Global Sensor Bearing Market

Market Size in USD Billion

CAGR :

%

USD

8.44 Billion

USD

12.88 Billion

2024

2032

USD

8.44 Billion

USD

12.88 Billion

2024

2032

| 2025 –2032 | |

| USD 8.44 Billion | |

| USD 12.88 Billion | |

|

|

|

|

Sensor Bearing Market Size

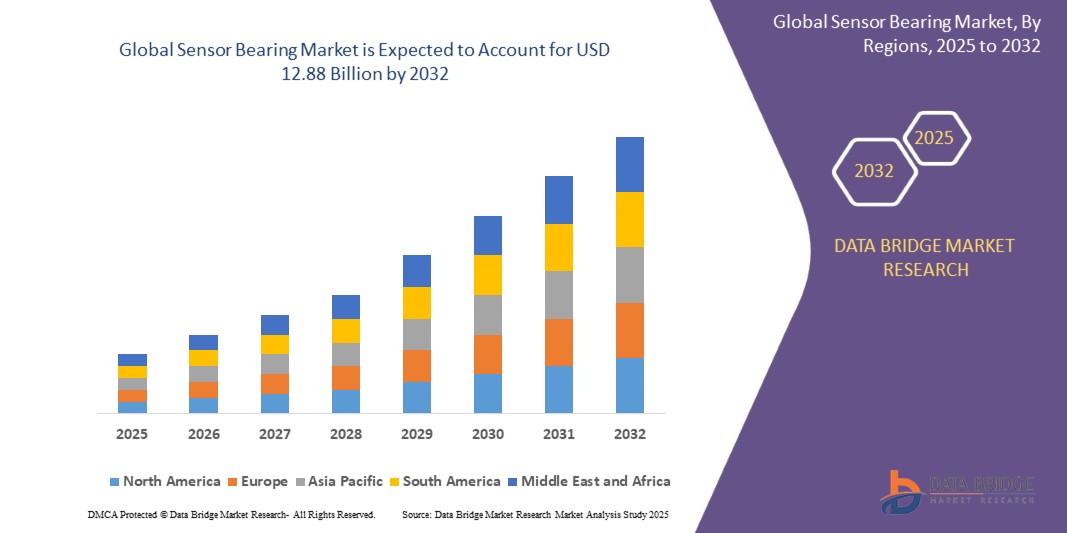

- The global Sensor Bearing market size was valued at USD 8.44 billion in 2024 and is expected to reach USD 12.88 billion by 2032, at a CAGR of 5.42% during the forecast period

- The market growth is largely fueled by the rising demand for enhanced automotive safety and performance systems, including ABS (Anti-lock Braking Systems) and ESC (Electronic Stability Control), which require advanced sensor-integrated bearings for real-time monitoring and control

- Furthermore, increased R&D investments and technological innovations, such as sensor bearings with higher sensitivity, integrated wireless data transmission, and compatibility with Industry 4.0 standards, are enhancing product functionality and expanding their use across automotive, aerospace, and industrial machinery sectors. These converging factors are accelerating the adoption of Sensor Bearing solutions, thereby significantly boosting the industry's growth

Sensor Bearing Market Analysis

- Sensor Bearings, offering integrated solutions that combine bearing performance with real-time condition monitoring, are becoming essential components across automotive, industrial, and aerospace applications due to their precision, durability, and alignment with smart manufacturing trends.

- The escalating demand for Sensor Bearings is primarily fueled by the growing adoption of Industry 4.0 technologies, rising emphasis on predictive maintenance, and the increasing integration of sensors in electric vehicles and industrial automation systems.

- Asia-Pacific dominates the Sensor Bearing market with the largest revenue share of 45.5% in 2025, characterized by advanced industrial infrastructure, strong presence of automotive OEMs, and early adoption of smart sensor technologies. The U.S. leads in product innovation and deployment, particularly in automotive safety systems, robotics, and aerospace applications.

- Asia-Pacific is expected to be the fastest-growing region in the Sensor Bearing market during the forecast period due to rapid industrialization, increasing investments in electric mobility, and expanding manufacturing capabilities in countries such as China, Japan, South Korea, and India.

- The automotive segment is expected to dominate the Sensor Bearing market with a market share of 41.56% in 2025, driven by its critical role in ABS, ESC, and powertrain systems. The rise in EV production and demand for energy-efficient components further supports the segment’s leading position.

Report Scope and Sensor Bearing Market Segmentation

|

Attributes |

Sensor Bearing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Sensor Bearing Market Trends

“Smart Manufacturing with AI-Integrated Sensor Bearings”

- A significant and accelerating trend in the global Sensor Bearing market is the integration of artificial intelligence (AI) and data-driven technologies to enable intelligent, real-time condition monitoring and predictive maintenance across industrial and automotive applications. This innovation is revolutionizing operational efficiency, safety, and equipment lifespan.

- For instance, companies like SKF and Schaeffler are leveraging AI and machine learning to develop sensor bearings capable of detecting vibration anomalies, load variations, and thermal fluctuations. These insights allow predictive maintenance systems to anticipate failures before they occur, minimizing downtime and reducing costs.

- AI-enhanced sensor bearings are increasingly being deployed in smart factories, where they collect and transmit real-time performance data to centralized systems. This enables automation of maintenance schedules, adaptive control systems, and improved energy efficiency.

- Additionally, digital twin technology is gaining traction, with sensor bearings playing a key role in simulating and optimizing machinery performance under real-world conditions. These digital models help manufacturers test and refine systems virtually before physical deployment.

- This trend toward intelligent, connected, and self-diagnosing components is driving investments in Industry 4.0 infrastructure. Major players such as NTN Corporation, Timken, and ABB are expanding their AI capabilities to stay competitive and meet rising demand for intelligent motion control systems.

- The demand for AI-integrated sensor bearings is rapidly growing across automotive, aerospace, and industrial sectors as businesses seek to improve reliability, reduce maintenance costs, and align with smart manufacturing and sustainability goals.

Sensor Bearing Market Dynamics

Driver

“Rising Demand Driven by Smart Automation and Predictive Maintenance”

- The increasing need for operational efficiency, machine reliability, and reduced downtime across industries is a significant driver for the growing demand for Sensor Bearings, which combine mechanical performance with real-time data monitoring to enable smart automation and predictive maintenance.

- For instance, in February 2024, SKF launched a new line of AI-enabled sensor bearings designed for industrial IoT applications, offering enhanced diagnostics and integration with factory automation systems. Such innovations by key players are expected to drive the growth of the Sensor Bearing industry during the forecast period.

- As manufacturers and OEMs shift toward Industry 4.0 and smart factory models, sensor bearings play a pivotal role in capturing critical operational data—such as temperature, vibration, and speed—which helps predict failures before they occur and extends equipment lifespan.

- Furthermore, the growing adoption of sensor bearings in electric vehicles, renewable energy systems, and high-speed machinery is boosting demand for intelligent motion components that support efficiency, sustainability, and safety.

- The increasing availability of high-speed data communication, advanced analytics, and edge computing technologies is enabling more widespread implementation of sensor bearings, while regulatory pressure for energy-efficient solutions is accelerating their uptake across automotive, aerospace, and industrial sectors globally.

Restraint/Challenge

“High Integration Costs and Limited Technological Awareness in Emerging Markets”

- The relatively high cost of sensor bearings—due to their complex design, embedded electronics, and precision manufacturing—poses a significant challenge to widespread adoption, especially in cost-sensitive industries and emerging markets where traditional bearings are still the norm.

- For instance, advanced sensor bearings developed by companies like Schaeffler, Timken, and SKF involve substantial investment in R&D and sophisticated production capabilities, making them less accessible to small and medium enterprises (SMEs) in developing regions.

- Limited awareness about the long-term benefits of predictive maintenance and real-time monitoring further restricts market growth. Many manufacturers in emerging economies are hesitant to shift from conventional maintenance models to smart, sensor-based systems due to lack of technical expertise and short-term cost considerations.

- Additionally, infrastructural limitations, such as inadequate digital connectivity and low penetration of industrial IoT platforms in regions like Africa, parts of Southeast Asia, and Latin America, hamper the effective deployment of sensor bearings.

- Overcoming these challenges will require strategic efforts, including cost-optimization through localized manufacturing, training programs for end-users, and partnerships with regional players to improve awareness and accessibility of sensor-based solutions in growing industrial hubs.

Sensor Bearing Market Scope

The market is segmented on the basis of functionality, application, and end-user.

- By Functionality

On the basis of functionality, the Sensor Bearing market is segmented into Speed, Temperature, Vibration, and Others. Speed sensor bearings dominate the market, accounting for the largest revenue share of approximately 39.2% in 2025, driven by their widespread application in automotive safety systems such as Anti-lock Braking Systems (ABS) and Electronic Stability Control (ESC). The integration of speed sensors with real-time feedback loops is critical for improving vehicle dynamics and reducing road accidents.

Temperature sensor bearings are witnessing strong adoption in industrial automation and heavy machinery, particularly in metal & mining and oil & gas sectors where overheating can lead to critical equipment failure.

- By Application

On the basis of application, the Sensor Bearing market is segmented into ABS, Material Handling Equipment, Electric Motors, and Others. ABS (Anti-lock Braking Systems) represents the largest application segment, contributing approximately 35.4% of total market revenue in 2025. The rising integration of safety technologies in both passenger and commercial vehicles, especially in North America and Europe, continues to drive segment dominance.

Electric Motors are expected to register the highest growth rate during the forecast period, with a projected CAGR of 5.9% from 2025 to 2032. The electrification of vehicles and the proliferation of electric motor-driven systems in industrial automation are major factors enhancing demand.

- By End-User

On the basis of end-user, the Sensor Bearing market is segmented into Automotive, Transportation, Metal & Mining, Aerospace & Defense, Oil & Gas, and Others. The Automotive sector dominates the market with a revenue share of about 41.6% in 2025, underpinned by the increasing adoption of sensor-integrated components for advanced driver assistance systems (ADAS), electrification, and vehicle diagnostics.

The Aerospace & Defense segment is set to witness strong growth due to increasing reliance on smart bearing solutions for mission-critical systems such as jet engines, navigation, and landing gears. These require high precision, durability, and real-time performance data.

Sensor Bearing Market Regional Analysis

- Asia-Pacific dominates the Sensor Bearing market, holding the largest revenue share of approximately 45.5% in 2024.

- This dominance is driven by rapid industrialization, urbanization, rising disposable incomes, and strong government initiatives supporting smart manufacturing and Industry 4.0 technologies.

- The presence of major manufacturing hubs in China, Japan, South Korea, and India, coupled with increasing adoption of sensor-integrated bearings across automotive, aerospace, and heavy industries, further fuels market growth in the region.

China Sensor Bearing Market Insight

China accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to its expanding middle class, rapid urbanization, and high rates of technological adoption. The country’s push towards smart cities and industrial automation, along with the availability of affordable Sensor Bearing options from strong domestic manufacturers, are key factors propelling the market in China.

Japan Sensor Bearing Market Insight

Japan’s market is gaining momentum due to its high-tech culture, advanced robotics industry, and rapid urbanization. The increasing number of smart homes and connected buildings is driving the adoption of sensor-bearing technology in various sectors, including manufacturing and transportation.

North America Sensor Bearing Market Insight

North America holds the second-largest share, accounting for approximately 38.11% of the global Sensor Bearing market in 2024. Market growth is fueled by advanced industrial infrastructure, high R&D investments, and early adoption of Industry 4.0 practices in manufacturing and automotive sectors. The U.S. leads within the region, driven by technological advancements, increased safety regulations, and growing demand for sensor-equipped automotive and aerospace components.

U.K. Sensor Bearing Market Insight

The U.S. market contributes a significant portion of North America’s share, bolstered by rising investments in electric vehicles (EVs), smart factories, and aerospace applications. Growing emphasis on safety, efficiency, and predictive maintenance continues to stimulate demand for sensor bearings.

Europe Sensor Bearing Market Insight

Europe accounts for a substantial portion of the market, supported by stringent safety standards and regulations across the region. The presence of leading automotive and aerospace manufacturers in Germany, France, and the U.K., along with government initiatives promoting automation and sustainability, sustains steady growth.

U.K. Sensor Bearing Market Insight

The U.K. market is expanding due to increasing smart home adoption and heightened focus on security and convenience, which boosts demand for sensor-equipped devices across residential and commercial sectors.

Germany Sensor Bearing Market Insight

Germany’s market growth is driven by strong automotive production, advanced manufacturing, and rising awareness of digital security. Integration of sensor bearings into home automation and industrial applications aligns well with local consumer and industrial expectations.

Sensor Bearing Market Share

The Sensor Bearing industry is primarily led by well-established companies, including:

- JTEKT Corporation (Japan)

- THE TIMKEN COMPANY (U.S.)

- mageba (Switzerland)

- Bailian (Group) Co., Ltd (China)

- Harbin Bearing Manufacturing Co., Ltd. (China)

- Nachi Europe GmbH (Germany)

- Schaeffler AG (Germany)

- NTN Corporation (Japan)

- SKF (Sweden)

- NSK Ltd. (Japan)

- Thomson Industries, Inc. (U.S.)

- Fersa Bearings (Spain)

- ABB (Switzerland)

- Thermometrics Corporation (U.S.)

- Waukesha Bearings (U.S.)

Latest Developments in Global Sensor Bearing Market

- In February 2024, Schaeffler launched its new-generation SmartCheck Sensor Bearings, featuring AI-driven predictive maintenance tailored for industrial applications

- In January 2024, Wafangdian Bearing introduced specialized sensor bearings designed for high-speed railway systems in China, enabling real-time monitoring of temperature, speed, and wear

- In September 2023, Schaeffler AG strategically expanded its product portfolio by launching new products in rotary table bearings, torque motors, and linear motors. This expansion features a variety of sizes for rotary table and rotary axis bearings, enhanced by the integration of bearing-mounted angular measuring systems. Additionally, the RKIB series of torque motors has been standardized and extended up to size 690, reinforcing the company’s ability to provide a comprehensive range of high-quality solutions

- In June 2018, SKF and the National Renewable Energy Laboratory (NREL) began a three-year collaboration to study wind turbine drivetrains. As part of this project, sensors will be installed in the bearings to monitor the condition of the gearbox and shaft bearings. This initiative provides SKF with an excellent opportunity to demonstrate its expertise in the wind energy sector

- In January 2018, SKF partnered with Koncar KEV by signing an agreement to supply bearings, axle boxes, and related equipment for their newest low-floor electric and diesel-electric multiple unit trains

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.