Global Metal Sheet Bending Machine Market

Market Size in USD Million

CAGR :

%

USD

988.10 Million

USD

1,516.42 Million

2024

2032

USD

988.10 Million

USD

1,516.42 Million

2024

2032

| 2025 –2032 | |

| USD 988.10 Million | |

| USD 1,516.42 Million | |

|

|

|

|

Metal Sheet Bending Machine Market Size

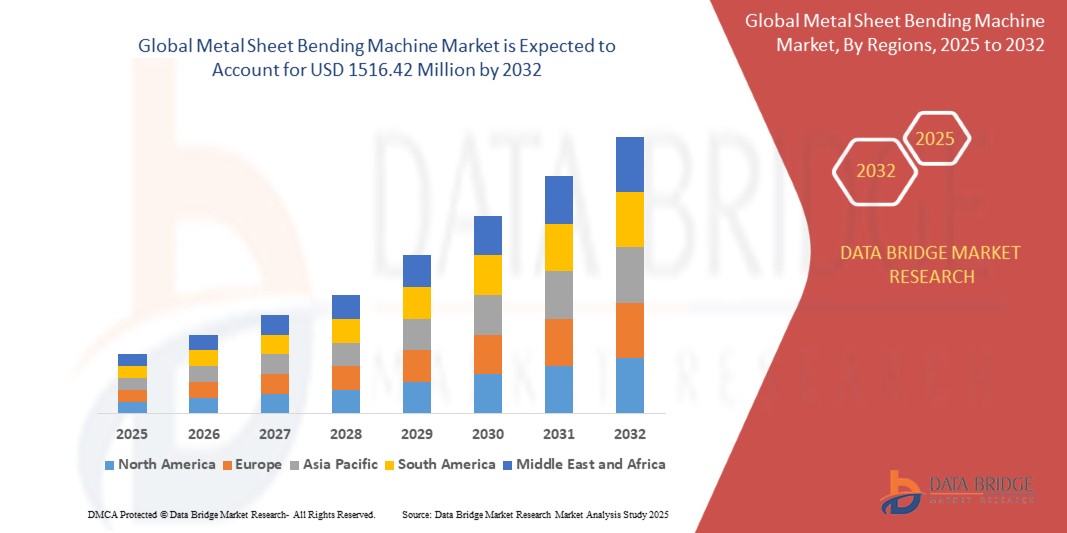

- The global metal sheet bending machine market was valued at USD 988.1 million in 2024 and is expected to reach USD 1516.42 million by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 5.50%, primarily driven by advancements in automation and CNC technology

- This growth is driven by factors such as high precision and consistency, faster production cycles, and lower reliance on skilled labor

Metal Sheet Bending Machine Market Analysis

- Metal sheet bending machines are essential tools used in various industries for shaping metal sheets into desired forms, commonly applied in manufacturing, automotive, construction, and electronics sectors

- Market growth is driven by rising industrial automation, demand for high-precision metal components, and the expanding manufacturing and fabrication sectors worldwide

- The market is evolving with advancements in CNC technology, integration of IoT for smart control, and the shift toward fully automated bending solutions

- For instance, companies are introducing CNC-powered bending machines equipped with touch-screen controls, real-time monitoring, and automated tool changers to enhance productivity and accuracy

- The metal sheet bending machine market is projected to grow steadily, fueled by the rise in infrastructure projects, increasing adoption of Industry 4.0 practices, and growing demand for efficient, high-speed fabrication equipment

Report Scope and Metal Sheet Bending Machine Market Segmentation

|

Attributes |

Metal Sheet Bending Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Metal Sheet Bending Machine Market Trends

“Rising Integration of Automation & Advanced Control Systems”

- One prominent trend in the global metal sheet bending machine market is the rising integration of automation & advanced control systems

- This trend is driven by the need for higher production efficiency, improved precision, reduced operational costs, and the growing demand for smart manufacturing solutions across industries

- For instance, companies such as TRUMPF and Amada are launching next-generation CNC-controlled bending machines equipped with automated tool changers, real-time performance monitoring, and intuitive user interfaces to enhance speed, accuracy, and operational efficiency

- The push for Industry 4.0, coupled with labor shortages and rising quality standards, is accelerating the adoption of intelligent and connected machines across automotive, electronics, and metal fabrication sectors

- As industries continue to modernize and prioritize operational efficiency, the integration of automation and advanced control systems is expected to be a key driver of market innovation, supporting faster production cycles, minimal human intervention, and broader adoption of smart fabrication technologies

Metal Sheet Bending Machine Market Dynamics

Driver

“Growth in Consumer Electronics and Appliance Manufacturing”

- The rapid expansion of consumer electronics and appliance manufacturing is a key driver of growth in the metal sheet bending machine market. As the demand for compact, durable, and aesthetically refined electronic products increases, manufacturers require advanced metal forming solutions for precise component fabrication

- This shift is particularly evident in the production of casings, internal frames, and structural parts for devices such as smartphones, laptops, home appliances, and wearable technology—where accuracy, speed, and design flexibility are crucial

- With the growing emphasis on lightweight materials, sleek designs, and miniaturization, metal sheet bending machines play a vital role in enabling intricate bends and maintaining high-quality standards across mass production

- Features such as automation, CNC precision, and integration with CAD/CAM software are becoming standard, catering to the evolving needs of electronics OEMs and ODMs

For instance,

- LG Electronics utilizes automated bending machines in the fabrication of appliance panels, ensuring consistency and reduced production downtime

- Sony and Panasonic are leveraging CNC-based metal sheet bending machines for the production of precision parts used in audio and video equipment, enhancing both design and functionality

- As consumer demand continues to rise for innovative, high-quality electronic products, the metal sheet bending machine market is expected to benefit significantly from this trend—driving technological advancements, production efficiency, and broader machine adoption across the electronics and appliance sectors

Opportunity

“Expansion into Emerging Economies”

- The growing industrialization and infrastructure development in emerging economies present a major opportunity for the metal sheet bending machine market. Rapid economic growth and urbanization are driving demand for metal fabrication in sectors such as construction, automotive, and consumer electronics

- Government initiatives promoting local manufacturing and industrial modernization are further supporting machinery investments, particularly in regions such as Asia-Pacific, Latin America, and the Middle East

- Increased access to financing, foreign direct investments, and technology transfer is encouraging small and mid-sized enterprises to adopt advanced bending solutions

For instance,

- TRUMPF has expanded its presence in India and Southeast Asia, offering region-specific solutions to meet local manufacturing demands

- Amada has established technical centers in Vietnam and Indonesia, focusing on training, service support, and tailored product offerings for emerging markets

- As competition intensifies in mature markets, global manufacturers tapping into these high-potential regions are well-positioned to expand their customer base, establish long-term partnerships, and drive sustained market growth through localized innovation and support

Restraint/Challenge

“High Initial Investment and Operational Costs”

- The high initial investment and operational costs pose a significant challenge for the metal sheet bending machine market. While automation and CNC technologies enhance productivity, the cost of acquiring such advanced systems remains prohibitive for many manufacturers, particularly SMEs

- These machines often require substantial capital outlay not only for purchase but also for setup, operator training, and integration with existing production systems. This financial burden can deter adoption, especially in cost-sensitive or developing markets

- In addition, ongoing expenses related to maintenance, software updates, and energy consumption further increase the total cost of ownership, limiting accessibility for smaller workshops or new entrants

For instance,

- Fabricators in regions such as South Asia and Eastern Europe often continue to rely on manual or semi-automatic machines, as the cost of transitioning to CNC-based systems exceeds their current financial capabilities

- Without more affordable financing models, modular solutions, or targeted government incentives, many businesses may struggle to modernize, which could slow overall market growth and widen the technological gap between large enterprises and smaller players

Metal Sheet Bending Machine Market Scope

The market is segmented on the basis of product type and application.

|

Segmentation |

Sub-Segmentation |

|

By Product Type |

|

|

By Application |

|

Metal Sheet Bending Machine Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Metal Sheet Bending Machine Market”

- Asia-Pacific dominates the metal sheet bending machine market, driven by the rapid industrialization, robust manufacturing output, and large-scale investments in construction, automotive, and electronics sectors

- China holds a significant share due to its massive manufacturing ecosystem, government-driven industrial policies, and widespread adoption of automation technologies in metal fabrication

- The availability of low-cost labor, a growing base of SMEs, and the regional expansion of key global players are further strengthening Asia-Pacific’s leadership position

- With its established manufacturing capabilities, increasing automation adoption, and rising demand for high-efficiency machines, Asia-Pacific is expected to remain the dominant and most mature market for metal sheet bending machines throughout the 2025–2032 forecast period

“North America is Projected to Register the Highest Growth Rate”

- North America is expected to witness the highest growth rate in the metal sheet bending machine market, driven by rising investments in advanced manufacturing, aerospace, and electric vehicle (EV) production

- U.S. leads the regional growth, supported by strong adoption of CNC-based machines, Industry 4.0 integration, and reshoring efforts in domestic manufacturing

- Growing demand for precision metal components in sectors such as defense, consumer electronics, and renewable energy is fueling the need for advanced bending technologies

- With a focus on operational efficiency, digital transformation, and high-quality production standards, North America is positioned as the fastest-growing regional market for metal sheet bending machines through 2032

Metal Sheet Bending Machine Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- TRUMPF (Germany)

- Amada Co., Ltd. (Japan)

- Bystronic Group (Switzerland)

- Cincinnati Incorporated (U.S.)

- Salvagnini Italia SPA (Italy)

- LVD Group NV (Belgium)

- Durmazlar Machinery Inc. (Turkey)

- EWM GmbH (Germany)

- MachineWeb, Inc (Canada)

- JPW Industries, Inc (U.S.)

- Ermaksan (Turkey)

- U.S. Industrial Machinery (U.S.)

Latest Developments in Global Metal Sheet Bending Machine Market

- In February 2023, TRUMPF launched the latest generation of its TruBend Series 8000 at its INTECH trade show, strengthening its market position with a solution designed for large-part bending. With an 880 mm open height and 700 mm stroke, the machine enhances efficiency for oversized components, addressing rising demand in heavy manufacturing and industrial applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Metal Sheet Bending Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Metal Sheet Bending Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Metal Sheet Bending Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.