Global Machine Direction Orientation Mdo Films Market

Market Size in USD Billion

CAGR :

%

USD

2.10 Billion

USD

3.18 Billion

2025

2033

USD

2.10 Billion

USD

3.18 Billion

2025

2033

| 2026 –2033 | |

| USD 2.10 Billion | |

| USD 3.18 Billion | |

|

|

|

|

Machine-Direction Orientation (MDO) Films Market Size

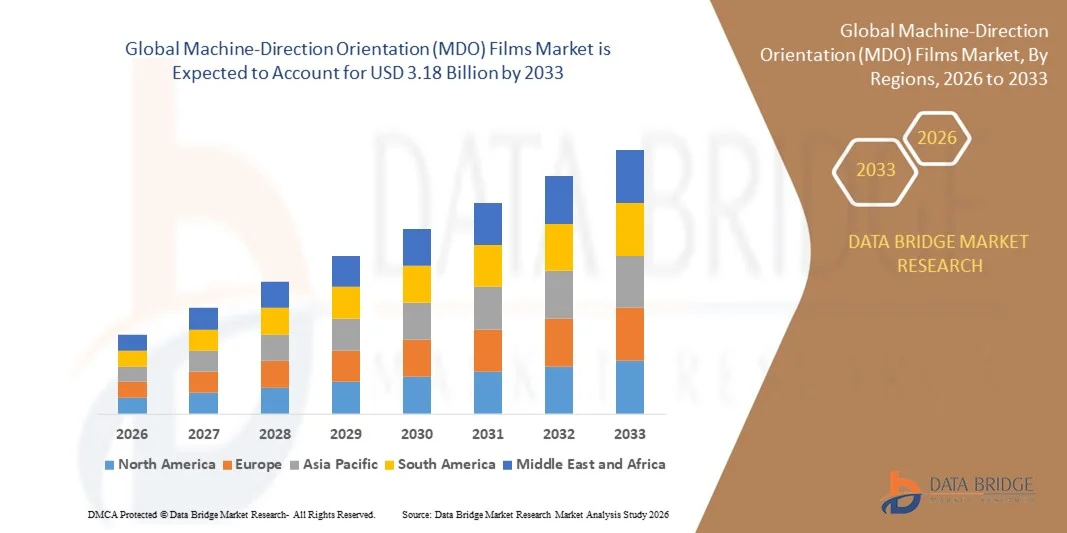

- The global Machine-Direction Orientation (MDO) Films market size was valued at USD 2.10 billion in 2025 and is expected to reach USD 3.18 billion by 2033, at a CAGR of 5.3% during the forecast period

- The market growth is largely driven by the rising shift toward sustainable, lightweight, and high-performance flexible packaging solutions, which is increasing the demand for Machine-Direction Orientation (MDO) films across food, personal care, homecare, and industrial applications

- In addition, continuous advancements in film orientation technologies and material innovations are enabling manufacturers to achieve superior strength, clarity, and downgauging benefits, strengthening the adoption of Machine-Direction Orientation (MDO) Films in global packaging operations

Machine-Direction Orientation (MDO) Films Market Analysis

- Machine-Direction Orientation (MDO) Films, engineered through a specialized stretching process that enhances mechanical properties, barrier performance, and printability, are becoming essential materials in modern flexible packaging due to their ability to offer recyclability, reduced material usage, and improved sustainability credentials. Their expanding role in replacing traditional multilayer structures further strengthens their relevance across industries striving for eco-efficient packaging

- The growing demand for Machine-Direction Orientation (MDO) Films is propelled by accelerating sustainability initiatives, stringent regulatory frameworks on plastic waste, and rapid adoption of recyclable mono-material packaging formats. As brands focus on reducing carbon footprints and achieving higher circularity, Machine-Direction Orientation (MDO) Films are increasingly preferred for their compatibility with PE-based recyclable structures, thereby fueling substantial market expansion

- North America dominated the Machine-Direction Orientation (MDO) Films market in 2025, due to strong demand for high-performance, lightweight, and recyclable flexible packaging solutions. The region’s packaging industry is rapidly transitioning toward mono-material structures to support sustainability goals, increasing the adoption of Machine-Direction Orientation (MDO) Films across food, personal care, and industrial applications

- Asia-Pacific is expected to be the fastest growing region in the Machine-Direction Orientation (MDO) Films market during the forecast period due to rapid industrial expansion, rising disposable incomes, and surging demand for flexible packaging across China, Japan, and India

- Blown film segment dominated the market with a market share of 58.8% in 2025, due to its ability to produce highly durable and uniform films with strong mechanical properties. Blown film lines offer superior control over thickness and orientation, making the process suitable for heavy-duty packaging, agricultural applications, and multilayer structures. Producers favor the technology for its flexibility in processing a wide range of polymers and for enabling consistent performance in large-volume production. Growing demand for high-strength packaging films and the ability of blown MDO systems to support downgauging contribute extensively to the segment's dominance

Report Scope and Machine-Direction Orientation (MDO) Films Market Segmentation

|

Attributes |

Machine-Direction Orientation (MDO) Films Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Machine-Direction Orientation (MDO) Films Market Trends

Rising Demand for Recyclable Mono-Material Flexible Packaging

- A major trend in the Machine-Direction Orientation (MDO) Films market is the increasing shift toward recyclable mono-material packaging structures as brands aim to align with global sustainability commitments. This shift is encouraging packaging converters to replace complex multilayer films with MDO-based PE solutions that support improved circularity

- For instance, companies such as Borealis AG are increasingly investing in advanced mono-material MDO PE film technologies that enable downgauging and recyclability in high-volume packaging applications. Such developments reflect how manufacturers are positioning themselves to meet tightening sustainability regulations across major markets

- The growing emphasis on reducing plastic waste is driving a rapid transition toward flexible packaging formats that can be efficiently collected and reprocessed. Machine-Direction Orientation (MDO) Films support this transition by offering enhanced mechanical strength and clarity, allowing them to be used in applications traditionally dependent on less sustainable film structures

- The trend is further strengthened by rising consumer preference for environmentally responsible packaging solutions across food, personal care, and household product categories. This is creating sustained demand for Machine-Direction Orientation (MDO) Films that deliver both performance efficiency and lower environmental impact

- As retail brands expand their recyclable packaging portfolios, Machine-Direction Orientation (MDO) Films are gaining traction due to their ability to maintain product safety while reducing material usage. These benefits are compelling major end users to adopt Machine-Direction Orientation (MDO) Films as a long-term packaging upgrade

- Overall, the increasing prioritization of sustainability goals, regulatory compliance, and material efficiency is solidifying the role of Machine-Direction Orientation (MDO) Films as a central component of future-ready mono-material flexible packaging solutions. The trend continues to accelerate as industries seek circular packaging formats that align performance with environmental responsibility

Machine-Direction Orientation (MDO) Films Market Dynamics

Driver

Increasing Adoption of High-Performance and Sustainable Packaging Films

- The market is driven by the rising need for high-performance packaging materials that offer strength, clarity, and downgauging benefits while supporting sustainable objectives. Companies across food, personal care, and homecare industries are increasingly shifting toward Machine-Direction Orientation (MDO) Films to enhance packaging efficiency

- For instance, Avery Dennison has expanded its sustainable film portfolio with MDO solutions designed to reduce environmental impact through lighter materials and improved recyclability. Such initiatives are accelerating the use of Machine-Direction Orientation (MDO) Films among global brands aiming to upgrade their packaging formats

- The demand is supported by the growing adoption of recyclable structures that offer enhanced mechanical properties and compatibility with PE recycling streams. Machine-Direction Orientation (MDO) Films are preferred due to their ability to deliver excellent stiffness and transparency compared to conventional polyethylene films

- Industries are also embracing these films for their ability to support cost-effective downgauging without compromising shelf appeal or functionality. This is making Machine-Direction Orientation (MDO) Films an attractive alternative for applications requiring lightweight yet durable packaging

- As sustainability standards continue to intensify across global markets, the adoption of Machine-Direction Orientation (MDO) Films is expected to rise steadily. These advantages collectively establish Machine-Direction Orientation (MDO) Films as a critical component of future packaging strategies focused on performance and environmental responsibility

Restraint/Challenge

High Initial Investment in Advanced MDO Film Production Technologies

- A key challenge for the market is the substantial capital investment required for advanced MDO production equipment, which can limit entry for smaller manufacturers. High machinery costs and the need for specialized technical expertise create barriers to rapid capacity expansion

- For instance, companies adopting new MDO lines often face increased operational expenses due to the installation of orientation units, precision control systems, and high-performance extrusion technologies. Such financial demands may slow adoption among converters operating with limited budgets

- The complexity of MDO film manufacturing also requires skilled operators and continuous process optimization to ensure consistent film quality. This adds to overall production costs and increases operational risks for manufacturers transitioning from conventional film technologies

- Integration of advanced MDO systems into existing production setups may require infrastructure upgrades and extended commissioning periods. These challenges can reduce the pace of technology adoption in emerging markets

- Despite these challenges, the industry is gradually addressing cost-related concerns through technological improvements and increasing global production capacities. As adoption expands, economies of scale and technological maturity are expected to ease investment barriers and support wider implementation of MDO film production systems

Machine-Direction Orientation (MDO) Films Market Scope

The market is segmented on the basis of material type, manufacturing process, application, and end user.

- By Material Type

On the basis of material type, the Machine-Direction Orientation (MDO) films market is segmented into polypropylene (PP), HDPE, LLDPE, LDPE, PET, and others. The polypropylene segment dominated the market with the largest revenue share in 2025 due to its superior balance of tensile strength, clarity, and cost-efficiency that supports wide packaging adoption. Manufacturers prefer PP-based Machine-Direction Orientation (MDO) Films for their strong orientation capabilities, enabling high stiffness, reduced gauge, and enhanced barrier properties suitable for food and consumer product packaging. The segment benefits further from increasing demand for recyclable mono-material structures as PP aligns with sustainability goals across FMCG brands. Growing use in stand-up pouches, labels, and flexible packaging formats continues to reinforce the dominance of PP in MDO film production.

The PET segment is anticipated to witness the fastest growth rate from 2026 to 2033 owing to its excellent dimensional stability, transparency, and suitability for premium packaging applications. PET-based Machine-Direction Orientation (MDO) Films are increasingly preferred in sectors requiring high optical performance and durability such as personal care and specialty food packaging. The material also supports superior printability and barrier enhancement when combined with coating technologies, making it a favored option for brand differentiation. Rising demand for lightweight packaging with high shelf appeal and ongoing advancements in PET orientation technologies drive segment expansion. The shift toward recyclable PET-based mono-material laminates further strengthens its projected growth.

- By Manufacturing Process

On the basis of manufacturing process, the Machine-Direction Orientation (MDO) Films market is segmented into blown film and cast film. The blown film segment dominated the market with the largest share of 58.8% in 2025 due to its ability to produce highly durable and uniform films with strong mechanical properties. Blown film lines offer superior control over thickness and orientation, making the process suitable for heavy-duty packaging, agricultural applications, and multilayer structures. Producers favor the technology for its flexibility in processing a wide range of polymers and for enabling consistent performance in large-volume production. Growing demand for high-strength packaging films and the ability of blown MDO systems to support downgauging contribute extensively to the segment's dominance.

The cast film segment is expected to witness the fastest growth rate from 2026 to 2033 driven by rising demand for films with exceptional clarity, enhanced softness, and precision-controlled thickness. Cast MDO technology is rapidly gaining popularity among manufacturers seeking high-speed production with superior optical quality suitable for premium packaging and labeling applications. The process enables smoother surfaces and better printability, supporting brand enhancement in food and personal care segments. Advancements in cast orientation equipment and the growing need for recyclable mono-material packaging solutions strengthen the outlook for this segment. Increasing adoption in shrink films and pouches is expected to accelerate its growth trajectory.

- By Application

On the basis of application, the Machine-Direction Orientation (MDO) Films market is segmented into bags and pouches, shrink labels, shrink wrap films, agro-textile, tapes, liners and coatings, and others. The bags and pouches segment dominated the market in 2025 owing to its widespread use in food, personal care, and household product packaging. Machine-Direction Orientation (MDO) Films offer high stiffness, enhanced barrier properties, and downgauging benefits that help brand owners reduce plastic usage while maintaining performance. Their compatibility with recyclable mono-material laminates further strengthens adoption among FMCG manufacturers shifting toward sustainable packaging. Increasing use of stand-up pouches, zipper pouches, and form-fill-seal applications supports segment leadership as brands prioritize lightweight and durable packaging formats.

The shrink labels segment is projected to witness the fastest growth from 2026 to 2033 due to escalating demand for high-clarity, high-shrink films used in beverages, cosmetics, and personal care products. MDO shrink label films provide excellent printability and wrapping performance, helping brands deliver visually appealing, 360-degree label coverage. Advancements in MDO technology enable improved shrink ratios, better temperature resistance, and enhanced sustainability through recyclable structures. The segment benefits from rising product differentiation strategies and increasing reliance on full-body labels in retail. Growth is further propelled by the adoption of recyclable shrink sleeves supported by evolving circular packaging initiatives.

- By End User

On the basis of end user, the Machine-Direction Orientation (MDO) Films market is segmented into healthcare, food and beverages, personal care, homecare, agriculture, and others. The food and beverages segment dominated the market in 2025 due to the expanding use of Machine-Direction Orientation (MDO) Films in snack packaging, confectionery wrappers, dairy packaging, and ready-to-eat meal solutions. The need for lightweight, cost-efficient, and recyclable packaging structures drives strong adoption of Machine-Direction Orientation (MDO) Films in this sector. High stiffness, transparency, and sealability make Machine-Direction Orientation (MDO) Films suitable replacements for traditional multilayer laminates. Growing consumer preference for sustainable packaging formats and rising sales of packaged foods have significantly boosted segment leadership across global markets.

The personal care segment is expected to experience the fastest growth rate from 2026 to 2033 as brands increasingly adopt Machine-Direction Orientation (MDO) Films for premium, lightweight, and visually appealing packaging. High printability, excellent film clarity, and superior shelf appeal make Machine-Direction Orientation (MDO) Films ideal for shampoo, skincare, and hygiene product packaging. Manufacturers also favor Machine-Direction Orientation (MDO) Films for their compatibility with recyclable mono-material laminates, aligning with the strong sustainability commitments of personal care brands. Rising demand for travel-size pouches, flexible refills, and sleek packaging formats supports rapid segment expansion. The shift toward high-quality, environmentally responsible packaging continues to accelerate growth in this segment.

Machine-Direction Orientation (MDO) Films Market Regional Analysis

- North America dominated the Machine-Direction Orientation (MDO) Films market with the largest revenue share in 2025, driven by strong demand for high-performance, lightweight, and recyclable flexible packaging solutions. The region’s packaging industry is rapidly transitioning toward mono-material structures to support sustainability goals, increasing the adoption of Machine-Direction Orientation (MDO) Films across food, personal care, and industrial applications

- Consumers and manufacturers in the region prioritize packaging formats that offer enhanced strength, downgauging benefits, and improved visual appeal, all of which align well with the properties of MDO films. This shift is further strengthened by the presence of advanced film production capabilities, established packaging converters, and rising preferences for environmentally responsible materials

- High disposable incomes, the growing influence of sustainability standards, and strong integration of packaging innovation continue to support the widespread adoption of MDO films, reinforcing their position in both consumer and industrial packaging categories

U.S. Machine-Direction Orientation (MDO) Films Market Insight

The U.S. Machine-Direction Orientation (MDO) Films market captured the largest revenue share in 2025 within North America, supported by rising demand for sustainable flexible packaging and increasing adoption of recyclable mono-material laminates in FMCG, retail, and personal care sectors. Consumers and brands continue to prioritize lightweight packaging formats offering strong performance and extended shelf life, contributing to wider use of Machine-Direction Orientation (MDO) Films in pouches, labels, and household product packaging. The presence of advanced orientation technology, leading film producers, and strong investment in packaging innovation has reinforced the U.S. as a dominant market for MDO film adoption.

Europe Machine-Direction Orientation (MDO) Films Market Insight

The Europe Machine-Direction Orientation (MDO) Films market is projected to expand at a substantial CAGR throughout the forecast period, driven by stringent sustainability regulations and a region-wide shift toward recyclable and downgauged packaging formats. Increasing demand for packaged foods, urban lifestyle expansion, and the industry’s preference for high-clarity and strong mono-material structures are enhancing MDO film consumption. Strong alignment with circular economy standards and widespread use in food, personal care, and household packaging applications support the growing adoption of Machine-Direction Orientation (MDO) Films across both new product development and packaging redesign projects.

U.K. Machine-Direction Orientation (MDO) Films Market Insight

The U.K. Machine-Direction Orientation (MDO) Films market is anticipated to grow at a noteworthy CAGR during the forecast period as the country focuses increasingly on sustainable and recyclable packaging driven by regulatory pressures and heightened consumer awareness of plastic waste. The region’s retail, food service, and e-commerce industries are accelerating the shift toward mono-material flexible packaging, making Machine-Direction Orientation (MDO) Films a preferred choice for maintaining strength, clarity, and environmental compliance. This transition continues to support expanding usage across a wide range of packaging formats and end-user sectors.

Germany Machine-Direction Orientation (MDO) Films Market Insight

The Germany Machine-Direction Orientation (MDO) Films market is expected to expand at a considerable CAGR, supported by the country’s advanced manufacturing landscape, strong sustainability commitments, and growing use of high-performance flexible packaging. Germany’s emphasis on technological innovation and quality drives the adoption of Machine-Direction Orientation (MDO) Films across food, industrial, and household applications. Regulatory support for recyclable packaging and the preference for durable, premium-quality film structures strengthen the country’s transition toward mono-material solutions where Machine-Direction Orientation (MDO) Films play a pivotal role.

Asia-Pacific Machine-Direction Orientation (MDO) Films Market Insight

The Asia-Pacific Machine-Direction Orientation (MDO) Films market is poised to grow at the fastest CAGR from 2026 to 2033, driven by rapid industrial expansion, rising disposable incomes, and surging demand for flexible packaging across China, Japan, and India. Increasing urbanization, expanding retail networks, and the region’s emergence as a manufacturing hub for packaging materials support mass-scale adoption of MDO film structures. Government-backed modernization, strong cost competitiveness, and growing preference for lightweight, visually appealing packaging are key contributors to APAC’s leadership in future MDO film development.

Japan Machine-Direction Orientation (MDO) Films Market Insight

The Japan Machine-Direction Orientation (MDO) Films market is gaining traction due to the country’s high-tech industrial base, strong focus on precision packaging, and growing preference for sustainable, high-performance materials. Demand for visually appealing, durable, and lightweight packaging supports the rising use of Machine-Direction Orientation (MDO) Films across food, cosmetics, and household products. The integration of MDO structures into mono-material laminates and advanced packaging machinery further enhances adoption, while demographic shifts such as an aging population drive the need for convenient and easy-to-handle packaging formats.

China Machine-Direction Orientation (MDO) Films Market Insight

The China Machine-Direction Orientation (MDO) Films market accounted for the largest revenue share in Asia-Pacific in 2025, supported by rapid urbanization, a large consumer base, and strong domestic production capabilities in flexible packaging. China’s expanding middle class and high uptake of packaged products strengthen demand for lightweight, recyclable packaging formats enabled by MDO film technology. The country’s investment in modern manufacturing, growth in smart packaging development, and availability of cost-competitive MDO film production contribute significantly to its dominant market position across consumer and industrial applications.

Machine-Direction Orientation (MDO) Films Market Share

The Machine-Direction Orientation (MDO) Films industry is primarily led by well-established companies, including:

- AVERY DENNISON CORPORATION (U.S.)

- TORAY INDUSTRIES, INC. (Japan)

- Lenzing Plastics (Austria)

- Klöckner Pentaplast (Germany)

- CCL Label (Canada)

- Eclipse Films (U.K.)

- NOWOFOL Kunststoffprodukte GmbH & Co. KG (Germany)

- UPM (Finland)

- Polythene UK Ltd. (U.K.)

- Borealis AG (Austria)

- Trico Specialty Films (U.S.)

- Futamura Group (Japan)

- Davis-Standard (U.S.)

- LA Plastpacks Pvt Ltd. (India)

- POLYSACK LTD. (Israel)

- Coveris (Austria)

- Windmöller & Hölscher (Germany)

- Hosokawa Micron Group (Japan)

Latest Developments in Global Machine-Direction Orientation (MDO) Films Market

- In June 2024, INEOS Olefins & Polymers Europe commissioned a new pilot multilayer blown film line with machine direction orientation (MDO) at its R&D center in Brussels, Belgium, marking the company as the first polymer manufacturer globally to introduce such a line. This initiative strengthens the technological advancement of the Machine-Direction Orientation (MDO) Films market by enabling enhanced product innovation, accelerating prototype development, and supporting the shift toward recyclable mono-material packaging solutions aimed at reducing landfill waste

- In March 2024, Borealis introduced its next-generation recyclable mono-material MDO film solutions intended to replace conventional multilayer packaging structures across food and personal care applications. This development significantly supports the market’s transition toward circular packaging by offering improved film clarity, strength, and barrier performance, enabling brands and converters to adopt high-efficiency MDO-based formats without requiring major production line changes

- In November 2023, Taghleef Industries expanded its MDO film production capabilities by installing a new orientation module in Europe to cater to accelerating demand for downgauged and high-performance flexible packaging. This capacity expansion strengthens supply availability, enhances production efficiency, and supports global brands seeking recyclable mono-material laminates, thereby contributing to broader market adoption of sustainable MDO films

- In August 2022, Avery Dennison Labels and Packaging Materials introduced two MDO film products incorporating post-consumer recycled content through its rMDO white and rMDO clear face stocks. This launch enables brand owners to meet rising sustainability requirements and regulatory expectations while maintaining performance across household, personal care, cosmetic, and food products, reinforcing the integration of recycled materials into advanced MDO film formats

- In February 2023, Klöckner Pentaplast unveiled an enhanced portfolio of Machine-Direction Orientation (MDO) Films engineered for high-clarity label and shrink-sleeve applications with improved printability and material efficiency. This innovation supports converters in achieving higher productivity while reducing plastic consumption, driving further penetration of Machine-Direction Orientation (MDO) Films into labeling and packaging segments aligned with sustainability-driven packaging transformation

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Machine Direction Orientation Mdo Films Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Machine Direction Orientation Mdo Films Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Machine Direction Orientation Mdo Films Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.