Global Paraxylene Market

Market Size in USD Billion

CAGR :

%

USD

58.78 Billion

USD

95.10 Billion

2024

2032

USD

58.78 Billion

USD

95.10 Billion

2024

2032

| 2025 –2032 | |

| USD 58.78 Billion | |

| USD 95.10 Billion | |

|

|

|

|

Global Paraxylene Market Size

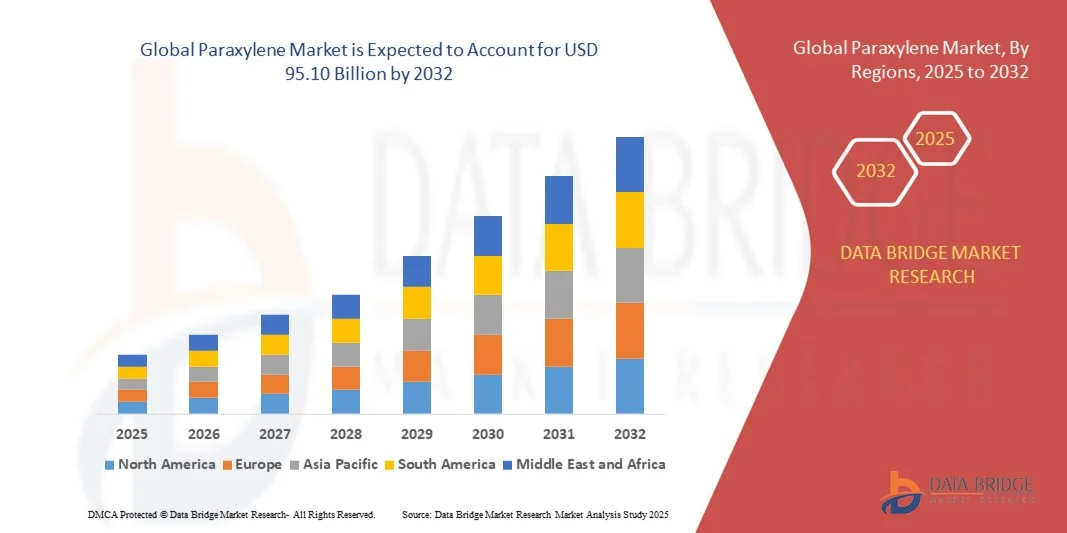

- The global Paraxylene Market size was valued at USD 58.78 billion in 2024 and is expected to reach USD 95.10billion by 2032, growing at a CAGR of 6.20%during the forecast period

- Market growth is primarily driven by increasing demand for polyethylene terephthalate (PET) in packaging and textile industries, especially in emerging economies, where consumption of bottled beverages and synthetic fibers is surging

- Additionally, advancements in production technologies and the shift towards bio-based paraxylene are enhancing sustainability and cost-efficiency, further propelling the market forward across various industrial applications

Global Paraxylene Market Analysis

- Paraxylene, a key aromatic hydrocarbon used primarily as a feedstock for producing purified terephthalic acid (PTA), is crucial to the manufacturing of polyethylene terephthalate (PET) plastics and polyester fibers, making it an essential component in packaging, textiles, and consumer goods industries

- The accelerating demand for PET bottles and polyester fabrics is a major driver of the paraxylene market, fueled by rising consumption of packaged beverages, fast fashion, and urban lifestyle shifts across both developed and emerging economies

- Asia-Pacific dominated the global paraxylene market with the largest revenue share of 35.7% in 2024, underpinned by robust growth in textile manufacturing, expanding petrochemical infrastructure, and high demand from countries like China and India, which serve as key production and consumption hubs

- North America is projected to witness steady growth during the forecast period, supported by technological advancements in bio-based paraxylene production and the region's increasing focus on sustainable and recyclable packaging solutions

- The Purified Terephthalic Acid (PTA) segment dominated the market with the largest market revenue share of 74.5% in 2024, driven by its widespread use in the production of polyester fibers and PET bottles.

Report Scope and Global Paraxylene Market Segmentation

|

Attributes |

Paraxylene Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Paraxylene Market Trends

Sustainability and Innovation in Bio-based Paraxylene Production

- A significant and accelerating trend in the global Paraxylene Market is the growing shift toward sustainable production methods, particularly the development and commercialization of bio-based paraxylene as an alternative to traditional fossil fuel-derived variants. This innovation aligns with global efforts to reduce carbon emissions and dependency on non-renewable resources.

- For instance, Virent Inc., a subsidiary of Marathon Petroleum, has developed a process to convert plant-based sugars into bio-paraxylene, enabling the production of 100% plant-based PET bottles. Similarly, Anellotech’s Bio-TCat process uses non-food biomass to produce aromatic chemicals like paraxylene, offering a renewable route to PET production without sacrificing performance or quality.

- Bio-based paraxylene technologies are not only environmentally friendly but also present opportunities for closed-loop recycling systems, further reducing plastic waste. Companies like Gevo and Toray Industries are actively investing in this space, aiming to scale production and meet the increasing demand for green packaging solutions from major beverage and textile brands.

- This transition is also driven by consumer and regulatory pressures, especially in North America and Europe, where brands are pledging to adopt sustainable packaging and governments are enforcing stricter carbon neutrality targets. As a result, petrochemical firms are collaborating with biotech companies to diversify their feedstock and lower their environmental footprint.

- Additionally, advancements in catalytic processes and biorefinery technologies are improving the cost-efficiency and scalability of bio-paraxylene production, making it a more viable competitor to its petroleum-based counterpart in the long term.

- The growing emphasis on sustainability, coupled with innovations in green chemistry, is expected to reshape the paraxylene industry landscape. Producers that can adapt to this shift by integrating renewable feedstocks and low-carbon technologies are likely to gain a competitive edge in the evolving global market.

Global Paraxylene Market Dynamics

Driver

Growing Demand Driven by Packaging and Polyester Industry Expansion

-

The rising global demand for polyester fibers and PET-based packaging materials is a primary growth driver for the global Paraxylene Market. With increasing urbanization, lifestyle changes, and the consumption of ready-to-eat and bottled beverages, the need for PET — a key derivative of paraxylene — has grown substantially.

- For Instance, emerging economies in Asia-Pacific, such as India, China, and Vietnam, are witnessing rapid growth in textile and food & beverage industries, where paraxylene-based products are extensively used. This is prompting both local and international producers to expand their paraxylene production capacities in the region.

- Polyester is widely used in clothing, home textiles, and industrial applications due to its durability, low cost, and versatility, all of which fuel paraxylene consumption. Additionally, growing environmental awareness is pushing brands toward recyclable PET packaging, further increasing demand for high-purity paraxylene in sustainable applications.

- The expansion of petrochemical infrastructure, especially in China and the Middle East, is enhancing the supply capabilities of paraxylene, helping meet the increasing global demand while also driving competitiveness in the market.

- Moreover, the integration of paraxylene production into larger refining and chemical complexes by major players — such as Reliance Industries and ExxonMobil — enables operational efficiency and cost advantages, positioning them strongly to address rising global consumption.

Restraint/Challenge

Environmental Concerns and Market Volatility Due to Petrochemical Dependency

- Environmental concerns associated with the production and use of paraxylene and its derivatives present a significant restraint to broader market expansion. Paraxylene is primarily derived from petroleum-based feedstocks like naphtha, and its production is energy-intensive, contributing to greenhouse gas emissions and raising alarms among regulators and environmental groups.

- For instance, in recent years, several proposed paraxylene projects in China faced public opposition due to health and environmental risks, prompting delays, cancellations, or relocation of facilities. These concerns are becoming more widespread globally, pressuring manufacturers to adopt greener practices and alternative production routes.

- In addition, the paraxylene market is highly susceptible to price volatility in crude oil and naphtha, which affects profit margins and supply chain stability. Producers and downstream industries, including PET manufacturers, face difficulties in cost forecasting and inventory management, especially during periods of geopolitical instability or global energy crises.

- Addressing these challenges requires significant investment in low-emission production technologies, development of bio-based paraxylene alternatives, and compliance with tightening environmental regulations. Companies like Virent and Anellotech are already working on scalable bio-paraxylene production processes, though commercial viability remains a hurdle due to high R&D costs and scaling limitations.

- While industry leaders are gradually shifting towards circular economy practices such as PET recycling and bio-based alternatives, the transition is capital-intensive and may be slow in regions with limited technological or regulatory support.

- To ensure sustainable market growth, the paraxylene industry must focus on innovation in cleaner technologies, greater supply chain transparency, and global cooperation to reduce the ecological footprint of its operations while balancing economic feasibility.

Global Paraxylene Market Scope

The market is segmented on the basis of application, type and end-user industry .

- By Application

On the basis of application, the paraxylene market is segmented by application into polyester fiber and PET bottles. The polyester fiber segment dominated the market with the largest revenue share of 51.7% in 2024, driven primarily by its extensive use in the textile industry. Polyester fibers, derived from paraxylene-based PTA, are widely used in apparel, home furnishings, and industrial fabrics due to their durability, flexibility, and cost-effectiveness. The surge in global textile demand, especially in emerging economies, continues to fuel the growth of this segment.

The PET bottles segment is expected to witness the fastest CAGR from 2025 to 2032, supported by rising consumer demand for lightweight, recyclable, and food-safe packaging in beverages and personal care sectors. The growing preference for sustainable packaging solutions and expanding beverage markets worldwide are accelerating the adoption of PET bottles derived from paraxylene, positioning this segment as a key growth driver.

- By Type

On the basis of type, the paraxylene market is segmented into Purified Terephthalic Acid (PTA) and Dimethyl Terephthalate (DMT). The PTA segment dominated the market with the largest market revenue share of 74.5% in 2024, driven by its widespread use in the production of polyester fibers and PET bottles. PTA is preferred by manufacturers due to its cost-effectiveness, high purity, and better processing characteristics in polyester manufacturing. The expanding textile and packaging industries, particularly in Asia-Pacific, are major contributors to the dominance of this segment.

The DMT segment is anticipated to witness the fastest growth rate of 6.9% from 2025 to 2032, fueled by increasing demand in specialty polyester applications and regions where DMT-based processes are still in use. Although largely replaced by PTA in several markets, DMT continues to gain traction in specific niche applications requiring higher thermal stability and purity levels. Technological advancements and renewed interest in diversified polyester production processes are also supporting the growth of this segment.

- By End-User Industry

On the basis of end-user industry, the paraxylene market by end-user industry is segmented into textile and packaging. The textile segment dominated with the largest market revenue share of 60.2% in 2024, driven by high demand for polyester fibers used in apparel, upholstery, and industrial textiles. Rapid growth in textile manufacturing hubs in Asia, along with rising consumer demand for affordable and durable synthetic fabrics, propels this segment’s dominance.

The packaging segment is expected to witness the fastest CAGR from 2025 to 2032, fueled by increasing demand for PET-based packaging in food, beverage, and personal care industries. PET packaging’s recyclability, lightweight properties, and alignment with sustainability trends are encouraging manufacturers to increase its usage, leading to robust growth in paraxylene consumption within the packaging industry.

Global Paraxylene Market Regional Analysis

- North America dominated the global paraxylene market with the largest revenue share of 35.7% in 2024, driven by the well-established textile and packaging industries along with advanced manufacturing infrastructure.

- The region benefits from high demand for polyester fibers and PET bottles, supported by strong consumer markets and an increasing focus on sustainable packaging solutions.

- Growth is further fueled by technological advancements in refining processes, robust supply chains, and significant investments by leading chemical manufacturers. High disposable incomes, stringent quality standards, and strong industrial output contribute to North America’s position as a key market for paraxylene, serving both domestic consumption and export demands.

U.S. Paraxylene Market Insight

The U.S. paraxylene market held the largest revenue share of 28% in North America in 2024, supported by strong demand from the textile and packaging industries. The country’s advanced manufacturing capabilities, coupled with increasing production of polyester fibers and PET bottles, drive market growth. Investments in refining technologies and sustainability initiatives further bolster the U.S. paraxylene market. Additionally, growing consumer demand for lightweight, durable packaging materials and textile products is expanding paraxylene consumption in various end-use sectors.

Europe Paraxylene Market Insight

Europe’s paraxylene market is projected to grow steadily during the forecast period, fueled by stringent environmental regulations and the increasing demand for sustainable packaging solutions. The region’s established textile industry and packaging sector contribute significantly to paraxylene consumption. Growing awareness around eco-friendly materials and recycling practices is encouraging manufacturers to innovate in purified terephthalic acid (PTA) and PET production, enhancing market expansion. The rise in construction and automotive industries also positively impacts paraxylene demand.

U.K. Paraxylene Market Insight

The U.K. paraxylene market is expected to grow at a moderate CAGR, driven by increasing investments in the packaging and textile sectors. The expanding e-commerce industry fuels demand for PET bottles and polyester-based textiles, while sustainability mandates encourage manufacturers to adopt greener production processes. The U.K.’s focus on innovation in the chemical industry and rising consumer preference for recycled polyester fibers further stimulate paraxylene consumption.

Germany Paraxylene Market Insight

Germany’s paraxylene market is anticipated to register considerable growth during the forecast period, supported by its strong chemical manufacturing base and leadership in sustainability initiatives. The country’s demand for high-quality polyester fibers and PET packaging materials is rising steadily, driven by automotive, textile, and food packaging industries. Germany’s commitment to environmental regulations encourages the development of bio-based and recycled paraxylene derivatives, expanding market opportunities.

Asia-Pacific Paraxylene Market Insight

The Asia-Pacific paraxylene market is poised to grow at the fastest CAGR of around 8.5% from 2025 to 2032, driven by rapid industrialization, urbanization, and increasing disposable incomes in China, India, Japan, and Southeast Asia. The region is the largest consumer and producer of paraxylene globally, owing to the booming textile and packaging industries. Government initiatives supporting manufacturing and smart city projects also accelerate paraxylene demand. Moreover, rising investments in petrochemical infrastructure and export-oriented production hubs contribute to the region’s dominance.

China Paraxylene Market Insight

China accounted for the largest market revenue share in Asia-Pacific in 2024, attributed to its vast textile manufacturing base and surging demand for PET bottles in the packaging sector. The country’s rapid urbanization, expanding middle class, and government support for chemical industry modernization drive paraxylene consumption. China is also a key exporter of PTA and PET products, strengthening its position in the global paraxylene market.

Japan Paraxylene Market Insight

Japan’s paraxylene market growth is driven by its advanced textile industry and high demand for innovative packaging solutions. The country emphasizes research and development in high-performance polyester fibers and sustainable PET materials. Japan’s focus on environmental conservation and recycling boosts demand for purified terephthalic acid derived from greener processes. Additionally, the automotive and electronics sectors contribute to paraxylene consumption through polyester-based components and packaging.

Global Paraxylene Market Share

The Paraxylene industry is primarily led by well-established companies, including:

- JX Nippon Oil & Energy Corp (Japan)

- China National Petroleum Corporation (CNPC) (China)

- Reliance (India)

- NPC Iran (Iran)

- GS Caltex (South Korea)

- ONGC (India)

- Orpic – Oman Oil Refineries and Petroleum Industries Company (Oman)

- Jurong Aromatics Corp (Singapore)

- China National Offshore Oil Corporation (CNOOC) (China)

- Lotte KP Chemical (South Korea)

- ExxonMobil (U.S.)

- Saudi Aramco (Saudi Arabia)

- Dalian Fujia Dahua (China)

- Idemitsu Kosan Co., Ltd. (Japan)

- Toyo (Japan)

- Teijin Fibers (Japan)

What are the Recent Developments in Global Paraxylene Market?

- In April 2023, Reliance Industries Limited, a leading global petrochemical company, announced the expansion of its paraxylene production capacity at its Jamnagar refinery complex in India. This expansion aims to meet the growing demand for purified terephthalic acid (PTA) and PET bottle-grade resin, driven by increasing consumption in textile and packaging industries. Reliance’s strategic investment highlights its commitment to strengthening supply chains and supporting downstream manufacturing, reinforcing its position as a key player in the global paraxylene market.

- In March 2023, Sinopec Corporation, China’s largest oil refiner, commissioned a new high-efficiency paraxylene production unit in its Shanghai petrochemical complex. This unit is designed to produce high-purity paraxylene to cater to the surging demand from the booming textile and packaging sectors across Asia-Pacific. Sinopec’s initiative demonstrates its focus on technological advancements and sustainability, aimed at optimizing production while reducing environmental impact in line with China’s green energy policies.

- In March 2023, LyondellBasell Industries launched a pilot project focused on developing bio-based paraxylene production in collaboration with several biotech firms. The project seeks to create more sustainable raw materials for polyester fiber and PET bottle manufacturing, targeting the reduction of carbon footprints in the global paraxylene supply chain. This innovation underscores LyondellBasell’s commitment to sustainability and circular economy principles in the petrochemical industry.

- In February 2023, Indorama Ventures, a global leader in PET production, announced a strategic partnership with key polyester fiber manufacturers to secure a steady supply of high-quality paraxylene. This collaboration aims to enhance supply chain efficiency and meet rising demand for eco-friendly polyester fibers and packaging solutions. Indorama Ventures’ efforts reflect the growing importance of integrated operations to maintain competitiveness in the evolving paraxylene market.

- In January 2023, ExxonMobil Chemical introduced a new high-performance paraxylene grade designed specifically for advanced textile and packaging applications. Unveiled at the World Petrochemical Conference, this product offers enhanced purity and processing efficiency, enabling manufacturers to produce lighter and stronger polyester fibers and PET bottles. ExxonMobil’s innovation highlights its dedication to meeting industry-specific needs while advancing the technological capabilities of paraxylene derivatives globally

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Paraxylene Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Paraxylene Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Paraxylene Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.