Global Roller Cone Drilling Bit Market

Market Size in USD Billion

CAGR :

%

USD

2.21 Billion

USD

3.40 Billion

2024

2032

USD

2.21 Billion

USD

3.40 Billion

2024

2032

| 2025 –2032 | |

| USD 2.21 Billion | |

| USD 3.40 Billion | |

|

|

|

|

Roller Cone Drilling Bit Market Size

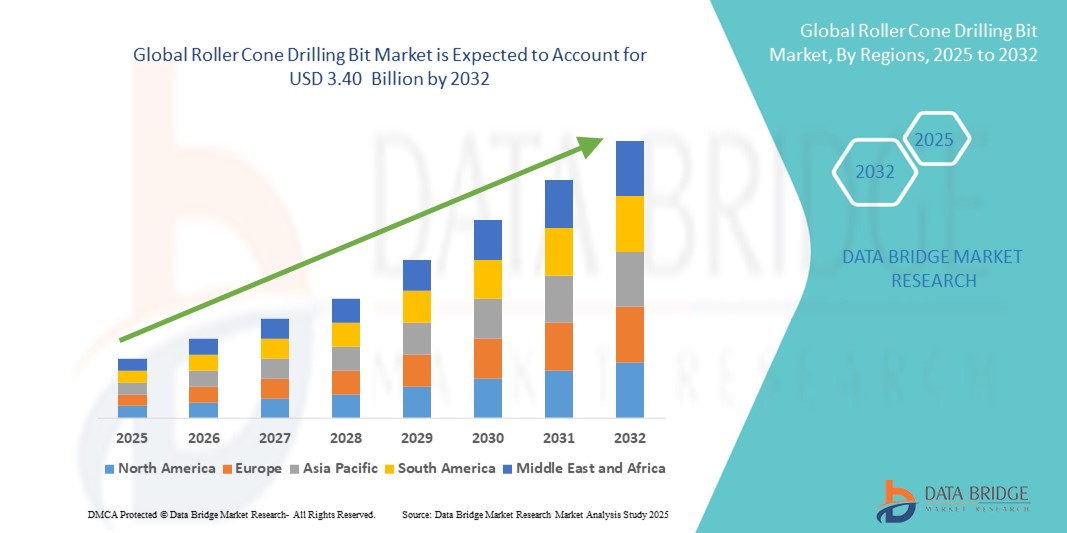

- The global roller cone drilling bit market size was valued at USD 2.21 billion in 2024 and is expected to reach USD 3.40 billion by 2032, at a CAGR of 5.50% during the forecast period

- The market growth is primarily driven by increasing global energy demand, expanding exploration and production activities, and advancements in drilling technologies for enhanced efficiency and durability

- Rising investments in oil and gas exploration, particularly in unconventional reserves, are boosting the demand for roller cone drilling bits across both onshore and offshore applications

Roller Cone Drilling Bit Market Analysis

- The roller cone drilling bit market is experiencing consistent growth due to the rising need for efficient drilling solutions in complex geological formations and deepwater exploration

- Growing adoption of advanced materials and designs, such as tungsten carbide inserts and sealed bearing systems, is encouraging manufacturers to innovate high-performance and durable drilling bits

- North America dominated the roller cone drilling bit market with the largest revenue share of 36.1% in 2024, driven by a robust oil and gas industry, significant shale gas exploration, and advanced drilling infrastructure

- Asia-Pacific is expected to be the fastest-growing region during the forecast period, propelled by rapid industrialization, increasing energy consumption, and growing offshore drilling activities in countries such as China, India, and Australia

- The fixed cutter bit segment dominated the largest market revenue share of 60% in 2024, driven by its superior performance in shale formations and hard rock drilling. Fixed cutter bits, particularly polycrystalline diamond compact (PDC) bits, offer enhanced durability and faster penetration rates with no moving parts, reducing maintenance costs and downtime

Report Scope and Roller Cone Drilling Bit Market Segmentation

|

Attributes |

Roller Cone Drilling Bit Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Roller Cone Drilling Bit Market Trends

Increasing Adoption of Advanced Materials and Automation Technologies

- The Global Roller Cone Drilling Bit Market is experiencing a notable trend toward the integration of advanced materials, such as polycrystalline diamond compact (PDC) and tungsten carbide, enhancing bit durability and performance

- Automation technologies, including AI-driven drilling optimization and real-time data analytics, are being incorporated to improve drilling efficiency and reduce operational downtime

- These advancements enable precise monitoring of bit performance, geological formations, and drilling conditions, allowing for proactive adjustments during operations

- For instance, companies are developing smart drilling bits embedded with sensors to provide real-time feedback on wear and tear, optimizing drilling parameters for various formations

- This trend is increasing the appeal of roller cone drilling bits for complex drilling operations, particularly in challenging geological environments, for both onshore and offshore applications

- Automated systems can analyze data on drilling speed, torque, and formation hardness, enabling operators to maximize efficiency and extend bit lifespan

Roller Cone Drilling Bit Market Dynamics

Driver

Growing Demand for Energy Exploration and Production

- The rising global demand for energy resources, particularly oil, gas, and geothermal energy, is a key driver for the Global Roller Cone Drilling Bit Market

- Roller cone drilling bits are critical for efficient exploration and extraction in diverse geological formations, supporting the expansion of drilling activities

- Government initiatives in regions such as North America, which dominated the market, are promoting increased drilling to meet energy demands and reduce reliance on foreign resources

- The proliferation of advanced drilling techniques, such as horizontal and directional drilling, supported by high-speed connectivity such as 5G, is enabling more precise and efficient operations

- Major oil and gas companies are increasingly integrating advanced roller cone bits as standard equipment to enhance operational efficiency and meet production targets

Restraint/Challenge

High Initial Costs and Environmental Regulatory Pressures

- The significant upfront costs associated with advanced roller cone drilling bits, including manufacturing, materials, and integration with automated systems, pose a barrier to adoption, particularly in cost-sensitive markets

- Retrofitting existing drilling rigs with advanced bits and supporting technologies can be complex and expensive

- In addition, stringent environmental regulations and concerns about the ecological impact of drilling operations present challenges, as compliance with emission standards and waste management requirements increases operational costs

- The varying regulatory frameworks across countries, particularly in Asia-Pacific, the fastest-growing region, complicate operations for global manufacturers and service providers

- These factors can limit market growth in regions with high environmental awareness or where budget constraints are significant

Roller Cone Drilling Bit market Scope

The market is segmented on the basis of type and location of deployment.

- By Type

On the basis of type, the global roller cone drilling bit market is segmented into roller cone bit and fixed cutter bit. The fixed cutter bit segment dominated the largest market revenue share of 60% in 2024, driven by its superior performance in shale formations and hard rock drilling. Fixed cutter bits, particularly polycrystalline diamond compact (PDC) bits, offer enhanced durability and faster penetration rates with no moving parts, reducing maintenance costs and downtime. Their ability to handle complex geological formations and high-temperature environments has made them the preferred choice for modern drilling operations, especially in unconventional reservoirs.

The roller cone bit segment is expected to register the fastest growth rate from 2025 to 2032, as demand grows for versatile drilling solutions in diverse geological conditions. Roller cone bits, with their rotating cones and cutting teeth, excel in medium to hard formations and are widely used in oil and gas, mining, and geothermal exploration. Their adaptability to varied rock types and cost-effectiveness in specific applications are driving renewed interest, particularly in emerging markets with expanding exploration activities.

- By Location of Deployment

On the basis of location of deployment, the global roller cone drilling bit market is categorized into onshore and offshore. The onshore segment accounted for the highest revenue share in 2024, supported by the surge in domestic energy production and the development of complex reservoirs, particularly in North America. Onshore drilling benefits from lower operational costs, easier access to resources, and increased adoption of automated rigs, which drive demand for high-performance drilling bits. The focus on unconventional drilling techniques, such as horizontal and directional drilling, further bolsters the onshore segment’s dominance.

The offshore segment is anticipated to grow at the fastest CAGR from 2025 to 2032, propelled by increasing exploration in deepwater and ultra-deepwater environments, particularly in regions such as Asia-Pacific and Latin America. Offshore drilling requires advanced drilling bits capable of withstanding high-pressure and high-temperature conditions, and roller cone bits are valued for their durability and efficiency in such challenging settings. Rising investments in offshore oil and gas projects, coupled with advancements in drilling technologies, are accelerating this segment’s growth.

Roller Cone Drilling Bit Market Regional Analysis

- North America dominated the roller cone drilling bit market with the largest revenue share of 36.1% in 2024, driven by a robust oil and gas industry, significant shale gas exploration, and advanced drilling infrastructure

- Operators prioritize roller cone drilling bits for their durability, versatility, and efficiency in penetrating diverse geological formations, particularly in shale and unconventional reservoirs.

- Growth is supported by advancements in bit technology, such as improved cutting structures and wear-resistant materials, alongside rising adoption in both onshore and offshore drilling operations

U.S. Roller Cone Drilling Bit Market Insight

The U.S. roller cone drilling bit market captured the largest revenue share of 72.7% in 2024 within North America, fueled by strong demand in shale gas exploration and growing operator focus on efficient drilling solutions. The trend toward optimizing drilling performance in complex reservoirs and increasing environmental regulations promoting sustainable practices further boost market expansion. Major oilfield service providers’ integration of advanced roller cone bits complements aftermarket sales, creating a dynamic product ecosystem.

Europe Roller Cone Drilling Bit Market Insight

The Europe roller cone drilling bit market is expected to witness significant growth, supported by regulatory emphasis on energy security and efficient resource extraction. Operators seek bits that enhance drilling efficiency while minimizing environmental impact. The growth is prominent in both onshore and offshore projects, with countries such as Russia and Norway showing significant uptake due to rising exploration activities and energy demands.

U.K. Roller Cone Drilling Bit Market Insight

The U.K. market for roller cone drilling bits is expected to witness notable growth, driven by demand for reliable drilling solutions in offshore North Sea projects. Increased focus on maximizing extraction efficiency and rising awareness of advanced bit technologies encourage adoption. Evolving regulations balancing operational efficiency with environmental compliance influence operator choices, supporting market growth.

Germany Roller Cone Drilling Bit Market Insight

Germany is expected to witness steady growth in the roller cone drilling bit market, attributed to its advanced energy sector and high focus on efficient drilling technologies. German operators prefer technologically advanced bits that enhance penetration rates and contribute to lower operational costs. The integration of these bits in both conventional and geothermal drilling projects supports sustained market growth.

Asia-Pacific Roller Cone Drilling Bit Market Insight

The Asia-Pacific region is expected to witness the fastest growth rate, driven by expanding oil and gas exploration and rising investments in countries such as China, India, and Australia. Increasing awareness of efficient drilling technologies and energy security is boosting demand. Government initiatives promoting sustainable energy exploration and advanced drilling solutions further encourage the use of roller cone drilling bits.

Japan Roller Cone Drilling Bit Market Insight

Japan’s roller cone drilling bit market is expected to witness rapid growth due to strong operator preference for high-quality, technologically advanced bits that enhance drilling efficiency and safety. The presence of major energy companies and integration of roller cone bits in offshore exploration accelerate market penetration. Rising interest in geothermal drilling also contributes to growth.

China Roller Cone Drilling Bit Market Insight

China holds the largest share of the Asia-Pacific roller cone drilling bit market, propelled by rapid urbanization, increasing energy demand, and growing exploration activities. The country’s expanding oil and gas sector and focus on energy independence support the adoption of advanced roller cone bits. Strong domestic manufacturing capabilities and competitive pricing enhance market accessibility.

Roller Cone Drilling Bit Market Share

The roller cone drilling bit industry is primarily led by well-established companies, including:

- Atlas Copco (Sweden)

- Baker Hughes Company (U.S.)

- Cangzhou Great Drill Bits Co., Ltd. (China)

- ESCO Corporation (U.S.)

- Halliburton Company (U.S.)

- IRWIN TOOLS (U.S.)

- New Tech Drilling Products LLC (U.S.)

- National Oilwell Varco Inc. (U.S.)

- Scientific Drilling International Inc. (U.S.)

- Kingdream Public Limited Company (China)

- Varel International, Inc. (U.S.)

- Torquato Drilling Accessories, Inc. (U.S.)

- Ulterra (U.S.)

What are the Recent Developments in Global Roller Cone Drilling Bit Market?

- In December 2023, Epiroc, a global productivity and sustainability partner for the mining and construction industries, announced its agreement to acquire Weco Proprietary Ltd., a South African manufacturer of precision-engineered rock drilling parts and provider of related repair services. Based near Johannesburg, Weco has over four decades of experience and primarily serves underground mining companies in Southern Africa. This acquisition aligns with Epiroc’s strategy to strengthen its product portfolio and expand its aftermarket capabilities, reinforcing its position in the mining and infrastructure sectors across the African region

- In May 2023, Sandvik Mining and Rock Solutions launched the Sandvik RR340, a single seal roller bearing rotary drill bit designed to enhance efficiency, safety, and cost-effectiveness in mining operations. The RR340 features an abrasion-resistant radial seal and low-friction bearing, which together deliver 45% longer service life and 25% more bearing hours compared to standard air bearing bits. These improvements reduce the frequency of bit changes, lower operational costs, and support autonomous drilling. The RR340 is available in sizes ranging from 6.75 to 12.25 inches, making it suitable for a wide range of drilling conditions

- In January 2023, Mincon Group plc launched its next-generation MP-series of down-the-hole (DTH) hammers, designed to deliver high-efficiency performance, top-tier penetration rates, and significant energy savings. This advanced product line helps customers reduce drilling costs and carbon emissions, aligning with global sustainability goals. The MP-series includes models ranging from the compact MP30 to the large-diameter MP400, all engineered for versatility across various ground conditions and applications. Manufactured in Mincon’s state-of-the-art facilities in Ireland and Finland, these hammers reflect decades of innovation and customer-driven design improvements

- In July 2022, Halliburton Company introduced the Hedron platform of fixed-cutter polycrystalline diamond compact (PDC) drill bits. While not a roller cone bit, this product launch highlights a broader industry trend of introducing advanced technologies to enhance drilling performance. The Hedron platform combines new technology with customization processes to offer high-performance, application-specific designs

- In November 2021, Varel Energy Solutions announced a major rebrand, reaffirming its commitment to innovation in drilling and downhole solutions. Formerly known as Varel International Energy Services, the company introduced a new name and identity to reflect its strategic vision for growth. This includes strengthening its product offerings through strategic acquisitions and organic investment in low-cost, adaptive manufacturing. The rebrand positions Varel as a leading value creator in the well construction energy sector, emphasizing its focus on customer experience, precision engineering, and global reach

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.