Global Mist Eliminators Market

Market Size in USD Billion

CAGR :

%

USD

2.05 Billion

USD

2.76 Billion

2024

2032

USD

2.05 Billion

USD

2.76 Billion

2024

2032

| 2025 –2032 | |

| USD 2.05 Billion | |

| USD 2.76 Billion | |

|

|

|

|

Mist Eliminators Market Size

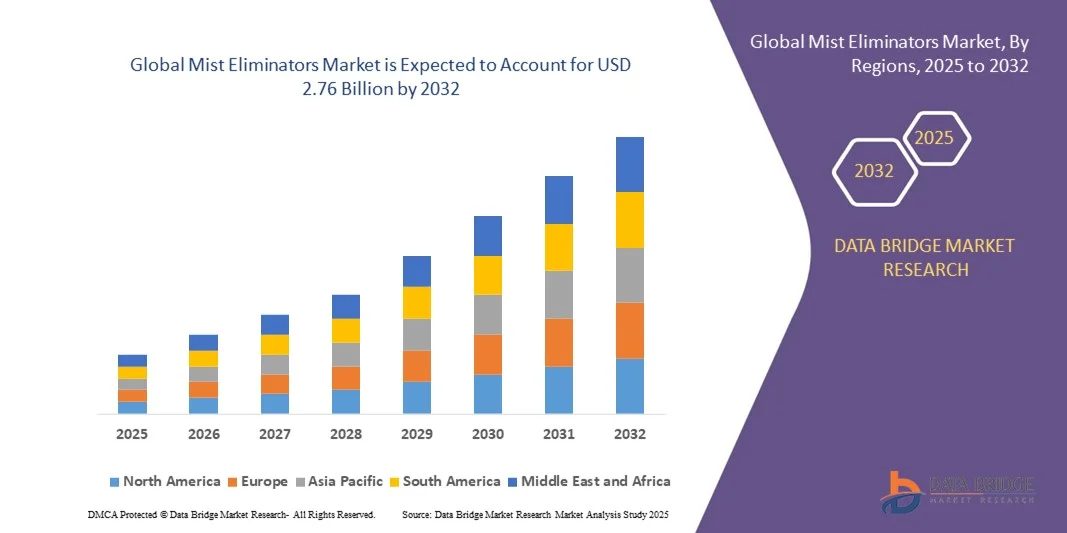

- The global mist eliminators market size was valued at USD 2.05 billion in 2024 and is expected to reach USD 2.76 billion by 2032, at a CAGR of 3.8% during the forecast period

- The market growth is largely fuelled by the increasing demand for high-efficiency separation solutions in chemical, petrochemical, and industrial gas processing plants, aimed at improving process efficiency and reducing equipment corrosion

- Rising focus on emission control, air quality, and regulatory compliance is further boosting adoption across industries, driving the need for reliable mist elimination technologies

Mist Eliminators Market Analysis

- Rising demand for high-efficiency separation solutions in chemical, petrochemical, and industrial gas processing plants is driving market growth. Mist eliminators improve operational efficiency, reduce corrosion, and prevent environmental contamination by capturing fine liquid droplets from gas streams

- Growing adoption of advanced materials and designs, such as vane-type, mesh-type, and fiber-bed mist eliminators, is enhancing performance, durability, and energy efficiency. These innovations allow industries to meet stricter environmental regulations and reduce maintenance costs

- Asia-Pacific dominated the mist eliminators market with the largest revenue share in 2024, driven by rapid industrialization, growing chemical and petrochemical production, and rising adoption of high-efficiency separation systems

- North America region is expected to witness the highest growth rate in the global mist eliminators market, driven by rising industrial output, focus on emission reduction, and adoption of energy-efficient mist elimination technologies

- The Wire Mesh segment held the largest market revenue share in 2024, driven by its high-efficiency droplet removal, ease of installation, and low maintenance requirements. Wire mesh mist eliminators are widely adopted in chemical processing, oil & gas, and power generation due to their versatility and cost-effectiveness

Report Scope and Mist Eliminators Market Segmentation

|

Attributes |

Mist Eliminators Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Mist Eliminators Market Trends

Increasing Adoption of High-Efficiency Mist Eliminators in Industrial Processes

- The growing use of mist eliminators is transforming industrial operations by improving the separation of liquid droplets from gas streams. These systems enhance operational efficiency, prevent equipment corrosion, reduce emissions in industries such as chemical processing, oil & gas, and power generation, and contribute to longer equipment lifespan. Enhanced droplet removal also minimizes process downtime, boosting overall plant productivity

- Rising demand for advanced separation technologies in refineries, petrochemical plants, and cooling towers is accelerating the adoption of wire mesh, vane, and fiber bed mist eliminators. These devices are particularly effective where droplet removal impacts safety, product quality, and environmental compliance. Improved gas-liquid separation also supports compliance with increasingly stringent emissions and safety regulations

- The ease of installation, low maintenance, and energy efficiency of modern mist eliminators make them attractive for plant operators across various sectors. Companies can achieve regulatory compliance and operational reliability without extensive retrofitting, reducing total cost of ownership. Modern designs also allow integration into existing systems with minimal operational disruption

- For instance, in 2023, several chemical plants in North America and Europe reported reduced corrosion rates, lower maintenance costs, and improved system uptime after implementing high-efficiency mist eliminators in process streams. Enhanced safety protocols and reduced downtime directly contributed to increased production efficiency and compliance with environmental standards

- While mist eliminators are driving enhanced process efficiency and regulatory compliance, their impact depends on continued innovation, material selection, and proper design. Manufacturers must focus on durable, energy-efficient, and application-specific solutions to fully capitalize on market growth. Adoption also requires continuous monitoring, performance testing, and optimization for different industrial environments

Mist Eliminators Market Dynamics

Driver

Rising Need for Process Efficiency and Emission Control in Industries

Increasing awareness about environmental compliance and process safety is driving the adoption of mist eliminators in chemical, petrochemical, and power generation plants. Efficient removal of mist droplets reduces equipment damage, improves operational efficiency, ensures compliance with emissions standards, and prevents hazardous emissions. This contributes to safer and more sustainable industrial operations

Industries are increasingly seeking cost-effective and reliable solutions for liquid-gas separation, boosting demand for high-performance mist eliminators such as mesh pads, vane packs, and fiber bed units. Enhanced separation reduces product loss, lowers operational costs, and improves overall process reliability. These solutions also support adherence to stricter environmental and safety regulations

Technological advancements, including corrosion-resistant materials and optimized designs, are further supporting adoption in high-temperature and high-pressure applications, improving system longevity and reducing operational costs. Innovations such as self-cleaning or modular mist eliminators enhance flexibility and reduce maintenance requirements, providing long-term operational benefits

For instance, in 2022, several oil refineries in Asia implemented wire mesh and vane mist eliminators, resulting in significant reductions in equipment downtime, improved product quality, and better compliance with regulatory standards. These improvements also helped optimize energy usage and lower operational risks

While demand is increasing, ensuring proper design, maintenance, and material compatibility remains crucial for maximizing efficiency and sustaining long-term adoption. Continuous R&D, operator training, and process monitoring are key to achieving consistent performance and reliability across diverse industrial applications

Restraint/Challenge

High Capital Cost and Maintenance Requirements for Advanced Mist Eliminators

- Advanced mist eliminator systems often require significant upfront investment, making them less accessible for smaller or cost-sensitive industrial operations. High installation costs can limit rapid adoption, particularly in emerging markets, and may delay return on investment. This can also restrict the implementation of advanced mist elimination technologies in retrofit projects

- Regular maintenance, including cleaning and replacement of mesh pads or vanes, is required to ensure consistent performance. Lack of trained personnel, limited maintenance infrastructure, and process interruptions in certain regions can reduce operational efficiency. Inadequate maintenance may also lead to reduced separation efficiency and increased emissions

- Supply chain constraints for specialized materials, such as corrosion-resistant alloys and high-performance fibers, may lead to delays and higher costs, restricting large-scale implementation. Limited availability of key components can affect timely production and increase overall project expenses

- For instance, in 2023, several chemical and petrochemical facilities in Sub-Saharan Africa reported extended downtime, increased maintenance costs, and process interruptions due to delayed replacement of high-efficiency mist eliminator components. This affected production schedules and compliance with safety and environmental standards

- While mist elimination technology continues to evolve, addressing cost, maintenance, and supply chain challenges is critical. Stakeholders must focus on durable, energy-efficient, scalable, and easily maintainable solutions to unlock long-term market potential, ensuring consistent performance across diverse industrial environments

Mist Eliminators Market Scope

The mist eliminators market is segmented on the basis of type, technology, material, application, end-use, and industry vertical.

- By Type

On the basis of type, the mist eliminators market is segmented into Wire Mesh, Vane, Fiber Bed, Cyclone, Baffle, and Others. The Wire Mesh segment held the largest market revenue share in 2024, driven by its high-efficiency droplet removal, ease of installation, and low maintenance requirements. Wire mesh mist eliminators are widely adopted in chemical processing, oil & gas, and power generation due to their versatility and cost-effectiveness.

The Vane segment is expected to witness the fastest growth rate from 2025 to 2032, driven by its superior performance in high-velocity gas streams and enhanced droplet separation. Vane mist eliminators are gaining traction in cooling towers, scrubbers, and separators, where high-efficiency mist removal improves operational safety and compliance with environmental regulations.

- By Technology

On the basis of technology, the market is segmented into Brownian Diffusion, Direct Interception, and Inertial Impaction. The Inertial Impaction segment held the largest revenue share in 2024, attributed to its effectiveness in capturing larger mist droplets in high-flow industrial processes. Inertial impaction is particularly favored in oil & gas and chemical industries for its reliability in reducing equipment corrosion and improving process efficiency.

The Brownian Diffusion segment is expected to witness the fastest growth rate from 2025 to 2032, driven by increasing adoption in fine mist and nanoparticle separation applications. This technology is gaining attention in high-precision processes where smaller particle capture is critical for regulatory compliance and product quality.

- By Material

On the basis of material, the market is segmented into Metal, PP, FRP, and Others. The Metal segment held the largest market share in 2024, driven by its durability, high-temperature resistance, and long service life. Metal mist eliminators are widely implemented in chemical plants, refineries, and power generation facilities for efficient and reliable mist removal.

The PP segment is expected to witness the fastest growth rate from 2025 to 2032, fueled by the increasing use of cost-effective, corrosion-resistant polypropylene materials in industrial applications. PP mist eliminators are particularly favored in wastewater treatment, desalination plants, and low-temperature chemical processes due to their affordability and chemical stability.

- By Application

On the basis of application, the market is segmented into Distillation, Crystallizers, Dehydrator, Evaporator, Cooling Towers, Knockout Drum, Scrubber, Separators, Gas Cleaning, Absorbers, Absolution, and Others. The Cooling Towers segment held the largest market revenue share in 2024, owing to the critical need for droplet removal to improve heat exchange efficiency and reduce environmental emissions.

The Scrubber segment is expected to witness the fastest growth rate from 2025 to 2032, driven by stringent environmental regulations and rising adoption of air pollution control technologies across industrial sectors. Scrubbers with mist eliminators enhance gas cleaning efficiency and ensure compliance with emission standards.

- By End Use

On the basis of end-use, the market is segmented into Mist Removal, Pollution Control, and Improvement of Impurity Separation. The Mist Removal segment held the largest revenue share in 2024, fueled by its essential role in maintaining equipment safety, reducing corrosion, and enhancing operational efficiency in industrial processes.

The Pollution Control segment is expected to witness the fastest growth rate from 2025 to 2032, driven by the increasing focus on environmental protection and regulatory compliance. Industries are adopting mist eliminators to minimize harmful emissions and improve sustainability practices.

- By Industry Vertical

On the basis of industry vertical, the market is segmented into Oil and Gas, Desalination, Power Generation, Chemical, Paper and Pulp, and Others. The Oil and Gas segment held the largest market share in 2024, attributed to the high demand for efficient droplet separation in refineries, petrochemical plants, and gas processing units.

The Desalination segment is expected to witness the fastest growth rate from 2025 to 2032, driven by the rising need for efficient mist removal in seawater desalination plants. Mist eliminators in this sector enhance water recovery, improve equipment lifespan, and ensure process efficiency.

Mist Eliminators Market Regional Analysis

- Asia-Pacific dominated the mist eliminators market with the largest revenue share in 2024, driven by rapid industrialization, growing chemical and petrochemical production, and rising adoption of high-efficiency separation systems

- Industrial operators in the region highly value the ability of mist eliminators to reduce corrosion, improve process efficiency, and ensure compliance with stringent environmental regulations

- This widespread adoption is further supported by increasing investments in manufacturing infrastructure, government initiatives promoting industrial safety, and rising awareness of emission control, establishing mist eliminators as a preferred solution across multiple sectors

China Mist Eliminators Market Insight

The China mist eliminators market captured the largest revenue share in 2024 within Asia-Pacific, fueled by expanding chemical, petrochemical, and power generation industries. High demand for efficient liquid-gas separation, along with government policies enforcing environmental compliance, is driving adoption. The availability of cost-effective, high-efficiency mist eliminator solutions and the presence of domestic manufacturers are key factors supporting growth across industrial applications.

Japan Mist Eliminators Market Insight

The Japan mist eliminators market is expected to witness rapid growth from 2025 to 2032 due to the country’s technologically advanced industrial sector, focus on emission control, and need for reliable droplet separation. Industries are increasingly implementing fiber bed, vane, and wire mesh mist eliminators to improve operational efficiency and reduce corrosion in process streams. Japan’s strong emphasis on industrial safety, automation, and sustainability is expected to drive adoption of advanced mist elimination systems.

North America Mist Eliminators Market Insight

The North America mist eliminators market is expected to witness steady growth from 2025 to 2032, driven by increasing adoption of high-efficiency separation systems in chemical, petrochemical, and power generation industries. Industrial operators in the region highly value the ability of mist eliminators to reduce corrosion, improve process efficiency, and ensure compliance with environmental regulations. Advanced industrial infrastructure, strict emission norms, and growing awareness of operational safety are supporting adoption across multiple sectors.

U.S. Mist Eliminators Market Insight

The U.S. mist eliminators market is expected to witness the fastest growth rate from 2025 to 2032, fueled by the demand for optimized liquid-gas separation systems in oil refineries, chemical plants, and cooling towers. Industries are prioritizing the reduction of equipment downtime, maintenance costs, and emissions through high-efficiency mesh, vane, and fiber bed eliminators. The trend of retrofitting existing plants with energy-efficient solutions and compliance with federal emission standards further drives market expansion.

Europe Mist Eliminators Market Insight

The Europe mist eliminators market is expected to witness growth from 2025 to 2032, driven by strict environmental regulations, industrial modernization, and the need for reliable droplet separation in power generation and chemical processing. European companies are increasingly implementing advanced vane, wire mesh, and fiber bed eliminators to maintain process safety and optimize operational efficiency. The region is experiencing growth across chemical, oil & gas, and industrial process applications, with retrofitting and new installations fueling demand.

U.K. Mist Eliminators Market Insight

The U.K. mist eliminators market is expected to witness growth from 2025 to 2032 due to increasing industrial automation, environmental compliance mandates, and a focus on reducing operational hazards. Industries are investing in high-performance mist elimination systems to improve process reliability and minimize emissions. The presence of a strong chemical and petrochemical sector, coupled with technological upgrades in energy and manufacturing plants, is expected to support continuous market growth.

Germany Mist Eliminators Market Insight

The Germany mist eliminators market is projected to witness growth from 2025 to 2032, fueled by stringent emission control regulations, industrial expansion, and demand for advanced separation technologies. German industries emphasize durable and energy-efficient mist eliminators to reduce maintenance costs and optimize plant operations. The integration of corrosion-resistant materials and modern designs in mist elimination systems aligns with the country’s focus on sustainability and industrial efficiency.

Mist Eliminators Market Share

The Mist Eliminators industry is primarily led by well-established companies, including:

- Filtermist International Limited (U.K.)

- Amacs Process Towers Internals (U.K.)

- Munters AB (Sweden)

- Hilliard Corporation (U.S.)

- Koch Engineered Solutions (U.S.)

- Sulzer Ltd (Switzerland)

- DuPont (U.S.)

- Boegger Industrial Limited (U.K.)

- REA Plastik Tech GmbH (Germany)

- Agilis Technologies (U.S.)

- Sullair, LLC (U.S.)

- Kimre, Inc. (U.S.)

- Air Quality Engineering (U.S.)

- KCH Services, Inc. (U.S.)

- Coastal Technologies, Inc. (U.S.)

- Okutani Ltd. (Japan)

- MMAQUA! (Germany)

- VARUN ENGINEERING (India)

- Chem Dist Process Solutions (U.S.)

- RVT Process Equipment GmbH (Germany)

- 3nine AB (Sweden)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.