Global Powder Coating Pretreatment Market

Market Size in USD Billion

CAGR :

%

USD

1.20 Billion

USD

1.90 Billion

2024

2032

USD

1.20 Billion

USD

1.90 Billion

2024

2032

| 2025 –2032 | |

| USD 1.20 Billion | |

| USD 1.90 Billion | |

|

|

|

|

Powder Coating Pretreatment Market Analysis

The powder coating pretreatment market is driven by the growing adoption of powder coatings in industries such as automotive, construction, and electronics due to their durability and eco-friendly properties. Pretreatment processes, including cleaning and surface conditioning, enhance coating adhesion and corrosion resistance, ensuring long-term performance. Rising demand for chromium-free and environmentally sustainable pretreatment solutions fuels market growth, supported by stringent environmental regulations and increasing awareness of sustainable practices. Technological advancements, such as nanotechnology-based treatments, are creating new opportunities. Asia-Pacific leads the market due to rapid industrialization, while North America and Europe experience steady growth driven by innovation and regulatory compliance.

Powder Coating Pretreatment Market Size

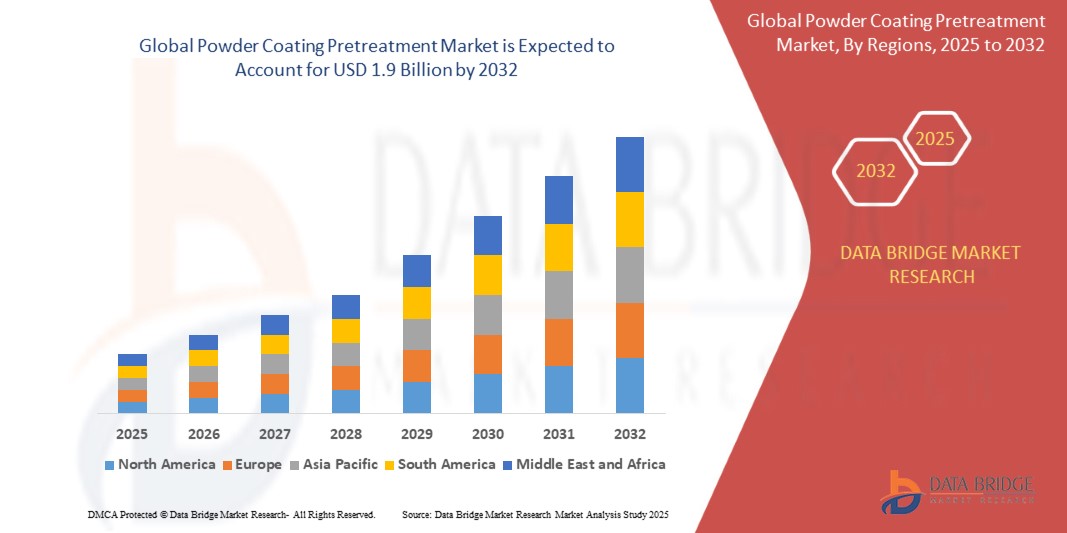

Global powder coating pretreatment market size was valued at USD 1.2 billion in 2024 and is projected to reach USD 1.9 billion by 2032, with a CAGR of 5.20% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Powder Coating Pretreatment Market Trends

“Increasing Demand for Eco-Friendly and Durable Coating Solutions”

The powder coating pretreatment market is witnessing significant growth, driven by increasing demand for eco-friendly and durable coating solutions across industries such as automotive, construction, and electronics. A key trend is the shift toward chromium-free and solvent-free pretreatment technologies, addressing environmental concerns and regulatory compliance. Manufacturers are adopting advanced technologies, including nanotechnology-based pretreatments, to enhance adhesion and corrosion resistance. Rising investments in infrastructure and automotive production, particularly in Asia-Pacific, are boosting market expansion. In addition, innovations in pretreatment processes to improve efficiency and reduce operational costs are gaining traction, further driving the growth of the powder coating pretreatment industry globally.

Report Scope and Powder Coating Pretreatment Market Segmentation

|

Report Metric |

Powder Coating Pretreatment Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada, Mexico, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa, Brazil, Argentina, Rest of South America |

|

Key Market Players |

DuBois Chemicals (U.S.), PPG Industries, Inc (U.S.), Jost International (U.S.), Sanchem, Inc. (U.S.), Bunty LLC (U.S.), NABU-Oberflächentechnik GmbH (Germany), Hillebrand Coating (Germany), Technofirma S.p.A. (Italy), Euroimpianti Srl (Italy), FOSHAN HAIHUA SURFACE TREATMENT TECHNOLOGY CO., LTD. (China), Keyi Industrial (Shanghai) Co., Ltd. (China), and SEW SURFACE COATING PVT. LTD. (India) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Powder Coating Pretreatment Market Definition

Powder coating pretreatment refers to the preparatory process applied to a substrate to ensure optimal adhesion and durability of the powder coating. This involves cleaning, degreasing, and treating the surface to remove contaminants like oils, dirt, rust, or previous coatings. Depending on the material, processes such as chemical cleaning, phosphate conversion coating, or sandblasting may be used. Pretreatment enhances corrosion resistance, promotes uniform coating application, and extends the product's lifespan. It is a critical step in industries like automotive, construction, and manufacturing, where high-performance coatings are essential for protecting components against environmental and mechanical wear.

Powder Coating Pretreatment Market Dynamics

Drivers

- Rising Demand for Durable Coatings in Industries

The increasing need for high-performance coatings in industries such as automotive, construction, and electronics is a major driver for the Powder Coating Pretreatment Market. As these industries emphasize longer product lifespans, corrosion resistance, and enhanced aesthetics, pretreatment processes have become essential to achieving desired outcomes. Powder coatings offer superior finishes due to their excellent durability, resistance to wear, and environmental protection. In the automotive sector, for example, components need to endure harsh conditions, such as high temperatures and exposure to chemicals, making pretreatment processes crucial. In the construction and consumer electronics industries, the need for weather-resistant coatings and finishes that maintain their appearance over time drives the demand for high-quality pretreatment methods. As global industries continue to focus on high-performance, long-lasting products, the demand for pretreatment solutions that improve coating adhesion and durability will remain strong, further fueling market growth.

- Rising Demand for Sustainability and Eco-Friendly Solutions

Sustainability concerns and tightening environmental regulations are significant drivers of growth in the Powder Coating Pretreatment Market. Governments and consumers are increasingly demanding environmentally friendly products, which has resulted in the rise of solvent-free, chromium-free, and low-VOC pretreatment processes. Traditional pretreatment methods often involve toxic chemicals such as phosphates, which are harmful to both the environment and human health. As a result, manufacturers are focusing on developing green alternatives that ensure both high-performance coatings and minimal environmental impact. Eco-friendly pretreatments reduce harmful emissions, improve workplace safety, and comply with stringent regulations. These technologies are gaining traction, especially as industries, such as automotive and construction, move toward more sustainable manufacturing practices. Companies are also incorporating water-based and biodegradable chemicals into their pretreatment processes, ensuring that their operations align with global environmental goals. This shift toward sustainable solutions provides substantial growth opportunities for the powder coating pretreatment market.

Opportunities

- Technological Advancements in Pretreatment Solutions

The development of innovative technologies presents a significant opportunity for the Powder Coating Pretreatment Market. One such advancement is the use of nanotechnology to improve the effectiveness of pretreatment processes. Nanotechnology allows for the creation of coatings that offer enhanced adhesion, durability, and corrosion resistance while using fewer chemicals. In addition, advances in chemical formulations are helping to improve the efficiency of pretreatment processes, making them more cost-effective and environmentally friendly. For example, new chemical treatments can achieve superior surface cleaning, degreasing, and phosphating with fewer steps and reduced resource consumption. As manufacturers strive to meet the evolving demands of the market, such innovations will continue to provide opportunities for growth. Moreover, the focus on sustainability is pushing companies to adopt water-based or chromium-free pretreatment technologies, improving both the safety of the coating process and the final product’s environmental footprint. These technological advancements are expected to drive significant growth in the market, enhancing product quality and reducing the environmental impact.

- Expansion in Emerging Markets

The expansion of industrial sectors in emerging markets, particularly in Asia-Pacific and Latin America, presents a major growth opportunity for the Powder Coating Pretreatment Market. As countries like China, India, Brazil, and Mexico experience industrial growth, the demand for advanced coatings and pretreatment solutions is rapidly increasing. These regions are seeing significant investments in manufacturing industries such as automotive, electronics, and construction, which require high-quality finishes for their products. In addition, the growing middle class in these regions is driving demand for durable, aesthetically pleasing consumer goods, such as household appliances and electronics. As a result, manufacturers are increasingly adopting advanced powder coating technologies to meet these rising demands. By offering affordable, effective pretreatment solutions tailored to the unique needs of these regions, companies can expand their market presence. These emerging markets also present opportunities for green and eco-friendly pretreatment solutions, as local regulations push for more sustainable manufacturing practices.

Restraints/Challenges

- High Initial Investment

One of the significant restraints in the Powder Coating Pretreatment Market is the high initial investment required to set up pretreatment systems. The installation of specialized equipment, such as cleaning, degreasing, and phosphating systems, can be expensive, especially for small- and medium-sized manufacturers. In addition to the initial setup costs, the need for specialized chemicals, safety equipment, and training programs to operate these systems further raises the financial barrier for adoption. For smaller companies in developing regions, such as parts of Southeast Asia or Latin America, these costs can be prohibitively high, preventing them from upgrading their pretreatment processes or adopting more advanced technologies. This financial challenge is compounded by the ongoing maintenance and operational costs of pretreatment systems, which can include the procurement of raw materials and handling waste disposal. While larger companies with the financial capacity can make these investments, smaller players may struggle to compete, limiting the market’s growth potential in certain regions.

- Compatibility with Various Substrates

A significant challenge in the Powder Coating Pretreatment Market is ensuring the compatibility of pretreatment processes with a wide range of substrates, including different metals, alloys, and other materials. Each substrate has unique properties that affect how it reacts to cleaning, degreasing, and phosphating treatments, making it difficult to standardize pretreatment processes. For instance, steel, aluminum, and galvanized steel require different approaches and treatment durations, and failure to match the proper pretreatment process to the substrate can result in poor adhesion or performance of the coating. Moreover, certain substrates, such as those with complex geometries or intricate surface textures, may require customized pretreatment solutions, which increases the complexity and cost of the process. This challenge is particularly relevant in industries like automotive, where components are made from various materials, and precise coating quality is required for durability and aesthetic appeal. As a result, manufacturers must continuously innovate and invest in research to create versatile, high-performance pretreatment solutions for a wide range of substrates..

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Global Powder Coating Pretreatment Market Scope

The market is segmented on the basis of product and application. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product

- Phosphate

- Chromate

- Chromate Free

- Blast Clean

Application

- Automotive & Transportation

- Appliances

- Construction

- Other Applications

Global Powder Coating Pretreatment Market Regional Analysis

The market is analyzed and market size insights and trends are provided by country, product, and application as referenced above.

The countries covered in the market are U.S., Canada, Mexico, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, rest of Asia-Pacific, Saudi Arabia, U.A.E., South Africa, Egypt, Israel, rest of Middle East and Africa, Brazil, Argentina, and rest of South America.

Asia-Pacific is expected to dominate the powder coating pretreatment market due to rapid industrialization, growing automotive and construction sectors, and increased demand for durable, high-quality coatings in diverse manufacturing applications.

Asia-Pacific is expected to be fastest growing with the highest CAGR in the powder coating pretreatment market due to rapid industrialization, increasing demand for automotive and manufacturing sectors, and expanding infrastructure in countries like China and India.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Global Powder Coating Pretreatment Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Powder Coating Pretreatment Market Leaders Operating in the Market are:

- DuBois Chemicals (U.S.)

- PPG Industries, Inc (U.S.)

- Jost International (U.S.)

- Sanchem, Inc. (U.S.)

- Bunty LLC (U.S.)

- NABU-Oberflächentechnik GmbH (Germany)

- Hillebrand Coating (Germany)

- Technofirma S.p.A. (Italy)

- Euroimpianti Srl (Italy)

- FOSHAN HAIHUA SURFACE TREATMENT TECHNOLOGY CO., LTD. (China)

- Keyi Industrial (Shanghai) Co., Ltd. (China)

- SEW SURFACE COATING PVT. LTD. (India)

Recent Developments in Global Powder Coating Pretreatment Market

- In November 2023, Henkel, a leading surface treatment provider, enhanced its manufacturing capacity in Spain by incorporating solvent-free and chromium-free metal pretreatment technologies into its European product portfolio, catering specifically to coating facilities

- In June 2024, Jotun introduced a groundbreaking CX-rated anticorrosive powder coating. This advanced solution leverages proven technology to protect critical equipment in harsh environments. As the industry's first powder coating designed specifically to shield steel in extreme conditions, it sets a new standard for durability and performance

- In June 2024, Henkel, a global leader in coating pretreatment solutions, launched Bonderite M-NT 41044, an advanced cleaner and coater technology designed to improve efficiency and sustainability in metal pretreatment. This innovation streamlines processing steps from ten to four, conserving water and energy while delivering excellent corrosion protection and paint adhesion.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Powder Coating Pretreatment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Powder Coating Pretreatment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Powder Coating Pretreatment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.