Global Railway Hydraulic Damper Market

Market Size in USD Billion

CAGR :

%

USD

3.36 Billion

USD

4.85 Billion

2025

2033

USD

3.36 Billion

USD

4.85 Billion

2025

2033

| 2026 –2033 | |

| USD 3.36 Billion | |

| USD 4.85 Billion | |

|

|

|

|

What is the Global Railway Hydraulic Damper Market Size and Growth Rate?

- The global railway hydraulic damper market size was valued at USD 3.36 billion in 2025 and is expected to reach USD 4.85 billion by 2033, at a CAGR of4.70% during the forecast period

- The increase in demand for transport infrastructure and advanced mass transportation systems, owning to the rapid urbanization and the extensive use of railway cars across the globe act as the major factors driving the railway hydraulic damper market

- The concerns regarding the substantial car body vibration due to high speed of railway cars and the high demand for hydraulic dampers to provide efficient suspension and vibration reaction with the continuous up gradation of speed and power accelerate the railway hydraulic damper market growth

What are the Major Takeaways of Railway Hydraulic Damper Market?

- The initiatives taken by government across various regions to strengthen their railway networks by investing in expanding their railway network and the increase in research and development activities in order to enhance the design, mechanism and arrangement of railway hydraulic dampers and their rising use in freight based rail locomotives as they are subject to heavy loads and mechanical stress which require periodic installation of these dampers also influence the railway hydraulic damper market

- In addition, government encouraging partnership with local railway hydraulic dampers manufacturers with the purpose of quick deployment of order, reduced transportation cost and increased efficiency in the production process positively affect the railway hydraulic damper market

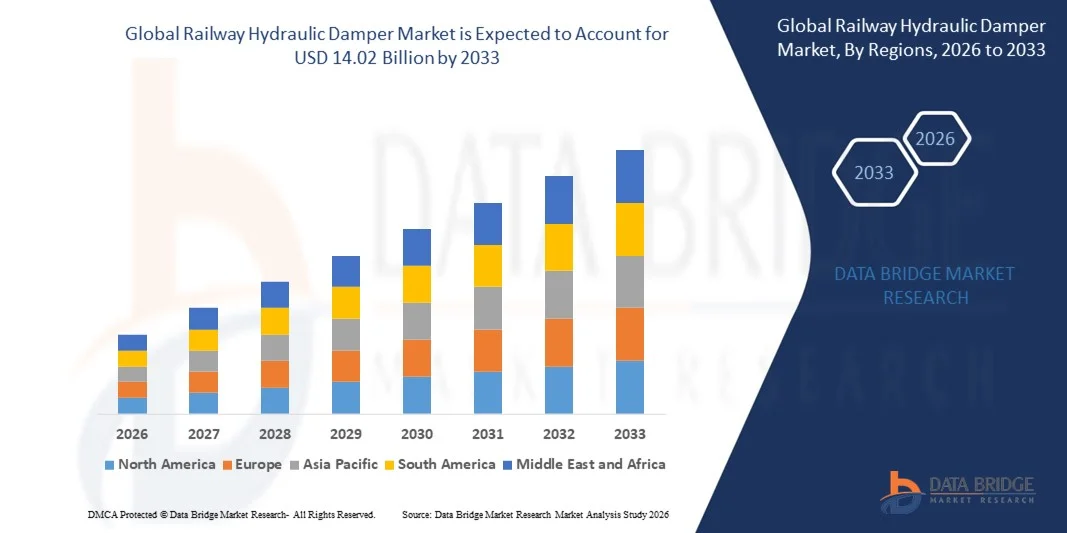

- North America dominated the railway hydraulic damper market with a 37.58% revenue share in 2025, driven by strong investments in advanced rolling stock, urban transit expansion, high-speed rail initiatives, and modernization of freight and metro systems across the U.S. and Canada

- Asia-Pacific is projected to register the fastest CAGR of 7.9% from 2026 to 2033, fueled by rapid expansion of high-speed rail corridors, metro projects, and freight modernization across China, Japan, India, South Korea, and Southeast Asia

- The 2–32 segment dominated the market with a 46.5% share in 2025, driven by widespread use in metro trains, regional rail, and commuter railcars

Report Scope and Railway Hydraulic Damper Market Segmentation

|

Attributes |

Railway Hydraulic Damper Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Railway Hydraulic Damper Market?

Increasing Shift Toward High-Performance, Lightweight, and Smart Railway Hydraulic Dampers

- The railway hydraulic damper market is experiencing a rapid shift toward compact, lightweight, and energy-efficient dampers designed to enhance vibration control across high-speed, metro, and freight rail systems

- Manufacturers are developing digitally monitored, electronically controlled, and self-adjusting damper systems to improve stability, ride comfort, wheel-rail interaction, and long-term performance reliability

- Growing adoption of smart suspension systems, real-time monitoring sensors, and predictive maintenance platforms is accelerating the demand for next-generation hydraulic dampers in modern rolling stock

- For instance, companies such as Knorr-Bremse, ZF, Dellner, and Koni have introduced enhanced damper systems featuring improved damping force control, heat resistance, and IoT-enabled monitoring capabilities

- Increasing need for speed stability, reduced maintenance downtime, and improved passenger comfort is driving the shift toward advanced hydraulic damping technologies

- As railway networks expand and high-speed rail projects accelerate globally, Railway Hydraulic Dampers will remain critical for dynamic stability, safety assurance, and long-term rolling stock efficiency

What are the Key Drivers of Railway Hydraulic Damper Market?

- Rising demand for high-speed trains, metro rail systems, and advanced rolling stock requiring superior vibration control and enhanced operational safety

- For instance, in 2025, major manufacturers such as Knorr-Bremse, ITT Enidine, and ZF Friedrichshafen expanded their damper portfolios with improved force-adjustable, temperature-resistant, and long-life hydraulic damping solutions

- Strong growth in railway modernization, fleet expansion, and infrastructure upgrades across the U.S., Europe, and Asia-Pacific is boosting damper installations

- Advancements in material engineering, thermal stability, damping force modulation, and anti-fatigue technologies are strengthening product efficiency and durability

- Increasing adoption of smart rail systems, predictive maintenance platforms, and sensor-based monitoring is driving demand for electronically enhanced hydraulic dampers

- Supported by rising railway investments, urban mobility programs, and safety regulations, the Railway Hydraulic Damper market is positioned for sustained long-term growth

Which Factor is Challenging the Growth of the Railway Hydraulic Damper Market?

- High costs associated with premium, high-performance, and electronically controlled hydraulic dampers limit adoption among smaller rail operators and developing regions

- For instance, during 2024–2025, fluctuations in steel prices, precision machining components, and electronic sensor costs increased manufacturing expenses for several global damper suppliers

- Integration complexities involving high-speed rail systems, advanced suspension architectures, and safety-critical components increase the need for skilled engineers and technical expertise

- Limited awareness in emerging markets regarding smart damper technologies, digital monitoring systems, and lifecycle cost benefits slows their penetration

- Competition from mechanical dampers, air suspension systems, and low-cost semi-active damping alternatives creates pricing pressure and product differentiation challenges

- To address these limitations, companies are focusing on cost-optimized designs, modular components, long-life seals, and software-integrated monitoring platforms to strengthen global adoption of Railway Hydraulic Dampers

How is the Railway Hydraulic Damper Market Segmented?

The market is segmented on the basis of type, industry, and sales channel.

- By Channel Count

On the basis of channel count, the railway hydraulic damper market is segmented into 2–32, 32–80, and >80 hydraulic damper configurations used across various rolling stock suspension systems. The 2–32 segment dominated the market with a 46.5% share in 2025, driven by widespread use in metro trains, regional rail, and commuter railcars. These configurations offer balanced damping force, compact structure, and cost-effective vibration control, making them suitable for general suspension applications and maintenance-friendly operations. Their ability to stabilize car bodies, reduce oscillations, and enhance passenger comfort supports strong adoption across global rail networks.

The >80 segment is projected to grow at the fastest CAGR from 2026 to 2033, supported by increasing demand in high-speed rail, heavy-haul freight locomotives, and advanced bogie systems requiring multi-stage, high-energy absorption damping for stability at elevated speeds.

- By Application

On the basis of application, the railway hydraulic damper market is segmented into Primary Suspension, Secondary Suspension, Bogie Applications, and Coupler/Anti-Yaw Systems. The Secondary Suspension segment dominated the market with a 38.7% share in 2025, as hydraulic dampers in this category play a critical role in controlling carbody vibration, improving ride comfort, and ensuring stability at medium and high speeds. These dampers manage lateral, vertical, and roll movements while supporting advanced suspension designs used in metro, light rail, and passenger coaches.

The Bogie Applications segment is expected to grow at the fastest CAGR during 2026–2033, driven by increasing deployment of high-speed trains, multi-axle bogie architectures, and enhanced requirements for yaw control, wheel-rail force optimization, and anti-hunting performance. Evolving bogie designs and smart suspension systems further accelerate this segment's demand.

- By Vertical

On the basis of vertical, the railway hydraulic damper market is segmented into Urban Transit, High-Speed Rail, Freight Rail, Metro & Light Rail, Monorail, Passenger Rail, and Locomotives. The Metro & Light Rail segment dominated the market with a 34.2% share in 2025, due to rapid urbanization, expansion of metro networks, and continuous need for reliable vibration control solutions. Hydraulic dampers in this segment ensure superior stability, reduced wear on bogies, and enhanced passenger safety.

The High-Speed Rail segment is expected to grow at the fastest CAGR from 2026 to 2033, driven by rising investments in high-speed corridors, increasing train speeds, and growing demand for advanced, high-force, thermally stable hydraulic dampers capable of meeting strict safety and performance standards.

Which Region Holds the Largest Share of the Railway Hydraulic Damper Market?

- North America dominated the railway hydraulic damper market with a 37.58% revenue share in 2025, driven by strong investments in advanced rolling stock, urban transit expansion, high-speed rail initiatives, and modernization of freight and metro systems across the U.S. and Canada. High adoption of smart suspension systems, vibration control solutions, and advanced bogie designs continues to fuel demand for hydraulic dampers in passenger, freight, and high-speed rail applications

- Leading companies in North America are introducing electronically controlled, multi-stage, and high-force dampers with enhanced durability, temperature resistance, and real-time monitoring capabilities, reinforcing the region’s technological edge. Continuous investments in railway modernization, predictive maintenance systems, and R&D for high-speed rolling stock support long-term market expansion

- Strong engineering expertise, advanced manufacturing infrastructure, and robust innovation ecosystems further strengthen North America’s market leadership

U.S. Railway Hydraulic Damper Market Insight

The U.S. is the largest contributor in North America, supported by extensive deployment of high-speed trains, metro systems, and freight locomotives requiring advanced hydraulic damping solutions. Rising adoption of smart suspension systems, predictive maintenance platforms, and vibration monitoring technologies intensifies demand for high-performance dampers. Presence of major rolling stock manufacturers, engineering R&D centers, and government-supported transit programs further drives market growth across the country.

Canada Railway Hydraulic Damper Market Insight

Canada contributes significantly to regional growth, driven by expanding urban transit networks, freight rail modernization projects, and advanced commuter rail programs. Hydraulic dampers are widely deployed for bogie stability, secondary suspension, and anti-yaw applications. Government initiatives supporting smart rail infrastructure, skilled workforce availability, and rising adoption of advanced monitoring systems strengthen market penetration across Canadian rail networks.

Asia-Pacific Railway Hydraulic Damper Market

Asia-Pacific is projected to register the fastest CAGR of 7.9% from 2026 to 2033, fueled by rapid expansion of high-speed rail corridors, metro projects, and freight modernization across China, Japan, India, South Korea, and Southeast Asia. Increasing deployment of high-speed rolling stock, urban transit systems, and advanced freight locomotives drives demand for energy-efficient, high-force, and digitally monitored hydraulic dampers. Growth in industrial rail logistics, smart rail networks, and predictive maintenance platforms further accelerates adoption of next-generation damping solutions.

China Railway Hydraulic Damper Market Insight

China is the largest contributor in Asia-Pacific due to massive high-speed rail investments, metro expansion, and strong government support for smart rail systems. Rising demand for high-speed trains, multi-axle bogies, and heavy-haul locomotives is driving adoption of advanced hydraulic dampers with high energy absorption, temperature stability, and long service life. Local manufacturing capacity and competitive pricing further boost domestic and export market growth.

Japan Railway Hydraulic Damper Market Insight

Japan shows steady growth, supported by modernization of high-speed and urban rail systems, precision bogie engineering, and advanced commuter train fleets. Hydraulic dampers with superior reliability, vibration absorption, and smart monitoring capabilities are increasingly adopted for passenger comfort, rail safety, and long-term operational efficiency. Continued focus on high-quality engineering standards reinforces long-term market expansion.

India Railway Hydraulic Damper Market Insight

India is emerging as a major growth hub, driven by expanding metro and high-speed rail projects, railway electrification, and modernization of freight networks. Rising adoption of secondary suspension dampers, smart bogie systems, and predictive maintenance technologies accelerates demand. Government-backed programs supporting rolling stock upgrades and urban transit development further fuel market growth.

South Korea Railway Hydraulic Damper Market Insight

South Korea contributes significantly due to rapid high-speed rail expansion, advanced commuter rail systems, and growing industrial rail logistics. Demand for hydraulic dampers with high damping forces, thermal stability, and long lifecycle performance is increasing. Strong R&D capabilities, advanced manufacturing infrastructure, and adoption of smart rail monitoring systems support sustained market growth.

Which are the Top Companies in Railway Hydraulic Damper Market?

The railway hydraulic damper industry is primarily led by well-established companies, including:

- KONI BV (Netherlands)

- SV Shocks (Finland)

- ACE Stoßdämpfer GmbH (Germany)

- mageba (Switzerland)

- Oleo International (U.K.)

- Dellner (Sweden)

- Siemens (Germany)

- Escorts Limited (India)

- Vibratech TVD (U.S.)

- Weforma (Germany)

- Wuxi BDC (China)

- CESEHSA (Mexico)

- ARC DAMPERS (India)

- SACATEC (Belgium)

What are the Recent Developments in Global Railway Hydraulic Damper Market?

- In October 2025, ZF Friedrichshafen AG unveiled its locally produced advanced railway dampers at the International Railway Equipment Exhibition (IREE) 2025 in New Delhi, featuring a maintenance-free twin-tube design with customized characteristic curves for Indian track conditions, marking a major step in ZF’s regional localization strategy, and reinforcing its commitment to cost-efficient, compliant, and supply chain–optimized solutions for domestic OEMs

- In March 2025, Siemens AG and Knorr-Bremse AG entered a strategic partnership to co-develop advanced noise-reduction dampers for high-speed rail applications, combining Siemens’ systems integration expertise with Knorr-Bremse’s damping technology leadership to improve ride comfort, acoustic efficiency, and establish standardized damper specifications, strengthening long-term relationships with global OEMs

- In August 2023, Knorr-Bremse, a German rail and vehicle components producer, received the Railway Technology Excellence Awards 2023, in recognition of the company’s innovation, research, and development across its commercial vehicle product portfolio, which includes dampers, compressors, electronic systems, braking systems, steering systems, and disc brakes, highlighting its leadership in rail technology

- In April 2022, Wabtec Corporation announced its new line of vertical hydraulic dampers, designed to enhance rail suspension performance, operational reliability, and passenger comfort, reinforcing Wabtec’s focus on advanced damping solutions for the global railway market

- In November 2020, UK-based manufacturer Sulzer Group launched its new line of hydraulic dampers for railroad operations, aimed at improving vibration control, durability, and ride stability, further strengthening its product portfolio in rail damping technologies

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.