Global Rubber Conveyor Belts Market

Market Size in USD Billion

CAGR :

%

USD

4.49 Billion

USD

6.05 Billion

2024

2032

USD

4.49 Billion

USD

6.05 Billion

2024

2032

| 2025 –2032 | |

| USD 4.49 Billion | |

| USD 6.05 Billion | |

|

|

|

|

Rubber Conveyor Belts Market Size

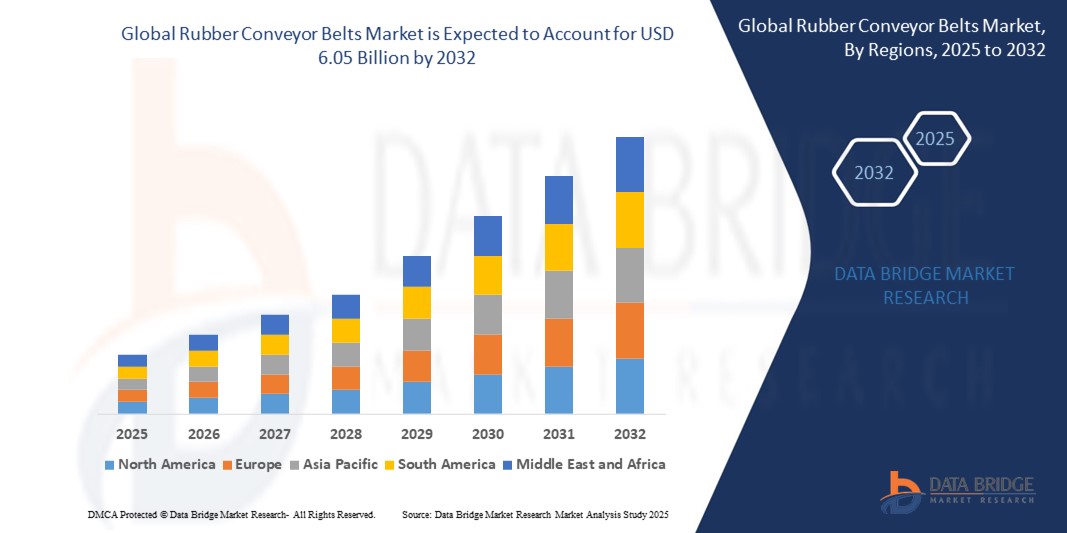

- The global rubber conveyor belts market size was valued at USD 4.49 billion in 2024 and is expected to reach USD 6.05 billion by 2032, at a CAGR of 3.80% during the forecast period

- The market growth is largely fueled by increasing demand for efficient bulk material handling across mining, cement, steel, and power generation industries, coupled with rapid industrialization and infrastructure expansion in emerging economies

- Furthermore, advancements in conveyor belt materials—such as heat-, abrasion-, and flame-resistant compounds—are improving durability and operational efficiency, prompting widespread adoption across heavy-duty applications. These converging factors are significantly boosting the deployment of rubber conveyor belts globally

Rubber Conveyor Belts Market Analysis

- Rubber conveyor belts are essential components in industrial material handling systems, designed to transport bulk goods efficiently across manufacturing, mining, and processing environments. These belts are engineered using reinforced materials to endure harsh conditions and are customized for various weight capacities and environmental resistances

- The rising demand is driven by increasing automation, stringent safety regulations, and the expansion of end-use industries such as mining, cement manufacturing, and recycling, all of which rely heavily on conveyor systems for productivity and cost-efficiency

- Asia-Pacific dominated the rubber conveyor belts market with a share of 37.5% in 2024, due to rapid industrialization, infrastructure expansion, and mining activities across emerging economies

- North America is expected to be the fastest growing region in the rubber conveyor belts market during the forecast period due to recovery in mining and metal industries, along with increased focus on energy infrastructure and industrial automation

- Heavy-weight segment dominated the market with a market share of 45.2% in 2024, due to widespread use in high-load operations such as mining, metal processing, and power generation. These belts are engineered to move massive quantities of materials over extended distances, offering exceptional durability and minimal maintenance requirements. Their design often includes reinforced layers and specialized compounds tailored for rugged environments

Report Scope and Rubber Conveyor Belts Market Segmentation

|

Attributes |

Rubber Conveyor Belts Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Rubber Conveyor Belts Market Trends

“Expanding into Aftermarket Services of Conveyor Belts”

- The rubber conveyor belts market is witnessing a significant shift as manufacturers increasingly focus on expanding their presence in aftermarket services, including maintenance, repair, and replacement of conveyor belts, to create new revenue streams and strengthen customer relationships

- For instance, Continental AG has launched dedicated aftermarket service programs that offer predictive maintenance, belt monitoring, and rapid replacement solutions, helping clients reduce downtime and extend the operational life of their conveyor systems

- The growing complexity of industrial operations and the need for uninterrupted material flow are driving end-users to seek comprehensive service packages that go beyond the initial purchase of conveyor belts

- Digitalization and the integration of IoT-based monitoring systems are enabling service providers to offer real-time performance tracking, predictive analytics, and remote diagnostics, which enhance the value proposition of aftermarket offerings

- As industries such as mining, cement, and logistics increasingly prioritize operational efficiency, the demand for tailored aftermarket solutions, including on-site technical support and training, is rising steadily

- The trend toward sustainability is prompting companies to offer services focused on recycling and refurbishing used conveyor belts, aligning with circular economy principles and helping customers meet their environmental goals

Rubber Conveyor Belts Market Dynamics

Driver

“Rising Demand for Bulk Material Handling”

- The increasing scale of operations in industries such as mining, agriculture, construction, and manufacturing is driving the demand for efficient bulk material handling solutions, with rubber conveyor belts playing a crucial role in streamlining transportation processes

- For instance, Bridgestone Corporation has reported a surge in orders for heavy-duty rubber conveyor belts from mining and port facilities across Asia-Pacific, reflecting the growing need for robust and reliable material handling systems in resource-intensive sectors

- The expansion of infrastructure projects and the modernization of logistics networks in emerging economies are further boosting the adoption of conveyor belts for high-volume, continuous material transport

- Automation and the integration of advanced conveyor systems are enabling industries to achieve higher throughput, reduce labor costs, and minimize material wastage, thereby increasing reliance on high-performance rubber conveyor belts

- The versatility and adaptability of rubber conveyor belts, which can be customized for various applications and operating environments, make them a preferred choice for diverse industrial sectors seeking to optimize their bulk handling operations

Restraint/Challenge

“Competition from Alternative Materials”

- The rubber conveyor belts market is facing increasing competition from alternative materials such as PVC, steel, and fabric-reinforced belts, which offer distinct advantages in terms of weight, cost, or specific application suitability

- For instance, Fenner Dunlop has observed a growing preference among certain customers for lightweight PVC and fabric conveyor belts in food processing and packaging industries, where hygiene, flexibility, and ease of cleaning are critical factors

- Technological advancements in alternative belt materials are enabling manufacturers to introduce products with enhanced durability, chemical resistance, and lower maintenance requirements, challenging the dominance of traditional rubber belts

- Price sensitivity among end-users, especially in cost-driven industries, is prompting a shift toward alternative materials that can offer comparable performance at a lower total cost of ownership

- Environmental regulations and sustainability concerns are encouraging the adoption of eco-friendly conveyor belt materials, pushing rubber belt manufacturers to innovate and differentiate their offerings to maintain market share

Rubber Conveyor Belts Market Scope

The market is segmented on the basis of type, material, application, and end-use.

- By Type

On the basis of type, the rubber conveyor belts market is segmented into oil & grease-resistant, flame-resistant, heat-resistant, chemical-resistant, and abrasion-resistant. The abrasion-resistant segment dominated the largest market revenue share in 2024, owing to its extensive deployment across high-wear industrial environments such as mining and metal processing. These belts are engineered to withstand continuous mechanical stress, surface impact, and rough handling, making them indispensable in bulk material handling operations. Industries prioritize abrasion-resistant belts due to their durability, longer service life, and reduced downtime, all of which directly contribute to operational efficiency and cost savings.

The flame-resistant segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by stringent safety regulations in underground mining and power generation facilities. Flame-resistant belts play a critical role in minimizing fire hazards in potentially explosive environments, and their growing adoption is supported by advancements in material science that enhance heat and ignition resistance without compromising performance.

- By Material

On the basis of material, the rubber conveyor belts market is segmented into steel reinforced conveyor belts, textile reinforced conveyor belts, and solid woven belts. The steel reinforced conveyor belts segment held the largest market revenue share in 2024, attributed to their superior tensile strength and resistance to heavy loads, making them the preferred choice for mining, cement, and bulk transportation industries. Their ability to handle long-distance conveying and abrasive materials under extreme conditions makes them critical to large-scale operations.

The textile reinforced conveyor belts segment is expected to witness the fastest CAGR from 2025 to 2032, owing to their flexibility, ease of installation, and cost-effectiveness in medium-duty applications. These belts are extensively used in manufacturing, recycling, and logistics sectors where weight efficiency and moderate strength are prioritized. Their growing demand also stems from the increasing adoption of lightweight and energy-efficient conveyor systems in emerging industrial sectors.

- By Application

On the basis of application, the rubber conveyor belts market is segmented into light-weight, medium-weight, and heavy-weight. The heavy-weight segment accounted for the largest market revenue share of 45.2% in 2024, supported by widespread use in high-load operations such as mining, metal processing, and power generation. These belts are engineered to move massive quantities of materials over extended distances, offering exceptional durability and minimal maintenance requirements. Their design often includes reinforced layers and specialized compounds tailored for rugged environments.

The medium-weight segment is projected to register the fastest growth rate from 2025 to 2032, primarily due to expanding usage in industries such as construction, packaging, and material recycling. This category balances strength with flexibility, offering optimal performance in settings that do not demand the robustness of heavy-weight belts but require greater capacity and endurance than light-duty variants.

- By End-Use

On the basis of end-use, the rubber conveyor belts market is segmented into mining, cement manufacturing, power generation, recycling, and metal processing. The mining segment dominated the largest market revenue share in 2024, driven by its high dependence on conveyor belts for continuous material movement in both surface and underground operations. Rubber conveyor belts are vital to ensuring uninterrupted transport of ores and minerals, contributing to productivity and reducing labor intensity.

The recycling segment is anticipated to witness the fastest CAGR from 2025 to 2032, as global emphasis on circular economy and environmental sustainability accelerates the adoption of automated waste sorting and material recovery systems. Conveyor belts in this sector are selected for their adaptability, chemical resistance, and ability to handle a diverse mix of materials, from plastics and paper to metals and glass, under varying operational conditions.

Rubber Conveyor Belts Market Regional Analysis

- Asia-Pacific dominated the rubber conveyor belts market with the largest revenue share of 37.5% in 2024, driven by rapid industrialization, infrastructure expansion, and mining activities across emerging economies

- The region’s robust growth in cement, steel, and power generation sectors, along with increasing demand for bulk material handling solutions, significantly contributes to market expansion

- Local manufacturing capabilities, rising investments in heavy industries, and government initiatives aimed at improving industrial output and transport infrastructure are accelerating the adoption of rubber conveyor belts

Japan Rubber Conveyor Belts Market Insight

The Japan market is growing steadily due to rising demand for energy-efficient and durable conveyor systems in the automotive and electronics manufacturing sectors. With a focus on automation and process optimization, Japanese companies are adopting high-performance rubber conveyor belts that enhance productivity and reduce maintenance. Environmental regulations are also prompting the use of advanced, recyclable belt materials.

China Rubber Conveyor Belts Market Insight

China held the largest share in the Asia-Pacific market in 2024, fueled by its dominant position in global mining, cement production, and steel manufacturing. Rapid industrial expansion and strong government support for domestic manufacturing are driving large-scale deployments of heavy-duty conveyor belts. Chinese manufacturers are investing in technologically advanced and wear-resistant belts to support both internal operations and export demands.

Europe Rubber Conveyor Belts Market Insight

The Europe market is projected to grow at a significant CAGR over the forecast period, supported by stringent safety and environmental regulations and increased adoption of automation in industrial processes. Demand is rising across recycling, metal processing, and logistics sectors, where conveyor belts are essential for efficient, high-volume material handling. Focus on sustainable and energy-efficient belt technologies is also boosting market development.

U.K. Rubber Conveyor Belts Market Insight

The U.K. market is expected to grow steadily, driven by modernization efforts in manufacturing and material recovery facilities. Government-backed infrastructure projects and focus on circular economy practices are enhancing demand for durable, energy-saving conveyor systems. The rise of e-commerce and automated warehouses further supports the adoption of lightweight and medium-duty rubber belts.

Germany Rubber Conveyor Belts Market Insight

Germany is witnessing substantial growth in its rubber conveyor belts market due to its leadership in industrial automation, engineering excellence, and focus on sustainable production practices. High demand from metal processing, automotive, and recycling industries, combined with advances in belt material technology, is driving the shift toward customized, high-performance conveyor solutions.

North America Rubber Conveyor Belts Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by recovery in mining and metal industries, along with increased focus on energy infrastructure and industrial automation. Emphasis on worker safety, operational efficiency, and sustainable materials is encouraging the use of flame-retardant and abrasion-resistant rubber belts. Integration of smart sensors in conveyor systems is also gaining traction in the region.

U.S. Rubber Conveyor Belts Market Insight

The U.S. market captured the largest revenue share in North America in 2024, supported by robust mining operations, large-scale recycling initiatives, and growing cement production. Upgrades in existing manufacturing plants and rising investments in renewable energy and construction projects are creating sustained demand for heavy-duty and heat-resistant conveyor belts. Focus on local production and technological innovations in belt design further solidify market growth.

Rubber Conveyor Belts Market Share

The rubber conveyor belts industry is primarily led by well-established companies, including:

- ContiTech AG (Germany)

- Bridgestone Corporation (Japan)

- Fenner Dunlop Division (UK)

- Yokohama Private India Ltd. (India)

- Bando Chemical Industries, LTD (Japan)

- Trelleborg AB (Sweden)

- GARLOCK FAMILY OF COMPANIES (U.S.)

- ARTEGO S.A (Poland)

- Intralox (U.S.)

- Volta Belting Technology Ltd (Israel)

- Fives (France)

- Goodyear Rubber Products, Inc. (U.S.)

- Qingdao Rubber 6 Conveyor Belt Co. (China)

Latest Developments in Global Rubber Conveyor Belts Market

- In February 2024, Fenner Dunlop and International Conveyor and Rubber announced a strategic partnership to deliver tailored conveyor belt solutions for the underground mining sector. This collaboration aims to address the specific challenges of subterranean operations—such as fire resistance, load endurance, and compliance with safety standards. The partnership is expected to enhance the companies' competitive positioning in the mining industry and drive demand for specialized, high-performance conveyor belts in this critical segment

- In October 2023, Bando Chemical Industries launched a high-performance, heat-resistant conveyor belt designed specifically for steel mill applications. Engineered to withstand extreme temperatures and harsh conditions, the product meets the growing need for durable and efficient material handling solutions in heavy industries. This innovation strengthens Bando’s portfolio in high-temperature applications and reinforces its presence in the steel manufacturing sector

- In September 2023, Intralox introduced a modular belt technology optimized for the food processing industry. The new design emphasizes improved hygiene and cleanability—two essential factors in food safety and regulatory compliance. This launch is expected to accelerate the adoption of advanced conveyor technologies in food processing plants, addressing operational concerns while supporting stringent sanitation standards

- In July 2023, Continental AG acquired WCCO Belting, a U.S.-based belting manufacturer, to expand its presence in the agricultural sector. The acquisition enhances Continental’s portfolio of specialty conveyor products and broadens its reach across North American farming markets. By integrating WCCO’s expertise and customer base, Continental is positioned to capitalize on rising demand for robust, application-specific conveyor belts in modern agriculture

- In May 2023, Yokohama Rubber Co., Ltd. completed the acquisition of Trelleborg Wheel Systems, marking a strategic expansion of its product offerings across industrial and off-highway segments. This acquisition enables Yokohama to leverage Trelleborg’s advanced material technologies and established distribution network, bolstering its global market position and strengthening synergies across its broader rubber product business, including conveyor belt solutions

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.