Global Pulp Moulding Machines Market

Market Size in USD Billion

CAGR :

%

USD

785.89 Billion

USD

1,187.93 Billion

2022

2030

USD

785.89 Billion

USD

1,187.93 Billion

2022

2030

| 2023 –2030 | |

| USD 785.89 Billion | |

| USD 1,187.93 Billion | |

|

|

|

|

Pulp Moulding Machines Market Analysis and Size

Now, the world is rapidly shifting towards environment-friendly and sustainable packaging solutions, as a result the demand for the biodegradable packaging is growing. The growing awareness regarding environmental degradation and its effect on lives, the various industry verticals adopt sustainable packaging solutions such as pulp moulding packaging. Eventually, it increases the demand for the pulp moulding machines and leading the growth of the market.

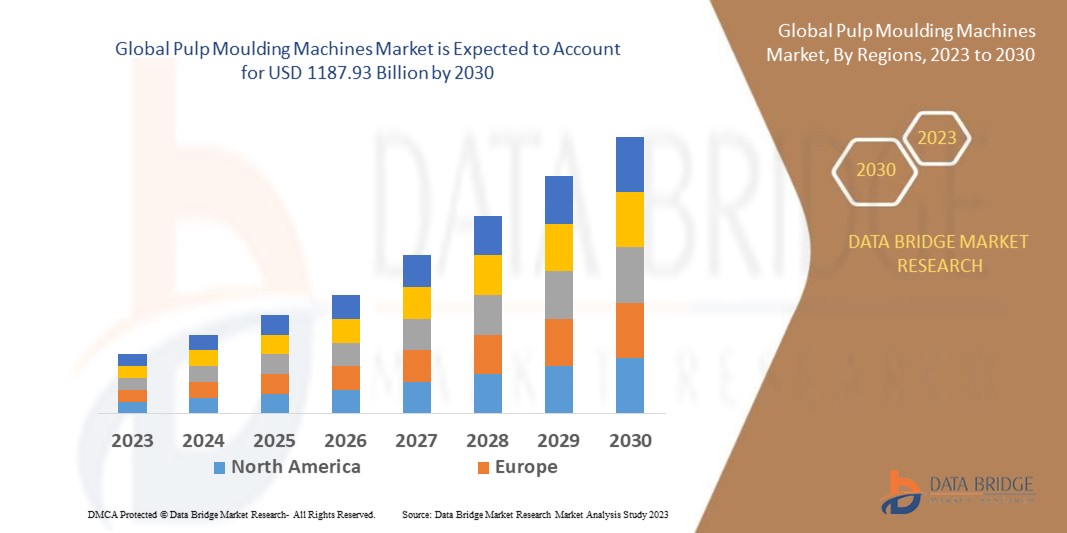

Data Bridge Market Research analyses that the pulp moulding machines market is expected to reach USD 1187.93 billion by 2030, which is USD 785.89 billion in 2022, registering a CAGR of 5.30% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Pulp Moulding Machines Market Scope and Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015 - 2020) |

|

Quantitative Units |

Revenue in USD Billion, Volumes in Units, Pricing in USD |

|

Segments Covered |

Type (Rotary and Reciprocating), Machine Type (Automatic, Semi-automatic and Manual), Pulp Type (Thick Wall, Transfer, Thermoformed and Processed), Capacity Type (Units Per Hour) (Less Than 1500, 1501 to 3500, 3501 to 5500 and Above 5500), Application (Trays, Boxes and Containers, Disposable Pulp Tableware, Finery Pack, Cardboard Lids, Drink Carrier and Others), End-Users (Food and Beverages, Electrical and Electronics, Automotive, Healthcare, Consumer Goods, Cosmetics and Personal Care, and Others) |

|

Countries Covered |

U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia and New Zealand, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, United Arab Emirate, Saudi Arabia, Egypt, Israel, South Africa, Rest of Middle East and Africa |

|

Market Players Covered |

SODALTECH (India), Xiangtan ZH Pulp Moulded Co.,Ltd (China), Henan Qinyang Shunfu Paper Machinery Co., LTD (China), Southern Pulp Machinery (Pty) Ltd (South Africa), Beston Group Co., Ltd. (Germany), DKM Plastic Injection Molding Machine (U.S.), Pulp Moulding Dies Inc. (Canada), Foshan BeSure Technology Co., Ltd. (China), Inmaco BV (Netherlands), ESCO Technologies Inc. (U.S.), UFP Technologies Inc, (U.S.), Maspack Limited (India), Dekelon Paper Making Machinery (China), Taiwan Pulp Molding Co., Ltd. (China), PULP MOLDING PACK CO., LTD (China) |

|

Market Opportunities |

|

Market Definition

Pulp moulding machines are those devices which are used to make packaging products by paper and pulp. In manufacturing products several stages are involved, including flocculation, deliberation and molding. To start the process, initially need to add chemicals such as caustic soda. Caustic soda aids in dissolving wood chips into fibers, and then divides them into small pieces with the help of centrifugal force. These machines are also recycles waste paper into fruit trays, seedling trays, cup holders, egg cartons, egg trays and others.

Pulp Moulding Machines Market Dynamics

Drivers

- High usage of automated pulp molding machines

Automated pulp molding machines controls the tasks without continuously being operated by a person. These pulp molding machines are high rate of mould interchangeability and have an automatic dry system. The demand for automated pulp molding machines is projected to increase in various end-user industries demanding highly pulp molding machines that surge their productivity. Many manufacturers are mainly focusing on producing highly efficient and easy-to-operate machines. The demand for highly automated pulp molding machines is high in both developed and developing countries which is expected to drive the growth of the market during the forecast period.

- Rising demand of pulp moulding machines for the production of packaging products

Pulp molding machines are widely used for the production of packaging products in numerous end-use sectors including electronics, food & beverage, healthcare, and industrial. Furthermore, increasing consumer-driven demand for environmentally friendly and sustainable packaging solutions is also anticipated to increase the growth of the pulp moulding machines market over the forecast period.

Opportunities

- Increasing usage of pulp moulding machines in foodservice industry

Pulp moulding machines are highly used in the foodservice industry for packaging numerous food products such as fruits, egg and vegetables. The packaging products of this machines such as plates, bowls, cups, clamshells are extensively used in the foodservice industry for packaging of ready-to-eat meals, on-the-go snacks and beverages. Increasing consumption of on-the-go and single-serve meal products because of hectic lifestyles is anticipated to surge the demand for pulp moulding machines in the foodservice sector and create numerous opportunities for market growth during the forecast period.

- Surging manufacturing facility and other advancement in the market

Rising manufacturing facilities and other advancement in pulp molding machines market by key players will generate immense opportunities for the market growth. For instance, Huhtamaki has arranged a new manufacturing facility to deal with growing demand for new and present egg packaging among consumers in South Africa. The leading pulp molding machines companies are planning to deliver broad range of locally formed packaging solutions to increase the market growth market.

Restraints/ Challenges

- Harmful effects of plastic packaging

The packaging products of pulp moulding machines solution helps to preserve spoilage and maintain the shelf life of products mainly frozen foods. These packaging solutions keep the frozen food safe from moisture, leak-proof, puncture-resistant and reliable. The firms of pulp moulding machines is progressively using plastic packaging owing to their excellent properties to preserve food contents from light, moisture and oxygen. As a result, the harmful effects of plastic packaging are inculcated in the food products, thus impeding the people's health. This factor is obstructing the growth of the market in the forecast period.

This pulp moulding machines market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growth application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the pulp moulding machines market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Recent Development

- In 2019, Qingdao Perfect Equipment and Parts Co., Ltd, a leading supplier in China, exported the paper-making machine with 5000 pieces per hour in Uzbekistan. With this expansion, the company goals to increase its global footprint and site.

Global Pulp Moulding Machines Market Scope

The pulp moulding machines market is segmented on the basis of type, machine type, pulp type, capacity type (units per hour), application and end-users. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Rotary

- Reciprocating

Machine Type

- Automatic

- Semi-automatic

- Manual

Pulp Type

- Thick Wall

- Transfer

- Thermoformed

- Processed

Capacity Type (Units per Hour)

- Less Than 1500

- 1501 to 3500

- 3501 to 5500

- Above 5500

Application

- Trays

- Boxes and Containers

- Disposable Pulp Tableware

- Finery Pack

- Cardboard Lids

- Drink Carrier

- Others

End-Users

- Food and Beverages

- Electrical and Electronics

- Automotive

- Healthcare

- Consumer Goods

- Cosmetics and Personal Care

- Others

Pulp Moulding Machines Market Regional Analysis/Insights

The pulp moulding machines market is analyzed and market size insights and trends are provided by country, type, machine type, pulp type, capacity type (units per hour), application and end-users as referenced above.

North America dominates the pulp moulding machines market in terms of revenue and market share becasue it has high productivity as compared to other machines, it consumes less energy which reduces the manufacturing and operating cost.

Asia-Pacific is expected to be the fastest developing region during the forecast period of 2023-2030. This is attributed to increasing adoption of new and advanced technologies which provide better results in less time.

The country section of the report also provides individual market impacting factors and changes in market regulation that impact the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Pulp Moulding Machines Market Share Analysis

The pulp moulding machines market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to pulp moulding machines market.

Some of the major players operating in the pulp moulding machines market are:

- SODALTECH (India)

- Xiangtan ZH Pulp Moulded Co.,Ltd (China)

- Henan Qinyang Shunfu Paper Machinery Co., LTD (China)

- Southern Pulp Machinery (Pty) Ltd (South Africa)

- Beston Group Co., Ltd. (Germany)

- DKM Plastic Injection Molding Machine (U.S.)

- Pulp Moulding Dies Inc. (Canada)

- Foshan BeSure Technology Co., Ltd. (China)

- Inmaco BV (Netherlands)

- ESCO Technologies Inc. (U.S.)

- UFP Technologies Inc, (U.S.)

- Maspack Limited (India)

- Dekelon Paper Making Machinery (China)

- Taiwan Pulp Molding Co., Ltd. (China)

- PULP MOLDING PACK CO., LTD (China)

- Meccanoplastica (Italy)

- W. Amsler Equipment Inc. (Canada)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Pulp Moulding Machines Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Pulp Moulding Machines Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Pulp Moulding Machines Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.