Global Mesh Nozzle Plates Market

Market Size in USD Million

CAGR :

%

USD

36.14 Million

USD

57.08 Million

2024

2032

USD

36.14 Million

USD

57.08 Million

2024

2032

| 2025 –2032 | |

| USD 36.14 Million | |

| USD 57.08 Million | |

|

|

|

|

Mesh Nozzle Plates Market Size

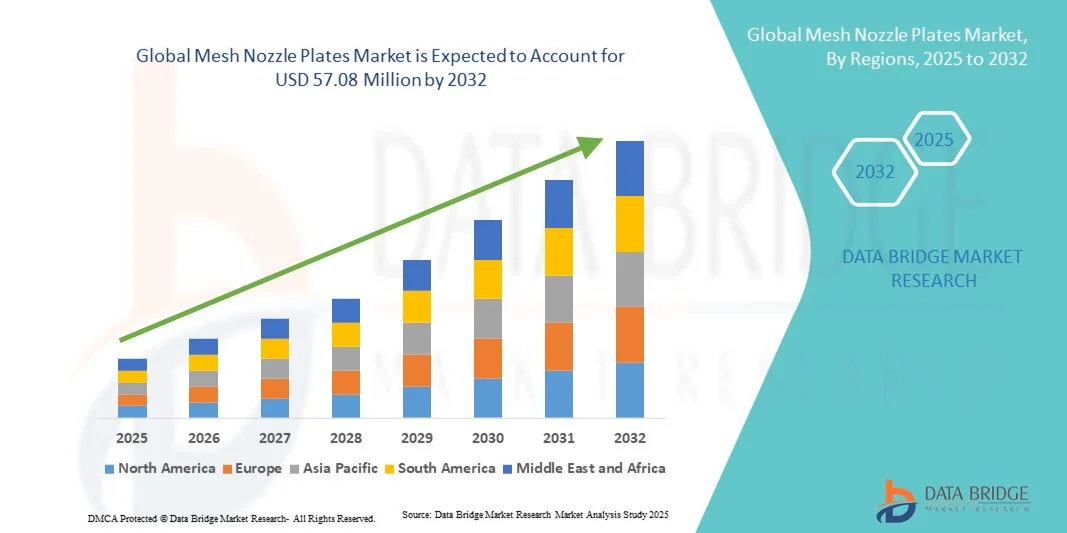

- The global mesh nozzle plates market size was valued at USD 36.14 Million in 2024 and is expected to reach USD 57.08 Million by 2032, at a CAGR of 5.88% during the forecast period

- The market growth is largely fueled by the increasing adoption of advanced fuel injection and printing technologies, along with continuous innovations in precision engineering, which enhance performance and efficiency across industrial and automotive applications

- Furthermore, rising demand for high-quality, durable, and efficient nozzle components in industries such as automotive, aerospace, and 3D printing is driving the adoption of mesh nozzle plates. These converging factors are accelerating the uptake of mesh nozzle plates solutions, thereby significantly boosting the industry's growth

Mesh Nozzle Plates Market Analysis

- The Mesh Nozzle Plates market refers to the global industry involved in the manufacturing and deployment of precision-engineered mesh nozzle plates, which are critical components in various printing, coating, and spraying applications, enabling uniform distribution of liquids, inks, or chemicals across surfaces

- Manufacturers are increasingly focusing on high-performance, durable, and corrosion-resistant nozzle plates to meet the growing demands of various sectors, including electronics, pharmaceuticals, and chemical industries

- North America dominated the mesh nozzle plates market with the largest revenue share of 41.5% in 2024, supported by advanced manufacturing facilities, strong presence of key players, and high adoption of automated coating and printing technologies. The U.S. experienced notable growth due to increasing demand in industries such as packaging, electronics, and automotive, driven by innovations in durable, high-precision, and customizable nozzle plate designs

- Asia-Pacific is expected to be the fastest-growing region in the mesh nozzle plates market during the forecast period, attributed to rapid industrialization, increasing urbanization, rising disposable incomes, and strong investments in manufacturing infrastructure in countries such as China, India, and Japan. Expanding production capabilities and adoption in emerging industrial sectors are key factors accelerating market growth in this region

- The Electroforming segment dominated the mesh nozzle plates market with the largest market revenue share of 45.2% in 2024, owing to its ability to produce highly precise, uniform, and reproducible micro-orifices essential for consistent spray quality

Report Scope and Mesh Nozzle Plates Market Segmentation

|

Attributes |

Mesh Nozzle Plates Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Mesh Nozzle Plates Market Trends

Enhanced Convenience Through Advanced Manufacturing and Material Integration

- A significant and accelerating trend in the global mesh nozzle plates market is the incorporation of high-precision engineering, advanced materials, and innovative manufacturing techniques to enhance performance, durability, and operational efficiency. Modern mesh nozzle plates are being designed to provide uniform flow distribution, high wear resistance, and improved compatibility with diverse industrial fluids and coatings

- For instance, leading manufacturers now utilize advanced laser-cutting and precision etching technologies to produce mesh nozzle plates with highly consistent orifice patterns, ensuring superior spray quality and minimal clogging. These enhancements are critical in industries such as fuel injection, chemical processing, and coating applications where precision and reliability are essential

- Developments in corrosion-resistant alloys, stainless steel composites, and ceramic coatings have increased the lifespan of mesh nozzle plates, reducing downtime and maintenance costs for industrial operations

- Integration with computational fluid dynamics (CFD) modeling allows engineers to optimize nozzle plate design for improved flow dynamics, reduced pressure drop, and enhanced energy efficiency, meeting the growing demand for sustainable industrial processes

- High-performance mesh nozzle plates are now being tailored for specific industrial applications, including precision spraying in automotive painting, chemical dosing, and high-temperature fluid handling, providing improved process control and operational consistency

- The trend toward miniaturization and compact design enables the deployment of mesh nozzle plates in space-constrained environments while maintaining performance, expanding their applicability across multiple sectors

- Growing emphasis on energy efficiency, cost reduction, and process optimization is driving the adoption of advanced mesh nozzle plates, as manufacturers seek solutions that balance performance with operational sustainability

- Customization options, including variable mesh densities and configurable orifice patterns, allow operators to fine-tune flow rates, atomization quality, and spray coverage, enhancing process flexibility

- The demand for mesh nozzle plates that offer high durability, precise flow control, and adaptability is growing rapidly across sectors such as automotive, chemical processing, agriculture, and industrial coatings

Mesh Nozzle Plates Market Dynamics

Driver

Growing Demand for Efficiency, Durability, and Precision in Industrial Applications

- The rising need for high-performance fluid handling and spraying systems across automotive, chemical, and coating industries is driving the demand for advanced mesh nozzle plates

- For instance, in March 2024, SprayTech Inc. introduced a new series of high-precision mesh nozzle plates optimized for fuel injection systems, offering improved atomization and reduced maintenance requirements. Such innovations by key manufacturers are expected to propel market growth

- Industries increasingly prioritize operational efficiency, uniform spray patterns, and reduced material wastage, which advanced mesh nozzle plates enable

- Enhanced durability through corrosion-resistant materials and wear-proof coatings minimizes downtime and replacement costs, boosting adoption

- CFD-assisted design and simulation enable optimized nozzle performance, reducing energy consumption and operational expenses

- Compact and customizable mesh nozzle plates allow deployment in diverse industrial setups, including space-constrained and high-temperature environments

- Growing industrial automation and precision manufacturing requirements are accelerating the adoption of high-quality nozzle plates

- Multi-sector applicability, including automotive painting, chemical spraying, and agricultural systems, expands the market potential

- Manufacturers are investing in R&D to develop mesh nozzle plates with enhanced longevity, flow precision, and minimal maintenance requirements

- Overall, the demand for process efficiency, reduced operational costs, and precision in fluid handling is driving the global Mesh Nozzle Plates market forward

Restraint/Challenge

High Material and Manufacturing Costs

- The relatively high cost of advanced mesh nozzle plates, due to precision engineering and specialized materials, can limit adoption among cost-sensitive industrial users

- Manufacturing complexities, such as laser etching and CFD-based design customization, add to production costs and may impact pricing strategies

- Maintenance and replacement requirements, though reduced, can still pose operational challenges in high-throughput industrial environments

- Variability in raw material quality, such as stainless steel or ceramic coatings, may affect product consistency and long-term performance

- Smaller manufacturers or budget-constrained industrial setups may prefer standard or conventional nozzle plates despite lower performance

- Extended lead times for custom-designed mesh nozzle plates can delay production cycles and impact workflow

- High initial investment in precision manufacturing equipment and training for handling specialized nozzle plates can be a barrier

- Ensuring compatibility with diverse fluids, pressures, and temperatures across industries requires careful material selection and design, adding technical complexity

- While durability and performance reduce long-term costs, the perceived premium for advanced nozzle plates may slow adoption

- Overcoming these challenges through optimized manufacturing processes, cost-effective material sourcing, and standardization can support sustained market growth in the Mesh Nozzle Plates segment

Mesh Nozzle Plates Market Scope

The market is segmented on the basis of material , manufacturing type and application.

- By Material

On the basis of material, the Mesh Nozzle Plates market is segmented into Metals and Alloys, Engineered Plastics, Ceramics/ Piezoceramics, and Others. The Metals and Alloys segment dominated the largest market revenue share of 42.8% in 2024, driven by their superior strength, thermal stability, and corrosion resistance, which make them ideal for high-precision industrial and medical applications. Metals and alloys, such as stainless steel and nickel-based composites, provide high durability and long service life, reducing maintenance and replacement costs. The segment benefits from widespread usage in fuel injection, chemical spraying, and precision coating systems. Its compatibility with diverse fluids and ability to withstand high pressure further reinforce its dominance. Continuous technological advancements, including laser-cut or micro-etched orifice patterns, enhance flow uniformity and operational efficiency. Manufacturers prefer metals and alloys for applications requiring high wear resistance, precise atomization, and temperature resilience. Regulatory approvals for medical and aerospace applications also support adoption. Overall, metals and alloys remain the dominant material segment due to performance, reliability, and versatility.

The Ceramics/ Piezoceramics segment is expected to witness the fastest CAGR of 20.5% from 2025 to 2032, fueled by their high chemical resistance, excellent electrical insulation properties, and suitability for applications in electronics, medical devices, and precision printing systems. Ceramics allow precise orifice fabrication with minimal wear, making them ideal for high-accuracy dosing and spraying tasks. Lightweight and thermally stable, ceramic nozzle plates are increasingly adopted in microfluidics and laboratory equipment. Advances in piezoceramic coating technology enhance durability, reduce clogging, and improve atomization quality. Growing demand in the cosmetics and pharmaceutical sectors for controlled liquid deposition accelerates adoption. Customized designs allow fine-tuning of spray patterns for medical and industrial processes. R&D efforts in material engineering and additive manufacturing methods further drive growth. Regulatory approvals for medical and electronics applications encourage uptake. Overall, ceramics/piezoceramics are rapidly gaining traction due to precision, durability, and application versatility.

- By Manufacturing Type

On the basis of manufacturing type, the Mesh Nozzle Plates market is segmented into Electroforming and Others. The Electroforming segment accounted for the largest market revenue share of 45.2% in 2024, owing to its ability to produce highly precise, uniform, and reproducible micro-orifices essential for consistent spray quality. Electroformed nozzle plates are widely used in critical applications such as medical devices, precision printing, and industrial spraying systems. The manufacturing technique allows high control over plate thickness, pore distribution, and surface finish, contributing to operational efficiency. Electroforming provides superior dimensional stability, minimal warping, and excellent wear resistance, supporting long-term performance. Its capability to create complex patterns with consistent flow characteristics makes it a preferred choice for high-end industrial and medical applications. Increased adoption in automated and precision machinery further reinforces market dominance. Technological innovations such as additive electroforming processes enhance efficiency and cost-effectiveness. Continuous demand in the automotive, pharmaceutical, and electronics sectors ensures sustained growth. Overall, electroforming dominates due to precision, durability, and broad applicability.

The Others manufacturing type segment is expected to witness the fastest CAGR of 18.9% from 2025 to 2032, driven by alternative production techniques such as laser etching, micro-drilling, and advanced additive manufacturing. These methods allow faster prototyping, customization, and reduced lead times compared to traditional processes. Industries requiring rapid design iterations and specialized orifice configurations, such as microfluidics, cosmetics, and electronics, are increasingly adopting these methods. Lightweight and cost-effective materials can be used with these processes, broadening application scope. Improvements in CNC machining and laser-assisted techniques enhance precision and surface quality. Increased demand for flexible manufacturing in small-batch or customized applications drives growth. Regulatory compliance and material versatility further support adoption. Overall, alternative manufacturing methods are growing quickly due to efficiency, flexibility, and precision advantages.

- By Application

On the basis of application, the Mesh Nozzle Plates market is segmented into Medical, Electronics, Cosmetics, Printers, and Others. The Medical segment dominated the largest market revenue share of 43.6% in 2024, driven by the critical need for precise fluid dosing, atomization, and spraying in diagnostic, therapeutic, and surgical applications. Mesh nozzle plates are widely used in medical devices, including nebulizers, lab dispensing systems, and microfluidic equipment. High precision, durability, and compatibility with sterile environments make them indispensable for healthcare applications. Customization options for mesh density and orifice design ensure accurate dosing, uniform flow, and operational consistency. Continuous innovations in material science, such as corrosion-resistant alloys and biocompatible coatings, enhance device safety and longevity. The segment benefits from stringent regulatory standards, rising healthcare expenditures, and increasing adoption of automated medical equipment. Overall, the medical application segment dominates due to its critical performance requirements and technological advancements.

The Electronics segment is expected to witness the fastest CAGR of 21.2% from 2025 to 2032, fueled by growing demand for precision spraying in semiconductor fabrication, coating processes, and printed circuit board assembly. Mesh nozzle plates enable fine control over fluid deposition, improving efficiency, reducing waste, and enhancing product quality. The segment benefits from the expansion of electronics manufacturing, miniaturization trends, and high-precision component requirements. Advanced materials such as ceramics and engineered plastics are preferred for high-temperature and chemical-resistant applications. Customizable orifice designs allow manufacturers to optimize spray patterns for diverse electronic processes. Rapid growth in consumer electronics and automation further accelerates adoption. R&D investments in high-precision nozzle technologies and integration with automated production lines enhance market growth. Overall, the electronics application segment is growing rapidly due to precision, efficiency, and increasing demand in high-tech manufacturing.

Mesh Nozzle Plates Market Regional Analysis

- North America dominated the mesh nozzle plates market with the largest revenue share of 41.5% in 2024 Supported by advanced manufacturing facilities, the strong presence of key players, and high adoption of automated coating and printing technologies

- This growth is further driven by rising demand in healthcare, continuous innovation, increasing investment in nanotechnology, and expanding applications across industrial and consumer markets

- The market experienced notable growth due to increasing demand in industries such as packaging, electronics, and automotive, driven by innovations in durable, high-precision, and customizable nozzle plate designs

U.S. Mesh Nozzle Plates Market Insight

The U.S. mesh nozzle plates market captured the largest revenue share within North America in 2024, fueled by rising industrial automation, increasing investments in electronics and automotive manufacturing, and growing demand for high-quality, precise coating and printing solutions. Companies are increasingly adopting advanced mesh nozzle plates to enhance production efficiency, reduce waste, and achieve consistent output across applications. The presence of established manufacturers and technological innovation further strengthens market expansion in the country.

Europe Mesh Nozzle Plates Market Insight

The Europe mesh nozzle plates market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by stringent quality and safety standards, increasing automation in production processes, and the need for energy-efficient manufacturing solutions. Germany, France, and the U.K. are key contributors, where industries such as pharmaceuticals, packaging, and electronics are actively integrating high-performance mesh nozzle plates to enhance productivity and operational precision.

U.K. Mesh Nozzle Plates Market Insight

The U.K. mesh nozzle plates market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by rising adoption in pharmaceutical, printing, and packaging industries. Companies are investing in modern production technologies requiring high-precision nozzle plates to meet international quality standards. The market is further supported by a strong industrial infrastructure and the increasing emphasis on reducing operational waste and enhancing efficiency.

Germany Mesh Nozzle Plates Market Insight

The Germany mesh nozzle plates market is expected to expand at a considerable CAGR during the forecast period, fueled by growing industrialization, the adoption of advanced manufacturing technologies, and the demand for sustainable and precise production equipment. German manufacturers are leveraging durable and corrosion-resistant nozzle plates to improve production consistency, minimize downtime, and enhance process efficiency in sectors such as electronics, automotive, and coatings.

Asia-Pacific Mesh Nozzle Plates Market Insight

The Asia-Pacific mesh nozzle plates market is poised to grow at the fastest CAGR during the forecast period of 2025 to 2032, driven by rapid industrialization, increasing urbanization, rising disposable incomes, and strong investments in manufacturing infrastructure in countries such as China, India, and Japan. Expanding production capabilities in emerging industrial sectors, combined with the adoption of advanced coating and printing technologies, are key factors accelerating market growth in this region.

Japan Mesh Nozzle Plates Market Insight

The Japan mesh nozzle plates market is gaining momentum due to the country’s focus on high-tech manufacturing, precision engineering, and automation. Industries such as electronics, automotive, and pharmaceuticals are adopting high-performance nozzle plates to ensure precise, consistent coating and printing processes. The emphasis on efficiency, quality, and sustainable manufacturing practices is further propelling market growth in Japan.

China Mesh Nozzle Plates Market Insight

The China mesh nozzle plates market accounted for the largest revenue share in Asia-Pacific in 2024, attributed to rapid industrial expansion, strong investments in manufacturing infrastructure, and increasing demand from electronics, automotive, and packaging industries. Local manufacturers are producing affordable, high-precision nozzle plates that cater to both domestic and international markets. Government support for industrial modernization and the rising adoption of automated production technologies are key drivers of market growth in China.

Mesh Nozzle Plates Market Share

The Mesh Nozzle Plates industry is primarily led by well-established companies, including:

- Temicon GmbH (Germany)

- Veco B.V. (Netherlands)

- MAIDENCREEK MANUFACTURING SALES, LLC (U.S.)

- Johnson Matthey (U.K.)

- MicroBase Technology Corp. (Taiwan)

- Informatic Component Technology Ltd. (U.K.)

- TEKCELEO (France)

- Piezo Direct (U.S.)

- Dongguan Cosson Electronic Plastic Co., Ltd. (China)

- APC International, Ltd. (U.S.)

- Aerogen Ltd. (Ireland)

Latest Developments in Global Mesh Nozzle Plates Market

- In July 2025, The Partner Companies acquired Precision Eforming, a specialist in electroforming technology. This acquisition enhances their capabilities in producing high-precision metal parts, including ultra-fine mesh products with precise features and tight tolerances. These advancements support critical applications in medical imaging, space exploration, and fuel filtration

- In April 2025, Veco Precision published a whitepaper detailing the advantages of electroforming in manufacturing micro-precision metal parts. The process enables the creation of nozzle plates with unique bell-mouth hole shapes, providing anti-clogging, non-blinding performance, and high open area and throughput. These features are particularly beneficial in applications requiring consistent performance and minimal downtime

- In April 2025, Veco Precision highlighted the role of electroforming in developing next-generation electrodes for aerosol drug delivery systems. Their vibrating mesh technology enables the release of millions of micron-sized droplets per second, enhancing the efficiency of nebulizers

- In February 2025, Veco Precision introduced micro nozzle plates with miniature holes down to 2 microns, achieved through electroforming. These high-precision nozzle plates offer excellent dispensing and jetting performance, catering to industries requiring fine feature accuracy and burr-free components

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.