Global Metallocene Polyolefin Market

Market Size in USD Billion

CAGR :

%

USD

17.62 Billion

USD

23.21 Billion

2024

2032

USD

17.62 Billion

USD

23.21 Billion

2024

2032

| 2025 –2032 | |

| USD 17.62 Billion | |

| USD 23.21 Billion | |

|

|

|

|

Metallocene Polyolefin Market Size

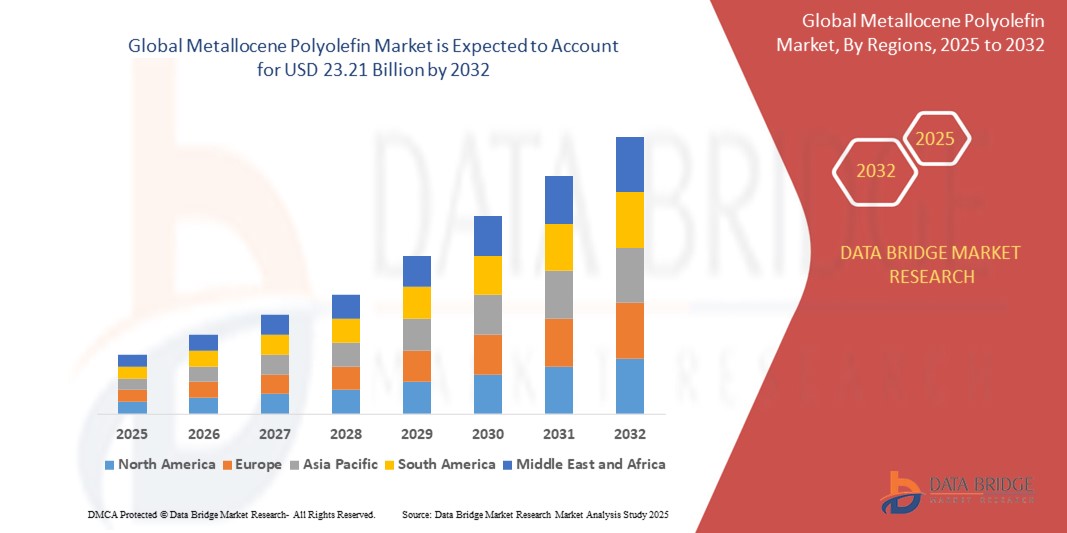

- The global metallocene polyolefin market size was valued at USD 17.62 billion in 2024 and is expected to reach USD 23.21 billion by 2032, at a CAGR of 3.50% during the forecast period

- The market growth is largely fueled by increasing demand for high-performance, lightweight, and recyclable materials across packaging, automotive, and consumer goods industries, driving widespread adoption of metallocene-based polyolefins

- Furthermore, ongoing advancements in catalyst technology and polymer processing are enhancing the mechanical, optical, and sealing properties of metallocene polyolefins, positioning them as a preferred alternative to conventional plastics and significantly boosting market expansion

Metallocene Polyolefin Market Analysis

- Metallocene polyolefins, comprising advanced grades of polyethylene and polypropylene, are increasingly critical to high-performance applications in packaging, automotive, construction, and consumer goods due to their superior strength, flexibility, and processability

- The escalating demand for metallocene polyolefins is primarily fueled by the shift toward sustainable, lightweight, and recyclable materials, along with rising performance requirements across end-use industries and continuous innovations in catalyst and polymer technology

- Asia-Pacific dominated the metallocene polyolefin market with a share of 30.5% in 2024, due to rapid industrialization, expanding packaging demand, and increasing consumption of high-performance plastics in automotive, construction, and consumer goods sectors

- North America is expected to be the fastest growing region in the metallocene polyolefin market during the forecast period due to rising demand for advanced packaging materials, automotive lightweighting, and increased use of high-performance plastics in construction and healthcare sectors

- Metallocene Polyethylene (mPE) segment dominated the market with a market share of 61.9% in 2024, due to its exceptional mechanical properties, superior toughness, and excellent optical clarity, making it a preferred material across high-performance film, packaging, and industrial applications. Industries favor mPE for its enhanced sealing performance, puncture resistance, and flexibility, which significantly outperform conventional polyethylene variants. Growing demand for advanced packaging films, particularly in food, healthcare, and consumer goods, continues to support the strong market position of mPE

Report Scope and Metallocene Polyolefin Market Segmentation

|

Attributes |

Metallocene Polyolefin Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Metallocene Polyolefin Market Trends

“Increasing Adoption of mPOs Due to Their Superior Strength”

- A significant and growing trend in the global metallocene polyolefin (mPO) market is the increased preference for these materials due to their enhanced mechanical strength, heat resistance, and processability compared to conventional polyolefins

- For instance, metallocene polyethylene (mPE) is widely adopted in film packaging applications for its exceptional seal integrity and optical clarity, offering manufacturers both performance and aesthetic benefits

- The ability of mPOs to deliver consistent resin quality with controlled molecular weight distribution enhances their performance in critical applications such as medical packaging, food-grade films, and automotive components

- The unique structural uniformity of mPOs results in films with excellent toughness, puncture resistance, and downgauging potential, which supports sustainability initiatives by reducing material usage

- This shift toward more advanced polyolefins is reshaping expectations across industries that rely on high-performance plastics, prompting manufacturers to invest in metallocene catalyst technologies for tailored polymer properties

- The rising demand for durable, sustainable, and high-clarity packaging solutions across food, personal care, and healthcare sectors is driving the widespread adoption of metallocene polyolefins globally

Metallocene Polyolefin Market Dynamics

Driver

“Growing Demand for Packaging”

- The surging demand for lightweight, recyclable, and high-performance packaging materials is a major factor propelling the growth of the metallocene polyolefin market

- For instance, in May 2022, LyondellBasell and Röchling Medical launched eyedrop containers made from CirculenRenew polymers—featuring mPE and mPP grades—which offer virgin-like quality with a sustainable profile. Such innovations are expanding the application of mPOs in medical and personal care packaging

- As packaging requirements become more specialized, industries increasingly favor mPOs for their ability to improve sealing, reduce film thickness, and deliver better aesthetics and functionality compared to traditional polyethylene and polypropylene

- The trend toward single-material, easily recyclable packaging solutions for food safety and shelf stability is boosting the penetration of mPOs in multilayer film structures. Growth in e-commerce, convenience food, and personal hygiene products further accelerates the demand for metallocene-based films, which offer improved mechanical and barrier properties

- Manufacturers are focusing on expanding mPO production capacities and collaborating with downstream converters to meet the evolving demands of sustainable and functional packaging

Restraint/Challenge

“Complex Manufacturing Process of Metallocene Polyolefin”

- The intricate and capital-intensive manufacturing process of metallocene polyolefins presents a key challenge to broader market expansion, especially in cost-sensitive regions

- For instance, the production of mPOs requires precision-controlled polymerization using metallocene catalysts, which are more expensive and require advanced reactor technologies compared to conventional Ziegler-Natta catalysts

- The need for stringent process controls, catalyst handling expertise, and specialized equipment contributes to higher production costs, creating pricing pressure for downstream applications

- This complexity limits the number of producers capable of manufacturing high-quality mPOs at scale, potentially constraining supply in fast-growing markets. In addition, fluctuations in raw material prices and challenges in optimizing formulations for specific end-uses can further impact profitability for manufacturers

- Overcoming these production hurdles through catalyst innovation, process optimization, and strategic investments will be essential to scaling up metallocene polyolefin availability and competitiveness in mass-market applications

Metallocene Polyolefin Market Scope

The market is segmented on the basis of type and application.

• By Type

On the basis of type, the metallocene polyolefin market is segmented into Metallocene Polyethylene (mPE) and Metallocene Polypropylene (mPP). The mPE segment dominated the largest market revenue share of 61.9% in 2024, attributed to its exceptional mechanical properties, superior toughness, and excellent optical clarity, making it a preferred material across high-performance film, packaging, and industrial applications. Industries favor mPE for its enhanced sealing performance, puncture resistance, and flexibility, which significantly outperform conventional polyethylene variants. Growing demand for advanced packaging films, particularly in food, healthcare, and consumer goods, continues to support the strong market position of mPE.

The mPP segment is anticipated to witness the fastest growth rate of 22.9% from 2025 to 2032, propelled by increasing usage in rigid packaging, automotive components, and consumer products requiring lightweight, durable materials. mPP offers superior impact strength, transparency, and heat resistance, making it suitable for complex injection molding and structural applications. The surge in demand for recyclable and high-performance plastics in the automotive and electronics industries further accelerates mPP's adoption, supported by its ability to produce thinner, lighter, yet stronger parts compared to conventional polypropylene.

• By Application

On the basis of application, the metallocene polyolefin market is segmented into Film & Sheet, Injection Molding, Pipes & Panels, Cables & Wires, Blow Molding, and Others. The Film & Sheet segment held the largest market revenue share in 2024, driven by the growing demand for high-strength, lightweight, and visually appealing packaging films, especially in food, medical, and industrial packaging sectors. Metallocene polyolefins, particularly mPE, provide excellent toughness, puncture resistance, and sealing properties, making them ideal for applications such as stretch films, shrink films, and barrier packaging. The shift toward sustainable, recyclable packaging solutions further amplifies the preference for metallocene-based films among manufacturers.

The Injection Molding segment is expected to witness the fastest CAGR from 2025 to 2032, supported by the rising need for precision-engineered, durable components in automotive, consumer electronics, and healthcare sectors. Metallocene polyolefins offer enhanced processability, consistent product quality, and superior dimensional stability, making them highly suitable for complex injection molding applications. The lightweight, high-performance characteristics of these materials align with industry efforts to improve fuel efficiency, reduce emissions, and enhance product aesthetics, particularly in automotive interiors and portable consumer goods.

Metallocene Polyolefin Market Regional Analysis

- Asia-Pacific dominated the metallocene polyolefin market with the largest revenue share of 30.5% in 2024, driven by rapid industrialization, expanding packaging demand, and increasing consumption of high-performance plastics in automotive, construction, and consumer goods sectors

- The region’s strong manufacturing base, rising disposable income, and growing demand for sustainable, lightweight materials in packaging and infrastructure are major contributors to market growth

- Furthermore, government initiatives promoting recyclable materials, coupled with expanding production capacities for metallocene polyethylene and polypropylene, are accelerating market adoption across both domestic and export-oriented industries

China Metallocene Polyolefin Market Insight

The China metallocene polyolefin market held the largest share in Asia-Pacific in 2024, driven by the country’s leadership in packaging production, automotive manufacturing, and infrastructure development. Rising demand for lightweight, durable materials in packaging, coupled with government policies supporting sustainable plastics, is fueling growth. Chinese manufacturers are investing in advanced catalyst technologies and expanding production of mPE and mPP to meet both domestic and global demand for high-performance polyolefins

India Metallocene Polyolefin Market Insight

The India market is experiencing robust growth due to increasing demand for flexible packaging in food, personal care, and e-commerce sectors. Rising urbanization, coupled with the need for cost-effective, recyclable packaging materials, is boosting adoption. Local manufacturers are expanding their metallocene polyolefin production capacity to cater to the surge in demand from packaging films, automotive components, and consumer goods applications

Europe Metallocene Polyolefin Market Insight

The Europe metallocene polyolefin market is projected to grow at a significant CAGR over the forecast period, supported by stringent environmental regulations, a strong focus on circular economy principles, and rising demand for lightweight, high-performance materials. The region’s advanced recycling infrastructure and emphasis on reducing carbon emissions are driving increased use of metallocene-based polyethylene and polypropylene in packaging, automotive, and construction industries

Germany Metallocene Polyolefin Market Insight

The Germany market is expected to witness steady growth, fueled by strong demand for innovative, sustainable materials across automotive, electrical, and packaging sectors. German manufacturers prioritize lightweight, high-strength polyolefins for automotive components to enhance fuel efficiency and meet emission targets. In addition, Germany’s leadership in material recycling and polymer research is accelerating the development and adoption of metallocene polyolefins

North America Metallocene Polyolefin Market Insight

North America market is projected to grow at the fastest CAGR from 2025 to 2032, driven by rising demand for advanced packaging materials, automotive lightweighting, and increased use of high-performance plastics in construction and healthcare sectors. Regulatory support for recyclable materials, coupled with strong innovation in polymer technologies, is accelerating market growth. The region's focus on sustainability and product performance is boosting demand for metallocene-based polyethylene and polypropylene

U.S. Metallocene Polyolefin Market Insight

The U.S. metallocene polyolefin market captured the largest revenue share in 2024 within North America, supported by the country’s robust packaging, automotive, and healthcare industries. Growing demand for sustainable packaging solutions, lightweight automotive components, and durable consumer goods is fueling adoption. U.S. producers are expanding capacity for metallocene-based products to meet increasing domestic demand for high-performance, recyclable polyolefins across various applications

Metallocene Polyolefin Market Share

The metallocene polyolefin industry is primarily led by well-established companies, including:

- Henkel AG & Co. KGAA (Germany)

- Polycast Industries Inc. (India)

- 3M (U.S.)

- Dow (U.S.)

- DuPont (U.S.)

- Wacker Chemie AG (Germany)

- Momentive Performance Materials Inc. (U.S.)

- Shin-Etsu Chemical Company Ltd. (Japan)

- Evonik Industries AG (Germany)

- Exxon Mobil Corporation. (U.S.)

- Total (France)

- LyondellBasell Industries Holdings B.V. (U.S.)

- Chevron Phillips Chemical Company LLC. (U.S.)

- SABIC (Saudi Arabia)

- Borealis AG. (Austria)

- LG Chem. (South Korea)

- Prime Polymer Co., Ltd. (Japan)

- INEOS AG (U.K.)

- GAIL (India) Limited. (India)

Latest Developments in Global Metallocene Polyolefin Market

- In August 2022, LyondellBasell, in collaboration with Röchling Medical, introduced eyedrop containers made from CirculenRenew polymers, which offer polyethylene and polypropylene grades equivalent to virgin resin quality. This development supports the growing demand for sustainable, high-performance polyolefins and enhances the adoption of recycled materials in the healthcare packaging sector, contributing to market expansion

- In May 2022, ExxonMobil announced the expansion of its olefinic elastomer production capacity at its Baytown, Texas facility, as part of a US$ 2 billion investment project. This capacity increase is expected to strengthen the supply of advanced polyolefin materials for automotive, construction, and packaging applications, supporting overall market growth

- In May 2022, Braskem committed over US$ 2 million to a joint project in the U.S., aimed at developing advanced recycling technology for complex packaging made from mixed inputs. This initiative aligns with the rising focus on circular economy practices and is expected to drive demand for sustainable, recyclable polyolefin materials in the packaging industry, positively impacting market growth

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Metallocene Polyolefin Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Metallocene Polyolefin Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Metallocene Polyolefin Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.