Global Polypropylene Dual Flap Dispensing Closure Market

Market Size in USD Billion

CAGR :

%

USD

1.08 Billion

USD

1.71 Billion

2024

2032

USD

1.08 Billion

USD

1.71 Billion

2024

2032

| 2025 –2032 | |

| USD 1.08 Billion | |

| USD 1.71 Billion | |

|

|

|

|

Polypropylene Dual Flap Dispensing Closure Market Size

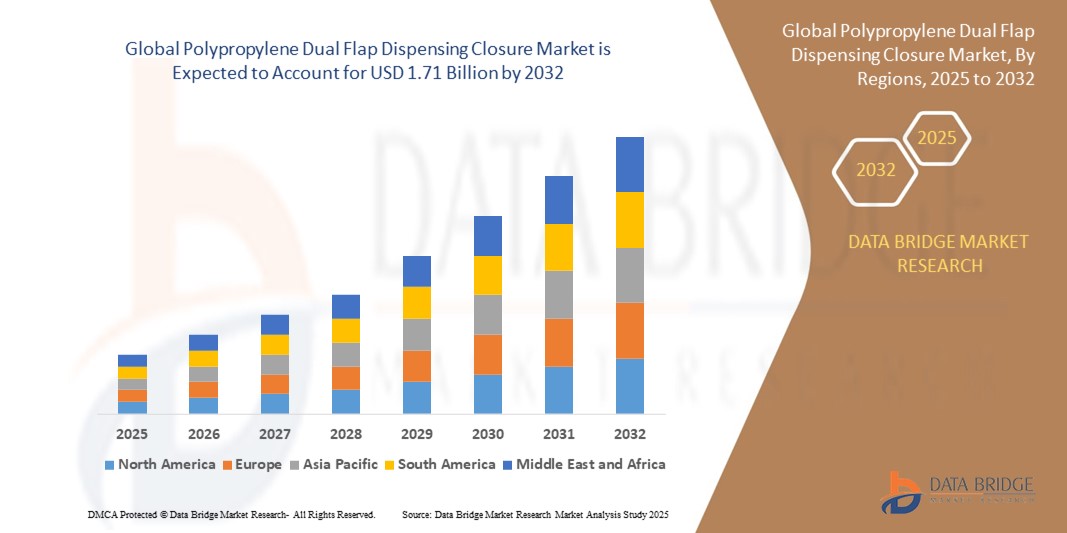

- The global polypropylene dual flap dispensing closure market size was valued at USD 1.08 billion in 2024 and is expected to reach USD 1.71 billion by 2032, at a CAGR of 5.8% during the forecast period

- The market growth is largely fueled by rising demand for convenient, hygienic, and portion-controlled dispensing solutions in packaged food, spice, and seasoning applications, particularly across household and foodservice sectors

- Furthermore, growing consumer preference for resealable, dual-function closures that support both pouring and sprinkling is driving innovation in polypropylene-based cap designs. These converging factors are significantly accelerating the uptake of dual flap dispensing closures, thereby boosting the industry’s growth

Polypropylene Dual Flap Dispensing Closure Market Analysis

- Polypropylene dual flap dispensing closures are lightweight, durable cap solutions designed to allow both controlled pouring and fine sprinkling, making them ideal for spices, sweeteners, and dry food products. Their versatility, resealability, and compatibility with various liner types enhance usability and product shelf life

- The increasing popularity of functional packaging, supported by the rise in on-the-go consumption, clean dispensing expectations, and food safety awareness, is fueling market demand. The segment is also benefitting from technological advances in closure design and the expansion of automated food packaging operations

- Asia-Pacific dominated the polypropylene dual flap dispensing closure market in 2024, due to the growing packaged food industry, large-scale condiment and spice consumption, and a robust FMCG sector

- North America is expected to be the fastest growing region in the polypropylene dual flap dispensing closure market during the forecast period due to high consumption of packaged foods, condiments, and sweeteners

- Heat induction seal foil liner segment dominated the market with a market share of 61.9% in 2024, due to its superior barrier properties and tamper-evident sealing capabilities. These liners provide extended shelf life by preventing oxygen and moisture ingress, which is crucial for preserving product integrity in food applications. The demand is especially high among manufacturers prioritizing leak-proof packaging for shipping and long-term storage. Their compatibility with high-speed automated sealing processes also supports large-scale production efficiency

Report Scope and Polypropylene Dual Flap Dispensing Closure Market Segmentation

|

Attributes |

Polypropylene Dual Flap Dispensing Closure Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Polypropylene Dual Flap Dispensing Closure Market Trends

Increasing Adoption of Sustainable and Recyclable Closure Materials

- The polypropylene dual flap dispensing closure market is witnessing growing adoption of sustainable and recyclable materials as brands and consumers increasingly prioritize environmentally responsible packaging solutions that reduce plastic waste and carbon footprint

- For instance, Guala Closures recently inaugurated a greenfield manufacturing facility in West Africa focused on producing recyclable polypropylene closures, highlighting industry commitment to sustainability and regional market expansion

- Advances in polypropylene resin technology enhance the recyclability, durability, and aesthetic quality of dual flap closures without compromising functionality, meeting both regulatory and consumer demands for eco-friendly packaging

- Consumer awareness campaigns and tighter regulations on single-use plastics encourage manufacturers to innovate around lightweight closure designs and incorporate recycled polypropylene content

- Growth of e-commerce and online retail channels boosts demand for secure, tamper-evident polypropylene closures that facilitate product integrity during shipping while supporting green packaging credentials

- Collaborations between resin suppliers, closure manufacturers, and brand owners accelerate adoption of closed-loop recycling systems and circular economy initiatives in personal care, food, and household product packaging

Polypropylene Dual Flap Dispensing Closure Market Dynamics

Driver

Versatility of Polypropylene

- Polypropylene’s inherent versatility—including chemical resistance, processability, cost-effectiveness, and favorable mechanical properties—makes it the preferred material for dual flap dispensing closures across diverse applications such as foodservice, cosmetics, pharmaceuticals, and household products

- For instance, polypropylene closures are extensively used in packaging spices, condiments, personal care products, and dry foods, valued for their tight sealing, repeated-use durability, and compatibility with colorants and branding features

- The material’s ability to provide precise flow control through flexible yet sturdy flaps supports consumer convenience trends, enhancing portion control and cleanliness in dispensing applications

- Lightweight yet impact-resistant, polypropylene contributes to lower overall packaging weight, reducing transportation costs and emissions

- Increasing innovation in polypropylene formulations and injection-molding processes enable customization of closure designs for improved tamper evidence, reuse, and product differentiation

- Polypropylene’s recyclability aligns well with emerging regulations and voluntary industry commitments, backing its ongoing preference over alternative plastic materials

Restraint/Challenge

Growing Environmental Concerns

- Despite polypropylene’s recyclable nature, growing environmental consciousness and regulatory scrutiny concerning plastic pollution pose challenges, pressuring manufacturers and brand owners to further reduce plastic usage or shift towards biodegradable alternatives

- For instance, environmental advocacy and regulations in regions such as the EU and parts of North America are accelerating initiatives to reduce virgin plastic content, necessitating investment in recycled polypropylene (rPP) and sustainable sourcing strategies that can impact manufacturing costs and supply chain complexity

- Consumer preferences for zero-waste or compostable packaging challenge polypropylene closures, especially in premium and niche market segments focusing on full biodegradability

- Fluctuations in the availability and quality of recycled polypropylene feedstocks can affect material consistency, product performance, and supply reliability

- Developing alternative bio-based polymers compatible with dual flap closure designs requires significant R&D investment and market acceptance efforts to compete with established polypropylene-based solutions

Polypropylene Dual Flap Dispensing Closure Market Scope

The market is segmented on the basis of liner type, application, and end uses.

- By Liner Type

On the basis of liner type, the market is segmented into Heat Induction Seal Foil Liner and Pressure Sensitive Liner. The Heat Induction Seal Foil Liner segment dominated the market share of 61.9% in 2024 due to its superior barrier properties and tamper-evident sealing capabilities. These liners provide extended shelf life by preventing oxygen and moisture ingress, which is crucial for preserving product integrity in food applications. The demand is especially high among manufacturers prioritizing leak-proof packaging for shipping and long-term storage. Their compatibility with high-speed automated sealing processes also supports large-scale production efficiency.

The Pressure Sensitive Liner segment is projected to witness the fastest growth rate from 2025 to 2032, driven by increasing demand for user-friendly packaging in the consumer goods sector. These liners require no additional heat or sealing equipment, making them ideal for small-batch producers and household brands. Their peel-and-use feature ensures easy access while maintaining basic tamper resistance. As sustainability gains traction, pressure-sensitive liners made from recyclable materials are also gaining popularity, supporting eco-conscious packaging trends.

- By Application

On the basis of application, the market is segmented into Spices, Condiments and Seasonings, Confectionary and Baking Products, Sweeteners, and Others. The Spices segment captured the largest revenue share in 2024, attributed to the growing global demand for convenient and hygienic dispensing of powdered or granulated products. Dual flap closures enable controlled pouring and sprinkling functions, improving consumer experience in the kitchen. This application benefits from the rise in premium spice blends and increased home cooking trends post-pandemic, particularly in Asia and North America.

The Sweeteners segment is expected to register the fastest CAGR from 2025 to 2032, spurred by the growing consumption of natural and low-calorie sweeteners in health-conscious demographics. Dual flap closures provide precise portion control, which is crucial for sweeteners used in beverages, cereals, and health foods. As more consumers shift to sugar alternatives, the need for intuitive, resealable packaging solutions with hygienic access is growing. The segment also benefits from the growth of tabletop sweetener formats and portable pack designs.

- By End Uses

On the basis of end uses, the market is segmented into Foodservice Outlets, Theaters and Malls, and Household. The Household segment held the highest revenue share in 2024, driven by the rising demand for clean, controlled dispensing solutions for pantry staples and daily-use food products. Consumers prefer dual flap closures for their dual-purpose design that allows both sprinkling and pouring, enhancing usability and reducing spillage. The increase in at-home food preparation and storage needs supports the adoption of such closures in various kitchen containers and retail packaging.

The Foodservice Outlets segment is anticipated to grow at the fastest rate from 2025 to 2032, due to the sector’s increasing focus on portion control, hygiene, and operational efficiency. These closures enable quick access and reduce cross-contamination risks in high-traffic environments such as fast food outlets and cafeterias. Their compatibility with bulk condiment and seasoning containers further strengthens their utility in commercial kitchens. As the foodservice industry continues expanding globally, particularly in emerging economies, demand for functional dispensing packaging is projected to accelerate.

Polypropylene Dual Flap Dispensing Closure Market Regional Analysis

- Asia-Pacific dominated the polypropylene dual flap dispensing closure market with the largest revenue share in 2024, driven by the growing packaged food industry, large-scale condiment and spice consumption, and a robust FMCG sector

- The region’s expanding middle-class population, rapid urbanization, and rising demand for convenient, resealable packaging solutions are fueling market growth

- Favorable manufacturing costs, increasing investments in food processing infrastructure, and evolving retail distribution networks are accelerating adoption across developing economies

China Polypropylene Dual Flap Dispensing Closure Market Insight

China held the largest share in the Asia-Pacific market in 2024 due to its dominant position in plastic packaging production and extensive food and condiment manufacturing base. High-volume exports of packaged goods, rising domestic consumption of spices and seasonings, and continuous innovation in cap design are driving demand. Government support for advanced packaging manufacturing and the presence of major closure producers strengthen China’s market leadership.

India Polypropylene Dual Flap Dispensing Closure Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, fueled by increasing consumption of packaged spices, sweeteners, and condiments across urban and semi-urban households. Government initiatives supporting domestic manufacturing and food safety, coupled with rising demand from the foodservice and retail sectors, are key contributors. Growth in local spice brands and consumer preference for hygienic, easy-to-use packaging is also propelling the market forward.

Europe Polypropylene Dual Flap Dispensing Closure Market Insight

The Europe market is expanding steadily due to growing demand for functional and sustainable food packaging across both retail and commercial segments. High consumer expectations for hygiene, portion control, and resealability are driving the adoption of advanced dispensing closures. Regulatory pressure on food safety and packaging recyclability is encouraging innovation in polypropylene-based closures. The region also benefits from well-established food and baking product industries.

Germany Polypropylene Dual Flap Dispensing Closure Market Insight

Germany’s market is supported by its strong packaging machinery sector, mature food processing industry, and demand for premium dispensing solutions in retail. High emphasis on quality, precision, and recyclability is fostering uptake of advanced closure formats. Germany also acts as a central hub for exporting packaged goods across Europe, reinforcing its leading market share in the region.

U.K. Polypropylene Dual Flap Dispensing Closure Market Insight

The U.K. market is driven by rising consumer demand for sustainable, convenient packaging in household and commercial settings. Strong presence of private-label condiment and spice brands, coupled with post-Brexit efforts to localize food packaging production, is spurring growth. Technological integration and design customization in closure formats are increasingly used to appeal to both functional and aesthetic preferences.

North America Polypropylene Dual Flap Dispensing Closure Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, supported by high consumption of packaged foods, condiments, and sweeteners. Rising preference for user-friendly, dual-function closures in household and foodservice settings is a key growth driver. The market benefits from strong R&D focus, increasing demand for sustainable materials, and widespread adoption of automation in food packaging operations.

U.S. Polypropylene Dual Flap Dispensing Closure Market Insight

The U.S. accounted for the largest share in the North America market in 2024, backed by its advanced packaging technology ecosystem and strong consumer preference for convenience. A mature food and condiment manufacturing sector, combined with innovation in resealable and controlled dispensing solutions, is propelling demand. High standards for food safety and packaging functionality, alongside presence of key closure manufacturers, further reinforce U.S. dominance.

Polypropylene Dual Flap Dispensing Closure Market Share

The polypropylene dual flap dispensing closure industry is primarily led by well-established companies, including:

- Mold-Rite Plastics (U.S.)

- MJS Packaging (U.S.)

- O.Berk (U.S.)

- Alameda Packaging (U.S.)

- Aaron Packaging Inc (U.S.)

- Illing Company (U.S.)

- MOCAP (U.S.)

- Cap & Seal (U.S.)

- Feldman Industries, Inc (U.S.)

- FLOCON, Inc. (U.S.)

- Kaufman Container (U.S.)

Latest Developments in Global Polypropylene Dual Flap Dispensing Closure Market

- In October 2024, Silgan Holdings Inc., a U.S.-based provider of consumer packaging solutions, acquired Weener Plastik GmbH to strengthen its global presence and broaden its portfolio in the dispensing solutions segment. The strategic acquisition is expected to enhance Silgan’s competitiveness in the closures market, including polypropylene dual-flap dispensing closures, and deliver €20 million in operational cost synergies within 18 months. The deal is anticipated to positively impact Silgan’s adjusted earnings per share for 2024. Weener Plastik GmbH, headquartered in the Netherlands, is recognized for its innovation in closure technologies and high-quality packaging solutions

- In July 2024, Berry introduced a new line of closures and couplings compatible with its Politainer combi pack, designed to support closed-system dispensing of sensitive liquids without exposure to air. This innovation strengthens Berry’s position in the high-performance packaging segment by addressing growing market demand for hygiene, safety, and product preservation in industrial and pharmaceutical applications. The development also enhances operational efficiency for end users, reinforcing Berry’s role in delivering advanced, contamination-free dispensing solutions in global liquid packaging markets

- In January 2023, MJS Packaging launched a versatile range of dual flap pour-and-shake dispensing closures tailored for spices, seasonings, and various food items. With availability in multiple sizes, colors, liners, and configurations, the product line supports customization and functionality for food packaging manufacturers. This move highlights MJS Packaging’s commitment to expanding its footprint in the food packaging segment by offering solutions that meet consumer demand for controlled dispensing, convenience, and aesthetic flexibility in everyday food applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Polypropylene Dual Flap Dispensing Closure Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Polypropylene Dual Flap Dispensing Closure Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Polypropylene Dual Flap Dispensing Closure Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.