOBAL BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 9 GLOBAL BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 10 BUTTERFLY VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 11 GLOBAL CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 12 GLOBAL CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 13 CHECK VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 14 GLOBAL GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 15 GLOBAL GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 16 GATE VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 17 GLOBAL GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 18 GLOBAL GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 19 GLOBE VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 20 GLOBAL PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 21 GLOBAL PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 22 GLOBAL PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 23 PLUG VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 24 GLOBAL DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 25 DIAPHRAGM VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 26 OTHER VALVES IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 27 GLOBAL LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 28 GLOBAL PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 29 PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 30 GLOBAL PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 31 PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 32 GLOBAL LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 33 MANUAL IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 34 ELECTRIC IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 35 PNEUMATIC IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 36 HYDRAULIC IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 37 GLOBAL LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 38 GLOBAL CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 39 CHEMICAL PROCESSING IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 40 GLOBAL PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 41 PETROCHEMICAL IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 42 GLOBAL WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 43 WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 44 GLOBAL PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 45 PHARMACEUTICAL IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 46 GLOBAL FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 47 FOOD AND BEVERAGE IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 48 GLOBAL PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 49 PULP AND PAPER IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 50 GLOBAL MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 51 MINING IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 52 OTHERS IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 53 GLOBAL LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 54 GLOBAL CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 55 CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 56 GLOBAL ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 57 ISOLATION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 58 GLOBAL REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 59 REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 60 GLOBAL BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 61 GLOBAL BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 62 GLOBAL SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 63 SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 64 OTHERS IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 65 GLOBAL LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 66 DIRECT IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 67 GLOBAL INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 68 INDIRECT IN LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 69 GLOBAL LINED VALVE MARKET, BY REGION, 2018-2033 (USD THOUSAND)

TABLE 70 ASIA PACIFIC LINED VALVE MARKET, BY COUNTRY, 2018-2033 (USD THOUSAND)

TABLE 71 ASIA PACIFIC LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 72 ASIA PACIFIC BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 73 ASIA PACIFIC BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 74 ASIA PACIFIC BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 75 ASIA PACIFIC BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 76 ASIA PACIFIC CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 77 ASIA PACIFIC CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 78 ASIA PACIFIC GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 79 ASIA PACIFIC GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 80 ASIA PACIFIC GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 81 ASIA PACIFIC GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 82 ASIA PACIFIC PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 83 ASIA PACIFIC PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 84 ASIA PACIFIC PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 85 ASIA PACIFIC DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 86 ASIA PACIFIC LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 87 ASIA PACIFIC PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 88 ASIA PACIFIC PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 89 ASIA PACIFIC LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 90 ASIA PACIFIC LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 91 ASIA PACIFIC CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 92 ASIA PACIFIC PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 93 ASIA PACIFIC WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 94 ASIA PACIFIC PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 95 ASIA PACIFIC FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 96 ASIA PACIFIC PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 97 ASIA PACIFIC MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 98 ASIA PACIFIC LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 99 ASIA PACIFIC CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 100 ASIA PACIFIC ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 101 ASIA PACIFIC REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 102 ASIA PACIFIC BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 103 ASIA PACIFIC SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 104 ASIA PACIFIC LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 105 ASIA PACIFIC INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 106 CHINA LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 107 CHINA BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 108 CHINA BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 109 CHINA BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 110 CHINA BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 111 CHINA CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 112 CHINA CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 113 CHINA GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 114 CHINA GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 115 CHINA GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 116 CHINA GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 117 CHINA PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 118 CHINA PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 119 CHINA PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 120 CHINA DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 121 CHINA LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 122 CHINA PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 123 CHINA PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 124 CHINA LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 125 CHINA LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 126 CHINA CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 127 CHINA PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 128 CHINA WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 129 CHINA PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 130 CHINA FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 131 CHINA PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 132 CHINA MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 133 CHINA LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 134 CHINA CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 135 CHINA ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 136 CHINA REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 137 CHINA BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 138 CHINA SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 139 CHINA LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 140 CHINA INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 141 INDIA LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 142 INDIA BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 143 INDIA BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 144 INDIA BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 145 INDIA BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 146 INDIA CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 147 INDIA CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 148 INDIA GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 149 INDIA GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 150 INDIA GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 151 INDIA GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 152 INDIA PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 153 INDIA PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 154 INDIA PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 155 INDIA DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 156 INDIA LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 157 INDIA PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 158 INDIA PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 159 INDIA LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 160 INDIA LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 161 INDIA CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 162 INDIA PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 163 INDIA WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 164 INDIA PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 165 INDIA FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 166 INDIA PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 167 INDIA MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 168 INDIA LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 169 INDIA CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 170 INDIA ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 171 INDIA REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 172 INDIA BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 173 INDIA SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 174 INDIA LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 175 INDIA INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 176 JAPAN LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 177 JAPAN BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 178 JAPAN BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 179 JAPAN BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 180 JAPAN BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 181 JAPAN CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 182 JAPAN CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 183 JAPAN GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 184 JAPAN GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 185 JAPAN GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 186 JAPAN GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 187 JAPAN PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 188 JAPAN PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 189 JAPAN PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 190 JAPAN DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 191 JAPAN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 192 JAPAN PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 193 JAPAN PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 194 JAPAN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 195 JAPAN LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 196 JAPAN CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 197 JAPAN PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 198 JAPAN WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 199 JAPAN PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 200 JAPAN FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 201 JAPAN PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 202 JAPAN MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 203 JAPAN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 204 JAPAN CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 205 JAPAN ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 206 JAPAN REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 207 JAPAN BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 208 JAPAN SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 209 JAPAN LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 210 JAPAN INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 211 SOUTH KOREA LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 212 SOUTH KOREA BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 213 SOUTH KOREA BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 214 SOUTH KOREA BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 215 SOUTH KOREA BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 216 SOUTH KOREA CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 217 SOUTH KOREA CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 218 SOUTH KOREA GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 219 SOUTH KOREA GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 220 SOUTH KOREA GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 221 SOUTH KOREA GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 222 SOUTH KOREA PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 223 SOUTH KOREA PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 224 SOUTH KOREA PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 225 SOUTH KOREA DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 226 SOUTH KOREA LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 227 SOUTH KOREA PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 228 SOUTH KOREA PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 229 SOUTH KOREA LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 230 SOUTH KOREA LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 231 SOUTH KOREA CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 232 SOUTH KOREA PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 233 SOUTH KOREA WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 234 SOUTH KOREA PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 235 SOUTH KOREA FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 236 SOUTH KOREA PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 237 SOUTH KOREA MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 238 SOUTH KOREA LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 239 SOUTH KOREA CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 240 SOUTH KOREA ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 241 SOUTH KOREA REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 242 SOUTH KOREA BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 243 SOUTH KOREA SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 244 SOUTH KOREA LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 245 SOUTH KOREA INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 246 INDONESIA LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 247 INDONESIA BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 248 INDONESIA BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 249 INDONESIA BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 250 INDONESIA BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 251 INDONESIA CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 252 INDONESIA CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 253 INDONESIA GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 254 INDONESIA GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 255 INDONESIA GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 256 INDONESIA GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 257 INDONESIA PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 258 INDONESIA PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 259 INDONESIA PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 260 INDONESIA DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 261 INDONESIA LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 262 INDONESIA PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 263 INDONESIA PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 264 INDONESIA LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 265 INDONESIA LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 266 INDONESIA CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 267 INDONESIA PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 268 INDONESIA WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 269 INDONESIA PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 270 INDONESIA FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 271 INDONESIA PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 272 INDONESIA MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 273 INDONESIA LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 274 INDONESIA CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 275 INDONESIA ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 276 INDONESIA REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 277 INDONESIA BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 278 INDONESIA SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 279 INDONESIA LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 280 INDONESIA INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 281 THAILAND LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 282 THAILAND BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 283 THAILAND BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 284 THAILAND BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 285 THAILAND BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 286 THAILAND CHECK VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 287 THAILAND CHECK VALVES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 288 THAILAND GATE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 289 THAILAND GATE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 290 THAILAND GLOBE VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 291 THAILAND GLOBE VALVES IN LINED VALVE MARKET, BY DESIGN TYPE, 2018-2033 (USD THOUSAND)

TABLE 292 THAILAND PLUG VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 293 THAILAND PLUG VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 294 THAILAND PLUG VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 295 THAILAND DIAPHRAGM VALVES IN LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 296 THAILAND LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 297 THAILAND PTFE (POLYTETRAFLUOROETHYLENE) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 298 THAILAND PFA (PERFLUOROALKOXY) IN LINED VALVE MARKET, BY PRODUCTION PROCESS, 2018-2033 (USD THOUSAND)

TABLE 299 THAILAND LINED VALVE MARKET, BY ACTUATION TYPE, 2018-2033 (USD THOUSAND)

TABLE 300 THAILAND LINED VALVE MARKET, BY END-USER INDUSTRY, 2018-2033 (USD THOUSAND)

TABLE 301 THAILAND CHEMICAL PROCESSING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 302 THAILAND PETROCHEMICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 303 THAILAND WATER AND WASTEWATER TREATMENT IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 304 THAILAND PHARMACEUTICAL IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 305 THAILAND FOOD AND BEVERAGE IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 306 THAILAND PULP AND PAPER IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 307 THAILAND MINING IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 308 THAILAND LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 309 THAILAND CORROSION-RESISTANT HANDLING FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 310 THAILAND ISOLATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 311 THAILAND REGULATION / MODULATION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 312 THAILAND BACKFLOW PREVENTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 313 THAILAND SAFETY & PROTECTION FUNCTION IN LINED VALVE MARKET, BY APPLICATION, 2018-2033 (USD THOUSAND)

TABLE 314 THAILAND LINED VALVE MARKET, BY DISTRIBUTION CHANNEL, 2018-2033 (USD THOUSAND)

TABLE 315 THAILAND INDIRECT SALES IN LINED VALVE MARKET, BY TYPE, 2018-2033 (USD THOUSAND)

TABLE 316 MALAYSIA LINED VALVE MARKET, BY PRODUCT TYPE, 2018-2033 (USD THOUSAND)

TABLE 317 MALAYSIA BALL VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 318 MALAYSIA BALL VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)

TABLE 319 MALAYSIA BUTTERFLY VALVES IN LINED VALVE MARKET, BY LINING MATERIAL, 2018-2033 (USD THOUSAND)

TABLE 320 MALAYSIA BUTTERFLY VALVES IN LINED VALVE MARKET, BY FUNCTIONAL DESIGN, 2018-2033 (USD THOUSAND)