Global Precision Milking Robot Market

Market Size in USD Billion

CAGR :

%

USD

3.42 Billion

USD

8.24 Billion

2025

2033

USD

3.42 Billion

USD

8.24 Billion

2025

2033

| 2026 –2033 | |

| USD 3.42 Billion | |

| USD 8.24 Billion | |

|

|

|

|

Precision Milking Robot Market Size

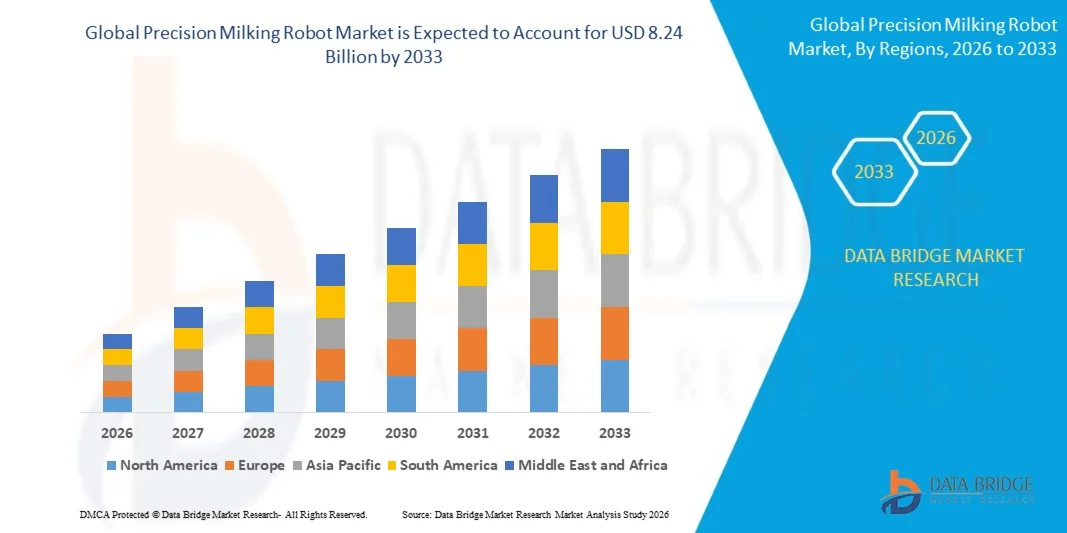

- The global precision milking robot market size was valued at USD 3.42 billion in 2025 and is expected to reach USD 8.24 billion by 2033, at a CAGR of 11.60% during the forecast period

- The market growth is largely fueled by increasing labor shortages in the dairy sector and the rising need to improve operational efficiency, prompting farmers to adopt automated milking technologies that reduce dependency on manual labor

- Furthermore, growing emphasis on animal welfare, consistent milk quality, and data-driven herd management is positioning precision milking robots as a critical solution for modern dairy farms. These combined factors are accelerating the adoption of robotic milking systems, thereby significantly supporting overall market growth

Precision Milking Robot Market Analysis

- Precision milking robots, which automate the milking process while monitoring cow health and milk yield, are becoming integral to modern dairy farming due to their ability to enhance productivity, improve animal comfort, and ensure consistent milk quality across varying herd sizes

- The increasing demand for precision milking robots is primarily driven by the modernization of dairy farms, rising investment in smart agriculture technologies, and the growing need for sustainable and efficient milk production practices

- North America dominated the precision milking robot market in 2025, due to the early adoption of advanced dairy automation technologies and the strong presence of large-scale commercial dairy farms

- Asia-Pacific is expected to be the fastest growing region in the precision milking robot market during the forecast period due to rapid modernization of the dairy sector and increasing demand for high-quality milk

- Hardware segment dominated the market with a market share of 63% in 2025, due to the high capital investment required for robotic milking units, sensors, robotic arms, and automated cleaning systems. Dairy farms prioritize hardware adoption as it directly replaces manual milking operations and delivers immediate labor reduction and productivity gains. Continuous advancements in robotic accuracy, durability, and animal-friendly design further strengthen demand for hardware components. The long operational life and critical functional role of hardware systems position this segment as the primary revenue contributor across both small and large-scale dairy farms

Report Scope and Precision Milking Robot Market Segmentation

|

Attributes |

Precision Milking Robot Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Precision Milking Robot Market Trends

“Rising Adoption of Fully Automated and Data-Driven Robotic Milking Systems”

- A significant trend in the precision milking robot market is the growing adoption of fully automated and data-driven milking systems, driven by the need to enhance farm productivity and reduce manual intervention in dairy operations. Automation is enabling consistent milking routines, improved animal comfort, and optimized milk yield across diverse herd sizes

- For instance, companies such as Lely and DeLaval offer advanced robotic milking systems equipped with sensors and analytics that monitor milk yield, cow behavior, and health indicators in real time. These systems support informed decision-making and improve overall farm management efficiency

- The integration of data analytics and artificial intelligence is strengthening herd-level insights by enabling early detection of health issues, estrus cycles, and productivity variations. This is positioning robotic milking systems as comprehensive herd management solutions rather than standalone milking equipment

- Large-scale dairy farms are increasingly adopting fully automated milking to handle higher herd volumes while maintaining operational consistency. This trend supports scalability and allows farms to sustain output despite labor constraints

- The shift toward precision livestock farming is further encouraging the use of connected milking robots that integrate with feeding, cooling, and farm management systems. This connectivity enhances operational visibility and supports long-term farm optimization

- Overall, the increasing reliance on automation and data-driven technologies is reinforcing the role of precision milking robots as essential tools in modern, technology-enabled dairy farming systems

Precision Milking Robot Market Dynamics

Driver

“Increasing Labor Shortages and Rising Operational Costs in Dairy Farming”

- The growing shortage of skilled labor in the dairy sector is a key driver accelerating adoption of precision milking robots, as farms seek to maintain productivity with reduced workforce dependency. Robotic milking systems enable continuous operations without the limitations of manual labor availability

- For instance, GEA Group and BouMatic provide robotic milking solutions designed to operate with minimal human supervision, helping farms control labor expenses and improve operational continuity. These systems directly address workforce challenges faced by both mid-sized and large dairy farms

- Rising wages and long working hours associated with traditional milking practices are increasing operational costs for dairy producers. Automation helps stabilize costs by reducing reliance on repetitive manual tasks

- As dairy farms expand in scale, managing labor-intensive operations becomes increasingly complex. Robotic milking systems offer a reliable solution to sustain growth while controlling operational overheads

- This sustained need to balance productivity, cost efficiency, and labor availability continues to strengthen this driver and supports long-term market growth

Restraint/Challenge

“High Initial Capital Investment and System Integration Complexity”

- The precision milking robot market faces challenges due to the high upfront capital investment required for purchasing and installing robotic milking systems. These costs can be a significant barrier, particularly for small and medium-sized dairy farms

- For instance, advanced robotic milking installations from manufacturers such as DeLaval involve substantial expenditure on hardware, infrastructure modification, and supporting software systems. This financial burden limits adoption among cost-sensitive farm operators

- System integration complexity also presents challenges, as robotic milking systems must align with existing farm layouts, herd management practices, and supporting equipment. This increases planning time and implementation effort

- The need for technical expertise to operate and maintain robotic systems further adds to long-term ownership costs. Farmers often require training and ongoing technical support to fully utilize system capabilities

- These combined cost and integration challenges continue to restrain market growth, emphasizing the need for more affordable, modular, and easily deployable robotic milking solutions

Precision Milking Robot Market Scope

The market is segmented on the basis of offering, milking robots system type, and herd size.

• By Offering

On the basis of offering, the Precision Milking Robot market is segmented into hardware, software, and service. The hardware segment dominated the market with the largest revenue share of 63% in 2025, supported by the high capital investment required for robotic milking units, sensors, robotic arms, and automated cleaning systems. Dairy farms prioritize hardware adoption as it directly replaces manual milking operations and delivers immediate labor reduction and productivity gains. Continuous advancements in robotic accuracy, durability, and animal-friendly design further strengthen demand for hardware components. The long operational life and critical functional role of hardware systems position this segment as the primary revenue contributor across both small and large-scale dairy farms.

The software segment is anticipated to witness the fastest growth rate from 2026 to 2033, driven by rising adoption of data-driven herd management and real-time monitoring solutions. Precision milking software enables milk yield analysis, cow health tracking, estrus detection, and predictive maintenance, helping farmers optimize operations and improve animal welfare. Increasing integration of artificial intelligence and cloud-based analytics enhances decision-making capabilities, making software a key growth engine. Growing awareness of precision dairy farming and the need for actionable insights continues to accelerate software adoption.

• By Milking Robots System Type

On the basis of milking robots system type, the market is segmented into single-stall unit, multi-stall unit, and automated milking rotary. The single-stall unit segment dominated the market in 2025 due to its suitability for small to medium-sized dairy farms and lower upfront investment compared to complex systems. These units offer flexibility, easier installation, and gradual scalability, making them attractive for farmers transitioning from conventional milking to automation. Single-stall systems also allow individualized cow monitoring, improving milk quality and animal health management. Their widespread adoption across emerging and developed dairy markets reinforces their dominant position.

The automated milking rotary segment is expected to register the fastest growth during the forecast period, driven by increasing demand from large-scale commercial dairy operations. Automated milking rotary systems enable high-throughput milking with minimal labor involvement, significantly improving efficiency for farms managing large herds. Their ability to handle continuous cow flow while maintaining consistent milking routines enhances productivity and reduces operational bottlenecks. Rising investments in industrial-scale dairy farming strongly support growth of this segment.

• By Herd Size

On the basis of herd size, the Precision Milking Robot market is segmented into below 100, between 100 and 1,000, and above 1,000. The between 100 and 1,000 segment accounted for the largest market share in 2025, as mid-sized dairy farms increasingly adopt automation to balance productivity and cost efficiency. These farms benefit from precision milking robots by reducing labor dependency while improving milk yield consistency and herd health monitoring. The scalability of robotic systems aligns well with the operational needs of this herd category, supporting steady adoption. Growing modernization of medium-scale dairy farms further sustains segment dominance.

The above 1,000 segment is projected to witness the fastest growth from 2026 to 2033, driven by expansion of large commercial dairy enterprises and rising demand for fully automated operations. Large herds require advanced milking solutions to manage labor shortages, operational complexity, and animal welfare standards. Precision milking robots enable centralized data management and high-volume milk production with lower per-unit costs. Increasing consolidation in the dairy industry accelerates adoption within this segment.

Precision Milking Robot Market Regional Analysis

- North America dominated the precision milking robot market with the largest revenue share in 2025, driven by the early adoption of advanced dairy automation technologies and the strong presence of large-scale commercial dairy farms

- Dairy producers in the region highly prioritize labor efficiency, animal welfare, and consistent milk quality, which accelerates the adoption of robotic milking solutions

- This widespread adoption is further supported by high farm-level investments, technological readiness, and increasing labor shortages, positioning precision milking robots as a core component of modern dairy operations

U.S. Precision Milking Robot Market Insight

The U.S. precision milking robot market captured the largest revenue share within North America in 2025, supported by the rapid modernization of dairy farms and growing emphasis on productivity optimization. Farmers are increasingly investing in robotic milking systems to address labor constraints and improve herd management efficiency. The integration of data analytics, real-time monitoring, and herd health tracking further strengthens market growth. Moreover, strong support from agricultural technology providers and favorable financing options continues to propel adoption across mid-sized and large dairy farms.

Europe Precision Milking Robot Market Insight

The Europe precision milking robot market is projected to expand at a substantial CAGR during the forecast period, primarily driven by strict animal welfare regulations and the rising focus on sustainable dairy farming practices. European dairy farmers are increasingly adopting automated milking systems to enhance milk traceability and reduce environmental impact. The region also benefits from strong government support for precision agriculture and high awareness of farm automation technologies. Growth is evident across both family-owned farms and large cooperative dairy operations.

U.K. Precision Milking Robot Market Insight

The U.K. precision milking robot market is anticipated to grow at a noteworthy CAGR over the forecast period, driven by increasing labor costs and the need for operational efficiency in dairy farming. Farmers are adopting robotic milking systems to maintain productivity amid workforce shortages. The growing emphasis on animal comfort, coupled with advancements in herd monitoring technologies, further supports market expansion. Adoption is particularly strong among progressive dairy farms investing in long-term automation strategies.

Germany Precision Milking Robot Market Insight

The Germany precision milking robot market is expected to expand at a considerable CAGR, fueled by the country’s strong focus on technological innovation and sustainable agriculture. German dairy farms emphasize precision farming practices to optimize milk yield and animal health. The availability of advanced robotic systems and strong domestic manufacturing capabilities supports adoption. Integration of milking robots with farm management software is becoming increasingly common, reinforcing market growth.

Asia-Pacific Precision Milking Robot Market Insight

The Asia-Pacific precision milking robot market is expected to grow at the fastest CAGR during the forecast period, driven by rapid modernization of the dairy sector and increasing demand for high-quality milk. Rising investments in large-scale dairy farms and improving awareness of automation benefits are accelerating adoption. Government initiatives supporting agricultural mechanization further contribute to market expansion. The region’s growing population and rising dairy consumption continue to create long-term growth opportunities.

Japan Precision Milking Robot Market Insight

The Japan precision milking robot market is gaining traction due to the country’s aging agricultural workforce and strong preference for automation. Dairy farmers are increasingly adopting robotic milking systems to maintain productivity with reduced labor dependency. High technological acceptance and focus on precision livestock farming support steady market growth. The integration of robotics with advanced monitoring systems aligns well with Japan’s emphasis on efficiency and quality.

China Precision Milking Robot Market Insight

The China precision milking robot market accounted for the largest revenue share within Asia-Pacific in 2025, driven by the rapid expansion of industrial-scale dairy farms. Growing demand for safe, high-quality dairy products is encouraging investment in automated milking technologies. Strong government support for modernizing agriculture and improving food security further fuels adoption. The presence of domestic and international technology providers enhances accessibility and accelerates market penetration.

Precision Milking Robot Market Share

The precision milking robot industry is primarily led by well-established companies, including:

- DeLaval (Sweden)

- GEA Group Aktiengesellschaft (Germany)

- Lely Holding SARL (Netherlands)

- SCR (Israel)

- S. A. Christensen & Co. (Denmark)

- Fullwood Packo (Belgium)

- Afimilk Ltd. (Israel)

- BouMatic (U.S.)

- Hokofarm Group (Netherlands)

- DAIRYMASTER (Ireland)

- LIC (New Zealand)

- System Happel (Germany)

- Stellapps Technologies Pvt. Ltd. (India)

- Spunhill (U.K.)

- Paul Mueller (U.S.)

- Pearson Education (U.K.)

- MILKWELL MILKING SYSTEMS (India)

- Milkplan (Greece)

Latest Developments in Global Precision Milking Robot Market

- In May 2025, Lely launched its advanced Astronaut A5 Next and Astronaut Max precision milking robots alongside the Lely Hub digital platform, marking a significant step toward fully connected and future-ready dairy farms. This launch strengthens automation, improves data continuity, and enhances cyber resilience at the farm level, enabling farmers to manage larger herds with greater accuracy and confidence. The development positively impacts the market by accelerating replacement demand and reinforcing the shift toward integrated hardware–software milking ecosystems

- In April 2025, BouMatic formed a strategic partnership with BROLIS Sensor Technology to integrate the MilkGenius in-line milk analyzer into its Gemini UP robotic milking systems. This integration enables real-time monitoring of milk composition and cow health during the milking process, improving early disease detection and milk quality assurance. The development increases the functional value of precision milking robots and supports wider adoption among data-focused dairy operations, strengthening overall market competitiveness

- In February 2025, DeLaval expanded deployment of its VMS V310 milking robot featuring enhanced mastitis detection and automated herd health analytics. These capabilities help farmers reduce veterinary costs, improve animal welfare, and maintain consistent milk output. The development drives market growth by addressing critical pain points in dairy management and reinforcing demand for intelligent, sensor-driven robotic milking solutions

- In January 2025, EIO Robotics secured Series B funding to scale manufacturing and commercial deployment of its robotic milking systems, with a strong focus on North American dairy farms. The funding supports technology refinement, production expansion, and wider market reach, lowering adoption barriers for farms seeking automation. This development contributes to increased competition and faster diffusion of precision milking robots across mid-sized and large-scale dairy operations

- In November 2024, GEA Group secured a large supply contract for its DairyRobot R9500 systems with a major European dairy cooperative, highlighting growing acceptance of robotic milking at an institutional level. The agreement reflects rising confidence in automation to manage high herd volumes efficiently while maintaining milk quality standards. This development positively influences the market by validating precision milking robots as a long-term investment for commercial dairy producers and cooperatives

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Precision Milking Robot Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Precision Milking Robot Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Precision Milking Robot Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.