Global Precast Concrete Market

Market Size in USD Billion

CAGR :

%

USD

122.12 Billion

USD

200.60 Billion

2024

2032

USD

122.12 Billion

USD

200.60 Billion

2024

2032

| 2025 –2032 | |

| USD 122.12 Billion | |

| USD 200.60 Billion | |

|

|

|

Precast Concrete Market Analysis

The precast concrete market is experiencing significant growth, driven by rapid urbanization, industrialization, and infrastructure development worldwide. Precast concrete, known for its durability, cost-efficiency, and reduced construction time, is increasingly adopted in residential, commercial, and industrial projects. Governments and private players are investing in smart cities, highways, bridges, and modular construction, further fueling market expansion. Advancements in technology, such as automated precast production, 3D printing, and high-performance concrete mixtures, are enhancing the efficiency and quality of precast components. In addition, the integration of IoT and AI-powered monitoring systems is optimizing manufacturing processes, logistics, and on-site assembly, reducing labor dependency and project delays. Sustainable construction practices, including carbon capture in cement manufacturing and the use of recycled materials, are gaining traction, aligning with global environmental regulations. Key market players are engaging in strategic mergers, acquisitions, and capacity expansions to strengthen their market position. With growing demand for prefabricated solutions in residential and non-residential sectors, the precast concrete market is poised for steady growth, offering high-quality, innovative, and sustainable building solutions worldwide.

Precast Concrete Market Size

The global precast concrete market size was valued at USD 122.12 billion in 2024 and is projected to reach USD 200.60 billion by 2032, with a CAGR of 6.40 % during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Precast Concrete Market Trends

“Rising Adoption of Modular Construction”

One prominent trend in the precast concrete market is the rising adoption of modular construction to accelerate project timelines and reduce labor costs. Modular construction utilizes precast concrete components, such as walls, beams, and slabs, which are manufactured in controlled environments and then transported to the construction site for quick assembly. This method enhances efficiency, quality control, and sustainability, making it an attractive choice for residential, commercial, and infrastructure projects. For instance, in Europe and North America, governments are increasingly promoting modular precast solutions for affordable housing and public infrastructure to address growing urbanization. Technological advancements, such as automated precast production and BIM (Building Information Modeling) integration, are further optimizing design accuracy and reducing material wastage. As demand for cost-effective, durable, and environmentally friendly construction methods rises, the modular precast trend is set to revolutionize the global precast concrete industry in the coming years.

Report Scope and Precast Concrete Market Segmentation

|

Attributes |

Precast Concrete Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

ACS, Actividades de Construcción y Servicios, SA (Spain), Bouygues Construction (France), Cemex S.A.B. De C.V. (Mexico), Balfour Beatty (U.K.), LAING O’ROURKE (U.K.), LARSEN & TOUBRO LIMITED (India), TAISEI CORPORATION (Japan), Skanska (Sweden), CRH (Ireland), Julius Berger Nigeria Plc (Nigeria), RED SEA INTERNATIONAL (Saudi Arabia), Elematic Oyj (Finland), Coreslab Structures (U.S.), Coltman Precast Concrete Limited (U.K.), Metromont LLC (U.S.), Oldcastle Infrastructure, Inc. (U.S.), SMEET (Qatar), ATCO Ltd (Canada), Vinci (France), and Kiewit Corporation (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Precast Concrete Market Definition

Precast concrete is a construction material that is manufactured by casting concrete in a controlled environment, such as a factory or precast plant, before being transported to the construction site for installation. This method ensures higher quality, durability, and consistency compared to traditional on-site casting.

Precast Concrete Market Dynamics

Drivers

- Rapid Urbanization and Infrastructure Development

The surge in urbanization and industrialization has created a rising demand for residential, commercial, and industrial spaces, leading to a greater reliance on precast concrete solutions. As cities expand, the need for faster, cost-effective, and durable construction methods has become critical. Governments and private investors are actively funding infrastructure projects, including highways, bridges, tunnels, metro systems, and smart city developments, where precast concrete is extensively used due to its high strength, uniform quality, and reduced construction time. For instance, India’s Smart Cities Mission and China’s Belt and Road Initiative (BRI) are heavily investing in prefabricated construction techniques, including precast concrete components, to ensure sustainable urban growth. The ability of precast concrete to support mass urban development with minimal environmental impact makes it a key driver in the global construction industry.

- Increasing demand for Cost and Time Efficiency

One of the primary advantages of precast concrete is its ability to reduce both construction time and costs, making it a preferred choice for large-scale infrastructure and real estate projects. Since precast concrete components are manufactured in controlled environments, they eliminate many of the inefficiencies associated with on-site casting, such as weather delays, inconsistent quality, and excess labor requirements. This efficiency is particularly beneficial in fast-growing economies, where governments and private developers need rapid construction solutions to meet increasing demands. For instance, Singapore’s adoption of Prefabricated Prefinished Volumetric Construction (PPVC) in housing projects has significantly reduced on-site labor by up to 50% and construction time by 30-40%, showcasing how precast concrete accelerates project completion while maintaining superior quality. As the focus on cost-effective and time-efficient construction intensifies, precast concrete continues to be a major driver in the construction industry worldwide.

Opportunities

- Increasing Advancements in Precast Technology

The integration of automation, robotics, and 3D printing in precast concrete manufacturing is revolutionizing the construction industry by enhancing precision, quality, and productivity. Automated production lines improve efficiency and consistency, reducing human errors and construction delays. 3D printing technology allows for the creation of complex precast structures with minimal material waste, making the process more cost-effective and sustainable. In addition, Building Information Modeling (BIM) is transforming design, logistics, and project planning, enabling seamless coordination among architects, engineers, and contractors. For instance, in the U.K., Laing O’Rourke has implemented BIM-driven precast concrete techniques in large-scale infrastructure projects, significantly reducing construction time and costs. These technological advancements are opening new market opportunities, allowing precast manufacturers to expand their offerings, improve customization, and meet the growing demand for smart construction solutions worldwide.

- Increasing Global Emphasis on Sustainability and Environmental Benefits

With an increasing global emphasis on sustainable construction, precast concrete is emerging as a preferred choice due to its durability, recyclability, and lower carbon footprint. Compared to traditional on-site casting, precast production generates less waste, reduces energy consumption, and minimizes site disruption, making it an eco-friendly alternative. The adoption of carbon capture technologies in cement production and the use of recycled aggregates are further enhancing the sustainability of precast materials. For instance, Holcim’s acquisition of HM Factory in Poland has strengthened its commitment to low-carbon precast solutions, aligning with the company’s goal to increase sustainable product offerings. As governments introduce stricter environmental regulations and encourage green building certifications, the demand for sustainable precast concrete solutions is expected to grow, presenting a significant market opportunity for manufacturers looking to cater to eco-conscious construction projects.

Restraints/Challenges

- High Initial Investment and Production Costs

Setting up a precast concrete manufacturing facility requires significant capital investment in specialized machinery, molds, curing systems, and material storage infrastructure. Unlike traditional on-site concrete casting, precast production demands controlled environments, automated processes, and high-precision equipment to ensure quality and efficiency. These factors contribute to high upfront costs, making it difficult for small and medium-sized enterprises (SMEs) to enter the market. In addition, transportation costs further escalate expenses. Since precast concrete elements are heavy and bulky, they require specialized trucks and cranes for loading, unloading, and installation. If the construction site is far from the manufacturing plant, logistics expenses increase significantly, reducing cost-effectiveness. For instance, a precast infrastructure project in a remote area may face high delivery costs, limiting its feasibility compared to on-site casting. As a result, these financial barriers hinder market expansion, restricting precast adoption primarily to large-scale projects backed by major construction firms. Unless cost-effective production methods or government incentives are introduced, the high initial investment remains a major challenge for industry growth.

- Skilled Labor Shortage

While precast concrete manufacturing reduces the need for on-site construction labor, it requires a highly skilled workforce for plant operations, mold preparation, quality control, and assembly. Unfortunately, many regions face a shortage of trained professionals, leading to production delays, quality issues, and inefficiencies. For instance, manufacturing precast elements involves precision engineering, requiring expertise in computer-aided design (CAD), mold fabrication, and curing techniques. A shortage of workers proficient in these areas affects production speed and quality consistency. In addition, the installation of precast components at the construction site demands skilled crane operators, riggers, and assemblers to ensure structural stability. If such expertise is unavailable, projects risk delays, misalignment, and safety hazards. This labor shortage presents a major challenge for market expansion, as companies struggle to maintain production efficiency while meeting project deadlines. Without investments in training programs, apprenticeships, and automation, the lack of skilled labor could slow down the adoption of precast concrete technology worldwide.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Precast Concrete Market Scope

The market is segmented on the basis of product type, construction type, application, and end user. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product Type

- Columns and Beams

- Walls and Barriers

- Floors and Roofs

- Utility Vaults

- Girders

- Pipes

- Paving Slabs

- Others

Construction Type

- Elemental Construction

- Permanent Modular Buildings

- Relocatable Buildings

Application

- Structural Components

- Architectural Components

- Bridge Components

End User

- Residential

- Non-Residential

- Agriculture

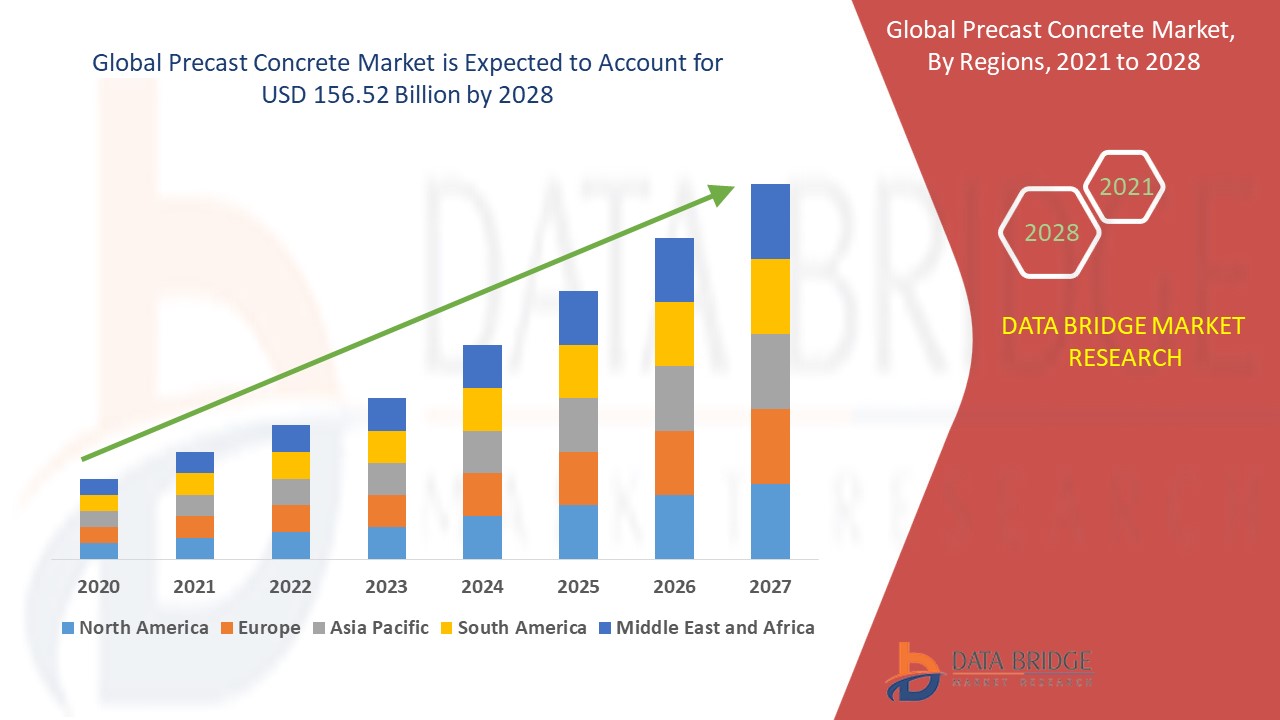

Precast Concrete Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, product type, construction type, application, and end user as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific dominates the precast concrete market due to rapid urbanization and industrialization, which have significantly increased demand for cost-effective and durable construction solutions. The region is witnessing large-scale infrastructure projects, including smart cities, highways, bridges, and commercial complexes, driving the adoption of precast concrete components. In addition, government initiatives promoting sustainable and efficient construction methods are further accelerating market growth. The growing need for high-quality, time-saving, and labor-efficient building solutions positions Asia-Pacific as a key player in the global precast concrete market.

Europe is expected to witness fastest growth in the precast concrete market during the forecast period, driven by the rising adoption of precast concrete products in non-residential and infrastructure projects. The region is experiencing increased demand for efficient, cost-effective, and sustainable construction methods, particularly in the development of commercial buildings, transportation networks, and public infrastructure. The implementation of precast concrete components has significantly reduced construction timelines and labor costs, making it a preferred choice for large-scale projects. In addition, stringent environmental regulations and a focus on sustainable construction practices are further propelling market expansion across Europe.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Precast Concrete Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Precast Concrete Market Leaders Operating in the Market Are:

- ACS, Actividades de Construcción y Servicios, SA (Spain)

- Bouygues Construction (France)

- Cemex S.A.B. De C.V. (Mexico)

- Balfour Beatty (U.K.)

- LAING O’ROURKE (U.K.)

- LARSEN & TOUBRO LIMITED (India)

- TAISEI CORPORATION (Japan)

- Skanska (Sweden)

- CRH (Ireland)

- Julius Berger Nigeria Plc (Nigeria)

- RED SEA INTERNATIONAL (Saudi Arabia)

- Elematic Oyj (Finland)

- Coreslab Structures (U.S.)

- Coltman Precast Concrete Limited (U.K.)

- Metromont LLC (U.S.)

- Oldcastle Infrastructure, Inc. (U.S.)

- SMEET (Qatar)

- ATCO Ltd (Canada)

- Vinci (France)

- Kiewit Corporation (U.S.)

Latest Developments in Precast Concrete Market

- In January 2024, Holcim Ltd. completed three acquisitions in Europe, strengthening its Solutions & Products business segment. The company acquired Artepref S.A. in Spain, W.A.T.T. Recycling in Greece, and Eco-Readymix Ltd in the U.K. These acquisitions contributed to Holcim’s business expansion and market growth

- In October 2023, Fabcon Precast acquired Bristol Precast, a division of Bristol Group, which specializes in engineered precast and prestressed concrete products across various U.S. states. This acquisition aims to enhance Fabcon Precast’s presence in the Mid-South U.S. market

- In February 2023, Holcim acquired HM Factory, a Poland-based precast concrete solutions provider. HM Factory serves Scandinavian and Polish construction markets, supporting Holcim’s strategy to expand its Solutions & Products segment to 30% of total net sales by 2025

- In September 2022, Tindall Corporation expanded its precast concrete floor slab system (T-SLAB) production by launching a new production line at its Mississippi manufacturing plant. This expansion helps the company strengthen its market presence in the precast concrete industry

- In May 2022, Boral Limited partnered with Calix Limited, a leading technology group, to assess the feasibility of developing a carbon capture plant in the NSW Southern Highlands. Supported by a Commonwealth grant, this project aims to capture and compress up to 100ktpa of CO₂ emissions generated from limestone decomposition in cement manufacturing

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Precast Concrete Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Precast Concrete Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Precast Concrete Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.