Global Metal Injection Molding Mim Market

Market Size in USD Billion

CAGR :

%

USD

4.65 Billion

USD

8.99 Billion

2024

2032

USD

4.65 Billion

USD

8.99 Billion

2024

2032

| 2025 –2032 | |

| USD 4.65 Billion | |

| USD 8.99 Billion | |

|

|

|

|

Metal Injection Molding (MIM) Market Size

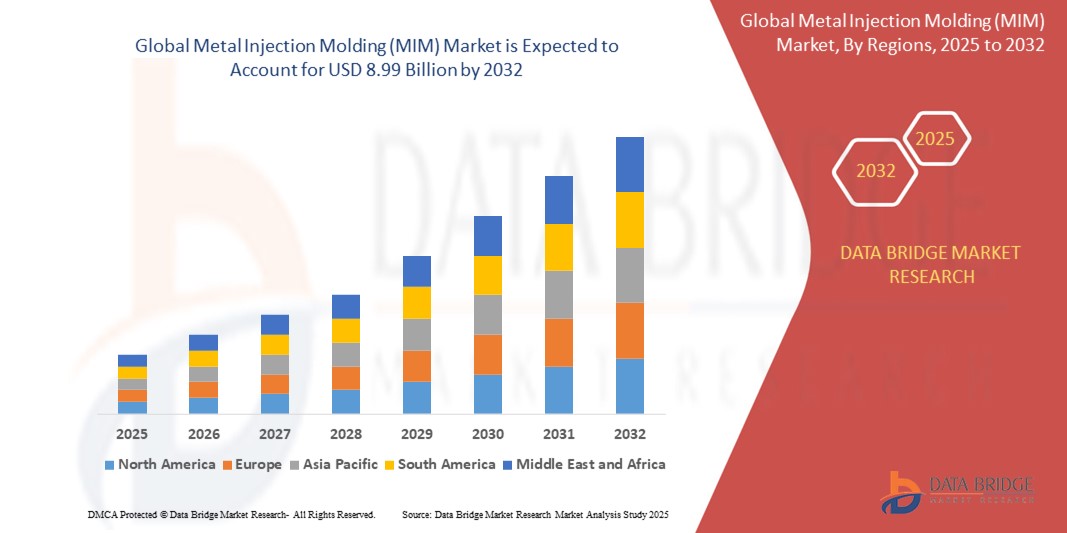

- The global metal injection molding (MIM) market size was valued at USD 4.65 billion in 2024 and is expected to reach USD 8.99 billion by 2032, at a CAGR of 8.60% during the forecast period

- The market growth is primarily driven by increasing demand for complex, high-precision components in industries such as automotive, medical, and electronics, coupled with advancements in MIM technology that enable cost-effective production of small, intricate metal parts

- Rising adoption of lightweight and durable materials in manufacturing, along with the growing trend toward miniaturization in consumer electronics and medical devices, is further propelling the market's expansion

Metal Injection Molding (MIM) Market Analysis

- Metal injection molding (MIM) is a versatile manufacturing process that combines the flexibility of plastic injection molding with the strength and durability of metal, enabling the production of complex, high-precision metal components for a wide range of applications

- The increasing demand for MIM is fueled by its ability to produce intricate parts with high dimensional accuracy, reduced material waste, and cost efficiency compared to traditional manufacturing methods such as machining or casting

- North America dominated the MIM market with the largest revenue share of 38.5% in 2024, driven by a strong presence of key industries such as automotive, aerospace, and medical, along with significant investments in advanced manufacturing technologies. The U.S. leads the region, supported by innovations from established players and growing adoption in medical and dental applications

- Asia-Pacific is expected to be the fastest-growing region during the forecast period, attributed to rapid industrialization, increasing automotive production, and rising demand for consumer electronics in countries such as China, Japan, and India

- The ferrous alloys segment dominated the largest market revenue share of 52% in 2024, driven by its widespread use in industries such as automotive, medical, and consumer electronics due to its high strength, corrosion resistance, and cost-effectiveness

Report Scope and Metal Injection Molding (MIM) Market Segmentation

|

Attributes |

Metal Injection Molding (MIM) Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Metal Injection Molding (MIM) Market Trends

“Integration of Advanced Materials and Automation Technologies”

- The Global Metal Injection Molding (MIM) Market is experiencing a significant trend toward the integration of advanced materials and automation technologies

- Innovations in material science, such as the development of eco-friendly and high-performance alloys such as titanium and stainless steel, enhance MIM's applicability across industries, improving mechanical properties and corrosion resistance

- Automation and AI-driven manufacturing processes are being adopted to optimize production efficiency, reduce waste, and ensure precision in complex part fabrication

- For instances, companies are leveraging AI for quality control, with 39% of manufacturers in the Asia Pacific region utilizing AI to enhance part accuracy and consistency

- These advancements make MIM increasingly attractive for producing intricate, high-strength components for industries such as automotive, aerospace, and medical, driving market growth

Metal Injection Molding (MIM) Market Dynamics

Driver

“Growing Demand for Complex, Lightweight Components Across Industries”

- The rising demand for intricate, lightweight, and high-strength components in industries such as automotive, aerospace, and medical is a major driver for the Global Metal Injection Molding (MIM) Market

- MIM enables the production of complex geometries with high precision, making it ideal for applications such as automotive gears, medical implants, and aerospace turbine blades

- Government incentives and increasing focus on fuel efficiency, particularly in the automotive sector, are boosting the adoption of MIM for lightweight parts, with the automotive industry holding a 33% share of global MIM demand

- The expansion of consumer electronics, particularly in Asia Pacific, which accounts for 44% of global MIM output for high-volume electronics, further fuels market growth

- North America dominates the market with a 27% share, driven by robust demand in automotive, aerospace, and medical applications, while Asia Pacific is the fastest-growing region, with a projected CAGR of 13.1% from 2024 to 2032, fueled by rapid industrialization and electronics manufacturing

Restraint/Challenge

“High Initial Costs and Raw Material Price Volatility”

- The high initial investment required for MIM equipment, tooling, and feedstock materials, such as ferrous alloys and tungsten alloys, poses a significant barrier to adoption, particularly for small-scale production units and emerging markets

- The cost of specialized metal powders and binders is often higher than those used in traditional manufacturing processes, limiting scalability for smaller manufacturers

- Volatility in raw material prices, including stainless steel and titanium, adds uncertainty and can impact profitability for MIM producers

- In addition, environmental concerns related to the energy-intensive sintering process and binder disposal present challenges, particularly in regions with stringent environmental regulations

- These factors may hinder market expansion, especially in cost-sensitive regions or industries requiring low-volume production

Metal Injection Molding (MIM) market Scope

The market is segmented on the basis of material and industry.

- By Material

On the basis of material, the global metal injection molding (MIM) market is segmented into ferrous alloys, tungsten alloys, hard metals, special material, and others. The ferrous alloys segment dominated the largest market revenue share of 52% in 2024, driven by its widespread use in industries such as automotive, medical, and consumer electronics due to its high strength, corrosion resistance, and cost-effectiveness. Stainless steel, a key ferrous alloy, is particularly dominant due to its versatility and mechanical properties, making it ideal for precision components such as gears, sensors, and surgical instruments.

The special material segment, including materials such as titanium and nickel alloys, is expected to witness the fastest growth rate of 10.8% from 2025 to 2032. This growth is fueled by increasing demand for lightweight, high-strength, and corrosion-resistant materials in aerospace, medical, and high-performance industrial applications. Advancements in material science, such as the development of eco-friendly and biocompatible alloys, further enhance adoption.

- By Industry

On the basis of industry, the global metal injection molding (MIM) market is segmented into consumer products, electronics, automotive, medical and dental, defense and firearms, industrial, aerospace, power tools, sporting goods, and others. The automotive segment dominated the market with a revenue share of 35% in 2024, driven by the high demand for lightweight, complex, and durable components such as gearboxes, engine parts, and turbochargers. The ability of MIM to produce intricate parts with high precision and cost-efficiency supports its widespread adoption in this sector.

The electronics segment is anticipated to experience the fastest growth rate of 12.5% from 2025 to 2032. This is driven by the rising demand for miniaturized, high-precision components such as smartphone housings, connectors, and laptop structural parts, particularly in Asia Pacific, where countries such as China and South Korea lead in consumer electronics production. The integration of MIM with advanced manufacturing technologies further accelerates its growth in this sector.

Metal Injection Molding (MIM) Market Regional Analysis

- North America dominated the metal injection molding (MIM) market with the largest revenue share of 38.5% in 2024, driven by a strong presence of key industries such as automotive, aerospace, and medical, along with significant investments in advanced manufacturing technologies. The U.S. leads the region, supported by innovations from established players and growing adoption in medical and dental applications

- Consumers prioritize MIM for producing complex, high-precision metal parts that enhance performance, reduce weight, and improve durability across industries such as automotive, medical, and electronics

- Growth is supported by advancements in MIM technology, including new material formulations such as eco-friendly binders and high-performance alloys, alongside increasing adoption in both OEM and aftermarket segments

U.S. Metal Injection Molding (MIM) Market Insight

The U.S. metal injection molding (MIM) market captured the largest revenue share of 77.9% in 2024 within North America, fueled by strong demand in the automotive, medical, and firearms sectors. The trend toward lightweight, high-strength components for fuel efficiency and the growing need for precision medical devices, such as surgical instruments and implants, drive market expansion. The U.S. also leads in firearms production, where MIM is widely used for durable, intricate components.

Europe Metal Injection Molding (MIM) Market Insight

The Europe MIM market is expected to witness significant growth, supported by a strong emphasis on automotive and medical device industries. Consumers demand high-precision MIM components that enhance vehicle performance and comply with stringent safety and environmental regulations. Growth is prominent in both OEM and aftermarket applications, with countries such as Germany and France leading due to their advanced manufacturing capabilities and focus on sustainability.

U.K. Metal Injection Molding (MIM) Market Insight

The U.K. market for MIM is expected to experience rapid growth, driven by increasing demand for precision components in automotive and aerospace applications. The rising adoption of electric vehicles (EVs) creates opportunities for MIM in battery packs and drivetrain systems. Consumer awareness of MIM’s ability to produce lightweight, durable parts and compliance with evolving regulations further boost market growth.

Germany Metal Injection Molding (MIM) Market Insight

Germany is expected to witness rapid growth in the MIM market, attributed to its advanced automotive manufacturing sector and high consumer focus on precision and energy efficiency. German manufacturers prefer MIM for producing complex components such as gears and sensors that reduce vehicle weight and improve fuel efficiency. The integration of MIM in premium vehicles and strong R&D infrastructure supports sustained market expansion.

Asia-Pacific Metal Injection Molding (MIM) Market Insight

The Asia-Pacific region is the fastest-growing MIM market, driven by rapid industrialization, expanding automotive and electronics production, and rising disposable incomes in countries such as China, India, and Japan. Increasing demand for miniaturized, high-performance components in consumer electronics and automotive applications boosts market growth. Government initiatives promoting manufacturing and cost-effective production further enhance MIM adoption.

Japan Metal Injection Molding (MIM) Market Insight

Japan’s MIM market is expected to witness rapid growth due to strong consumer demand for high-quality, precision-engineered components in automotive, electronics, and medical devices. The presence of major automotive manufacturers and the integration of MIM in OEM applications accelerate market penetration. Rising interest in aftermarket customization and advanced material innovations also contribute to growth.

China Metal Injection Molding (MIM) Market Insight

China holds the largest share of the Asia-Pacific MIM market, propelled by rapid urbanization, increasing vehicle ownership, and strong demand for precision components in electronics and automotive sectors. The country’s growing middle class and focus on advanced manufacturing support the adoption of MIM for complex parts such as smartphone components and automotive gears. Competitive pricing and robust domestic production capabilities enhance market accessibility.

Metal Injection Molding (MIM) Market Share

The metal injection molding (MIM) industry is primarily led by well-established companies, including:

- Molex (USA)

- Proterial, Ltd. (Japan)

- GKN Powder Metallurgy (UK)

- Seiko Epson Corporation (Japan)

- SZS Co., Ltd. (China)

- Jiangsu Gian MIM Parts (China)

- Schunk Mobility (Germany)

- INDO-MIM (India)

- Reich MIM GmbH (Germany)

- ARC Group Worldwide (USA)

- CHENMING ELECTRONIC TECH. CORP. (Taiwan)

- PSM Industries (USA)

- Alpha Precision Group (USA)

- MPP (USA)

- Optimim (USA)

What are the Recent Developments in Global Metal Injection Molding (MIM) Market?

- In March 2025, the Metal Powder Industries Federation (MPIF) released the 2025 edition of MPIF Standard 35-MIM, the definitive guide for Metal Injection Molded (MIM) parts. This updated standard introduces new material specifications for MIM-CpTi (Commercially Pure Titanium), MIM-Ti-6Al-4V (Titanium Alloy), and MIM-420 HIP’d & HT (Stainless Steel). It also includes revised data for MIM-17-4 PH, enhancing guidance on corrosion-resistant stainless steel. These updates provide engineers with the most current property data to support the design and specification of advanced MIM components

- In April 2024, INDO-MIM, a global leader in Metal Injection Molding (MIM), inaugurated a state-of-the-art manufacturing facility in Chennai, India. Spanning over 26,700 square meters, the new plant is designed with advanced infrastructure to support high-precision MIM production, reinforcing INDO-MIM’s position as the world’s largest MIM capacity holder. The facility incorporates sustainable design principles aimed at achieving Gold Level IGBC Certification, and features optimized temperature control, modern interiors, and efficient utility distribution. This expansion enhances INDO-MIM’s global manufacturing footprint and supports growing demand across automotive, aerospace, medical, and industrial sectors

- In November 2023, Sodick Plustech introduced the m:MIM machine, a cutting-edge solution specifically engineered to tackle the unique challenges of metal injection molding (MIM). Featuring a two-stage V-LINE® injection system, the m:MIM offers precise fill control, high injection responsiveness, and stable melt conditions, enabling the production of defect-free, near-net-shape parts. The machine also incorporates highly lubricated steel components to reduce wear from metal powders and supports high injection holding pressure with enhanced temperature control. This innovation marks a significant advancement in MIM machine technology

- In August 2023, several prominent Metal Injection Molding (MIM) manufacturers announced significant investments in automation technologies to enhance production efficiency, reduce costs, and improve part consistency. These investments include the integration of robotic handling systems, automated debinding and sintering lines, and real-time quality monitoring tools. The shift reflects a broader industry trend toward smart manufacturing, driven by rising global demand for high-precision, cost-effective components in sectors such as automotive, medical, and electronics. Automation is enabling MIM producers to scale operations while maintaining stringent quality standards and reducing labor-intensive processes

- In July 2023, INDO-MIM, a global leader in Metal Injection Molding (MIM), completed the acquisition of CMG Technologies, a prominent UK-based MIM manufacturer located in Woodbridge, Suffolk. This strategic move strengthens INDO-MIM’s presence in Europe and enhances its capabilities in sinter-based metal additive manufacturing. The acquisition allows INDO-MIM to offer on-shore manufacturing for European clients while leveraging CMG’s expertise in precision engineering. CMG will continue to operate under its existing leadership, ensuring continuity and growth under the INDO-MIM umbrella

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Metal Injection Molding Mim Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Metal Injection Molding Mim Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Metal Injection Molding Mim Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.