Global Process Oil Market

Market Size in USD Billion

CAGR :

%

USD

5.07 Billion

USD

6.70 Billion

2024

2032

USD

5.07 Billion

USD

6.70 Billion

2024

2032

| 2025 –2032 | |

| USD 5.07 Billion | |

| USD 6.70 Billion | |

|

|

|

|

Process Oil Market Size

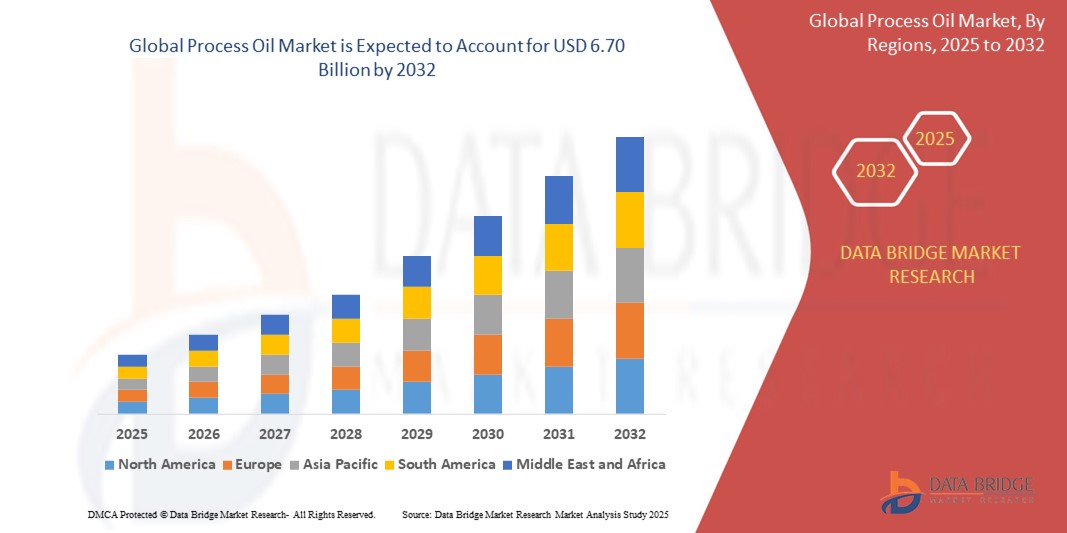

- The global process oil market size was valued at USD 5.07 billion in 2024 and is expected to reach USD 6.70 billion by 2032, at a CAGR of 3.55% during the forecast period

- The market growth is largely fuelled by the rising demand from the automotive, manufacturing, and polymer industries, driven by their widespread use in rubber processing, adhesives, and lubricants

- In addition, increasing industrialization in emerging economies and the growing focus on improving product performance and energy efficiency are contributing to the expansion of the process oil market

Process Oil Market Analysis

- The process oil market is witnessing steady growth supported by consistent demand across industrial manufacturing and rubber compounding applications

- Manufacturers are focusing on enhancing formulation quality and compatibility to cater to diverse end-use sectors

- Asia Pacific dominated the process oil market with the largest revenue share in 2024, driven by robust growth in industrial manufacturing, automotive production, and rubber processing sectors across major economies

- Europe region is expected to witness the highest growth rate in the global process oil market, driven by increasing regulatory pressure to adopt safer, non-carcinogenic formulations and rising demand for sustainable industrial solutions across key sectors

- The naphthenic segment held the largest market revenue share in 2024, supported by its excellent low-temperature properties and superior solvency, making it ideal for a wide range of industrial applications. Naphthenic process oils are widely used in rubber processing and polymer production due to their compatibility and performance advantages in dynamic conditions

Report Scope and Process Oil Market Segmentation

|

Attributes |

Process Oil Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Process Oil Market Trends

“Shift Toward Sustainable and Bio-Based Process Oils”

- The process oil market is experiencing a noticeable shift toward sustainable and bio-based alternatives as industries focus on reducing environmental impact and complying with regulatory standards

- Manufacturers are increasingly investing in the development of plant-derived process oils to replace conventional petroleum-based variants, especially in rubber and plastic processing

- For instance, Nynas introduced a range of bio-based oils aimed at improving sustainability without compromising performance, and Ergon has expanded its environmentally friendly product lines

- This trend is being further accelerated by consumer demand for eco-conscious products in the automotive and personal care industries, which are major end users of process oils

- Companies adopting green formulations are also gaining competitive advantages by differentiating their offerings, aligning with circular economy goals, and enhancing their brand image in global markets

Process Oil Market Dynamics

Driver

“Expanding Automotive and Tire Manufacturing Sector”

- The automotive and tire manufacturing sector plays a major role in driving the process oil market, with process oils being essential for rubber compounding and tire production

- These oils improve key rubber properties such as elasticity, durability, and resistance to wear, making them critical in manufacturing high-performance tires

- Growing vehicle production in developing countries is leading to increased demand for tires, thereby boosting process oil consumption

- The rise of electric vehicles is encouraging innovation in tire designs and materials, requiring more specialized and high-quality process oil formulations

- For instance, Bridgestone has ramped up investment in advanced tire technologies, highlighting the growing need for performance-enhancing process oils in modern vehicle applications

Restraint/Challenge

“Stringent Environmental Regulations and Health Concerns”

- The process oil market faces a major challenge from increasingly strict environmental regulations and health concerns related to petroleum-based oils

- Conventional process oils, especially those derived from aromatic hydrocarbons, may contain polycyclic aromatic hydrocarbons, which are harmful to both human health and the environment

- Regulatory frameworks such as the European Union’s REACH regulation are imposing tighter restrictions on acceptable PAH content in process oils

- As a result, companies are being forced to reformulate products or switch to safer alternatives, often leading to increased production costs and supply chain adjustments

- For instance, several European manufacturers have had to overhaul their product lines and invest in REACH-compliant formulations to maintain market access and meet safety standards

Process Oil Market Scope

The market is segmented on the basis of type, containing materials, and application.

• By Type

On the basis of type, the process oil market is segmented into naphthenic, non-carcinogenic, aromatic, and paraffinic. The naphthenic segment held the largest market revenue share in 2024, supported by its excellent low-temperature properties and superior solvency, making it ideal for a wide range of industrial applications. Naphthenic process oils are widely used in rubber processing and polymer production due to their compatibility and performance advantages in dynamic conditions.

The non-carcinogenic segment is expected to witness the fastest growth rate from 2025 to 2032, driven by increasing regulatory pressure to reduce harmful substances and the rising adoption of safer alternatives. These oils are gaining popularity across industries such as automotive and personal care, where product safety and compliance with environmental standards are key priorities. Their low toxicity and minimal environmental impact make them a favorable substitute for traditional aromatic oils.

• By Containing Materials

On the basis of containing materials, the process oil market is segmented into peptizers, fatty acid derivatives, petroleum oils, polymers, and waxes. The petroleum oils segment dominated the market in 2024, owing to its widespread use across multiple applications, including tire manufacturing, rubber compounding, and polymer processing. Its cost-effectiveness, availability, and well-established performance characteristics continue to support high adoption levels.

The fatty acid derivatives segment is expected to witness the fastest growth rate from 2025 to 2032, as demand increases for eco-friendly and plant-based processing solutions. These derivatives offer improved biodegradability and are increasingly being used in specialty applications where sustainability and low environmental impact are critical, such as textiles and packaging.

• By Application

On the basis of application, the process oil market is segmented into tire and rubber, polymer, textile, and others. The tire and rubber segment accounted for the largest share of the market in 2024, driven by the heavy use of process oils in enhancing the performance and durability of rubber components. Tire manufacturers rely on process oils to achieve the desired flexibility, strength, and wear resistance in both synthetic and natural rubber compounds.

The polymer segment is expected to witness the fastest growth rate from 2025 to 2032, propelled by increasing demand for advanced plastic materials in industries such as automotive, packaging, and construction. Process oils in this segment help modify flow properties, improve processing efficiency, and enhance the physical characteristics of final polymer products, making them essential in modern polymer manufacturing.

Process Oil Market Regional Analysis

• Asia Pacific dominated the process oil market with the largest revenue share in 2024, driven by robust growth in industrial manufacturing, automotive production, and rubber processing sectors across major economies.

• The region benefits from cost-effective labor, abundant raw materials, and a strong presence of key manufacturers, supporting large-scale production and export of process oils.

• The rise in infrastructure development, increasing demand for tires, and rapid industrialization further contribute to the expanding use of process oils in multiple end-use industries across Asia Pacific.

China Process Oil Market Insight

The China process oil market held the largest revenue share in Asia Pacific in 2024, supported by strong domestic manufacturing, high demand from the tire and rubber industry, and large-scale industrial operations. The country’s expanding automotive sector and extensive polymer production contribute significantly to process oil consumption. In addition, the presence of leading domestic suppliers and ongoing advancements in product formulation are helping meet the evolving requirements of diverse applications, from plastics to textiles.

Japan Process Oil Market Insight

The Japan process oil market is expected to witness the fastest growth rate from 2025 to 2032, driven by its advanced manufacturing sector and strong presence in the automotive and electronics industries. Japanese manufacturers emphasize precision, performance, and environmental compliance, leading to increased adoption of high-quality and refined process oils. The demand for cleaner, non-carcinogenic, and low-aromatic oils is rising in alignment with the country’s sustainability goals and strict regulatory standards. Furthermore, Japan’s focus on innovation and technology is encouraging the development of specialized process oils tailored for high-performance applications.

North America Process Oil Market Insight

The North America process oil market is expected to witness the fastest growth rate from 2025 to 2032, due to stable demand across the automotive, industrial, and polymer sectors. High standards for product performance, combined with a strong emphasis on R&D, are fostering innovation in low-toxicity and high-efficiency process oil formulations. Demand is also supported by the region’s mature manufacturing base and growing focus on environmentally responsible production methods in line with regulatory compliance.

U.S. Process Oil Market Insight

The U.S. process oil market accounted for the largest revenue share in North America in 2024, backed by established demand from the tire, polymer, and textile industries. The country’s emphasis on quality standards and sustainable industrial practices encourages manufacturers to adopt advanced and safer oil formulations. In addition, the presence of major market players and continuous innovation in refining and application technologies is driving the domestic market forward.

Europe Process Oil Market Insight

The Europe process oil market is expected to witness the fastest growth rate from 2025 to 2032, primarily driven by regulatory push for safer and non-carcinogenic formulations. European industries are increasingly shifting to bio-based and low-aromatic process oils to meet environmental and health standards. This shift is further supported by advanced manufacturing capabilities, strong environmental policies, and growing awareness about workplace and product safety in key markets such as Germany, France, and Italy.

Germany Process Oil Market Insight

The Germany process oil market is expected to witness the fastest growth rate from 2025 to 2032, supported by the country’s strong industrial base, automotive innovation, and focus on sustainable production. Manufacturers are prioritizing high-performance and eco-friendly formulations to comply with national and EU-level environmental directives. Germany’s reputation for engineering excellence and innovation positions it as a key player in shaping future trends in process oil applications across Europe.

U.K. Process Oil Market Insight

The U.K. process oil market is expected to witness the fastest growth rate from 2025 to 2032, supported by demand from the country’s automotive, industrial, and polymer sectors. Regulatory emphasis on environmental protection and worker safety is accelerating the shift toward safer and more sustainable process oil alternatives. In addition, manufacturers are investing in R&D to meet rising performance expectations while reducing the environmental impact, making the U.K. a key contributor to Europe’s transition to cleaner industrial solutions.

Process Oil Market Share

The Process Oil industry is primarily led by well-established companies, including:

- Royal Dutch Shell (Netherlands)

- Exxon Mobil Corporation (U.S.)

- Total (France)

- Indian Oil Corporation Ltd (India)

- Petroliam Nasional Berhad (PETRONAS) (Malaysia)

- Repsol (Spain)

- HPCL (Hindustan Petroleum Corporation Limited) (India)

- Idemitsu Kosan Co., Ltd (Japan)

- Unipetrol (Czech Republic)

- Panama Petrochem Ltd (India)

- Nynas AB (Sweden)

- H&R GROUP (Germany)

- Apar Industries (India)

- Gandhar Oil (India)

- HollyFrontier Corporation (U.S.)

Latest Developments in Global Process Oil Market

- In December 2022, Royal Dutch Shell plc expanded its portfolio by acquiring a 49% stake in Blue Tide Environmental LLC through its Pennzoil-Quaker State subsidiary. Blue Tide Environmental LLC aims to establish a global network of facilities for recycling lubricants

- In February 2022, Chevron announced a strategic initiative with Bunge to form a joint venture worth USD 600 million. This partnership is focused on enhancing the processing of soybean oil to support Chevron's operations. The collaboration targets doubling daily production to 14,000 tons by the end of 2024, producing refined oil as a sustainable feedstock. This initiative aligns with Chevron's strategy to produce low-carbon diesel and jet fuel

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Process Oil Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Process Oil Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Process Oil Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.