Global Polyvinylidene Chloride Pvdc Shrink Bags Market

Market Size in USD Billion

CAGR :

%

USD

2.09 Billion

USD

2.74 Billion

2025

2033

USD

2.09 Billion

USD

2.74 Billion

2025

2033

| 2026 –2033 | |

| USD 2.09 Billion | |

| USD 2.74 Billion | |

|

|

|

|

Polyvinylidene Chloride (PVDC) Shrink Bags Market Size

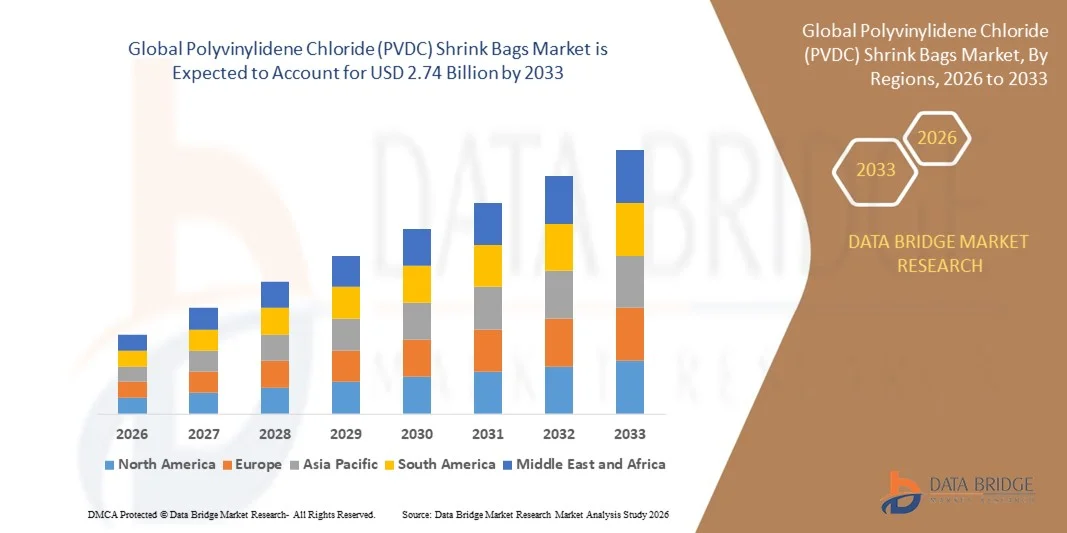

- The global Polyvinylidene Chloride (PVDC) shrink bags market size was valued at USD 2.09 billion in 2025 and is expected to reach USD 2.74 billion by 2033, at a CAGR of 3.4% during the forecast period

- The market growth is largely fueled by the increasing demand for high-barrier packaging solutions in the food and pharmaceutical industries, which ensure extended shelf life, product safety, and freshness during storage and transportation

- Furthermore, rising consumer preference for packaged, ready-to-cook, and processed food products is driving food processors and retailers to adopt Polyvinylidene Chloride (PVDC) shrink bags that provide superior sealing performance, moisture resistance, and protection against oxygen and microbial contamination, significantly boosting market growth

Polyvinylidene Chloride (PVDC) Shrink Bags Market Analysis

- PVDC shrink bags, offering high-barrier, durable, and flexible packaging for fresh meat, processed meat, poultry, seafood, and other perishable products, are becoming increasingly vital for maintaining product quality, reducing spoilage, and supporting efficient cold-chain logistics in both domestic and export markets

- The escalating demand for Polyvinylidene Chloride (PVDC) shrink bags is primarily fueled by growing adoption of modern food processing and packaging technologies, increasing regulatory emphasis on food safety, and the need for sustainable and high-performance packaging solutions that enhance operational efficiency and product shelf appeal

- North America dominated the Polyvinylidene Chloride (PVDC) shrink bags market with a share of 34.7% in 2025, due to increasing demand for packaged fresh and processed meat, poultry, and seafood, as well as rising awareness of high-barrier packaging solutions

- Asia-Pacific is expected to be the fastest growing region in the Polyvinylidene Chloride (PVDC) shrink bags market during the forecast period due to increasing urbanization, rising disposable incomes, and the growing demand for packaged fresh and processed food products in countries such as China, Japan, and India

- Round bottom sealed shrink bags segment dominated the market with a market share of 43% in 2025, due to their superior sealing integrity and ability to minimize product leakage during storage and transport. Their rounded construction ensures even shrink performance across irregularly shaped products, improving product presentation in retail environments. These bags are widely adopted by meat processors because they deliver consistent shrink properties that enhance shelf appeal and reduce contamination risks. The segment also benefits from strong usage in export-oriented food applications where extended shelf stability is a priority. Growing demand for high-barrier packaging solutions in international logistics further strengthens the position of round bottom sealed variants

Report Scope and Polyvinylidene Chloride (PVDC) Shrink Bags Market Segmentation

|

Attributes |

Polyvinylidene Chloride (PVDC) Shrink Bags Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Polyvinylidene Chloride (PVDC) Shrink Bags Market Trends

“Growing Demand for High-Barrier Food Packaging”

- The increasing need for extended shelf life and superior protection for perishable products is driving the demand for Polyvinylidene Chloride (PVDC) shrink bags in the global food packaging market. These bags are highly effective in reducing oxygen and moisture transmission, which helps maintain freshness and quality over longer storage and transportation periods

- For instance, Amcor plc (U.K.) has introduced high-barrier Polyvinylidene Chloride (PVDC) shrink bags for processed meat and seafood products, enabling manufacturers to meet stringent food safety and export standards. Such initiatives by leading companies are fostering broader adoption of Polyvinylidene Chloride (PVDC) shrink bags across various food segments

- The trend of replacing traditional packaging with high-barrier PVDC films is gaining momentum as food processors increasingly focus on minimizing spoilage and waste. Polyvinylidene Chloride (PVDC) shrink bags offer consistent shrink properties, excellent sealing performance, and enhanced product visibility, contributing to their growing popularity

- Integration of Polyvinylidene Chloride (PVDC) shrink bags with automated packaging lines and vacuum-sealing systems is facilitating faster production, reduced manual handling, and better operational efficiency. This compatibility with modern processing equipment strengthens the overall adoption in large-scale manufacturing

- Consumer preference for high-quality packaged foods that maintain freshness and nutritional value is influencing market trends. The ability of Polyvinylidene Chloride (PVDC) shrink bags to preserve color, texture, and flavor while extending shelf life is establishing them as the packaging of choice for premium food products

- The focus on high-barrier, durable, and sustainable packaging solutions is expected to continue driving the Polyvinylidene Chloride (PVDC) shrink bags market. As manufacturers and retailers prioritize product integrity, convenience, and reduced spoilage, the adoption of Polyvinylidene Chloride (PVDC) shrink bags is likely to expand across both domestic and international markets

Polyvinylidene Chloride (PVDC) Shrink Bags Market Dynamics

Driver

Growing Consumption of Packaged and Processed Food Products

- Rising global demand for packaged, ready-to-cook, and processed food items is a key driver for the Polyvinylidene Chloride (PVDC) shrink bags market. Consumers increasingly prefer convenient and hygienic food options, which encourages manufacturers to adopt high-performance shrink packaging

- For instance, Sealed Air Corporation (U.S.) has developed Polyvinylidene Chloride (PVDC) shrink bags for fresh and processed meat that extend shelf life and maintain product quality. Such product innovations by major companies are expected to stimulate market growth in the forecast period

- The growth of retail and e-commerce channels is boosting demand for packaged foods that can withstand transportation and handling. Polyvinylidene Chloride (PVDC) shrink bags provide the barrier properties and durability required to deliver products safely to end consumers

- Expansion in food processing infrastructure and cold-chain logistics is facilitating broader use of PVDC shrink bags. Manufacturers benefit from the combination of high-barrier protection and operational efficiency offered by these films

- Increasing awareness of food safety regulations and standards is driving adoption. Polyvinylidene Chloride (PVDC) shrink bags help processors comply with hygiene and quality requirements while ensuring longer product freshness, contributing to sustained market expansion

Restraint/Challenge

High Production Costs of PVDC Shrink Bags

- The relatively high cost of PVDC resin and multi-layer film production presents a challenge for market growth. Smaller processors and cost-sensitive manufacturers may find adoption difficult due to the investment required for high-performance PVDC shrink bags

- For instance, the implementation of advanced PVDC films by companies such as Berry Global Inc. (U.S.) involves significant capital expenditure for manufacturing and quality control. Such high costs can limit market penetration in developing regions or among price-sensitive customers

- Maintaining consistent quality in large-scale production is resource-intensive and requires specialized equipment and skilled labor. These factors contribute to the higher price of Polyvinylidene Chloride (PVDC) shrink bags compared to alternative packaging materials

- The environmental concerns associated with traditional PVDC films also require investment in sustainable or recyclable alternatives, which can increase production costs. Companies must balance performance requirements with sustainability initiatives to remain competitive

- Overcoming cost-related challenges through technological innovation, process optimization, and scale efficiency will be crucial for long-term market growth. Strategic focus on balancing quality, performance, and affordability is expected to define the competitive landscape in the Polyvinylidene Chloride (PVDC) shrink bags market

Polyvinylidene Chloride (PVDC) Shrink Bags Market Scope

The market is segmented on the basis of product type, barrier type, thickness type, abuse strength, and application.

- By Product Type

On the basis of product type, the Polyvinylidene Chloride (PVDC) shrink bags market is segmented into round bottom sealed shrink bags, straight bottom sealed shrink bags, and side sealed shrink bags. Round bottom sealed shrink bags dominated the market with the largest share of 43% in 2025 due to their superior sealing integrity and ability to minimize product leakage during storage and transport. Their rounded construction ensures even shrink performance across irregularly shaped products, improving product presentation in retail environments. These bags are widely adopted by meat processors because they deliver consistent shrink properties that enhance shelf appeal and reduce contamination risks. The segment also benefits from strong usage in export-oriented food applications where extended shelf stability is a priority. Growing demand for high-barrier packaging solutions in international logistics further strengthens the position of round bottom sealed variants.

The side sealed shrink bags segment is anticipated to witness the fastest growth from 2026 to 2033, driven by rising usage in processed meat, poultry, and seafood applications requiring custom-fit packaging formats. These bags offer flexible size adaptability, enabling manufacturers to package diverse product dimensions with improved operational efficiency. Their streamlined sealing structure supports faster production line compatibility, making them attractive for high-throughput facilities. In addition, increasing investments in advanced PVDC barrier technologies are boosting the performance of side sealed bags against oxygen and moisture transmission. The segment is also expanding due to preference for lightweight yet durable packaging in modern retail distribution.

- By Barrier Type

On the basis of barrier type, the Polyvinylidene Chloride (PVDC) shrink bags market is segmented into low barrier, medium barrier, high barrier, and ultra high barrier. The high barrier segment dominated the market in 2025 owing to its widespread use in fresh and processed meat applications that require stringent protection against oxygen exposure. High barrier PVDC films significantly extend product shelf life by suppressing oxidation, microbial growth, and moisture loss. Food retailers prefer these bags as they help maintain freshness, color stability, and flavor retention throughout storage and distribution. Their strong performance in cold-chain logistics has strengthened adoption among meat exporters targeting long-distance markets. Continuous improvements in multi-layer PVDC film engineering further support their dominance.

The ultra high barrier segment is projected to record the fastest growth from 2026 to 2033, supported by rising demand from premium meat processors and pharmaceutical companies that require maximum protection for sensitive products. Ultra high barrier shrink bags are increasingly preferred in scenarios where extended shelf life and strict product integrity standards are critical. Advancements in PVDC resin processing have enhanced their resistance to puncture, gas transmission, and moisture ingress. Exporters in regions with fluctuating climatic conditions are adopting these bags to ensure consistent product quality during transit. Growth is also driven by expanding regulatory emphasis on safety and extended freshness in packaged meat and specialty goods.

- By Thickness Type

On the basis of thickness type, the market is segmented into up to 50 micron, 50 to 70 micron, 70 to 90 micron, 90 to 110 micron, and above 110 micron. The 70 to 90 micron segment dominated the market in 2025 due to its balanced strength, flexibility, and shrink efficiency, making it suitable for fresh meat and poultry packaging. This thickness range offers optimal puncture resistance during handling, reducing risks of bag failure on automated lines. Manufacturers prefer this category because it ensures strong sealing properties while maintaining cost-effectiveness in high-volume operations. Its compatibility with vacuum sealing technologies contributes to extended product shelf life. Demand also benefits from its adaptability across multiple food categories with varying weight and shape.

The above 110 micron segment is expected to witness the fastest growth from 2026 to 2033, driven by increasing preference for premium-grade packaging used in high-abuse applications. These thicker bags provide enhanced durability for transporting heavy cuts of meat, bone-in products, and export-grade items that face rough handling. Their reinforced structure offers superior barrier performance under fluctuating temperatures. As processors expand into global markets, thicker Polyvinylidene Chloride (PVDC) shrink bags are being adopted to ensure product safety throughout extended logistics cycles. Growth is also supported by rising demand in industrial and pharmaceutical applications requiring strong puncture resistance.

- By Abuse Strength

On the basis of abuse strength, the Polyvinylidene Chloride (PVDC) shrink bags market is segmented into high abuse and low abuse. The high abuse segment dominated the market in 2025 due to its extensive application in bone-in meat, heavy poultry products, and large seafood items that require superior resistance to puncture and tearing. These bags help maintain package integrity during shipping and storage where mechanical stress is higher. Food processors rely on high abuse bags to reduce product wastage associated with packaging failures. Strong adoption in export markets further strengthens the segment’s dominance due to long transportation routes. Retailers benefit from enhanced durability that preserves product appearance and safety.

The low abuse segment is projected to grow at the fastest rate from 2026 to 2033, supported by rising demand for lightweight packaging used in boneless meat, processed foods, cosmetics, and various non-food items. Low abuse bags offer cost advantages while still providing adequate barrier protection for delicate items that do not require heavy-duty strength. Manufacturers prefer these bags for applications where weight reduction and material efficiency are priorities. Growth is also influenced by expansion of small-scale food processors adopting economical packaging formats. Increasing usage in electronics and personal care sectors further accelerates demand.

- By Application

On the basis of application, the market is segmented into fresh meat, processed meat, poultry, seafood, electronics, cosmetics and personal care, healthcare and pharmaceuticals, industrial, and others. The fresh meat segment dominated the market in 2025 due to high dependency on Polyvinylidene Chloride (PVDC) shrink bags for maintaining freshness, preventing oxidation, and extending shelf stability. Meat processors rely on these bags to preserve color, flavor, and moisture levels throughout distribution. Fresh meat exporters also drive demand as PVDC barriers enable longer storage without compromising quality. The ability of shrink bags to conform tightly around meat cuts improves retail presentation, supporting premium product positioning. Growth is reinforced by expanding cold-chain infrastructure worldwide.

The processed meat segment is expected to register the fastest growth from 2026 to 2033, driven by the rising global consumption of packaged and convenience-based meat products. Processed meat manufacturers prefer Polyvinylidene Chloride (PVDC) shrink bags for their consistent shrink performance and ability to maintain product shape. Growing demand for sausages, cured meats, and ready-to-cook products fuels segment expansion. Advancements in barrier technology improve preservation of flavor and texture, supporting wider application across retail and foodservice. Increasing production automation in processed meat industries also boosts usage of high-efficiency shrink packaging.

Polyvinylidene Chloride (PVDC) Shrink Bags Market Regional Analysis

- North America dominated the Polyvinylidene Chloride (PVDC) shrink bags market with the largest revenue share of 34.7% in 2025, driven by increasing demand for packaged fresh and processed meat, poultry, and seafood, as well as rising awareness of high-barrier packaging solutions

- Food processors and retailers in the region highly value the extended shelf life, product protection, and superior sealing performance offered by Polyvinylidene Chloride (PVDC) Shrink Bags, particularly for export-oriented and cold-chain applications

- This widespread adoption is further supported by well-established cold-chain infrastructure, advanced food processing technologies, and high regulatory standards for food safety, establishing Polyvinylidene Chloride (PVDC) shrink bags as a preferred packaging solution for both domestic and international markets

U.S. Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The U.S. Polyvinylidene Chloride (PVDC) shrink bags market captured the largest revenue share in 2025 within North America, fueled by the strong adoption of vacuum-packed meat, poultry, and seafood products. Processors are increasingly prioritizing packaging that maintains product quality, reduces spoilage, and improves shelf presentation. The growing demand for ready-to-cook and convenience-based food products, combined with stringent food safety regulations, further drives market expansion. Moreover, integration with automated packaging lines and multi-layer PVDC films enhances efficiency and durability, significantly contributing to market growth.

Europe Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The Europe Polyvinylidene Chloride (PVDC) shrink bags market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by the increasing need for high-barrier packaging to ensure product freshness and compliance with strict food safety regulations. Rising urbanization and growing consumption of packaged meat and seafood products are fostering the adoption of Polyvinylidene Chloride (PVDC) shrink bags. European manufacturers also favor these bags due to their superior shrink performance, operational efficiency, and ability to support sustainable packaging initiatives. The market is witnessing growth across both retail and industrial applications.

U.K. Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The U.K. Polyvinylidene Chloride (PVDC) shrink bags market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing consumer demand for packaged fresh and processed food products. Concerns regarding product spoilage and the need for longer shelf life are encouraging food processors and retailers to adopt Polyvinylidene Chloride (PVDC) shrink bags. In addition, the U.K.’s well-developed cold-chain and retail infrastructure supports efficient distribution, further stimulating market growth.

Germany Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The Germany Polyvinylidene Chloride (PVDC) shrink bags market is expected to expand at a considerable CAGR during the forecast period, fueled by growing awareness of food safety and technological advancements in packaging. Germany’s advanced food processing industry, combined with strong export-oriented operations, promotes the adoption of high-barrier Polyvinylidene Chloride (PVDC) shrink bags. These bags are increasingly integrated into automated packaging systems, ensuring consistent product quality and reducing spoilage during storage and transportation.

Asia-Pacific Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The Asia-Pacific Polyvinylidene Chloride (PVDC) shrink bags market is poised to grow at the fastest CAGR during the forecast period of 2026 to 2033, driven by increasing urbanization, rising disposable incomes, and the growing demand for packaged fresh and processed food products in countries such as China, Japan, and India. Government initiatives supporting modern food processing and cold-chain development are driving adoption. In addition, APAC’s position as a major manufacturing hub for packaging films is enhancing affordability and availability of Polyvinylidene Chloride (PVDC) shrink bags for domestic and export markets.

Japan Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The Japan Polyvinylidene Chloride (PVDC) shrink bags market is gaining momentum due to high demand for premium packaging solutions that ensure product safety and extend shelf life. The market benefits from the country’s technologically advanced food processing industry, aging population seeking convenient ready-to-cook products, and emphasis on hygienic packaging. Integration with automated packaging systems further drives adoption in both residential and commercial food sectors.

China Polyvinylidene Chloride (PVDC) Shrink Bags Market Insight

The China Polyvinylidene Chloride (PVDC) shrink bags market accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to rapid urbanization, a growing middle class, and high consumption of packaged fresh and processed meat products. China is emerging as a leading market for advanced packaging solutions, with domestic manufacturers offering cost-effective, high-barrier Polyvinylidene Chloride (PVDC) shrink bags. Expansion of cold-chain infrastructure, coupled with government initiatives promoting food safety and modern retail, is propelling market growth.

Polyvinylidene Chloride (PVDC) Shrink Bags Market Share

The Polyvinylidene Chloride (PVDC) shrink bags industry is primarily led by well-established companies, including:

- Bemis Company, Inc. (U.S.)

- Amcor plc (U.K.)

- KUREHA CORPORATION (Japan)

- Sealed Air Corporation (U.S.)

- WINPAK LTD. (Canada)

- FLEXOPACK SA (Switzerland)

- Coveris (Austria)

- Allfo (Germany)

- PREMIUMPACK GmbH (Germany)

- Schur Flexibles Holding GesmbH (Austria)

- Messe Frankfurt Exhibition GmbH (Germany)

- Sunrise Packaging Material (Jiangyin) Co., Ltd (China)

- KUPLAST MATEJKA KUMAR S.P. (Czech Republic)

- Spektar d.o.o. (Slovenia)

- Green Packaging Material (Jiangyin) Co., Ltd (China)

- Atlantis-Pak (U.K.)

- Globus Group (Italy)

- Inauen Group (Switzerland)

- Gap Foil (Germany)

- Astar Packaging Pte Ltd (Singapore)

Latest Developments in Global Polyvinylidene Chloride (PVDC) Shrink Bags Market

- In September 2025, Amcor plc (GB) announced a partnership with a leading food manufacturer to develop customized Polyvinylidene Chloride (PVDC) shrink bags that extend shelf life while reducing environmental impact. This collaboration strengthens Amcor’s market position by enhancing its sustainable packaging portfolio and aligning with growing consumer and regulatory demand for eco-friendly solutions. The partnership is likely to drive further adoption of high-performance Polyvinylidene Chloride (PVDC) shrink bags across food processing and retail sectors, reinforcing Amcor’s leadership in innovation-driven packaging solutions

- In August 2025, Sealed Air Corporation (US) launched a new line of eco-friendly Polyvinylidene Chloride (PVDC) shrink bags aimed at reducing plastic waste and promoting sustainable packaging. This initiative enhances Sealed Air’s market presence by appealing to environmentally conscious customers and meeting increasing regulatory pressure for responsible packaging. By positioning itself as a leader in sustainable solutions, Sealed Air is expected to strengthen brand loyalty and expand its share in both domestic and international PVDC shrink bag markets

- In July 2025, Berry Global Inc. (US) expanded its manufacturing capabilities in Eastern Europe to improve production efficiency and meet rising regional demand for PVDC shrink bags. This strategic expansion allows Berry to respond rapidly to local market needs, optimize supply chain operations, and enhance competitiveness in Europe. The move also reinforces Berry’s ability to serve large-scale food processors with reliable, high-quality PVDC shrink bags, supporting long-term market growth

- In June 2025, Mondi Group (AT/GB) introduced an advanced high-barrier PVDC shrink bag line with improved puncture resistance and oxygen barrier properties. This development strengthens Mondi’s position in the premium segment of the market by addressing the growing demand for extended shelf life packaging in fresh and processed meat, poultry, and seafood applications. The new product line is expected to drive adoption among large-scale processors seeking durable, high-performance packaging solutions while supporting sustainability goals

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Polyvinylidene Chloride Pvdc Shrink Bags Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Polyvinylidene Chloride Pvdc Shrink Bags Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Polyvinylidene Chloride Pvdc Shrink Bags Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.