Global Nylon Monofilament Market

Market Size in USD Billion

CAGR :

%

USD

1.37 Billion

USD

2.25 Billion

2024

2032

USD

1.37 Billion

USD

2.25 Billion

2024

2032

| 2025 –2032 | |

| USD 1.37 Billion | |

| USD 2.25 Billion | |

|

|

|

|

Nylon Monofilament Market Size

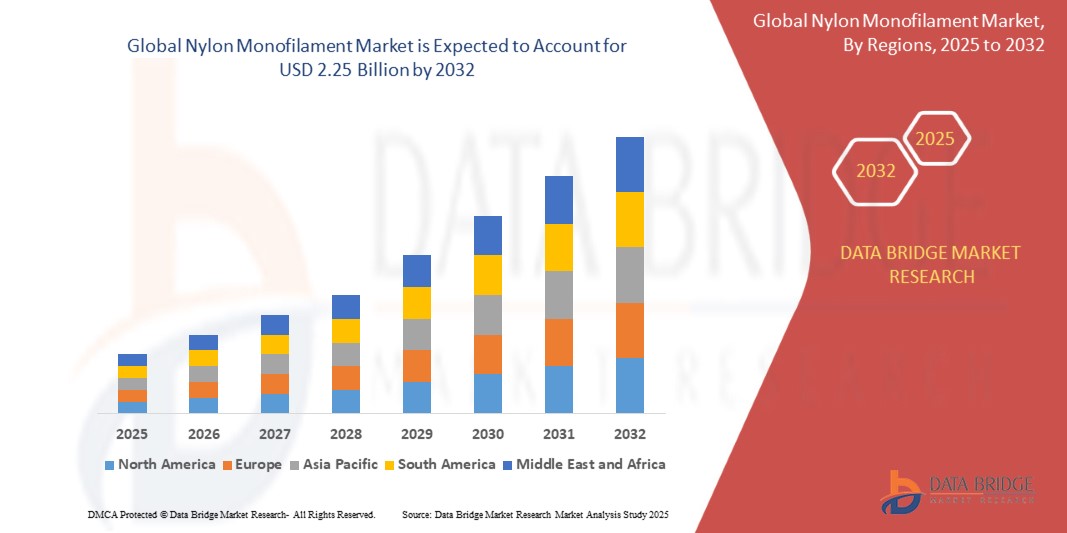

- The global nylon monofilament market size was valued at USD 1.37 billion in 2024 and is expected to reach USD 2.25 billion by 2032, at a CAGR of 6.40% during the forecast period

- The market growth is largely fueled by the increasing demand for high-performance synthetic fibers across diverse industries such as fishing, automotive, industrial, and consumer goods, driving widespread adoption of nylon monofilaments

- Furthermore, technological advancements in polymer processing, recycling initiatives, and the development of high-strength, durable, and sustainable monofilaments are enabling manufacturers to meet evolving performance and environmental requirements. These factors are accelerating the uptake of nylon monofilaments, thereby significantly boosting the industry's growth

Nylon Monofilament Market Analysis

- Nylon monofilaments are single-strand synthetic fibers made from polyamide polymers, primarily Nylon 6 and Nylon 66, offering high tensile strength, durability, chemical resistance, and flexibility. These fibers are used in applications such as fishing nets, automotive components, medical devices, and industrial products

- The escalating demand for nylon monofilaments is primarily driven by rapid industrialization, growth in the automotive and consumer goods sectors, increasing focus on sustainable and recyclable materials, and the need for reliable, high-performance fibers in both domestic and international markets

- Asia-Pacific dominated the nylon monofilament market with a share of 65.1% in 2024, due to expanding industrial and automotive manufacturing, increasing demand for fishing nets and consumer goods, and a strong presence of polymer production hubs

- North America is expected to be the fastest growing region in the nylon monofilament market during the forecast period due to robust demand for nylon monofilaments in automotive, industrial, and medical applications

- Nylon 6 segment dominated the market with a market share of 45.9% in 2024, due to its excellent balance of strength, flexibility, and chemical resistance. Nylon 6 monofilaments are widely used across multiple industries due to their ease of processing, consistent quality, and ability to maintain durability under high stress conditions. Manufacturers and end-users often prefer Nylon 6 for applications requiring long-lasting performance, such as fishing nets and industrial threads. The market also benefits from the availability of cost-effective production techniques and extensive supply chains that make Nylon 6 highly accessible. Its versatility in blending with other materials and compatibility with coatings further strengthens its demand across industrial and consumer applications

Report Scope and Nylon Monofilament Market Segmentation

|

Attributes |

Nylon Monofilament Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Nylon Monofilament Market Trends

Increasing Focus on Sustainable and Eco-Friendly Products

- Manufacturers are shifting toward biodegradable and recycled nylon monofilaments to meet consumer preferences and new regulations on plastics. These strategies help improve brand equity and drive customer loyalty in environmentally sensitive markets

- For instance, BASF launched eco-friendly nylon monofilament products using recycled content, targeting producers who want to cut landfill waste and minimize their carbon footprint across fishing, agriculture, and textile sectors

- Development in extrusion and polymerization technologies is boosting the performance and tensile strength of nylon monofilaments, supporting broader application in fishing lines, agriculture nets, and industrial textiles without sacrificing environmental goals

- Smart textile designers are incorporating nylon monofilament in healthcare and sportswear for moisture-wicking and antibacterial properties, reflecting rising demand for next-gen functional fabrics globally

- As aquaculture expands, demand for high-performance nylon monofilament fishing nets is surging. Regions such as Asia-Pacific are seeing strong investments in sustainable solutions for large-scale fish farming

- Global regulations on plastic pollution and waste management are prompting R&D in compostable and enzyme-cleavable nylon monofilaments, although cost and scalability challenges remain for immediate widespread adoption

Nylon Monofilament Market Dynamics

Driver

Growing Demand for Nylon Monofilament in Fishing Nets

- Strength, flexibility, and durability make nylon monofilament ideal for fishing nets as global commercial and recreational fishing activities expand. Sustainable fishing practices further drive adoption due to reduced bycatch and longer service life

- For instance, Garware Technical Fibres supplies advanced nylon monofilament nets for commercial fisheries that combine light weight with improved durability, capturing a leadership position in premium marine and aquaculture solutions

- Governments and environmental bodies are encouraging the use of efficient nets that minimize ecological impact, leading to increased market share for nylon monofilament designs

- Growing population and global protein demand require higher fish yields, fueling expansion in industrial fishing and aquaculture, with nylon monofilament nets supporting these intensive operations

- Technological innovations continue to improve net durability and ease of handling, appealing to both large fishing operations and small-scale rural programs seeking reliable gear

Restraint/Challenge

Volatility in Raw Material Prices

- Nylon monofilament depends on petroleum-based inputs such as caprolactam, exposing producers to unstable crude oil and feedstock pricing that can inflate costs and disrupt supply contracts, lowering profitability

- For instance, BASF and other providers increased product pricing in 2024 to offset surging raw material costs following tightening benzene and caprolactam supply chains worldwide

- Regulatory changes, such as new environmental standards in the EU, can further elevate production costs and pressure industry margins for both virgin and recycled nylon monofilaments

- Price-sensitive markets in fisheries and textiles may substitute alternative materials or delay purchases, intensifying competition and eroding demand during periods of raw material volatility

- Sustained cost pressures are pushing manufacturers to invest in R&D for cost-efficient and renewable feedstock options, but these solutions require time and capital before market scale is achieved

Nylon Monofilament Market Scope

The market is segmented on the basis of type and application.

• By Type

On the basis of type, the Nylon Monofilament market is segmented into Nylon 6, Nylon 66, and Others. The Nylon 6 segment dominated the largest market revenue share of 45.9% in 2024, driven by its excellent balance of strength, flexibility, and chemical resistance. Nylon 6 monofilaments are widely used across multiple industries due to their ease of processing, consistent quality, and ability to maintain durability under high stress conditions. Manufacturers and end-users often prefer Nylon 6 for applications requiring long-lasting performance, such as fishing nets and industrial threads. The market also benefits from the availability of cost-effective production techniques and extensive supply chains that make Nylon 6 highly accessible. Its versatility in blending with other materials and compatibility with coatings further strengthens its demand across industrial and consumer applications.

The Nylon 66 segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by increasing demand in automotive and high-performance industrial applications. Nylon 66 monofilaments offer superior thermal stability, tensile strength, and wear resistance compared to other types, making them ideal for engineering and technical uses. Growing awareness of material performance in critical applications, combined with expanding automotive and industrial manufacturing, is accelerating the uptake of Nylon 66. Its ability to withstand harsh environmental conditions and repeated mechanical stress enhances its appeal for demanding applications. In addition, technological advancements in Nylon 66 processing and the development of specialized variants are expected to fuel rapid growth in this segment over the forecast period.

• By Application

On the basis of application, the Nylon Monofilament market is segmented into Fishing Net, Medical, Automotive, Consumer Goods, and Others. The Fishing Net segment dominated the largest market revenue share in 2024, driven by the widespread use of Nylon monofilaments in commercial and recreational fishing due to their high tensile strength, flexibility, and resistance to water absorption. Nylon monofilaments provide durability in harsh marine environments and maintain performance under prolonged exposure to sunlight and saltwater, which is crucial for long-lasting fishing equipment. The segment also benefits from strong demand in emerging economies where fishing remains a major economic activity. Manufacturers continue to innovate in coating and texturing technologies to enhance the usability and lifespan of fishing nets, further strengthening market growth. The established reputation of Nylon monofilaments for reliability in aquatic applications ensures continued dominance in this segment.

The Automotive segment is expected to witness the fastest CAGR from 2025 to 2032, driven by rising adoption of Nylon monofilaments in advanced automotive applications, including tire reinforcement, wiring insulation, and precision components. The growing focus on lightweight, durable materials in the automotive sector is boosting demand for high-performance monofilaments that improve fuel efficiency and mechanical reliability. Nylon monofilaments are increasingly used in complex applications requiring high strength, dimensional stability, and resistance to heat and chemicals. Expanding automotive production in Asia-Pacific, along with stringent safety and performance regulations, is expected to accelerate the adoption of Nylon monofilaments in this segment. Ongoing material innovations and cost optimization strategies are further contributing to rapid market growth.

Nylon Monofilament Market Regional Analysis

- Asia-Pacific dominated the nylon monofilament market with the largest revenue share of 65.1% in 2024, driven by expanding industrial and automotive manufacturing, increasing demand for fishing nets and consumer goods, and a strong presence of polymer production hubs

- The region’s cost-effective manufacturing landscape, rising investments in synthetic fiber production, and growing exports of high-quality monofilaments are accelerating market expansion

- The availability of skilled labor, favorable government policies, and rapid industrialization across developing economies are contributing to increased consumption of nylon monofilament across multiple sectors

China Nylon Monofilament Market Insight

China held the largest share in the Asia-Pacific nylon monofilament market in 2024, owing to its status as a global leader in polymer manufacturing and industrial textile production. The country's strong industrial base, favorable government policies supporting synthetic fiber expansion, and extensive export capabilities for monofilaments are major growth drivers. Demand is also bolstered by ongoing investments in automotive, consumer goods, and technical textile applications for both domestic and international markets.

India Nylon Monofilament Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by rapidly expanding fishing and aquaculture sectors, increasing automotive production, and growing adoption in consumer goods. The "Make in India" initiative, along with investments in polymer processing infrastructure, is strengthening the demand for nylon monofilament. In addition, rising exports of high-strength monofilaments and expanding R&D capabilities in synthetic fibers are contributing to robust market expansion.

Europe Nylon Monofilament Market Insight

The Europe nylon monofilament market is expanding steadily, supported by stringent quality standards, high demand for high-performance fibers, and growing investments in sustainable and specialty polymer production. The region places strong emphasis on durability, environmental compliance, and advanced material formulations, particularly in automotive, medical, and industrial applications. Increasing use of nylon monofilaments in technical textiles and custom applications is further enhancing market growth.

Germany Nylon Monofilament Market Insight

Germany’s nylon monofilament market is driven by its leadership in automotive manufacturing, precision industrial applications, and strong polymer industry heritage. The country has well-established R&D networks and collaboration between universities and polymer manufacturers, fostering continuous innovation in high-performance monofilaments. Demand is particularly strong for use in automotive components, industrial threads, and specialty technical applications.

U.K. Nylon Monofilament Market Insight

The U.K. market is supported by a mature industrial base, growing efforts to localize polymer and synthetic fiber production, and increasing demand for high-quality monofilaments in automotive, medical, and consumer goods. With rising focus on R&D, academic-industry collaboration, and sustainable production practices, the U.K. continues to play a significant role in high-value synthetic fiber markets.

North America Nylon Monofilament Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by robust demand for nylon monofilaments in automotive, industrial, and medical applications. A strong focus on lightweight and durable materials, advancements in material science, and growing reliance on high-strength fibers are boosting demand. In addition, reshoring of polymer manufacturing and increasing collaboration between end-users and specialty fiber producers are supporting market expansion.

U.S. Nylon Monofilament Market Insight

The U.S. accounted for the largest share in the North America market in 2024, underpinned by its expansive automotive and industrial sectors, strong R&D infrastructure, and significant investment in polymer production. The country’s focus on innovation, regulatory compliance, and sustainability is encouraging the use of high-performance nylon monofilaments across multiple applications. Presence of key manufacturers and a mature distribution network further solidify the U.S.'s leading position in the region.

Nylon Monofilament Market Share

The nylon monofilament industry is primarily led by well-established companies, including:

- BASF SE (Germany)

- DuPont (U.S.)

- DSM (Netherlands)

- Solvay (Belgium)

- Evonik Industries AG (Germany)

- Lanxess (Germany)

- Aahi Kasei Corporation. (Japan)

- Honeywell International Inc. (U.S.)

- EMS-CHEMIE HOLDING AG (Switzerland)

Latest Developments in Global Nylon Monofilament Market

- In February 2025, INVISTA obtained a patent for an advanced nylon recycling process aimed at enhancing nylon 6,6 production by increasing the availability of high-quality post-industrial recycling (PIR) feedstock. The company also filed a patent application for a process enabling up to 100% post-consumer recycled (PCR) content in new nylon 6,6 components. This development is expected to significantly impact the nylon monofilament market by promoting sustainable production, reducing reliance on virgin materials, and enabling manufacturers to meet the rising demand for eco-friendly monofilaments in automotive, industrial, and consumer applications

- In February 2024, The Filament Company inaugurated a new manufacturing plant in Goa, India, following the acquisition of Shaun Filaments, a leading local filament producer. This expansion strengthens Perlon’s global footprint, increases production capacity, and improves efficiency in nylon monofilament manufacturing. The development is expected to accelerate market growth in Asia-Pacific by meeting rising regional demand for high-performance monofilaments across fishing, industrial, and automotive sectors

- In June 2023, KastKing launched its TriPolymer Advanced Monofilament, an innovative fishing line created through a unique tri-extrusion process that combines three types of nylon into a single product. This advancement sets a new benchmark in the fishing monofilament segment by offering superior strength, durability, and knot performance. The introduction of this technology is likely to drive consumer adoption, enhance brand competitiveness, and increase demand for high-performance nylon monofilaments in recreational and commercial fishing applications

- In April 2023, Asahi Kasei partnered with Microwave Chemicals to initiate a joint demonstration project aimed at developing a chemical recycling process for polyamide 66 (PA66) using microwave technology. This process breaks down PA66 waste, including manufacturing scraps and post-consumer materials from airbags and automotive parts, to directly recover monomers hexamethylenediamine (HMD) and adipic acid (ADA). The initiative is expected to impact the nylon monofilament market by enabling more sustainable production of PA66 monofilaments, reducing carbon footprint, and supporting the growing emphasis on circular economy solutions in industrial and automotive applications

- In November 2022, DSM Engineering Materials introduced a high-tenacity nylon monofilament specifically designed for automotive airbag applications. This development provides enhanced mechanical strength, heat resistance, and dimensional stability, which improves safety and reliability in automotive components. The launch is anticipated to bolster the adoption of specialized nylon monofilaments in the automotive sector, driving market expansion and encouraging investment in high-performance polymer applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Nylon Monofilament Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Nylon Monofilament Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Nylon Monofilament Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.