Global Polyaspartic Coatings Market

Market Size in USD Billion

CAGR :

%

USD

390.90 Billion

USD

607.22 Billion

2024

2032

USD

390.90 Billion

USD

607.22 Billion

2024

2032

| 2025 –2032 | |

| USD 390.90 Billion | |

| USD 607.22 Billion | |

|

|

|

|

Polyaspartic Coatings Pipes Market Analysis

The polyaspartic coatings market continues to expand due to its durability and fast-curing properties. These coatings, formulated with aliphatic polyisocyanates and aliphatic diamines, offer superior chemical resistance and longevity. Their advanced composition makes them suitable for corrosion protection and flooring topcoats across various industries.

The construction industry increasingly applies polyaspartic coatings in industrial and commercial flooring for long-term performance. The automotive and transportation sectors incorporate these coatings for anti-corrosion protection in vehicles and infrastructure. Rising interest in sustainable solutions influences product innovation and regulatory compliance.

Manufacturers focus on low-VOC and water-based formulations to align with environmental standards. Hybrid polyaspartic coatings gain attention for their enhanced flexibility and weather resistance. Companies invest in technological advancements and regional expansions to strengthen market presence. The industry continues to evolve, with ongoing developments in performance, application, and sustainability shaping its growth.

Polyaspartic Coatings Market Size

The pre-insulated pipes market size was valued at USD 390.90 billion in 2024 and is projected to reach USD 607.22 billion by 2032, with a CAGR of 5.66% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Polyaspartic Coatings Market Trends

“Shifting Toward Bio-Based and Environmentally Friendly Coatings”

The shift toward bio-based and environmentally friendly coatings is a key trend in the polyaspartic coatings market, driven by increasing environmental regulations and consumer demand for sustainable solutions. As industries face stricter VOC emissions regulations, bio-based polyaspartic coatings are gaining popularity due to their reduced environmental impact. These coatings utilize renewable raw materials, offering enhanced sustainability without compromising on performance. For instance, manufacturers such as BASF and AkzoNobel are developing polyaspartic coatings using bio-based polyols, which help lower the carbon footprint of the product. This shift not only meets regulatory requirements but also aligns with corporate sustainability goals, especially in the construction and automotive sectors. As a result, companies are increasingly incorporating these coatings into their product offerings, responding to both environmental concerns and market demand for eco-friendly alternatives.

Report Scope and Polyaspartic Coatings Market Segmentation

|

Attributes |

Polyaspartic Coatings Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

Covestro AG (Germany), PPG Industries, Inc. (U.S.), Akzo Nobel N.V. (Netherlands), BASF (Germany), Sika AG (Switzerland), Carboline (U.S.), LATICRETE International, Inc. (U.S.), ProkemSC (Egypt), rhinolinings.com (U.S.), VIP Coatings Intl GmbH & Co.KG (Germany), Hempel A/S (Denmark), Rust-Oleum Corporation (U.S.), polyaspartic-resin.com (China) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Polyaspartic Coatings Market Definition

Polyaspartic Coatings are a type of fast-curing, high-performance protective coating made from polyaspartic polyurea compounds. These coatings are known for their excellent durability, resistance to abrasion, UV stability, and rapid curing properties, which make them ideal for a wide range of industrial applications. In the context of the market, polyaspartic coatings are increasingly popular in sectors such as construction, automotive, flooring, and marine due to their superior performance and versatility. They offer a faster turnaround time compared to traditional coatings, improving operational efficiency and reducing downtime. The market for polyaspartic coatings is growing, driven by rising demand for environmentally friendly solutions, the need for high-performance coatings that can withstand extreme conditions, and the shift towards more sustainable, low-VOC formulations.

Polyaspartic Coatings Market Dynamics

Drivers

- Higher Efficiency Compared to Conventional Coating Technology

One of the key market drivers for polyaspartic coatings is their higher efficiency compared to conventional coating technologies. Unlike traditional epoxy or polyurethane systems, which require extended curing times and multiple layers, polyaspartic coatings cure rapidly, often within a few hours, significantly reducing the time needed to return surfaces to service. This fast curing not only enhances operational efficiency but also minimizes downtime in industries such as automotive, construction, and manufacturing. For instance, in the automotive sector, polyaspartic coatings are used for quick-turnaround projects, allowing vehicles to be coated and returned to service much faster than with traditional coatings. Additionally, polyaspartic coatings often eliminate the need for multiple layers, offering the same or superior performance with a single coat. This streamlining of the coating process leads to increased productivity, reduced labor costs, and improved overall performance, driving the growing adoption of polyaspartic coatings in various industrial applications.

- Growing Emphasis on Sustainability and Eco-Friendly Solutions

The growing emphasis on sustainability and eco-friendly solutions is a significant market driver for polyaspartic coatings. As environmental regulations tighten and consumers become more environmentally conscious, industries are increasingly seeking coatings that align with sustainability goals. Polyaspartic coatings, particularly those with bio-based components, offer a lower environmental impact compared to traditional coatings, as they are formulated with reduced volatile organic compounds (VOCs), minimizing air pollution. For instance, in the construction sector, polyaspartic coatings are gaining traction for their ability to provide long-lasting, high-performance finishes without the harmful emissions associated with conventional epoxy or polyurethane coatings. Furthermore, their faster curing times reduce energy consumption during application, contributing to a lower overall carbon footprint. With regulatory bodies and companies prioritizing eco-friendly solutions, the demand for polyaspartic coatings is expected to grow as businesses seek to meet sustainability targets and reduce environmental impact across various industries.

Opportunities

- Emerging Application Areas of Polyaspartic Coatings

The ability of polyaspartic coatings to replace traditional epoxy and polyurethane coatings is a highly valued trait, driving significant demand in both industrial and commercial applications. Polyaspartic coatings offer numerous advantages over these conventional technologies, such as faster curing times, enhanced abrasion resistance, greater UV stability, and superior flexibility. These features make polyaspartic coatings ideal for environments where durability and minimal downtime are crucial. Unlike epoxy and polyurethane, which may require long curing periods and multiple layers, polyaspartic coatings provide a quicker, more efficient solution, making them a preferred choice in various sectors.

For instance, in the industrial flooring market, polyaspartic coatings are replacing epoxy and polyurethane systems due to their ability to withstand heavy machinery, foot traffic, and harsh chemicals, while curing quickly to reduce operational downtime. This efficiency and performance boost has led to increased adoption in manufacturing plants, warehouses, and even high-end retail spaces. The growing demand for these coatings in such applications presents significant opportunities for market players to expand their product offerings, enhance innovation, and tap into new, high-growth industries such as automotive, construction, and marine, driving future market growth.

- Rise in Commercial and Residential Construction

The rise in commercial and residential construction presents a significant opportunity for the polyaspartic coatings market. As urbanization accelerates and infrastructure development intensifies, there is a growing need for high-performance coatings in both new buildings and renovation projects. Polyaspartic coatings are increasingly being used in commercial spaces, residential buildings, and public infrastructure due to their superior durability, UV stability, and fast curing times. Their ability to provide long-lasting, resistant finishes with minimal maintenance makes them ideal for high-traffic areas, including floors, walls, and facades.

For instance, in commercial spaces such as shopping malls and office buildings, polyaspartic coatings are being adopted for flooring applications, as they can withstand heavy foot traffic and resist stains and chemicals. In residential construction, these coatings are gaining popularity for exterior applications, offering long-term protection against weathering and UV damage. The growing demand for high-performance, low-maintenance coatings in construction projects is driving significant opportunities for market players to expand their product offerings.

Restraints/Challenges

- Limited Awareness

Despite the performance advantages, many end-users, especially in smaller industries or regions, may have limited awareness or understanding of polyaspartic coatings. Traditional coatings, such as epoxy and polyurethane, are more established, and customers may be hesitant to switch to a newer, albeit more advanced, technology due to unfamiliarity. For instance, in smaller manufacturing facilities or local contractors, epoxy-based coatings are often the go-to solution due to their lower cost and long-standing presence in the market. These businesses may be reluctant to adopt polyaspartic coatings because they are unfamiliar with their benefits, such as rapid curing times and enhanced durability. As a result, despite polyaspartic coatings offering superior performance, the initial reluctance to adopt new technologies can slow their penetration in markets where traditional coatings have long been the norm. This challenge highlights the need for educational initiatives and awareness campaigns to drive adoption.

- Need for Specialized Application Expertise

The need for specialized application expertise is a significant challenge in the polyaspartic coatings market. While polyaspartic coatings offer numerous benefits, such as fast curing times and superior durability, their application requires precision and technical knowledge. Improper mixing, incorrect curing time, or failure to prepare the substrate correctly can result in poor adhesion, uneven finishes, or compromised performance, leading to costly repairs and reduced durability. For instance, in industries such as automotive or flooring, where polyaspartic coatings are increasingly used, inexperienced applicators may struggle to achieve consistent results, affecting the overall quality of the product. This challenge is particularly pronounced in regions with limited training resources, making it difficult for companies to scale their usage without investing in skilled labor. As a result, market expansion may be hindered in areas where the workforce lacks the required technical expertise for proper application.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Polyaspartic Coatings Market Scope

The market is segmented on the basis of type, technology, system, and end user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Pure Polyaspartic Coatings

- Hybrid Polyaspartic Coatings

Technology

- Water

- Solvent

- Powder

System

- Quartz

- Metallic

End User

- Building and Construction

- Transportation

- Industrial

- Power Generation

- Landscape

- Others

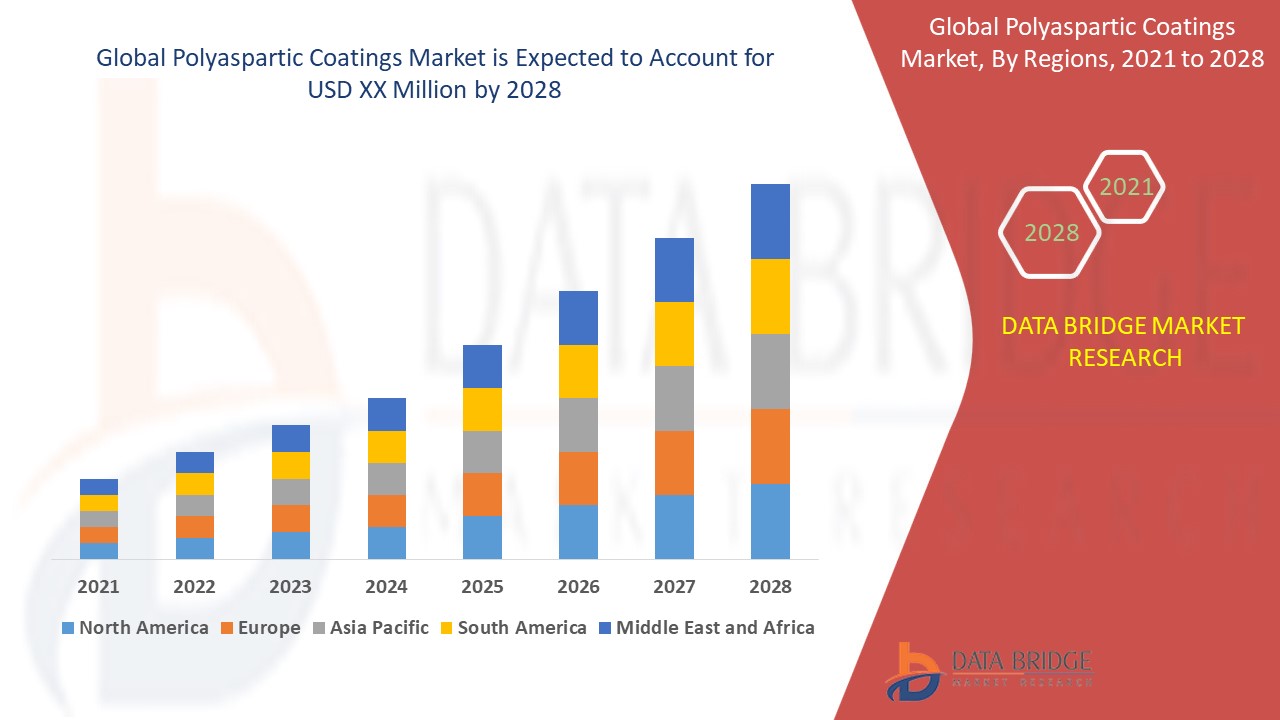

Polyaspartic Coatings Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, type, technology, system, and end user as referenced above.

The countries covered in the market report are U.S., Canada, Mexico in North America, Germany, Sweden, Poland, Denmark, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in Asia-Pacific (APAC), Brazil, Argentina, Rest of South America as a part of South America, U.A.E, Saudi Arabia, Oman, Qatar, Kuwait, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

North America is expected to dominate the polyaspartic coatings market during the forecast year of 2025-2032, driven by stringent building regulations and the increasing focus on reducing volatile organic compound (VOC) emissions. The region's emphasis on sustainability, particularly in construction and infrastructure projects, makes polyaspartic coatings a preferred choice due to their low-VOC formulations and high-performance characteristics. These coatings are increasingly being adopted in industries that prioritize both regulatory compliance and long-lasting results.

Asia-Pacific region is projected to experience the highest growth rate in the polyaspartic coatings market during the forecast period of 2025-2032 supported by rapid industrialization, urbanization, and a growing demand for advanced coating solutions. Countries such as China and India are experiencing booming construction and manufacturing sectors, increasing the need for durable, fast-curing coatings that can withstand harsh environmental conditions. As innovation in coating technologies accelerates, polyaspartic coatings are set to see strong adoption, particularly in industries such as automotive, construction, and infrastructure development.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Polyaspartic Coatings Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Polyaspartic Coatings Market Leaders Operating in the Market Are:

- Covestro AG (Germany)

- PPG Industries, Inc. (U.S.)

- Akzo Nobel N.V. (Netherlands)

- BASF (Germany)

- Sika AG (Switzerland)

- Carboline (U.S.)

- LATICRETE International, Inc. (U.S.)

- ProkemSC (Egypt)

- rhinolinings.com (U.S.)

- VIP Coatings Intl GmbH & Co.KG (Germany)

- Hempel A/S (Denmark)

- Rust-Oleum Corporation (U.S.)

- polyaspartic-resin.com. (China)

Latest Developments in Polyaspartic Coatings Market

- In January 2020, BASF introduces an innovative waterproofing membrane, MasterSeal® 730 UVS in Asia. The impact of this launch on the polyaspartic coatings market is notable, as it emphasizes the growing trend toward advanced, high-performance materials for construction applications. While polyaspartic coatings are widely used for their fast curing and superior protection in flooring and structural coatings, the increasing availability of specialized solutions such as MasterSeal 730 UVS presents a competitive challenge. Polyaspartic coatings manufacturers may need to enhance their formulations and expand their offerings to maintain market share in the highly competitive waterproofing and construction sectors, where versatility, ease of application, and long-lasting performance are paramount

- In August 2020, The Sherwin-Williams Company launched Environlastic 2500, a high-performance coating designed specifically for structural and steel protection. This product is tailored for use in demanding environments, such as bridges, highways, large manufacturing plants, ports, and machinery, where durability and long-lasting protection are critical

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Polyaspartic Coatings Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Polyaspartic Coatings Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Polyaspartic Coatings Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.