Global Mixed Xylenes Market

Market Size in USD Billion

CAGR :

%

USD

60.57 Billion

USD

77.33 Billion

2024

2032

USD

60.57 Billion

USD

77.33 Billion

2024

2032

| 2025 –2032 | |

| USD 60.57 Billion | |

| USD 77.33 Billion | |

|

|

|

|

Mixed Xylene Market Size

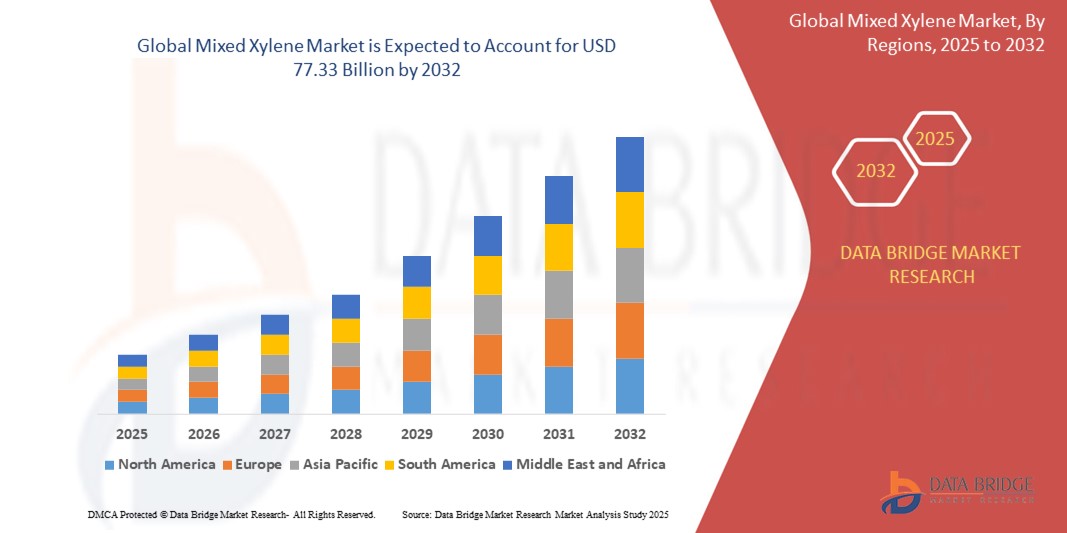

- The global mixed xylene market size was valued at USD 60.57 billion in 2024 and is expected to reach USD 77.33 billion by 2032, at a CAGR of 3.10% during the forecast period

- The market growth is primarily driven by increasing demand for mixed xylene in various industrial applications, particularly in the production of paints, coatings, and chemicals, fueled by rapid industrialization and urbanization globally

- Rising consumer preference for high-performance solvents and raw materials in manufacturing processes is further propelling the adoption of mixed xylene, establishing it as a critical component in multiple industries

Mixed Xylene Market Analysis

- Mixed xylene, a mixture of three isomers (ortho-xylene, meta-xylene, and para-xylene), is a vital chemical used in solvents, fuel blending, and as a raw material for producing chemicals such as terephthalic acid and phthalic anhydride

- The escalating demand for mixed xylene is driven by its widespread use in the paints and coatings industry, growing chemical manufacturing sectors, and increasing applications in fuel blending due to its high octane rating

- Asia-Pacific dominated the mixed xylene market with the largest revenue share in 2024, attributed to rapid industrialization, large-scale chemical production, and high demand from the paints and coatings sector, particularly in countries such as China and India

- North America is expected to be the fastest-growing region during the forecast period, driven by advancements in chemical manufacturing, increasing demand for high-quality solvents, and expanding applications in the gasoline and petrochemical industries

- The isomer grade segment dominates the largest market revenue share of 70.0% in 2024, driven by its extensive use in the production of para-xylene, a key precursor for polyethylene terephthalate (PET) plastics used in packaging and textiles

Report Scope and Mixed Xylene Market Segmentation

|

Attributes |

Mixed Xylene Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Mixed Xylene Market Trends

“Rising Preference for Isomer-Grade Mixed Xylene”

- somer-grade mixed xylene is increasingly preferred due to its high purity and efficiency in producing paraxylene, a key raw material for polyester and PET resin manufacturing

- These grades offer superior chemical stability, making them ideal for high-performance applications in the chemical and plastics industries

- In regions with growing industrial activity, such as Asia-Pacific, isomer-grade mixed xylene is favored for its role in producing durable, high-quality materials

- Major chemical manufacturers are incorporating isomer-grade mixed xylene into their production processes to meet the rising demand for sustainable and high-strength polymers

- For instance, companies such as Reliance Industries in India offer isomer-grade mixed xylene as a premium product to support advanced manufacturing needs

- Distributors and suppliers are increasingly bundling isomer-grade mixed xylene with value-added services to attract industrial buyers

Mixed Xylene Market Dynamics

Driver

“Rising Demand for High-Performance Chemicals and Polymers”

- Growing consumer and industrial demand for high-quality plastics, polyesters, and coatings is driving the need for mixed xylene, particularly isomer-grade, as a critical raw material

- Mixed xylene enhances the production of paraxylene, which is essential for manufacturing PET bottles, textiles, and packaging materials, improving product durability and performance

- The expansion of industries such as automotive, packaging, and textiles, especially in Asia-Pacific, is boosting the demand for mixed xylene in solvent and raw material applications

- Manufacturers are responding by increasing production capacity or partnering with mixed xylene suppliers to ensure a steady supply for downstream industries

- For instance, ExxonMobil has expanded its production of mixed xylene to support the growing demand for chemicals in high-growth markets such as Asia-Pacific

- The rise of sustainable packaging and lightweight materials in electric vehicle manufacturing is further fueling the adoption of mixed xylene for producing energy-efficient and eco-friendly products

Restraint/Challenge

“Regulatory Restrictions on Volatile Organic Compounds (VOCs)”

- Stringent environmental regulations on VOC emissions limit the use of solvent-grade mixed xylene in applications such as paints, coatings, and thinners, affecting market growth

- Different countries have varying VOC standards, complicating compliance for manufacturers and distributors operating globally

- Excessive use of solvent-grade mixed xylene is often viewed as an environmental risk due to its contribution to air pollution and health concerns

- For instance, regulations in the European Union and North America require low-VOC formulations, restricting the use of solvent-grade mixed xylene in certain applications

- These strict regulations discourage the use of mixed xylene in aftermarket applications and may result in penalties, deterring some potential buyers and limiting market expansion

Mixed Xylene Market Scope

The market is segmented on the basis of grade, application, and end use.

- By Grade

On the basis of grade, the mixed xylene market is segmented into isomer grade and solvent grade. The isomer grade segment dominates the largest market revenue share of 70.0% in 2024, driven by its extensive use in the production of para-xylene, a key precursor for polyethylene terephthalate (PET) plastics used in packaging and textiles. Isomer grade mixed xylene is favored for its high purity and compatibility with petrochemical processes, particularly in the production of terephthalic acid (PTA)

The solvent grade segment is anticipated to witness the fastest growth rate of 7.5% from 2025 to 2032, fueled by increasing demand in paints, coatings, adhesives, and other industrial applications. Solvent grade mixed xylene is valued for its excellent solvency properties and ability to reduce drying rates, making it ideal for formulating high-performance paints and coatings used in automotive, construction, and industrial sectors.

- By Application

On the basis of application, the mixed xylene market is segmented into fuel blending, solvents, thinners, and raw material. The raw material segment held the largest market revenue share of 83.4% in 2024, driven by its critical role as a feedstock in the production of para-xylene, ortho-xylene, and meta-xylene isomers, which are essential for manufacturing PET, phthalic anhydride, and other chemicals. The rising global demand for polyester fibers and plastics, particularly in textiles and packaging, significantly contributes to this segment's dominance.

The solvents segment is expected to witness the fastest CAGR of 7.8% from 2025 to 2032, driven by its widespread use in paints, coatings, adhesives, and cleaning agents. The rapid expansion of the construction and automotive industries, coupled with the need for high-performance solvents, fuels the growth of this segment, particularly in emerging economies with increasing industrialization.

- By End Use

On the basis of end use, the mixed xylene market is segmented into paints and coatings, pesticides, chemicals, gasoline, printing, rubber and leather, and others. The chemicals segment accounted for the largest market revenue share of 82.6% in 2024, driven by the extensive use of mixed xylene as a raw material in the production of terephthalic acid (PTA) and other chemical intermediates for plastics and polymers. The growing demand for PET in packaging and textiles, along with advancements in petrochemical processes, supports this segment's leading position.

The paints and coatings segment is expected to witness the fastest CAGR of 8.2% from 2025 to 2032, propelled by the increasing demand for high-performance paints, varnishes, and coatings in construction, automotive, and industrial applications. The expansion of urbanization and infrastructure development in emerging markets, along with the need for durable and aesthetically appealing finishes, drives the adoption of mixed xylene in this segment.

Mixed Xylene Market Regional Analysis

- Asia-Pacific dominated the mixed xylene market with the largest revenue share in 2024, attributed to rapid industrialization, large-scale chemical production, and high demand from the paints and coatings sector, particularly in countries such as China and India

- North America is expected to be the fastest-growing region during the forecast period, driven by advancements in chemical manufacturing, increasing demand for high-quality solvents, and expanding applications in the gasoline and petrochemical industries

U.S. Mixed Xylene Market Insight

The U.S. mixed xylene market is poised for steady growth during the forecast period, driven by the robust demand for polyester-based products and the expanding paints and coatings sector. The automotive and construction industries, which rely heavily on mixed xylene as a solvent, are key contributors to market growth. Furthermore, the U.S.'s strong chemical manufacturing base and investments in shale gas exploration are ensuring a stable supply of raw materials, fostering market expansion. The adoption of innovative production processes to meet environmental regulations is also shaping the market positively.

Europe Mixed Xylene Market Insight

The European mixed xylene market is projected to grow at a steady CAGR during the forecast period, driven by the region's strong chemical and automotive industries. Stringent environmental regulations and a focus on sustainable production methods are encouraging the adoption of high-quality mixed xylene in eco-friendly applications. The demand for mixed xylene in the production of polyester fibers and as a solvent in industrial coatings is rising, particularly in countries such as Germany and the U.K. The region's emphasis on circular economy practices and advancements in chemical recycling technologies further supports market growth.

U.K. Mixed Xylene Market Insight

The U.K. mixed xylene market is anticipated to grow at a considerable CAGR, driven by the rising demand for polyester fibers and coatings in the textile and construction industries. The country's focus on sustainable chemical production and its robust e-commerce and retail infrastructure are facilitating market growth. In addition, the increasing use of mixed xylene in automotive applications, such as high-performance paints, is boosting demand. The U.K.'s commitment to reducing carbon emissions and adopting eco-friendly solvents is further propelling the market.

Germany Mixed Xylene Market Insight

The German mixed xylene market is expected to expand at a notable CAGR, fueled by the country's leadership in the chemical and automotive sectors. The increasing use of mixed xylene in high-performance coatings and polyester production aligns with Germany's focus on innovation and sustainability. The country's well-developed industrial infrastructure and commitment to green chemistry are driving the adoption of mixed xylene in environmentally conscious applications. In addition, the integration of mixed xylene in advanced manufacturing processes is contributing to its growing demand in both residential and commercial sectors.

Asia-Pacific Mixed Xylene Market Insight

The Asia-Pacific mixed xylene market is poised to grow at the fastest CAGR of over 7% in 2025, driven by rapid industrialization, urbanization, and the expanding petrochemical sector in countries such as China, India, and Japan. The region's dominance in polyester production, coupled with rising demand for paints, coatings, and adhesives, is fueling market growth. Government initiatives promoting industrial development and the availability of cost-effective raw materials are enhancing the affordability and accessibility of mixed xylene. The region's emergence as a manufacturing hub for petrochemical products further supports market expansion.

Japan Mixed Xylene Market Insight

The Japan mixed xylene market is gaining momentum due to the country's advanced chemical industry and high demand for polyester-based products. The integration of mixed xylene in the production of high-performance coatings and adhesives, particularly in the automotive and electronics sectors, is driving growth. Japan's focus on technological innovation and sustainability is fostering the adoption of eco-friendly solvents and materials. In addition, the country's aging infrastructure and increasing renovation activities are spurring demand for mixed xylene in construction-related applications.

China Mixed Xylene Market Insight

The China mixed xylene market accounted for the largest revenue share in the Asia-Pacific region in 2025, driven by the country's massive petrochemical industry and rapid urbanization. The growing demand for polyester fibers, resins, and solvents in the textile, automotive, and construction sectors is a key growth driver. China's focus on developing smart cities and its strong domestic manufacturing base for petrochemical products are propelling the market. In addition, the availability of affordable mixed xylene and advancements in production technologies are expanding its adoption across various applications.

Mixed Xylene Market Share

The mixed xylene industry is primarily led by well-established companies, including:

- Exxon Mobil Corporation (U.S.)

- Flint Hills Resources (U.S.)

- PTT Global Chemical Public Company Limited (Thailand)

- Reliance Industries Limited (India)

- BASF SE (Germany)

- Merck KGaA (Germany)

- Braskem (Brazil)

- Honeywell International Inc. (U.S.)

- Formosa Chemicals & Fibre Corp. (Taiwan)

- SK geo centric Co., Ltd (South Korea)

- LOTTE Chemical CORPORATION (South Korea)

- MP Biomedicals (U.S.)

- Huntsman International LLC (U.S.)

- NUTAN CHEMICALS (India)

- Tokyo Chemical Industry (India) Pvt. Ltd. (Japan)

What are the Recent Developments in Global Mixed Xylene Market?

- In April 2023, BioBTX B.V. and Agilyx ASA announced a strategic partnership to scale up BioBTX’s renewable aromatics technology. This collaboration integrates Agilyx’s pyrolysis process with BioBTX’s catalytic conversion, enabling the production of sustainable benzene, toluene, and xylene (BTX) from post-consumer plastic waste. The initiative aims to establish a commercial demonstration plant, supporting the global demand for eco-friendly chemical solutions. The partnership reinforces circular economy principles, advancing renewable carbon sourcing for industrial applications

- In January 2023, Reliance Industries Limited (RIL) kept the Mixed Xylene (MX) price steady at INR 78/kg (approximately USD 1/kg) in the Indian market. This consistent pricing strategy aims to support stable demand growth, particularly in PET production and solvent applications. By maintaining a competitive rate, RIL reinforces its strong market position in the Asia-Pacific region, ensuring cost-effective supply for industrial consumers. The decision aligns with global trends in xylene pricing, contributing to market stability.

- In April 2021, Indian Oil Corporation Limited (IOCL) awarded a million EPCC contract to Tecnimont Private Limited for an integrated paraxylene (PX) and purified terephthalic acid (PTA) facility in Paradip, Odisha. The project aims to produce 800 kilotons of PX annually, supporting mixed xylene supply for PTA production and addressing the growing demand for PET in packaging and textiles. The facility is expected to be operational by 2024, reinforcing India’s petrochemical industry

- In September 2021, Mitsubishi Gas Chemical (MGC) announced the expansion of meta-xylenediamine (MXDA) production in Europe, addressing rising demand in epoxy, polyamide, and isocyanate sectors. The company is constructing a 25,000 MTA plant in Rotterdam through its new subsidiary, MGC Specialty Chemicals Netherlands B.V., with operations set to begin in mid-2024. MXDA is widely used in epoxy coatings for infrastructure applications, offering excellent anticorrosion properties. The expansion strengthens MGC’s global market presence, ensuring stable supply worldwide

- In January 2021, INEOS completed the $5 billion acquisition of BP’s global Aromatics & Acetyls division, expanding its petrochemical portfolio and market reach. The deal includes 15 manufacturing sites worldwide and 10 joint ventures, strengthening INEOS’s presence in the polyester and acetyls industries. The newly integrated businesses, INEOS Aromatics and INEOS Acetyls, enhance global supply chains for PTA, PX, acetic acid, and derivatives, supporting food, pharmaceuticals, paints, adhesives, and packaging sectors

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Mixed Xylenes Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Mixed Xylenes Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Mixed Xylenes Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.