Global Refrigeration Insulation Materials Market

Market Size in USD Billion

CAGR :

%

USD

4.75 Billion

USD

7.81 Billion

2024

2032

USD

4.75 Billion

USD

7.81 Billion

2024

2032

| 2025 –2032 | |

| USD 4.75 Billion | |

| USD 7.81 Billion | |

|

|

|

|

Global Refrigeration Insulation Materials Market Size

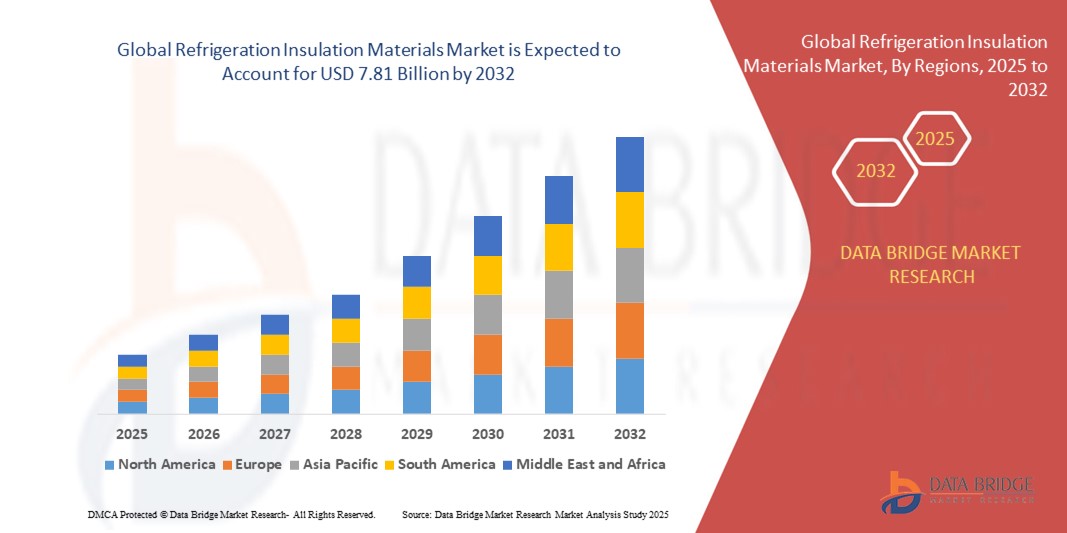

- The global refrigeration insulation materials market was valued at USD 4.75 billion in 2024 and is projected to reach USD 7.81 billion by 2032, growing at a CAGR of 6.40% during the forecast period.

- Market expansion is primarily driven by increasing demand for energy-efficient refrigeration systems across the food & beverage, pharmaceutical, and logistics industries, where temperature control is critical.

- Additionally, stringent environmental regulations and the shift toward sustainable building practices are encouraging the use of advanced insulation materials, thereby propelling the growth of the refrigeration insulation materials market worldwide.

Global Refrigeration Insulation Materials Market Analysis

- Refrigeration insulation materials, designed to minimize thermal loss and improve energy efficiency, are critical components in modern refrigeration systems used across residential, commercial, and industrial applications, supporting sustainability, regulatory compliance, and operational cost reduction

- The escalating demand for refrigeration insulation materials is primarily fueled by the rapid expansion of cold chain logistics, increasing consumption of perishable goods, and rising environmental awareness pushing the adoption of low-emission, energy-efficient insulation solutions

- Europe dominated the global refrigeration insulation materials market with the largest revenue share of 38.5% in 2024, driven by rapid industrialization, growing investments in cold storage infrastructure, and the strong presence of food processing and pharmaceutical industries, particularly in China, India, and Southeast Asia

- Asia-Pacific is expected to be the fastest growing region in the refrigeration insulation materials market during the forecast period due to stringent environmental regulations, increasing energy efficiency mandates, and rising adoption of sustainable construction and retrofitting practices

- The Polyurethane and Polyisocyanurate segment dominated the market with the largest revenue share of 47.3% in 2024, attributed to its excellent thermal insulation properties, lightweight nature, and moisture resistance.

Report Scope and Global Refrigeration Insulation Materials Market Segmentation

|

Attributes |

Refrigeration Insulation Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Refrigeration Insulation Materials Market Trends

Energy Efficiency and Sustainability Driving Material Innovation

- A significant and accelerating trend in the Global Refrigeration Insulation Materials Market market is the growing emphasis on energy efficiency and environmental sustainability, leading to continuous innovation in insulation technologies and materials. This trend is being driven by stricter global regulations on energy consumption and emissions, as well as increased awareness of climate change and the need for greener solutions across industries.

- For instance, companies like Kingspan Group plc and Owens Corning are investing heavily in the development of next-generation insulation materials with low thermal conductivity and reduced environmental impact. These innovations include the use of blowing agents with low Global Warming Potential (GWP) and recyclable or bio-based materials in insulation panels and foams.

- New formulations in Polyurethane (PUR) and Polyisocyanurate (PIR) insulation, such as those by BASF SE, are not only enhancing thermal performance but also meeting global sustainability benchmarks, including compliance with LEED, BREEAM, and other green building certification systems. These high-performance materials are increasingly favored in cold storage facilities, refrigerated transport, and commercial refrigeration units.

- Manufacturers are also incorporating digital monitoring and control features into refrigeration systems, enabling better thermal management and reduced energy waste. For example, integrated sensors can detect temperature fluctuations and optimize insulation performance in real time, significantly improving overall system efficiency.

- This shift towards sustainable refrigeration solutions is also supported by the circular economy movement, with companies like Saint-Gobain and Johns Manville focusing on recyclable insulation products and closed-loop manufacturing processes to reduce material waste and carbon footprints.

- The demand for eco-friendly and energy-efficient insulation materials is rapidly increasing across sectors such as food processing, pharmaceuticals, and logistics, as businesses seek to meet evolving environmental standards while reducing operational costs and enhancing system longevity.

Global Refrigeration Insulation Materials Market Dynamics

Driver

Growing Demand Driven by Cold Chain Expansion and Energy Efficiency Regulations

-

The rising global demand for temperature-sensitive goods such as pharmaceuticals, fresh produce, and frozen foods is significantly driving the need for advanced refrigeration insulation materials, particularly in cold chain logistics, retail refrigeration, and industrial cold storage applications

- For instance, in February 2024, Kingspan Group plc announced the expansion of its Kooltherm insulation product line tailored specifically for cold storage and food processing facilities, highlighting the industry’s focus on high-performance, energy-efficient materials

- As governments and regulatory bodies enforce stricter energy efficiency and environmental standards—such as the EU’s F-Gas Regulation and the U.S. Department of Energy’s updated rules—companies are investing in innovative insulation solutions to meet these evolving requirements

- Increasing urbanization and rising middle-class income in emerging economies are also fueling demand for reliable cold chain infrastructure, further propelling the adoption of high-quality insulation materials capable of minimizing energy loss and maintaining consistent internal temperatures

- Food safety concerns, vaccine preservation requirements, and growing e-commerce-driven grocery delivery services are expanding the application of advanced insulation across various end-use industries. Lightweight, high-R-value materials like PUR, PIR, and vacuum insulation panels are being adopted to improve performance and reduce operational costs

- The industry is also witnessing a shift toward prefabricated insulated panels and modular refrigeration systems, offering faster installation, better thermal efficiency, and compliance with green building certifications—further reinforcing the importance of insulation in the global refrigeration landscape

Restraint/Challenge

Volatility in Raw Material Prices and Environmental Impact Concerns

- The production of traditional refrigeration insulation materials such as PUR and PIR heavily depends on petrochemical derivatives, making the industry vulnerable to fluctuations in crude oil prices and the availability of key chemical feedstocks

- For instance, spikes in the prices of isocyanates and polyols in 2024 led to increased production costs for several manufacturers, putting pressure on margins and potentially delaying infrastructure projects in price-sensitive markets

- Environmental concerns related to the lifecycle of insulation materials—such as non-recyclability, emission of harmful blowing agents, and end-of-life disposal issues—pose additional challenges, especially in regions with strict environmental regulations

- To mitigate these concerns, companies like Owens Corning and Saint-Gobain are investing in the development of eco-friendly alternatives, including bio-based insulation foams, recycled content materials, and non-halogenated blowing agents

- Despite these innovations, the relatively high cost of sustainable insulation options and the need for specialized manufacturing processes can limit their widespread adoption, particularly in developing regions with budget constraints

- Overcoming these challenges will require ongoing investment in material innovation, tighter supply chain management, and greater collaboration across the industry to improve both economic and environmental performance of refrigeration insulation materials

Global Refrigeration Insulation Materials Market Scope

The refrigeration insulation materials market is segmented on the basis of type, application, temperature range and end user industry.

- By Type

On the basis of type, the Global Refrigeration Insulation Materials Market is segmented into Elastomeric Foam, Polyurethane and Polyisocyanurate (PU/PIR), Extruded Polystyrene Foam (XPS), Fiberglass, Phenolic Foam, Polyethylene Terephthalate (PET) Foam, and Others. The Polyurethane and Polyisocyanurate segment dominated the market with the largest revenue share of 47.3% in 2024, attributed to its excellent thermal insulation properties, lightweight nature, and moisture resistance. PU/PIR foams are widely used in cold storage facilities, refrigerated transport, and commercial refrigeration due to their high R-values and durability.

The Elastomeric Foam segment is expected to witness the fastest CAGR of 22.1% from 2025 to 2032, driven by increasing demand in cryogenic and refrigerated transport applications where flexibility, low thermal conductivity, and resistance to vibration are critical. The versatility of elastomeric foam and its ease of installation in complex piping systems contribute significantly to its growing adoption.

- By Application

On the basis of application, the Global Refrigeration Insulation Materials Market market is segmented into Commercial, Industrial, Cryogenic, and Refrigerated Transportation. The Commercial segment accounted for the largest market revenue share of 39.6% in 2024, driven by the expansion of retail refrigeration, foodservice, and cold storage infrastructure globally. Commercial refrigeration units rely heavily on high-performance insulation materials to ensure energy efficiency and product preservation.

The Cryogenic segment is anticipated to witness the fastest CAGR of 23.4% from 2025 to 2032, fueled by the rising demand for liquefied natural gas (LNG) transport, medical gas storage, and industrial gas applications requiring insulation at ultra-low temperatures. The growth of cryogenic insulation reflects increased investments in energy and healthcare sectors, where maintaining extremely low temperatures is crucial.

- By Temperature Range

On the basis of temperature range, the market is segmented into -160°C to -50°C, -49°C to 0°C, 1°C to 100°C, and 101°C to 650°C. The -49°C to 0°C segment dominated the market in 2024, holding a revenue share of 44.2%, as this temperature range covers the majority of refrigeration and cold storage applications in food preservation and pharmaceuticals. Insulation materials designed for this range balance cost-effectiveness with high thermal efficiency, making them widely applicable across industries.

The -160°C to -50°C segment is expected to witness the fastest growth rate of 24.1% from 2025 to 2032, driven by increasing LNG infrastructure, cryogenic storage needs, and advancements in ultra-low temperature insulation technology. This segment demands specialized materials like elastomeric foams and vacuum insulated panels to ensure safety and energy efficiency at extreme cold conditions.

- By End-User Industry

On the basis of end-user industry, the Global Refrigeration Insulation Materials Market market is segmented into Food and Beverages, Chemicals and Pharmaceuticals, Oil and Gas and Petrochemicals, and Others. The Food and Beverages segment dominated the market with the largest revenue share of 41.7% in 2024, propelled by the growing cold chain logistics for perishable goods, expanding frozen food consumption, and stringent food safety regulations worldwide. Advanced insulation materials help preserve product quality while reducing energy consumption across the supply chain.

The Chemicals and Pharmaceuticals segment is projected to register the fastest CAGR of 21.9% from 2025 to 2032, due to the critical need for temperature-controlled environments in drug manufacturing, storage, and transport, as well as growing demand for specialty chemicals that require precise thermal management.he refrigeration insulation materials market is segmented on the basis of type, application, temperature range and end user industry.

Global Refrigeration Insulation Materials Market Regional Analysis

- Europe dominated the Global Refrigeration Insulation Materials Market market with the largest revenue share of 38.5% in 2024, driven by the rapid expansion of cold storage infrastructure, advanced refrigerated transportation networks, and stringent energy efficiency regulations.

- The region benefits from strong industrial growth in food and beverage processing, pharmaceuticals, and petrochemicals, which demand high-performance insulation solutions to maintain product integrity and reduce operational costs.

- Additionally, increasing investments in sustainable and energy-efficient refrigeration systems, coupled with the presence of major insulation material manufacturers and innovative technology adoption, have fueled market growth. High disposable incomes and government incentives promoting green building practices further encourage the widespread use of advanced refrigeration insulation materials across commercial, industrial, and logistics sectors.

U.K. Refrigeration Insulation Materials Market Insight

The U.K. market for refrigeration insulation materials is expected to grow steadily during the forecast period, supported by increasing demand from the commercial refrigeration and cold chain logistics sectors. The country’s focus on energy-efficient building codes and carbon reduction targets is pushing the adoption of superior insulation technologies. Moreover, the expanding food and beverage processing industry and cold storage facilities create strong demand for reliable insulation solutions. The U.K.’s growing e-commerce and grocery delivery services, requiring efficient refrigerated transportation, also stimulate the market.

Germany Refrigeration Insulation Materials Market Insight

Germany’s market is anticipated to witness considerable growth driven by the nation’s emphasis on sustainability, innovation, and energy-efficient building practices. The country’s well-established food processing and pharmaceutical industries require robust refrigeration insulation to maintain product quality and meet stringent regulatory standards. Increasing investment in cold chain infrastructure upgrades and the adoption of environmentally friendly refrigerants necessitate advanced insulation materials. Furthermore, growing industrial automation and smart factory initiatives promote the integration of high-performance insulation solutions across multiple sectors.

Europe Refrigeration Insulation Materials Market Insight

Europe is projected to register substantial CAGR growth throughout the forecast period, largely driven by rigorous energy efficiency standards and environmental regulations aimed at reducing greenhouse gas emissions. Rising demand for sustainable refrigeration systems in food processing, pharmaceuticals, and chemical industries is boosting the adoption of high-performance insulation materials. Urbanization, coupled with modernization of cold storage facilities and refrigerated transport fleets, is further accelerating market expansion. Additionally, increasing investments in retrofitting older facilities with advanced insulation solutions contribute significantly to the region’s growth.

Asia-Pacific Refrigeration Insulation Materials Market Insight

Asia-Pacific is expected to experience the fastest CAGR of 24% from 2025 to 2032, driven by rapid urbanization, rising disposable incomes, and expanding cold storage and refrigerated transport infrastructure in countries like China, India, Japan, and South Korea. Government initiatives promoting food safety, cold chain development, and energy efficiency are catalyzing the demand for advanced refrigeration insulation materials. Additionally, the region’s emergence as a manufacturing hub for insulation products and components is lowering costs and improving accessibility, fostering widespread adoption across commercial, industrial, and logistics sectors.

Japan Refrigeration Insulation Materials Market Insight

Japan’s market growth is propelled by the country’s high emphasis on quality, safety, and technological advancement in refrigeration systems. The expansion of smart cold chain logistics and automated refrigerated warehouses contributes to rising demand for innovative insulation materials capable of supporting precise temperature control. Japan’s aging population also drives demand for reliable, energy-efficient refrigeration in healthcare and pharmaceutical sectors. Integration of IoT technologies with refrigeration systems enhances operational efficiency, further boosting the market.

China Refrigeration Insulation Materials Market Insight

China accounted for the largest market revenue share within Asia-Pacific in 2024, fueled by rapid urbanization, growing middle-class consumption, and strong industrial activity in food processing and pharmaceuticals. The country’s extensive development of smart cities and cold chain infrastructure projects supports increasing demand for effective refrigeration insulation materials. Moreover, government policies emphasizing energy conservation and environmental protection are accelerating adoption. The presence of numerous domestic manufacturers offering cost-effective insulation solutions also strengthens market growth, especially in emerging urban and rural areas.

Global Refrigeration Insulation Materials Market Share

The Refrigerater Insulation Materials industry is primarily led by well-established companies, including:

- Armacell (Germany)

- Owens Corning (U.S.)

- Kingspan Group plc (Ireland)

- Morgan Advanced Materials (United Kingdom)

- ETEX (Belgium)

- Isover (France)

- BASF SE (Germany)

- Kflex (Italy)

- Aspen Aerogel (U.S.)

- Zhejiang Zhenshen Insulation Technology Corp. Ltd. (China)

- Johns Manville (U.S.)

- Zotefoams (U.K.)

- NMC sa (Belgium)

- Cabot Corporation (U.S.)

- Lydall, Inc. (U.S.)

- Saint-Gobain (France)

What are the Recent Developments in Global Refrigeration Insulation Materials Market?

- In April 2023, Armacell, a global leader in flexible insulation materials, launched a new initiative in South Africa to enhance energy efficiency and reduce refrigeration costs for commercial cold storage facilities. By introducing its advanced elastomeric foam solutions tailored to regional climate challenges, Armacell is reinforcing its commitment to sustainable refrigeration practices and addressing the growing demand for high-performance insulation in emerging markets.

- In March 2023, Kingspan Group plc, a pioneer in high-performance insulation technologies, unveiled its latest polyurethane and polyisocyanurate insulation panels designed specifically for industrial refrigeration applications in North America. These next-generation panels offer superior thermal resistance and durability, contributing to lower energy consumption and improved environmental compliance in cold storage warehouses and food processing plants.

- In March 2023, Owens Corning successfully implemented a large-scale refrigeration insulation retrofit project as part of the Bengaluru Cold Chain Expansion Program. Utilizing their advanced extruded polystyrene (XPS) foam insulation solutions, Owens Corning helped optimize temperature control and reduce energy usage across multiple cold storage units, showcasing the critical role of insulation materials in urban cold chain infrastructure development.

- In February 2023, BASF SE, a leading chemical producer and insulation material innovator, announced a strategic partnership with key players in the refrigerated transportation industry to supply high-performance phenolic foam insulation for refrigerated trucks and containers. This collaboration aims to enhance the durability and thermal efficiency of refrigerated transport, supporting safer and more energy-efficient cold chain logistics.

- In January 2023, Johns Manville, a subsidiary of Berkshire Hathaway and a major supplier of fiberglass insulation solutions, introduced its new line of sustainable fiberglass insulation products tailored for cryogenic refrigeration applications. Unveiled at the International Refrigeration Expo 2023, these materials provide superior thermal insulation at ultra-low temperatures, underscoring Johns Manville’s focus on innovation and environmental stewardship in refrigeration insulation.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Refrigeration Insulation Materials Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Refrigeration Insulation Materials Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Refrigeration Insulation Materials Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.