Global Quantum Enabled Biomanufacturing Market

Market Size in USD Million

CAGR :

%

USD

495.00 Million

USD

1,965.30 Million

2024

2032

USD

495.00 Million

USD

1,965.30 Million

2024

2032

| 2025 –2032 | |

| USD 495.00 Million | |

| USD 1,965.30 Million | |

|

|

|

|

Quantum-Enabled Biomanufacturing Market Size

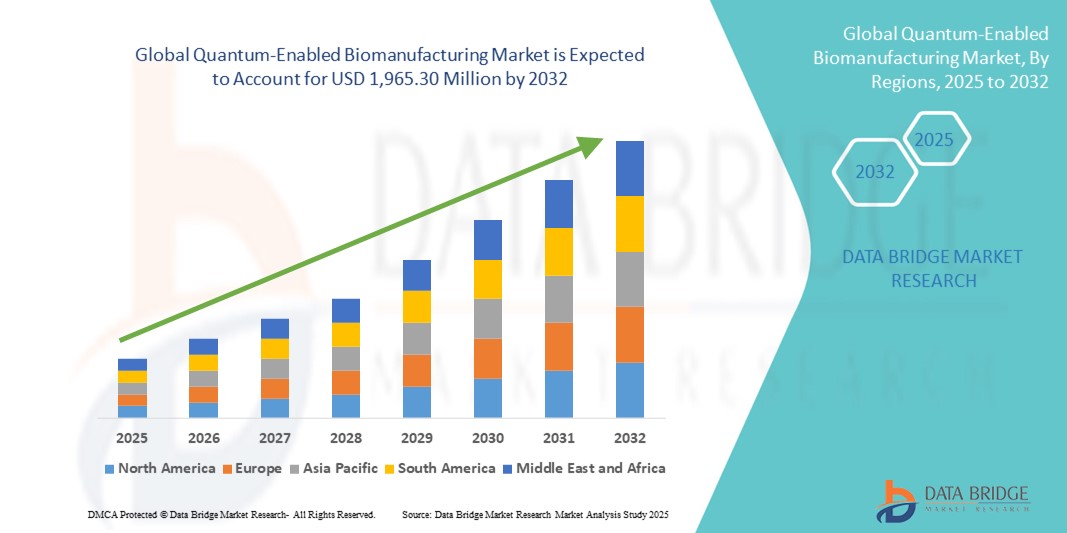

- The global quantum-enabled biomanufacturing market size was valued at USD 495.00 million in 2024 and is expected to reach USD 1,965.30 million by 2032, at a CAGR of 18.81% during the forecast period

- The market growth is largely driven by the integration of quantum computing technologies into advanced biomanufacturing processes, enhancing molecular modeling, process optimization, and predictive analytics in real-time

- Furthermore, increasing demand for precision biologics, personalized medicine, and accelerated drug development timelines is positioning quantum-enabled biomanufacturing as a transformative solution in life sciences. These converging trends are rapidly advancing the adoption of quantum-powered platforms, significantly propelling the industry’s expansion

Quantum-Enabled Biomanufacturing Market Analysis

- Quantum-enabled biomanufacturing, which integrates quantum computing into biologics production, is becoming a transformative force in pharmaceutical manufacturing, enabling enhanced molecular simulations, optimized bioprocessing, and real-time analytics across both upstream and downstream operations

- The increasing demand for personalized medicine, biologics, and efficiency in drug development is driving the adoption of quantum technologies, as they offer faster molecule screening, predictive quality control, and scalable production solutions compared to traditional methods

- North America dominated the quantum-enabled biomanufacturing market with the largest revenue share of 39.2% in 2024, driven by early adoption of quantum platforms, substantial biopharma R&D investment, and a concentration of leading quantum computing and biotech firms across the U.S., which is advancing integration into commercial-scale biomanufacturing

- Asia-Pacific is expected to be the fastest growing region in the quantum-enabled biomanufacturing market during the forecast period, due to expanding biologics production infrastructure, government-backed quantum research programs, and rising healthcare demand across countries such as China, India, and South Korea

- The monoclonal antibodies segment dominated the quantum-enabled biomanufacturing market with a share of 42.1% in 2024, owing to their complex production requirements, strong market demand, and compatibility with quantum-enhanced modeling for improving yield, purity, and efficiency across critical production stages

Report Scope and Quantum-Enabled Biomanufacturing Market Segmentation

|

Attributes |

Quantum-Enabled Biomanufacturing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Quantum-Enabled Biomanufacturing Market Trends

Fusion of Quantum Computing and AI for Advanced Bioprocessing

- A significant and accelerating trend in the global quantum-enabled biomanufacturing market is the integration of quantum computing with artificial intelligence (AI) to optimize complex bioprocessing workflows. This convergence is dramatically enhancing the accuracy, speed, and efficiency of biologics development and manufacturing

- For instance, biopharma companies are adopting quantum-accelerated platforms for protein folding simulations and process modeling, allowing for rapid identification of ideal production parameters. Emerging platforms combine quantum simulations with AI to improve upstream yield and downstream purification efficiency

- AI integration enables predictive analytics, anomaly detection, and adaptive control in manufacturing, while quantum algorithms provide the computational power to model and optimize biomolecular interactions at a level not feasible with classical systems. For example, AI‑driven digital twins powered by quantum algorithms can simulate entire biomanufacturing cycles in silico, helping reduce batch failures and improve scale-up accuracy

- The synergy of quantum-AI platforms facilitates better decision-making across R&D and production by enabling faster hypothesis testing, real-time feedback, and reduced experimental cycles. This is especially valuable in accelerating the development of complex therapeutics such as monoclonal antibodies and gene therapies

- As quantum technology matures and becomes more accessible via cloud‑based quantum computing-as-a-service (QCaaS), integration into AI-driven biomanufacturing platforms is expected to become standard practice. Companies such as D-Wave, IBM, and startups in the quantum biotech space are actively collaborating with biomanufacturers to pilot these capabilities

- This trend toward intelligent, adaptive, and high‑performance quantum-biomanufacturing ecosystems is fundamentally reshaping how drugs are discovered and produced. Demand for such technologies is rising across both pharmaceutical innovators and contract manufacturers, especially as biologics become a dominant share of new drug pipelines

Quantum-Enabled Biomanufacturing Market Dynamics

Driver

Rising Demand for Precision Biologics and Scalable Biomanufacturing

- The growing global demand for precision biologics such as monoclonal antibodies, recombinant proteins, and personalized cell & gene therapies is a major driver of the quantum-enabled biomanufacturing market. These therapies require sophisticated development tools and production systems that can benefit significantly from quantum computing's modeling power and process control accuracy

- For instance, in 2024, several collaborations were announced between quantum computing companies and major biopharma firms aimed at enhancing biologics development pipelines through quantum-enhanced simulation and AI-driven process control. Such initiatives reflect the increasing confidence in quantum-AI platforms to reduce cost, development time, and risks in biologics production

- Quantum-enabled systems provide superior predictive capabilities for process outcomes, reducing trial-and-error experimentation and improving batch-to-batch consistency. These benefits are particularly appealing to biopharmaceutical companies under pressure to deliver innovative therapies at scale and under tight regulatory timelines

- Furthermore, the shift toward continuous and modular biomanufacturing, coupled with the need for real-time monitoring and adaptive control, is accelerating demand for intelligent systems that can be augmented with quantum computing

- The scalability of quantum-driven platforms and their potential to handle complex, data-heavy modeling tasks make them ideally suited for supporting the global transition to faster, more flexible, and more precise biologic production pipelines

Restraint/Challenge

Limited Access to Quantum Infrastructure and Integration Complexity

- One of the key challenges in the quantum-enabled biomanufacturing market is the limited availability of mature quantum infrastructure and the high level of complexity involved in integrating quantum platforms into existing biomanufacturing environments

- Most pharmaceutical manufacturers are still in the early exploration phase of quantum adoption, and the lack of standardized tools or proven implementation models creates hesitation. In addition, the need for specialized talent capable of working at the intersection of quantum physics, bioengineering, and AI further complicates adoption

- For instance, while cloud-accessible quantum computing platforms such as IBM Quantum and Rigetti are lowering entry barriers, many potential users still lack the internal capability or confidence to translate quantum insights into real-world production enhancements

- Moreover, regulatory frameworks for biomanufacturing have yet to evolve to address the validation of quantum-assisted processes, which can delay deployment in GMP-compliant environments

- The high costs associated with quantum technology development and integration also pose a barrier, especially for smaller biotechs and contract manufacturers operating on limited budgets. Until scalable, affordable, and validated solutions become more widely available, adoption may be limited to well-funded organizations with a strategic focus on innovation

- Overcoming these challenges will require continued progress in hybrid quantum-classical platforms, industry-specific quantum software development, and collaborative efforts between quantum tech providers and the biomanufacturing ecosystem to establish use-case proof points and regulatory clarity

Quantum-Enabled Biomanufacturing Market Scope

The market is segmented on the basis of technology, workflow, application, and end user.

- By Technology

On the basis of technology, the quantum-enabled biomanufacturing market is segmented into quantum systems & platforms, quantum algorithms & software, and biomanufacturing equipment. The Quantum Algorithms & Software segment dominated the market in 2024 due to its critical role in molecular simulations, optimization of bioprocess parameters, and integration with AI-driven digital twins. These advanced tools significantly reduce development cycles and enhance process predictability across biologics manufacturing.

The Quantum Systems & Platforms segment is expected to register the fastest growth rate from 2025 to 2032, as quantum computing hardware becomes more commercially accessible through cloud-based platforms and partnerships with biotech firms. These systems enable high-throughput modeling and are increasingly being piloted in upstream R&D workflows.

- By Workflow

On the basis of workflow, the quantum-enabled biomanufacturing market is segmented into upstream biomanufacturing, single‑use technologies, and downstream biomanufacturing. The Upstream Biomanufacturing segment accounted for the largest revenue share in 2024, as quantum tools are heavily deployed to optimize cell culture conditions, genetic expression systems, and fermentation parameters. Early-stage production is often the most resource-intensive and benefits significantly from quantum-accelerated modeling.

The Single-Use Technologies segment is projected to grow at the highest CAGR from 2025 to 2032, driven by the rising trend of modular and flexible manufacturing systems. These disposable platforms are increasingly being integrated with real-time quantum-AI systems to ensure scalable and contamination-free production, especially in contract manufacturing settings.

- By Application

On the basis of application, the quantum-enabled biomanufacturing market is segmented into monoclonal antibodies (mAbs), vaccines, recombinant proteins, hormones, and cell & gene therapies. The Monoclonal Antibodies segment dominated the market with the largest share of 42.1% in 2024, due to their complexity, high global demand, and compatibility with quantum-enhanced process optimization especially for cell growth and purification workflows.

The Cell & Gene Therapies segment is expected to witness the fastest growth from 2025 to 2032, fueled by the increasing clinical and commercial pipeline in regenerative medicine and the critical need for ultra-precise, small-batch manufacturing where quantum platforms offer substantial benefits in variability control and personalization.

- By End User

On the basis of end user, the quantum-enabled biomanufacturing market is segmented into biopharmaceutical companies, contract manufacturing organizations (CMOS), and academic & research institutes. Biopharmaceutical Companies held the largest market share in 2024, driven by their heavy investment in innovative biologics, in-house production facilities, and adoption of cutting-edge technologies to streamline R&D and commercial-scale manufacturing.

The Academic & Research Institutes segment is expected to grow at the highest CAGR from 2025 to 2032, owing to increased collaborations with quantum tech firms and grant-driven pilot projects exploring quantum applications in early-stage drug discovery and bioprocess development. These institutions are key drivers of innovation and proof-of-concept validation in the field.

Quantum-Enabled Biomanufacturing Market Regional Analysis

- North America dominated the quantum-enabled biomanufacturing market with the largest revenue share of 39.2% in 2024, driven by early adoption of quantum platforms, substantial biopharma R&D investment, and a concentration of leading quantum computing and biotech firms across the U.S., which is advancing integration into commercial-scale biomanufacturing

- Organizations across the region are leveraging quantum-AI solutions to enhance biologics development, with a strong emphasis on precision, speed, and scalability, particularly in therapeutic areas such as oncology, immunology, and rare diseases

- This leadership is further reinforced by a well-established pharmaceutical ecosystem, presence of top-tier quantum tech firms, academic research collaborations, and government-backed quantum research initiatives, positioning North America as the hub for early implementation and commercialization of quantum-enabled biomanufacturing technologies

U.S. Quantum-Enabled Biomanufacturing Market Insight

The U.S. quantum-enabled biomanufacturing market captured the largest revenue share of 79.2% in 2024 within North America, driven by strong federal investments in quantum computing, thriving biotech clusters, and robust industry-academia partnerships. Leading biopharma companies are rapidly integrating quantum algorithms into drug discovery and biologics development pipelines. The convergence of AI, quantum systems, and biomanufacturing is propelling innovation in personalized medicine and bioprocess optimization, solidifying the U.S. as the global frontrunner in quantum-biotech convergence.

Europe Quantum-Enabled Biomanufacturing Market Insight

The Europe quantum-enabled biomanufacturing market is projected to expand at a substantial CAGR during the forecast period, fueled by the region’s strong emphasis on sustainable healthcare manufacturing and digital transformation. Public-private initiatives such as Quantum Flagship and Horizon Europe support research in quantum sciences and biopharma integration. Countries such as Germany, France, and the Netherlands are seeing increasing deployment of quantum platforms to streamline upstream and downstream biologics production, particularly in cell and gene therapy applications.

U.K. Quantum-Enabled Biomanufacturing Market Insight

The U.K. quantum-enabled biomanufacturing market is expected to grow at a noteworthy CAGR, driven by national investments in quantum technologies and biotech R&D under the UK National Quantum Strategy. The country's advanced pharmaceutical manufacturing base and leadership in synthetic biology are fostering the integration of quantum modeling tools to accelerate biologics formulation, especially in monoclonal antibodies and vaccines. Collaborations between startups, academia, and the NHS are further supporting adoption.

Germany Quantum-Enabled Biomanufacturing Market Insight

The Germany quantum-enabled biomanufacturing market is anticipated to expand at a considerable CAGR during the forecast period, driven by the country’s leadership in industrial automation and bioprocessing. Quantum computing centers such as Fraunhofer and active participation in EU-wide programs are accelerating pilot projects in quantum-biomanufacturing. The demand for efficient biomanufacturing workflows, such as single-use systems and precision protein synthesis, is boosting the integration of quantum-powered simulations and process controls.

Asia-Pacific Quantum-Enabled Biomanufacturing Market Insight

The Asia-Pacific quantum-enabled biomanufacturing market is poised to grow at the fastest CAGR of 25.4% from 2025 to 2032, supported by rising healthcare expenditure, digital infrastructure development, and strong biotech ecosystems in China, Japan, and South Korea. Governments in the region are heavily investing in quantum computing research and industrial biotech integration. This growth is further accelerated by the region’s manufacturing capabilities and the increasing focus on developing complex biologics and personalized therapeutics.

Japan Quantum-Enabled Biomanufacturing Market Insight

The Japan quantum-enabled biomanufacturing market is gaining traction due to the nation’s deep-rooted expertise in precision manufacturing and quantum hardware innovation. Biopharmaceutical companies are exploring quantum-enhanced modeling to improve yield and purity in biologics production. As Japan leads advancements in both quantum hardware and regenerative medicine, integration across these domains is expected to significantly accelerate therapeutic innovation and cost efficiency in complex biomanufacturing workflows.

India Quantum-Enabled Biomanufacturing Market Insight

The India quantum-enabled biomanufacturing market accounted for the largest market revenue share in Asia-Pacific in 2024, driven by rapid growth in biopharma, rising domestic biotech startups, and expanding R&D expenditure. National initiatives such as the National Quantum Mission are enabling early-stage applications in vaccine development and biosimilar production. India’s emerging role as a global hub for affordable biologics manufacturing, coupled with increasing access to quantum resources through academia and international partnerships, is propelling market growth.

Quantum-Enabled Biomanufacturing Market Share

The quantum-enabled biomanufacturing industry is primarily led by well-established companies, including:

- IBM Corporation (U.S.)

- Google (U.S.)

- IonQ, Inc. (U.S.)

- Rigetti Computing, Inc. (U.S.)

- D-Wave Quantum Inc. (Canada)

- Microsoft Corporation (U.S.)

- QC Ware Corp. (U.S.)

- Xanadu Quantum Technologies Inc. (Canada)

- Zapata Computing, Inc. (U.S.)

- Pasqal (France)

- Quantinuum (U.S.)

- Classiq Technologies Ltd. (Israel)

- Cambridge Quantum (U.K)

- Qubit Pharmaceuticals (France)

- ProteinQure (Canada)

- Seeqc (U.S.)

- Q-CTRL (Australia)

- QunaSys Inc. (Japan)

- Quantum Brilliance (Germany)

- Atos Quantum (France)

What are the Recent Developments in Global Quantum-Enabled Biomanufacturing Market?

- In July 2025, Moderna and IBM publicly demonstrated a quantum-enabled biotechnology pipeline aimed at enhancing—but not replacing—classical computing for mRNA medicine design. Leveraging conditional value at risk (CVaR)-based variational quantum algorithms (VQAs), the researchers achieved record-scale simulations of mRNA secondary structures (up to 80 qubits, 60-nucleotide sequences) that matched performance of commercial classical solvers. This milestone highlights the practical synergy of hybrid quantum-classical approaches in accelerating the discovery and optimization of mRNA therapeutics

- In June 2024, India and the United States agreed to initiate new cooperation in quantum science and technology and to develop a joint strategic framework for optimizing the biopharmaceutical supply chain. The announcement, made through a joint Fact Sheet following the second meeting of the US-India Initiative on Critical and Emerging Technology (iCET) in New Delhi, outlined plans for a workshop on post-quantum cryptography at the University of California, Los Angeles, and for facilitating visits by Indian technical experts from academia and industry to US national laboratories and quantum institutions

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.