Global Metal Wire Rolling Machine Market

Market Size in USD Billion

CAGR :

%

USD

6.76 Billion

USD

10.37 Billion

2024

2032

USD

6.76 Billion

USD

10.37 Billion

2024

2032

| 2025 –2032 | |

| USD 6.76 Billion | |

| USD 10.37 Billion | |

|

|

|

|

Metal Wire Rolling Machine Market Size

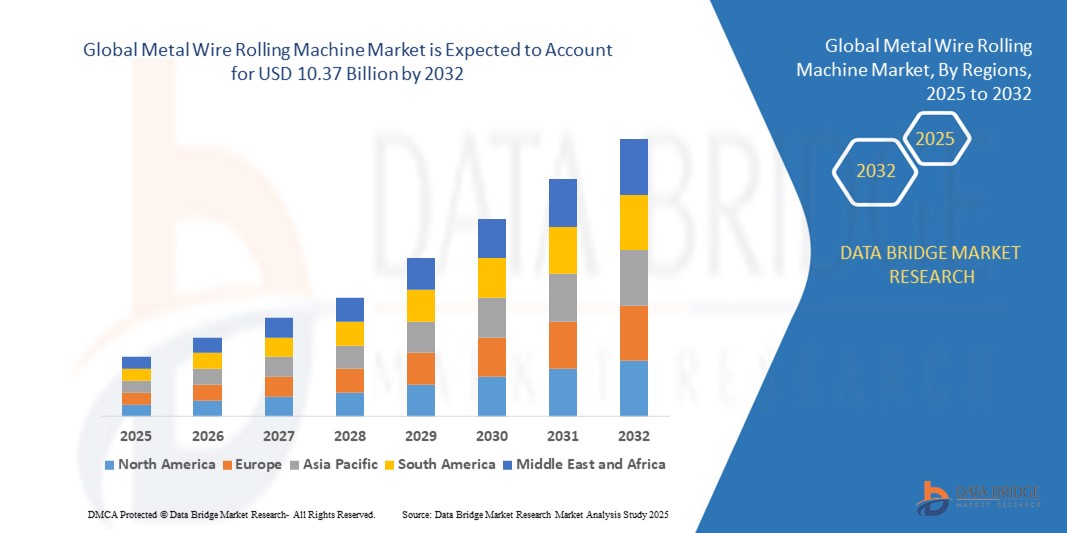

- The global metal wire rolling machine market size was valued at USD 6.76 billion in 2024 and is expected to reach USD 10.37 billion by 2032, at a CAGR of 5.5% during the forecast period

- The market growth is largely fueled by increasing industrialization and infrastructure development across construction, automotive, and electrical sectors, driving higher demand for metal wire production and advanced rolling machines

- Furthermore, rising adoption of automated, energy-efficient, and precision-engineered rolling equipment is enabling manufacturers to improve productivity, reduce operational costs, and maintain consistent wire quality. These converging factors are accelerating investments in modern rolling machines, thereby significantly boosting the industry's growth

Metal Wire Rolling Machine Market Analysis

- Metal wire rolling machines are industrial equipment designed to shape, reduce, or finish metal wires through controlled rolling processes. These machines include rough rolling frames, medium rolling racks, and specialized systems for producing coated or enameled wires, serving various industrial applications

- The escalating demand for these machines is primarily fueled by the need for high-quality wire products, technological advancements in rolling equipment, and growing industrial output in emerging economies. Enhanced precision, automation, and digital integration are further driving the adoption of modern wire rolling solutions across global manufacturing sectors

- North America dominated the metal wire rolling machine market with a share of over 35% in 2024, due to increasing demand from construction, automotive, and electrical industries

- Asia-Pacific is expected to be the fastest growing region in the metal wire rolling machine market during the forecast period due to rapid industrialization, urbanization, and rising demand for construction and electrical wires in countries such as China, Japan, and India

- Rough rolling frame segment dominated the market with a market share of 62.5% in 2024, due to its robust construction and capability to handle high-volume wire production with consistent quality. Manufacturers prefer rough rolling frames for their durability and ability to operate under heavy load conditions, making them ideal for large-scale metal wire production facilities. This segment also benefits from lower maintenance requirements and compatibility with various wire diameters, which enhances operational efficiency and reduces downtime. The widespread adoption in industrial wire manufacturing plants further strengthens its market position, as it provides a reliable solution for primary wire rolling operations

Report Scope and Metal Wire Rolling Machine Market Segmentation

|

Attributes |

Metal Wire Rolling Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Metal Wire Rolling Machine Market Trends

Rising Technological Advancements

- Rapid technological progress in metal wire rolling machines is driving enhanced precision, automation, and production efficiency, transforming manufacturing capabilities across industries

- For instance, leading manufacturers such as Bongard Machines, Bühler Group, and Fives Group are integrating Industry 4.0 features such as real-time monitoring, predictive maintenance, and automated quality control into their wire rolling equipment, improving operational reliability and minimizing downtime

- Development of hybrid mechanical-hydraulic systems and energy-efficient motor drives enhances machine performance while reducing power consumption and operational costs

- Advanced control systems and digitized process automation enable the production of highly complex wire profiles with tighter tolerances, catering to the rising demand for custom and specialty wires

- Increasing adoption of modular and reconfigurable machine designs allows flexible manufacturing lines, facilitating quick changeovers and scalability in response to dynamic market requirements

- Use of AI-enabled analytics and cloud-based data platforms is optimizing production workflows and enabling smart manufacturing practices in wire rolling operations

Metal Wire Rolling Machine Market Dynamics

Driver

Rising Industrialization and Infrastructure Development

- Growth in global industrialization, urbanization, and massive infrastructure projects spur demand for wire rolling machines that produce essential wire components for construction, automotive, and electrical industries

- For instance, North American and Asian manufacturers such as Carell Corporation and Danieli Group are capitalizing on expanding infrastructure investments and industrial output to boost production capacity with advanced wire rolling technologies

- Increasing automotive production, especially electric vehicles, requires high-precision wire components manufactured efficiently using modern rolling machines

- Infrastructure development in emerging regions and smart city projects support the rising need for sustainable and resilient wire products requiring sophisticated rolling technologies

- Growing investments in construction, utilities, and telecommunications sectors globally demand reliable wire rolling machinery for producing reinforcement, cabling, and wiring products

Restraint/Challenge

High Initial Investment Costs

- The substantial capital expenditure involved in procuring advanced wire rolling machines equipped with automation, Industry 4.0 capability, and energy-efficient systems limits adoption for smaller manufacturers or startups

- For instance, emerging market players often face financial barriers in acquiring high-tech equipment from established companies such as Niehoff Machinery and Rautomead Limited, reducing competitiveness against larger enterprises

- Maintenance and calibration of sophisticated machinery involve additional operational costs, requiring skilled labor and specialized service support

- Price volatility in raw materials and components used in machine manufacturing—such as steel and electronics—raises procurement costs and complicates budgeting for new investments

- Extended lead times and supply chain uncertainties in electronic parts and control systems further escalate initial costs and project timelines for plant modernization

Metal Wire Rolling Machine Market Scope

The market is segmented on the basis of type and application.

- By Type

On the basis of type, the metal wire rolling machine market is segmented into rough rolling frame and medium rolling rack. The rough rolling frame segment dominated the largest market revenue share of 62.5% in 2024, driven by its robust construction and capability to handle high-volume wire production with consistent quality. Manufacturers prefer rough rolling frames for their durability and ability to operate under heavy load conditions, making them ideal for large-scale metal wire production facilities. This segment also benefits from lower maintenance requirements and compatibility with various wire diameters, which enhances operational efficiency and reduces downtime. The widespread adoption in industrial wire manufacturing plants further strengthens its market position, as it provides a reliable solution for primary wire rolling operations.

The medium rolling rack segment is anticipated to witness the fastest growth rate from 2025 to 2032, fueled by its increasing use in mid-sized production setups and specialized wire applications. Medium rolling racks offer flexibility in handling different wire materials and gauges, making them suitable for customized wire rolling processes. Their ease of integration with automated systems and energy-efficient operation appeals to manufacturers looking to optimize production costs. Additionally, rising demand from emerging economies for versatile and compact rolling solutions is accelerating the adoption of medium rolling racks, making it a rapidly expanding segment in the market.

- By Application

On the basis of application, the metal wire rolling machine market is segmented into metal wire rolling machines and plastic wire rolling machines. The metal wire rolling machines segment held the largest market revenue share in 2024, driven by the expanding demand for high-strength wires in construction, automotive, and electrical industries. These machines are preferred for their ability to produce uniform, high-quality metal wires at large scales, which is critical for industrial applications. Advanced features such as automated tension control, precision rollers, and durable frames make metal wire rolling machines a reliable choice for manufacturers. The segment’s dominance is further supported by ongoing investments in industrial infrastructure and modernization of wire production facilities globally.

The plastic wire rolling machines segment is expected to witness the fastest CAGR from 2025 to 2032, driven by the rising use of coated wires and plastic-covered cables in electrical and electronics sectors. Plastic wire rolling machines offer specialized processing capabilities that enable consistent coating thickness and enhanced wire protection. Their flexibility in handling different polymer materials and compatibility with smaller-scale production units contributes to their rapid adoption. Furthermore, growing demand for lightweight and insulated wires in emerging markets is boosting the deployment of plastic wire rolling machines, positioning this segment as the fastest-growing in the market.

Metal Wire Rolling Machine Market Regional Analysis

- North America dominated the metal wire rolling machine market with the largest revenue share of over 35% in 2024, driven by increasing demand from construction, automotive, and electrical industries

- Manufacturers in the region prioritize high-efficiency and precision rolling machines to meet large-scale production requirements

- The market growth is supported by technologically advanced manufacturing infrastructure, high capital investment capacity, and an emphasis on automation and energy-efficient operations.

U.S. Metal Wire Rolling Machine Market Insight

The U.S. metal wire rolling machine market captured the largest revenue share in North America in 2024, fueled by rapid industrialization and the growing need for high-quality metal wires in various sectors. Rising adoption of automated and energy-efficient rolling systems is boosting productivity and reducing operational costs. Manufacturers are increasingly investing in durable rolling frames and versatile racks to accommodate diverse wire diameters and materials. Additionally, government initiatives supporting industrial modernization and technological upgrades are accelerating the market expansion.

Europe Metal Wire Rolling Machine Market Insight

The Europe metal wire rolling machine market is projected to expand steadily during the forecast period, primarily driven by stringent quality standards and the growing demand for high-performance wires in automotive and construction sectors. The region benefits from advanced manufacturing infrastructure, skilled labor, and the integration of precision machinery for industrial wire production. Germany, France, and Italy are leading markets, with emphasis on automation, energy efficiency, and sustainability enhancing the adoption of metal wire rolling machines across both new and existing facilities.

Germany Metal Wire Rolling Machine Market Insight

The Germany metal wire rolling machine market is expected to grow at a notable CAGR during the forecast period, driven by advanced engineering capabilities and a focus on high-quality industrial production. German manufacturers are investing in precision rolling equipment and versatile frames to support diverse wire specifications. The strong industrial base, combined with rising adoption of automated systems and sustainable manufacturing practices, is further promoting market expansion in Germany.

Asia-Pacific Metal Wire Rolling Machine Market Insight

The Asia-Pacific metal wire rolling machine market is poised to grow at the fastest CAGR during 2025–2032, fueled by rapid industrialization, urbanization, and rising demand for construction and electrical wires in countries such as China, Japan, and India. The region’s manufacturing hubs offer cost-effective production solutions, and local adoption of modern rolling machines is increasing due to efficiency and precision advantages. Rising investment in infrastructure projects and growing industrial output are further accelerating market growth, making APAC the fastest-growing region globally.

China Metal Wire Rolling Machine Market Insight

The China metal wire rolling machine market accounted for the largest revenue share in Asia-Pacific in 2024, supported by extensive industrial activity, rapid urban expansion, and the need for high-quality wires in construction, automotive, and electronics industries. Domestic manufacturers are increasingly adopting advanced rolling frames and racks to enhance productivity and operational efficiency. Government initiatives promoting industrial modernization and smart manufacturing practices are also contributing significantly to market growth.

Japan Metal Wire Rolling Machine Market Insight

The Japan metal wire rolling machine market is witnessing significant growth due to high-tech manufacturing capabilities and demand for precision-engineered wire products. Industrial facilities are increasingly deploying automated and energy-efficient rolling machines to improve output quality and reduce operational costs. The emphasis on reliability, precision, and integration with advanced production lines is driving the adoption of both rough rolling frames and medium rolling racks in the country.

Metal Wire Rolling Machine Market Share

The metal wire rolling machine industry is primarily led by well-established companies, including:

- Bongard Machines (France)

- GRT Machinery (Taiwan)

- Carell Corporation (U.S.)

- Fives Group (France)

- Bühler Group (Switzerland)

- Danieli Group (Italy)

- Itoh Denki (Japan)

- Rautomead Limited (U.K.)

- NIEHOFF Machinery and Systems (Germany)

- Koch Metal Works (U.S.)

- M.E.C. srl (Italy)

Latest Developments in Global Metal Wire Rolling Machine Market

- In November 2023, the Wire Rod Mill at SAIL-Bhilai Steel Plant set a new production record by manufacturing 1,675 tons (1,727 coils) of 6 mm plain wire. This achievement highlights the growing efficiency and capacity expansion in India’s wire production sector, reflecting the increasing demand for high-quality wire products in construction, automotive, and electrical industries. The milestone reinforces the competitive edge of Indian steel manufacturers and demonstrates the adoption of advanced rolling technologies to meet market needs, thereby strengthening the overall metal wire rolling machine market in the region

- In August 2023, Primetals Technologies announced the launch of a new high-speed wire rod mill designed to enhance productivity and energy efficiency. This innovation caters to the growing demand for high-quality wire products in industries such as automotive and construction. The introduction of this advanced mill underscores the industry's shift towards automation and energy-efficient solutions in wire production

- In May 2022, SMS group unveiled its latest generation of wire rod mills featuring integrated digitalization tools. These mills offer real-time monitoring and predictive maintenance capabilities, aiming to reduce downtime and improve operational efficiency. This development reflects the industry's trend towards smart manufacturing and Industry 4.0 integration

- In July 2021, FUHR and MAG Machines GmbH collaborated to construct enameled rectangular wire production lines. This strategic partnership focuses on delivering reliable and cost-effective machinery, leveraging each company’s technical expertise to address evolving market requirements. By combining advanced engineering capabilities and production efficiency, the collaboration supports manufacturers in enhancing product quality and operational performance. This initiative has positively impacted the global wire rolling machine market by introducing innovative solutions that meet the growing demand for specialized wire types in electronics, automotive, and industrial applications

- In February 2021, Danieli announced the acquisition of a majority stake in a leading Italian wire drawing machine manufacturer. This strategic move aims to expand Danieli's product portfolio and strengthen its position in the global wire processing market. The acquisition aligns with the industry's consolidation trend and the increasing demand for comprehensive solutions in wire production

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.