Global Non Thermal Pasteurization In Juice Industry Market

Market Size in USD Million

CAGR :

%

USD

979.31 Million

USD

1,759.61 Million

2025

2033

USD

979.31 Million

USD

1,759.61 Million

2025

2033

| 2026 –2033 | |

| USD 979.31 Million | |

| USD 1,759.61 Million | |

|

|

|

|

Non-Thermal Pasteurization in Juice Industry Market Size

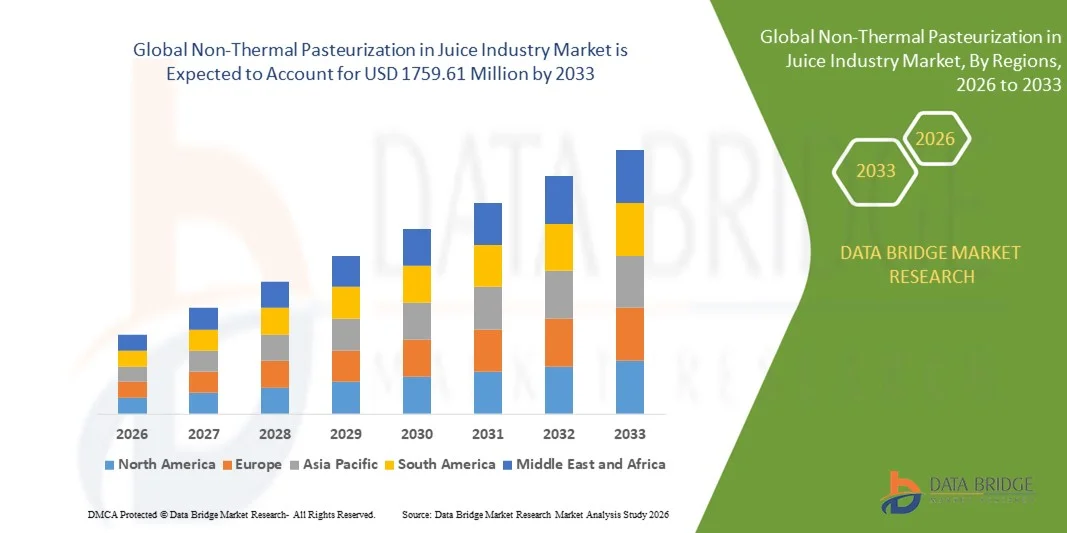

- The global non-thermal pasteurization in juice industry market size was valued at USD 979.31 million in 2025 and is expected to reach USD 1759.61 million by 2033, at a CAGR of 7.60% during the forecast period

- The market growth is largely fueled by the increasing demand for fresh, nutrient-rich, and minimally processed juices, driving juice manufacturers to adopt advanced non-thermal pasteurization technologies such as High Pressure Processing (HPP) and Pulse Electric Field (PEF)

- Furthermore, rising consumer awareness regarding health, food safety, and clean-label products is establishing non-thermal pasteurization as a preferred processing method for juices, enabling manufacturers to maintain natural taste, color, and nutritional value while extending shelf life. These converging factors are accelerating the uptake of non-thermal processing solutions, thereby significantly boosting the industry’s growth

Non-Thermal Pasteurization in Juice Industry Market Analysis

- Non-thermal pasteurization techniques, offering microbial inactivation without the use of heat, are increasingly vital in the juice industry due to their ability to preserve flavor, nutrients, and overall quality of beverages, making them suitable for premium, functional, and ready-to-drink juices

- The escalating demand for non-thermal pasteurization is primarily fueled by growing consumer preference for fresh and minimally processed products, stringent food safety regulations, and the need for innovative processing solutions that extend shelf life while maintaining product integrity

- North America dominated the non-thermal pasteurization in juice industry market with a share of 42.5% in 2025, due to increasing demand for fresh, nutrient-rich juices and advanced processing technologies

- Asia-Pacific is expected to be the fastest growing region in the non-thermal pasteurization in juice industry market during the forecast period due to increasing urbanization, rising disposable incomes, and growing awareness of healthy beverages in countries such as China, Japan, and India

- Liquid segment dominated the market with a market share of 69% in 2025, due to the high demand for fruit and vegetable juices and beverages requiring extended shelf life without compromising nutritional content. Liquid juices benefit significantly from non-thermal pasteurization techniques as they preserve vitamins, minerals, and natural flavors better than conventional thermal methods. Consumers increasingly prefer fresh-tasting, nutrient-rich beverages, which has accelerated the adoption of liquid-based non-thermal pasteurization. Manufacturers also favor liquid products for easier integration with automated processing lines and large-scale production facilities. The growing trend of functional beverages and ready-to-drink juices further reinforces the dominance of the liquid segment, enhancing market revenue and technological investments

Report Scope and Non-Thermal Pasteurization in Juice Industry Market Segmentation

|

Attributes |

Non-Thermal Pasteurization in Juice Industry Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Non-Thermal Pasteurization in Juice Industry Market Trends

Increasing Use of High-Pressure Processing (HPP)

- A significant trend in the non-thermal pasteurization in juice industry market is the rising adoption of high-pressure processing (HPP) technologies, driven by the increasing consumer demand for fresh, minimally processed, and nutrient-rich juices. HPP allows juice manufacturers to extend shelf life while preserving flavor, color, and nutritional content, making it a preferred method over conventional thermal pasteurization

- For instance, companies such as Hiperbaric and Avure Technologies supply industrial-scale HPP equipment that is widely implemented by juice brands such as Suja Juice and Odwalla. These systems enable producers to meet quality standards, improve food safety, and maintain product integrity without compromising nutrients

- The market is also witnessing the integration of HPP with other non-thermal technologies such as pulsed electric fields and ultraviolet (UV) treatment to achieve more efficient microbial inactivation. This combined approach enhances operational flexibility and ensures compliance with stringent food safety regulations

- Consumer preference for ready-to-drink, cold-pressed, and functional juices is further driving the demand for HPP and other non-thermal pasteurization solutions. These methods are increasingly positioned as premium processing techniques that reinforce product differentiation in competitive beverage markets

- Retailers and foodservice providers are emphasizing clean-label and preservative-free juices, which is motivating juice manufacturers to invest in non-thermal processing. This trend is fostering partnerships between technology providers and beverage producers to expand the availability of high-quality, fresh juices

- The growing global focus on health, wellness, and sustainability is sustaining market growth for non-thermal pasteurization technologies. These solutions are reinforcing industry efforts to meet nutritional standards while minimizing environmental impact through energy-efficient processing

Non-Thermal Pasteurization in Juice Industry Market Dynamics

Driver

Rising Demand for Fresh and Nutrient-Rich Juices

- The increasing consumer awareness of health and nutrition is driving demand for juices that retain natural flavor, vitamins, and antioxidants, which non-thermal pasteurization methods preserve more effectively than traditional thermal processes. This trend is encouraging juice producers to adopt HPP and other advanced technologies

- For instance, Suja Juice employs HPP to maintain the freshness and nutrient content of its cold-pressed juices, enabling the brand to cater to health-conscious consumers seeking minimally processed beverages

- Retail and e-commerce channels are expanding offerings of fresh and functional juices, supporting higher adoption of non-thermal pasteurization techniques to meet quality expectations. These channels incentivize manufacturers to maintain consistent product standards and longer shelf life without chemical additives

- The growing functional beverage segment, including juices enriched with probiotics, antioxidants, and plant extracts, is further propelling non-thermal pasteurization adoption. Preserving these active compounds enhances product efficacy and market appeal

- The rising focus on global wellness trends, preventive healthcare, and dietary improvements continues to strengthen this driver. Juice manufacturers are increasingly leveraging non-thermal pasteurization to offer premium products that meet evolving consumer expectations

Restraint/Challenge

High Equipment and Operational Costs

- The high capital expenditure required for HPP and other non-thermal pasteurization technologies is a significant barrier for small and medium-scale juice manufacturers, limiting widespread adoption. Advanced equipment, specialized maintenance, and trained personnel contribute to elevated operational costs

- For instance, Avure Technologies’ industrial-scale HPP systems involve substantial investment and energy consumption, which may be challenging for smaller juice producers to afford

- Operational complexity associated with HPP, including batch handling, pressure vessel maintenance, and regulatory compliance, increases production costs and requires skilled labor. These factors limit scalability and create financial pressure on manufacturers

- The reliance on continuous technological upgrades to maintain efficiency and safety standards further adds to cost constraints. Companies must balance investment in equipment with anticipated returns and market demand

- Market penetration in developing regions is constrained due to limited access to advanced non-thermal processing equipment and high installation expenses. This challenge continues to impact global market expansion and adoption rates

Non-Thermal Pasteurization in Juice Industry Market Scope

The market is segmented on the basis of form and technique.

- By Form

On the basis of form, the non-thermal pasteurization in juice industry market is segmented into solid and liquid. The liquid segment dominated the market with the largest market revenue share of 69% in 2025, driven by the high demand for fruit and vegetable juices and beverages requiring extended shelf life without compromising nutritional content. Liquid juices benefit significantly from non-thermal pasteurization techniques as they preserve vitamins, minerals, and natural flavors better than conventional thermal methods. Consumers increasingly prefer fresh-tasting, nutrient-rich beverages, which has accelerated the adoption of liquid-based non-thermal pasteurization. Manufacturers also favor liquid products for easier integration with automated processing lines and large-scale production facilities. The growing trend of functional beverages and ready-to-drink juices further reinforces the dominance of the liquid segment, enhancing market revenue and technological investments.

The solid segment is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by innovations in solid fruit-based products such as purees, concentrates, and pulps. For instance, companies such as Nestlé are investing in solid juice concentrates treated with high-pressure processing to retain flavor and nutrients. Solid formulations allow for longer storage and ease of transport while maintaining the quality expected by consumers. In addition, the increasing interest in smoothie powders, fruit snacks, and fortified fruit products contributes to the rising adoption of solid forms in the juice industry. Solid-based products also provide versatility for blending with other ingredients, enabling manufacturers to develop innovative offerings for health-conscious consumers.

- By Technique

On the basis of technique, the non-thermal pasteurization in juice industry market is segmented into High Pressure Processing (HPP), Pulse Electric Field (PEF), Microwave Volumetric Heating (MVH), Ultrasonic, Irradiation, and Others. The HPP segment held the largest market revenue share in 2025, driven by its proven ability to inactivate pathogens and spoilage microorganisms without the use of heat, thereby preserving the taste, color, and nutritional profile of juices. HPP has been widely adopted by leading juice manufacturers for premium fresh juices and cold-pressed beverages due to its reliability and scalability. The technique is particularly favored in the beverage industry as it enables compliance with stringent food safety regulations while delivering products that meet consumer expectations for freshness. Consumer preference for minimally processed and clean-label juices continues to reinforce the dominance of HPP.

The PEF segment is expected to witness the fastest CAGR from 2026 to 2033, propelled by its energy-efficient processing and suitability for continuous production lines. For instance, companies such as PurePulse Technologies are implementing PEF systems to enhance juice extraction efficiency while maintaining nutritional quality. PEF technology facilitates targeted microbial inactivation with minimal impact on sensory attributes, making it ideal for high-quality fruit and vegetable juices. In addition, its flexibility for integration into existing juice processing lines drives rapid adoption among manufacturers seeking innovative, sustainable solutions. The technique’s ability to support premium and functional juice products contributes to its anticipated high growth rate.

Non-Thermal Pasteurization in Juice Industry Market Regional Analysis

- North America dominated the non-thermal pasteurization in juice industry market with the largest revenue share of 42.5% in 2025, driven by increasing demand for fresh, nutrient-rich juices and advanced processing technologies

- Consumers in the region highly value juices processed using non-thermal techniques for their preserved nutritional content, flavor, and extended shelf life

- This widespread adoption is further supported by high disposable incomes, health-conscious consumers, and the growing trend of premium cold-pressed and functional beverages, establishing non-thermal pasteurization as a preferred solution for juice manufacturers

U.S. Non-Thermal Pasteurization in Juice Industry Market Insight

The U.S. market captured the largest revenue share in 2025 within North America, fueled by rising demand for fresh and minimally processed juices. Consumers are increasingly prioritizing nutrient retention and natural taste, encouraging manufacturers to adopt non-thermal pasteurization methods such as High Pressure Processing (HPP) and Pulse Electric Field (PEF). The growing preference for organic, cold-pressed, and functional juice products, along with robust distribution networks, further drives the market. Moreover, strong investments in advanced processing facilities and continuous innovation in juice preservation techniques significantly contribute to market growth.

Europe Non-Thermal Pasteurization in Juice Industry Market Insight

The Europe market is projected to expand at a substantial CAGR during the forecast period, primarily driven by stringent food safety regulations and increasing consumer demand for fresh and high-quality juices. The rise in health-conscious lifestyles, coupled with the popularity of organic and functional beverages, is fostering the adoption of non-thermal pasteurization techniques. European manufacturers are increasingly incorporating these technologies into both commercial juice production and premium retail offerings. The market is witnessing notable growth across countries such as Germany, France, and Italy, with non-thermal processing being integrated into new product development and reformulations.

U.K. Non-Thermal Pasteurization in Juice Industry Market Insight

The U.K. market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing consumer preference for fresh, minimally processed, and nutrient-rich juices. In addition, rising awareness regarding food safety, product quality, and health benefits is encouraging juice producers to adopt non-thermal pasteurization techniques. The U.K.’s strong retail and e-commerce channels, combined with innovative beverage launches, continue to support market expansion.

Germany Non-Thermal Pasteurization in Juice Industry Market Insight

The Germany market is expected to expand at a considerable CAGR during the forecast period, fueled by rising health consciousness and demand for high-quality, fresh juices. Germany’s well-developed beverage industry, combined with strong regulatory frameworks emphasizing food safety and sustainability, promotes the adoption of non-thermal pasteurization methods. Juice manufacturers are increasingly leveraging these techniques to deliver premium products with preserved taste, nutrients, and extended shelf life.

Asia-Pacific Non-Thermal Pasteurization in Juice Industry Market Insight

The Asia-Pacific market is poised to grow at the fastest CAGR during the forecast period of 2026 to 2033, driven by increasing urbanization, rising disposable incomes, and growing awareness of healthy beverages in countries such as China, Japan, and India. The region’s expanding middle class and shift toward functional and premium juices are driving the adoption of non-thermal pasteurization techniques. Government initiatives supporting food safety and modern processing technologies are also accelerating market growth.

Japan Non-Thermal Pasteurization in Juice Industry Market Insight

The Japan market is gaining momentum due to the country’s high demand for premium, minimally processed, and nutrient-rich juices. Japanese consumers prioritize product safety, natural taste, and freshness, which supports the adoption of techniques such as HPP and PEF. Integration of advanced processing solutions in juice production facilities, coupled with innovations in functional beverages, continues to drive market expansion.

China Non-Thermal Pasteurization in Juice Industry Market Insight

The China market accounted for the largest revenue share in Asia-Pacific in 2025, attributed to rapid urbanization, rising disposable incomes, and increasing health awareness. China is experiencing strong demand for fresh, cold-pressed, and functional juices, leading manufacturers to adopt non-thermal pasteurization methods. The push toward modern beverage processing, government support for food safety standards, and the presence of large-scale juice producers are key factors propelling market growth in China.

Non-Thermal Pasteurization in Juice Industry Market Share

The non-thermal pasteurization in juice industry is primarily led by well-established companies, including:

- JBT Corporation (U.S.)

- thyssenkrupp AG (Germany)

- Robert Bosch GmbH (Germany)

- CHIC Group (U.S.)

- American Pasteurization Company (U.S.)

- Hain Celestial (U.S.)

- MULTIVAC (Germany)

- Stansted Fluid Power Products Ltd. (U.K.)

- Dukane Corp. (U.S.)

- Pulsemaster (U.S.)

- Universal Pure (U.S.)

- Harwood Engineering Company, Inc. (U.S.)

- EXDIN Solutions (U.S.)

- Hormel Foods Corporation (U.S.)

- Bühler (Switzerland)

- Emerson Electric Co. (U.S.)

Latest Developments in Global Non-Thermal Pasteurization in Juice Industry Market

- In 2024, Lyras AS received regulatory approval for its new ultraviolet (UV) non-thermal pasteurization system in the European Union, enabling commercial deployment of UV-based non-thermal processing in beverage and dairy applications. This development allows juice manufacturers to implement UV technology at scale, enhancing product safety while preserving natural taste, color, and nutritional content. The approval strengthens manufacturers’ ability to produce clean-label, preservative-free juices, supporting growing consumer demand for minimally processed and health-oriented beverages. It also encourages further investment in alternative non-thermal techniques, expanding the overall market for innovative juice processing solutions

- In 2024, Hiperbaric S.A. partnered with a major U.S. beverage company to integrate High Pressure Processing (HPP) technology into its production lines, focusing on fresh, preservative-free juices. This partnership accelerates the adoption of HPP in large-scale juice manufacturing, providing producers with proven methods to extend shelf life without compromising flavor or nutrients. The collaboration highlights the increasing importance of non-thermal techniques in meeting consumer expectations for high-quality, fresh-tasting beverages. It also reinforces HPP as a preferred technology for premium juice segments, driving competitive innovation and market growth

- In 2024, HPP Food Technology SL secured Series B funding to accelerate the development of advanced non-thermal pasteurization equipment, enabling faster innovation and commercialization of efficient processing solutions. The funding allows the company to enhance R&D capabilities, refine existing technologies, and scale production of next-generation systems. This investment supports the broader juice industry by providing more effective, reliable, and versatile non-thermal pasteurization options, encouraging manufacturers to adopt advanced equipment that ensures safety, extends shelf life, and maintains nutritional value

- In 2024, Universal Pure expanded its HPP tolling capacity with a new facility in Texas, catering to rising demand for outsourced non-thermal processing services. This expansion allows more juice producers to access high-pressure processing without the need for capital-intensive equipment investments, making non-thermal pasteurization more accessible across the industry. It facilitates the production of fresh, high-quality juices at scale while maintaining key nutrients and flavors. The increased capacity also supports growing demand from functional and cold-pressed juice segments, reinforcing the market’s growth trajectory

- In 2024, JBT Corporation launched a new High Pressure Processing (HPP) system designed to enhance food safety and extend shelf life without heat, addressing the industry’s need for effective non-thermal solutions. This system enables juice manufacturers to preserve natural taste, color, and nutrients while ensuring microbial safety, meeting stringent regulatory standards and consumer expectations. The launch strengthens the adoption of HPP technology across the juice industry, supporting the production of premium, minimally processed beverages and driving innovation in processing methods

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Non Thermal Pasteurization In Juice Industry Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Non Thermal Pasteurization In Juice Industry Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Non Thermal Pasteurization In Juice Industry Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.