Global Nickel Alloy Market

Market Size in USD Billion

CAGR :

%

USD

13.96 Billion

USD

21.58 Billion

2024

2032

USD

13.96 Billion

USD

21.58 Billion

2024

2032

| 2025 –2032 | |

| USD 13.96 Billion | |

| USD 21.58 Billion | |

|

|

|

|

Nickel Alloy Market Size

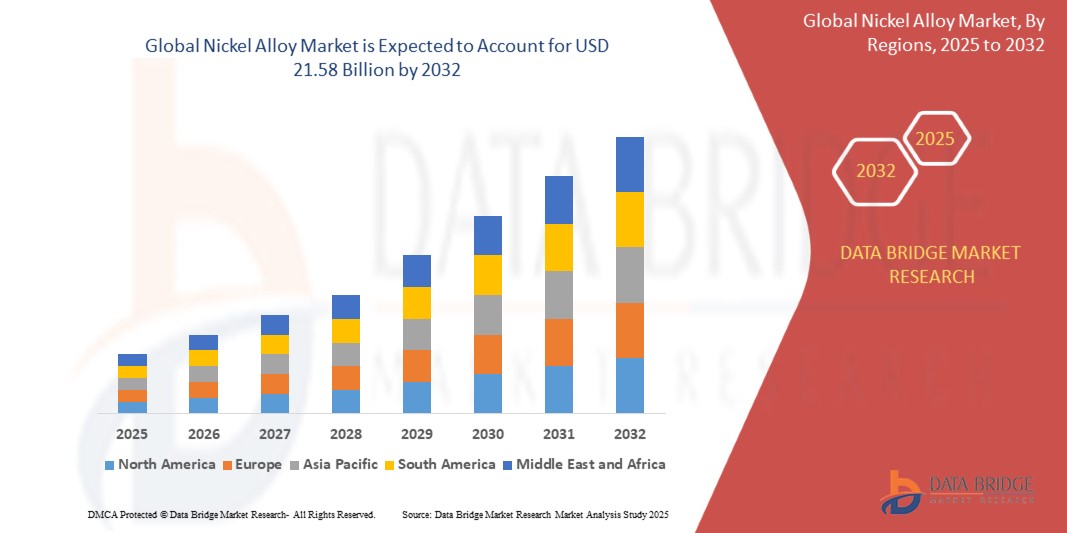

- The global nickel alloy market size was valued at USD 13.96 billion in 2024 and is expected to reach USD 21.58 billion by 2032, at a CAGR of 5.59% during the forecast period

- The market growth is largely fueled by the rising demand for high-performance materials with superior strength, heat resistance, and corrosion resistance across industries such as aerospace, energy, chemical, and automotive. Increasing investments in renewable energy, electric vehicles, and advanced manufacturing are driving the need for reliable nickel-based alloys that perform under extreme conditions

- Furthermore, technological advancements in alloy design, additive manufacturing, and precision engineering are expanding the application scope of nickel alloys in critical components, boosting market expansion globally

Nickel Alloy Market Analysis

- Nickel alloys are high-performance materials composed primarily of nickel combined with other elements such as chromium, iron, molybdenum, titanium, and cobalt, offering exceptional mechanical strength, corrosion resistance, and thermal stability. These alloys are widely used in demanding environments across energy, aerospace, marine, chemical processing, and automotive industries

- The escalating demand for nickel alloys is primarily fueled by rapid industrialization, growing focus on energy efficiency, and the increasing requirement for materials capable of withstanding high temperatures, harsh chemicals, and corrosive environments in critical infrastructure and advanced technologies

- Asia-Pacific dominated the nickel alloy market with a share of 72.5% in 2024, due to significant industrial expansion, rapid urbanization, and strong demand from energy, aerospace, and chemical sectors

- Europe is expected to be the fastest growing region in the nickel alloy market during the forecast period due to increasing demand for sustainable, high-performance materials in aerospace, energy, and automotive industries

- Heat resistant segment dominated the market with a market share of 38.7% in 2024, due to increasing demand for alloys that maintain structural stability and mechanical properties under elevated temperatures. These alloys play a crucial role in aerospace engines, industrial furnaces, and power plants where components face prolonged exposure to extreme heat. Their ability to resist thermal deformation, oxidation, and creep ensures operational safety and efficiency in high-temperature environments

Report Scope and Nickel Alloy Market Segmentation

|

Attributes |

Nickel Alloy Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Nickel Alloy Market Trends

“Rising Adoption of Nickel Superalloys for 3D Printing”

- A significant and accelerating trend in the global nickel alloy market is the rising adoption of nickel-based superalloys for 3D printing applications such as aerospace, energy, and semiconductor manufacturing

- For instance, companies such as EOS and Alloyed Ltd. are introducing high-performance nickel superalloy powders specifically designed for additive manufacturing, enabling the production of complex, defect-resistant components for critical environments

- The integration of nickel superalloys with advanced 3D printing methods such as Laser Powder Bed Fusion (LPBF) and Electron Beam Melting (EBM) is driving innovation in part design, material efficiency, and rapid prototyping

- Nickel superalloys offer properties such as superior mechanical strength, thermal stability, and corrosion resistance, making them ideal for applications in jet engines, power generation, and deep-sea exploration

- This trend toward additive manufacturing is fundamentally reshaping supply chains and manufacturing strategies in industries that require high-performance materials. Companies such as UC Santa Barbara and Oak Ridge National Laboratory are developing new alloy compositions to overcome traditional processing limitations

- The demand for 3D printable nickel superalloys is growing rapidly across both established and emerging sectors, as manufacturers increasingly prioritize material performance, design flexibility, and sustainability in production processes

Nickel Alloy Market Dynamics

Driver

“Economic Growth and Industrialization”

- The expansion of global economic activity and rapid industrialization, particularly in emerging markets, is a significant driver for the increased demand for nickel alloys

- For instance, Voestalpine and Nippon Yakin Kogyo are investing in advanced production facilities and new product lines to supply high-performance nickel alloys for infrastructure, transportation, and energy projects

- As countries develop, the need for materials with high strength, durability, and resistance to extreme environments is driving the adoption of nickel alloys in sectors such as aerospace, automotive, chemical processing, and power generation

- The shift toward modernization and technological advancement is making nickel alloys essential for critical applications such as turbine engines, heat exchangers, and industrial machinery

- The convenience of using nickel alloys in a wide range of industrial applications, coupled with their recyclability and compliance with environmental regulations, is propelling market growth. The rise of electric vehicles and renewable energy infrastructure further contributes to the expanding use of nickel alloys in battery and component manufacturing

Restraint/Challenge

“Fluctuating Raw Material Prices”

- Concerns surrounding the volatility of nickel prices, which serve as the primary raw material for nickel alloys, pose a significant challenge to cost management and market stability

- For instance, fluctuations in global nickel supply and demand, influenced by factors such as mining output, geopolitical tensions, and economic cycles, have led to unpredictable pricing for nickel alloys and related products

- Addressing these challenges through long-term supply agreements, diversified sourcing strategies, and investment in recycling technologies is crucial for maintaining profitability and competitiveness. Companies such as CF Industries and Orica are emphasizing risk management and transparent procurement practices in response to price volatility

- The high cost and complexity of nickel extraction, refining, and alloying processes can be a barrier for smaller manufacturers and new entrants, impacting overall market accessibility

- Overcoming these challenges through industry collaboration, adoption of alternative materials, and ongoing engagement with suppliers and regulators will be vital for sustained market growth and resilience in the face of raw material price fluctuations

Nickel Alloy Market Scope

The market is segmented on the basis of product, form, function, and application.

- By Product

On the basis of product, the nickel alloy market is segmented into Nickel-Chromium-Iron Alloys, Nickel-Chromium Alloys, Nickel-Chromium-Molybdenum Alloys, Wrought Nickel, Nickel-Chromium-Cobalt Alloys, Nickel-Copper Alloys, Nickel-Iron Alloys, Nickel-Molybdenum Alloys, and Nickel-Titanium Alloys. The Nickel-Chromium-Iron Alloys segment dominated the largest market revenue share in 2024, driven by their extensive use in heat exchangers, pressure vessels, and nuclear reactors due to their superior corrosion resistance and mechanical strength. Their ability to maintain structural integrity under extreme temperatures and harsh environments makes them highly suitable for critical infrastructure in energy and power generation sectors. Moreover, these alloys exhibit excellent oxidation resistance, contributing to their widespread demand in aerospace and industrial applications.

The Nickel-Titanium Alloys segment is anticipated to witness the fastest growth rate from 2025 to 2032, primarily fueled by rising demand for shape memory alloys in medical devices and aerospace components. Nickel-Titanium alloys, commonly known as Nitinol, offer unique properties such as superelasticity and shape memory effect, making them highly desirable for applications such as stents, guidewires, actuators, and high-performance aerospace assemblies. The ongoing advancements in minimally invasive surgical procedures and the growing trend towards lightweight, high-strength materials in the aviation sector further accelerate the adoption of Nickel-Titanium alloys.

- By Form

On the basis of form, the nickel alloy market is segmented into Bar, Rods, Tubing, Plate, Sheets, Wire, Billets, Pipe, Ingots, Strips, Flanges, Ball, Angles, Pipe Fittings, Channels, Coils, and Forgings. The Plate segment held the largest market revenue share in 2024, attributed to its widespread use in heat exchangers, pressure vessels, marine structures, and industrial equipment where high strength, corrosion resistance, and durability are critical. Nickel alloy plates offer excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, making them indispensable in offshore oil & gas, desalination, and chemical processing industries.

The Wire segment is expected to register the fastest CAGR from 2025 to 2032, driven by its growing application in electrical components, medical devices, and aerospace industries. Nickel alloy wires are widely utilized for their excellent electrical conductivity, thermal stability, and corrosion resistance in environments requiring high-performance connections or heating elements. Additionally, their role in producing stents, orthodontic devices, and electronic sensors is expanding, supported by ongoing innovations in medical technology and electronics manufacturing.

- By Function

On the basis of function, the nickel alloy market is segmented into High Performance and Electronics Grade, Heat Resistant, and Corrosion Resistant. The Heat Resistant segment accounted for the largest market revenue share of 38.7% in 2024, driven by increasing demand for alloys that maintain structural stability and mechanical properties under elevated temperatures. These alloys play a crucial role in aerospace engines, industrial furnaces, and power plants where components face prolonged exposure to extreme heat. Their ability to resist thermal deformation, oxidation, and creep ensures operational safety and efficiency in high-temperature environments.

The High Performance and Electronics Grade segment is projected to grow at the fastest rate from 2025 to 2032, fueled by the rising need for precision materials in semiconductor manufacturing, advanced electronics, and electric vehicle (EV) components. Electronics grade nickel alloys offer exceptional purity, controlled microstructure, and enhanced electrical and magnetic properties, making them ideal for critical applications in microchips, connectors, and battery systems. The ongoing digitalization and electrification trends globally are further propelling the demand for high-performance nickel alloys.

- By Application

On the basis of application, the nickel alloy market is segmented into Energy and Power, Aerospace and Defense, Chemical, Oil & Gas, Electrical and Electronics, Automotive, and Others. The Energy and Power segment dominated the largest market revenue share in 2024, supported by the increasing deployment of nickel alloys in nuclear reactors, gas turbines, and renewable energy systems. Their ability to withstand extreme temperatures, corrosive environments, and high mechanical stress ensures reliable performance in critical power generation infrastructure. As countries invest heavily in sustainable and resilient energy solutions, the demand for durable nickel alloys continues to grow.

The Aerospace and Defense segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by the aerospace industry's continuous focus on lightweight, high-strength, and heat-resistant materials to enhance fuel efficiency and performance. Nickel alloys are extensively utilized in jet engines, turbine blades, exhaust systems, and structural components where reliability under high-stress, high-temperature conditions is vital. Additionally, the increasing global defense spending and advancements in aircraft design further support the robust growth of nickel alloy consumption in this segment.

Nickel Alloy Market Regional Analysis

- Asia-Pacific dominated the nickel alloy market with the largest revenue share of 72.5% in 2024, driven by significant industrial expansion, rapid urbanization, and strong demand from energy, aerospace, and chemical sectors

- Countries such as China, India, Japan, and South Korea are investing heavily in infrastructure, renewable energy projects, and advanced manufacturing, fueling the consumption of high-performance nickel alloys

- The region’s robust automotive production and growing focus on lightweight, corrosion-resistant materials in aerospace and defense applications are also key factors supporting market dominance

China Nickel Alloy Market Insight

The China nickel alloy market accounted for the largest revenue share within Asia-Pacific in 2024, fueled by the country's leadership in steel production, rapid industrialization, and high demand for alloys in chemical processing, energy infrastructure, and electric vehicle manufacturing. China's government policies promoting renewable energy and large-scale investments in aerospace and defense sectors further drive the adoption of advanced nickel alloys. The presence of major domestic manufacturers and a strong export market contributes significantly to market growth.

Japan Nickel Alloy Market Insight

The Japan nickel alloy market is experiencing steady growth due to its strong presence in advanced manufacturing, aerospace, and electronics industries. Japan's emphasis on technological innovation, high-quality materials, and precision engineering creates strong demand for nickel alloys with superior corrosion resistance and high-temperature stability. The country’s push toward hydrogen energy, electric vehicles, and space exploration further elevates the use of specialized nickel alloys in critical applications.

Europe Nickel Alloy Market Insight

The Europe nickel alloy market is projected to grow at the fastest CAGR during the forecast period, driven by increasing demand for sustainable, high-performance materials in aerospace, energy, and automotive industries. Stringent environmental regulations, a strong focus on reducing emissions, and the region’s leadership in renewable energy infrastructure are accelerating the use of corrosion-resistant and heat-resistant nickel alloys. European industries are also investing in advanced materials for hydrogen storage, power generation, and electric mobility solutions, fostering market expansion.

Germany Nickel Alloy Market Insight

The Germany nickel alloy market is anticipated to witness substantial growth, supported by the country's strong engineering, automotive, and industrial base. Germany’s commitment to energy transition, decarbonization, and advanced manufacturing boosts demand for nickel alloys in renewable energy systems, EV production, and chemical processing equipment. The country's focus on technological advancement and sustainability is driving the adoption of high-performance alloys across critical industries.

U.K. Nickel Alloy Market Insight

The U.K. nickel alloy market is gaining traction due to increasing investments in aerospace, defense, and offshore wind energy sectors. Nickel alloys are essential for ensuring reliability and longevity in high-stress environments, aligning with the U.K.’s goals for sustainable infrastructure development. Growing demand for corrosion-resistant materials in oil & gas operations, alongside initiatives to expand renewable energy capacity, contributes to market growth.

Nickel Alloy Market Share

The nickel alloy industry is primarily led by well-established companies, including:

- AMETEK, Inc., (U.S.)

- Polymet, (U.S.)

- Ulbrich Stainless Steels and Special Metals Inc., (U.S.)

- NIPPON STEEL CORPORATION, (Japan)

- Acciaierie Valbruna S.p.a., (Italy)

- Rolled Alloys Inc., (U.S.)

- JLC Electromet Pvt. Ltd., (India)

- HAYNES INTERNATIONAL, (U.S.)

- thyssenkrupp AG, (Germany)

- voestalpine AG, (Austria)

- Alloy Wire International, (U.K.)

- Precision Castparts Corp., (U.S.)

- Aperam, (Luxembourg)

- ATI, (U.S.)

- Sandvik AB, (Sweden)

- CRS Holdings, LLC, (U.S.)

Latest Developments in Global Nickel Alloy Market

- In July 2024, X-Mining introduced a new Iron-Nickel-Cobalt Alloy Powder, enhancing the supply of advanced alloy materials for critical applications in aerospace, defense, and energy sectors. This launch is expected to strengthen the company’s position in high-performance alloy markets and support growing demand for lightweight, durable materials

- In July 2024, Aubert & Duval, in collaboration with Alloyed, unveiled the ABD-1000AM nickel superalloy, designed specifically for additive manufacturing. This development is anticipated to accelerate innovation in 3D printing of high-performance components, expanding the application scope of nickel alloys in aerospace, medical, and industrial sectors

- In June 2023, Rolled Alloys Inc. received a new certification, ISO 9001:2015/AS 9100:D, for its quality management system. This certification is specifically for the company's manufacturing and distribution of heavy metals mill products made from stainless steel and nickel alloys. The recognition highlights the company's commitment to quality, which is expected to boost its overall sales

- In September 2022, Hitachi Metals launched ADMUSTER C21P, a nickel-based alloy tailored for metal additive manufacturing, addressing the industry's rising need for alloys optimized for 3D printing. This product introduction is expected to drive market growth by enhancing material performance and design flexibility for complex components in high-temperature and corrosive environments

- In March 2021, Sandvik Additive Manufacturing and its subsidiary BEAMIT established a strategic partnership with Immensa Additive Manufacturing Group, a prominent AM solution provider in the MENA region. The aim is to broaden the range of advanced AM-based high-end components. This collaboration will utilize Sandvik's leading position in materials technology and metal powders, including nickel-based superalloys, specifically tailored for additive manufacturing

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Nickel Alloy Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Nickel Alloy Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Nickel Alloy Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.