Global Membrane Contactor Market

Market Size in USD Million

CAGR :

%

USD

323.38 Million

USD

500.07 Million

2025

2033

USD

323.38 Million

USD

500.07 Million

2025

2033

| 2026 –2033 | |

| USD 323.38 Million | |

| USD 500.07 Million | |

|

|

|

|

Global Membrane Contactor Market Size

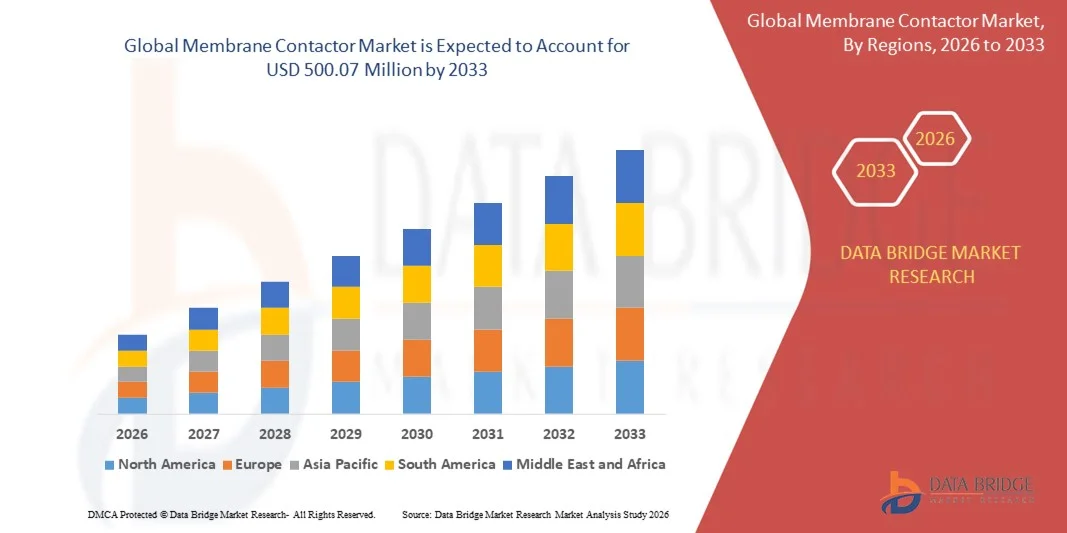

- The Global Membrane Contactor Market was valued at USD 323.38 million in 2025 and is projected to reach USD 500.07 million by 2033, expanding at a CAGR of 5.60% over the forecast period.

- The market’s expansion is driven by increasing adoption of advanced separation technologies across water treatment, chemical processing, and gas purification applications, supported by rising industrial digitalization and efficiency-focused process upgrades.

- Additionally, growing demand for compact, energy-efficient, and high-performance mass-transfer solutions is positioning membrane contactors as a preferred alternative to traditional systems, accelerating their deployment and significantly strengthening overall industry growth.

Global Membrane Contactor Market Analysis

- Membrane contactors, enabling efficient gas–liquid and liquid–liquid mass transfer through selective membranes, are becoming essential components across modern industrial processes due to their high efficiency, modular design, and seamless integration within advanced water treatment, chemical processing, and biopharmaceutical systems.

- The rising demand for membrane contactors is primarily driven by the global push for sustainable treatment technologies, increasing concerns over water purity and emissions control, and a growing preference for compact, energy-efficient alternatives to traditional separation equipment.

- Asia-Pacific dominated the Global Membrane Contactor Market with the largest revenue share of 34% in 2025, supported by early adoption of advanced filtration technologies, strong industrial infrastructure, and a robust presence of leading manufacturers, with the U.S. experiencing notable growth in applications such as CO₂ removal, nitrogen generation, and high-purity water systems across key industries.

- Europe is expected to be the fastest-growing region in the Global Membrane Contactor Market during the forecast period due to rapid industrialization, increasing investment in water treatment facilities, and expanding manufacturing activities across emerging economies.

- The polypropylene segment dominated the market with the largest revenue share of 48.6% in 2025, driven by its cost-effectiveness, strong chemical resistance, and broad suitability across degassing, stripping, and deoxygenation applications.

Report Scope and Global Membrane Contactor Market Segmentation

|

Attributes |

Membrane Contactor Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Membrane Contactor Market Trends

Enhanced Efficiency Through Automation and Advanced Process Intelligence

- A significant and accelerating trend in the Global Membrane Contactor Market is the deepening integration of membrane contactor systems with advanced automation, data analytics, and process-intelligent control platforms. This fusion of technologies is greatly enhancing operational reliability, efficiency, and optimization across industrial applications.

- For instance, leading manufacturers now integrate membrane contactors with real-time monitoring solutions that track dissolved gas levels, flow rates, and membrane performance, enabling automated adjustments to maintain optimal mass-transfer efficiency. Similarly, advanced control systems used in high-purity water production and CO₂ removal applications ensure continuous and precise operation with minimal manual intervention.

- AI-driven analytics in membrane contactor systems enable capabilities such as predictive maintenance, membrane fouling forecasting, and process optimization based on historical performance patterns. Some next-generation systems also leverage machine learning to refine operational parameters over time, reducing energy consumption and improving overall throughput. Furthermore, automation platforms allow remote system control, enabling operators to adjust performance settings or receive alerts from any location.

- Seamless integration with digital plant platforms—such as SCADA, IoT-enabled sensors, and industrial automation software—facilitates centralized management of multiple treatment or processing units. Through a unified interface, operators can monitor membrane performance alongside filtration, chemical dosing, and other treatment systems, resulting in a more streamlined and automated industrial workflow.

- This trend toward smarter, more autonomous mass-transfer systems is reshaping expectations for industrial efficiency. Consequently, companies across water treatment, pharmaceuticals, and chemical manufacturing are increasingly developing or adopting membrane contactors enhanced with automation-ready features and intelligent monitoring capabilities.

- The demand for membrane contactors that support advanced automation, predictive analytics, and integrated digital control is growing rapidly across both established and emerging industrial sectors, as organizations prioritize efficiency, reliability, and digital transformation in their operations.

Global Membrane Contactor Market Dynamics

Driver

Growing Need Driven by Rising Water Quality Requirements and Industrial Expansion

- Increasing concerns over water purity, stringent environmental regulations, and the expanding need for high-efficiency mass-transfer technologies are major drivers of the growing demand for membrane contactors across industries.

- For instance, leading manufacturers are introducing advanced degassing and gas-transfer solutions designed for semiconductor fabrication, pharmaceuticals, and high-purity water systems, helping industries meet tighter purity and emissions standards. Such advancements are expected to accelerate market growth over the forecast period.

- As industries become more aware of the limitations of conventional degassing and stripping methods, membrane contactors offer strong advantages through features such as continuous operation, compact size, lower energy use, and improved separation performance—providing a compelling modernization alternative.

- Furthermore, increasing adoption of automated and digitally integrated treatment systems is making membrane contactors a core component of upgraded industrial processes, offering seamless integration with existing filtration, desalination, and chemical-processing platforms.

- The technology’s ability to provide high reliability, easy scalability, and precise control of dissolved gases is driving its growing use across water treatment plants, food and beverage production, microelectronics, and chemical industries worldwide. The rapid expansion of manufacturing in Asia-Pacific, combined with rising environmental compliance requirements, further contributes to sustained global demand.

Restraint/Challenge

Concerns Regarding Fouling, Maintenance Needs, and High Initial Investment

- Challenges surrounding membrane fouling, periodic maintenance requirements, and the higher initial costs of advanced membrane systems pose obstacles to wider market adoption, particularly among smaller industrial operators.

- For instance, reports highlighting fouling issues in poorly optimized systems have made some facilities hesitant to transition from traditional degassing methods, especially in applications with high organic loads or challenging feedwater conditions.

- Addressing these concerns through improved membrane materials, anti-fouling surface technologies, and optimized pretreatment is critical for building industry confidence. Manufacturers increasingly emphasize innovations such as hydrophobic coatings, easier module replacement, and automated cleaning cycles to reassure potential users. Additionally, the capital cost of high-performance membrane contactors—particularly in specialized applications such as semiconductor-grade water production—can be a barrier for cost-sensitive markets. While more economical polypropylene-based modules are becoming available, premium systems using advanced fluoropolymers or automation features remain more expensive.

- Although prices are gradually declining as technology scales, the perception of membrane contactors as a higher-cost investment can still limit adoption in regions with lower industrial budgets or limited regulatory pressure.

- Overcoming these challenges through better membrane durability, cost-effective system design, workforce training, and education on long-term operational savings will be essential for sustaining global market growth.

Global Membrane Contactor Market Scope

Membrane contactor market is segmented on the basis of membrane type and application.

- By Membrane Type

On the basis of membrane type, the Global Membrane Contactor Market is segmented into polypropylene (PP), polytetrafluoroethylene (PTFE), and others. The polypropylene segment dominated the market with the largest revenue share of 48.6% in 2025, driven by its cost-effectiveness, strong chemical resistance, and broad suitability across degassing, stripping, and deoxygenation applications. PP membrane contactors are widely used in industrial water treatment, beverage carbonation control, and nitrogen generation systems, making them the preferred choice for facilities seeking reliable yet affordable mass-transfer solutions. Their compatibility with a variety of operating environments and lower maintenance requirement further strengthen demand.

The PTFE segment is expected to witness the fastest CAGR from 2026 to 2033, supported by its superior hydrophobicity, thermal stability, and extended lifespan. PTFE membranes are increasingly adopted in high-purity applications—including pharmaceuticals, microelectronics, and ultrapure water production—where stringent performance standards necessitate advanced membrane materials. Growing investment in semiconductor fabrication and precision manufacturing continues to accelerate PTFE adoption globally.

- By Application

On the basis of application, the Global Membrane Contactor Market is segmented into water and wastewater treatment, food processing, power and steam generation, oil and gas, and others. The water and wastewater treatment segment accounted for the largest revenue share of 42.3% in 2025, driven by rising global demand for high-purity water, increasing regulatory pressure on dissolved gas removal, and growing adoption of advanced treatment technologies across municipal and industrial facilities. Membrane contactors offer clear advantages such as energy-efficient degassing, compact design, and compatibility with both new and retrofit systems, making them a preferred solution for modern treatment plants. Their expanding use in desalination pre-treatment, boiler feedwater conditioning, and dissolved oxygen removal further reinforces segment dominance.

The power and steam generation segment is expected to witness the fastest CAGR from 2026 to 2033, fueled by the need for precise dissolved gas control in high-pressure boilers and the growing upgrade of thermal power plants. As power producers seek efficiency improvements and lower corrosion risks, membrane contactors are being rapidly adopted as a critical component of modern condensate and feedwater systems.

Global Membrane Contactor Market Regional Analysis

- Asia-Pacific dominated the Global Membrane Contactor Market with the largest revenue share of 34% in 2025, driven by rising demand for advanced water treatment, industrial modernization, and the widespread adoption of high-efficiency gas-transfer technologies across key sectors such as power, pharmaceuticals, and food and beverage.

- Industries in the region place strong emphasis on process optimization, reliability, and regulatory compliance, making membrane contactors highly attractive due to their superior degassing performance, compact design, and seamless integration with existing treatment and production systems.

- This rapid uptake is further supported by well-established industrial infrastructure, high investment capacity, and a strong presence of leading membrane technology manufacturers. The increasing focus on sustainability, reduced operational costs, and automated water-quality management continues to reinforce membrane contactors as a preferred solution for both large-scale industrial facilities and high-purity applications across North America.

U.S. Global Membrane Contactor Market Insight

The U.S. Global Membrane Contactor Market captured the largest revenue share of 81% in 2025 within North America, driven by strong industrial demand for high-efficiency gas transfer, degassing, and deoxygenation technologies. Growth is fueled by rapid modernization across water treatment facilities, chemical processing plants, and semiconductor manufacturing, where high-purity water and precise dissolved-gas control are critical. Increasing adoption of automation and IoT-enabled monitoring systems further supports the uptake of membrane contactors. Moreover, the presence of leading technology developers and strong environmental regulations encouraging low-energy, compact, and reliable treatment systems significantly contribute to the U.S. market’s expansion.

Europe Global Membrane Contactor Market Insight

The Europe Global Membrane Contactor Market is projected to expand at a substantial CAGR during the forecast period, primarily driven by stringent environmental regulations and the growing need for advanced water and process treatment across industrial sectors. Rising urbanization and expanding industrial activity are increasing demand for dissolved gas removal, CO₂ stripping, and solvent recovery solutions. European industries value the energy efficiency, modularity, and high performance offered by membrane contactors. Adoption is strong across municipal water treatment, pharmaceuticals, food processing, and power generation, with membrane systems increasingly integrated into both new facilities and retrofit modernization projects.

U.K. Global Membrane Contactor Market Insight

The U.K. Global Membrane Contactor Market is anticipated to grow at a noteworthy CAGR over the forecast period, driven by heightened focus on sustainable water treatment, industrial optimization, and reduced operational footprints. Industries are increasingly selecting membrane contactors to improve process reliability, meet regulatory compliance, and achieve more efficient degassing and stripping operations. The U.K.’s strong adoption of digital monitoring, automation, and smart plant technologies further enhances market growth, as membrane contactors integrate seamlessly with advanced process-control systems.

Germany Global Membrane Contactor Market Insight

The Germany Global Membrane Contactor Market is expected to expand at a considerable CAGR during the forecast period, fueled by rising emphasis on precision engineering, sustainability, and advanced manufacturing technologies. German industries—particularly food and beverage, pharmaceuticals, and specialty chemicals—are adopting membrane contactors to achieve higher purity levels and improve overall process efficiency. The country’s robust industrial infrastructure and commitment to environmental innovation support strong deployment of membrane contactors, especially in high-performance water systems and controlled gas-transfer applications.

Asia-Pacific Global Membrane Contactor Market Insight

The Asia-Pacific Global Membrane Contactor Market is poised to grow at the fastest CAGR of 24% from 2026 to 2033, driven by rapid industrialization, rising water treatment needs, and expansion in sectors such as electronics, power generation, and chemicals. Countries including China, Japan, and India are accelerating adoption due to increasing regulatory pressure to improve water quality and reduce emissions. APAC’s role as a major manufacturing hub is also boosting demand for high-purity water systems, while technological advancements and cost-effective membrane production enhance accessibility across both large industries and emerging markets.

Japan Global Membrane Contactor Market Insight

The Japan Global Membrane Contactor Market is gaining momentum due to the country’s highly technical industrial base and demand for precision water purification and controlled gas-transfer solutions. Growth is driven by the semiconductor, pharmaceutical, and electronics sectors, which require consistent high-quality water and highly reliable treatment technologies. Integration of membrane contactors with IoT-enabled monitoring and automated control systems is becoming increasingly common. Additionally, Japan’s aging infrastructure and focus on energy-efficient, compact systems are expected to further strengthen adoption.

China Global Membrane Contactor Market Insight

The China Global Membrane Contactor Market accounted for the largest revenue share in Asia-Pacific in 2025, supported by rapid industrial expansion, growing investments in manufacturing, and strict regulations surrounding water and air quality. China’s strong domestic production ecosystem and the government’s push toward smart industrial facilities and advanced water treatment significantly boost membrane contactor adoption. The technology is increasingly used across petrochemicals, power plants, electronics manufacturing, and municipal water systems. The availability of competitively priced membrane modules and a large base of local suppliers further accelerates market growth.

Global Membrane Contactor Market Share

The Membrane Contactor industry is primarily led by well-established companies, including:

• 3M Company (U.S.)

• Pentair plc (U.S.)

• Mitsubishi Chemical Corporation (Japan)

• Pall Corporation (U.S.)

• Koch Membrane Systems (U.S.)

• GE Water & Process Technologies (U.S.)

• Dow Water & Process Solutions (U.S.)

• Suez Water Technologies & Solutions (France)

• Toray Industries, Inc. (Japan)

• Parker Hannifin Corporation (U.S.)

• Huber Technology (Germany)

• Membrana GmbH (Germany)

• Veolia Water Technologies (France)

• Alfa Laval AB (Sweden)

• Toyobo Co., Ltd. (Japan)

• Aquatech International (U.S.)

• Hyflux Ltd. (Singapore)

• Lanxess AG (Germany)

• Koch-Glitsch (U.S.)

• Dongyue Group (China)

What are the Recent Developments in Global Membrane Contactor Market?

- In April 2024, 3M Company, a global leader in membrane and filtration technologies, introduced an enhanced series of hollow-fiber membrane contactors designed to improve dissolved-gas removal in industrial water treatment systems. This initiative underscores 3M’s commitment to delivering high-performance, energy-efficient mass-transfer solutions tailored to the needs of rapidly modernizing industries. By leveraging its extensive R&D capabilities and global expertise, 3M is strengthening its position in the expanding Global Membrane Contactor Market while addressing sector-specific challenges such as purity requirements and operational efficiency.

- In March 2024, Pentair plc launched its next-generation Membrane Degassing Modules for applications in food and beverage processing and high-purity water systems. Engineered for improved gas-transfer efficiency and reduced energy consumption, these modules support safer and more controlled production environments. This development highlights Pentair’s dedication to advancing industrial fluid-management technologies and providing innovative solutions that enhance reliability and performance across critical operations.

- In March 2024, Mitsubishi Chemical Group deployed an upgraded membrane contactor system in a major semiconductor manufacturing facility in Japan. The project integrates high-performance PTFE membranes with automated monitoring to ensure ultrapure water quality. This initiative demonstrates Mitsubishi Chemical’s leadership in precision water-treatment technologies and reflects the growing importance of membrane contactors in advanced manufacturing sectors that require stringent dissolved-gas control.

- In February 2024, Pall Corporation (Danaher) announced a strategic partnership with a global pharmaceutical manufacturer to integrate membrane contactor technology into large-scale bioprocessing operations. The collaboration aims to enhance gas transfer, increase production consistency, and reduce contamination risks in biologics manufacturing. This initiative reinforces Pall’s mission to drive innovation in life-science processing solutions while addressing the evolving needs of regulated industries.

- In January 2024, Koch Membrane Systems unveiled its latest Gastran™ Membrane Contactor Series, designed for industrial water degassing, CO₂ removal, and boiler feedwater treatment. The product launch took place at the International Water Conference, highlighting Koch’s ongoing commitment to providing efficient, compact, and scalable membrane-based solutions. The new series reflects the company’s focus on helping industries optimize operations, reduce corrosion risks, and achieve higher water-quality standards through advanced membrane contactor technologies.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Membrane Contactor Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Membrane Contactor Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Membrane Contactor Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.