Global Sheet Molding Compound Smc Market

Market Size in USD Billion

CAGR :

%

USD

1.54 Billion

USD

2.51 Billion

2024

2032

USD

1.54 Billion

USD

2.51 Billion

2024

2032

| 2025 –2032 | |

| USD 1.54 Billion | |

| USD 2.51 Billion | |

|

|

|

|

Sheet Molding Compound (SMC) Market Size

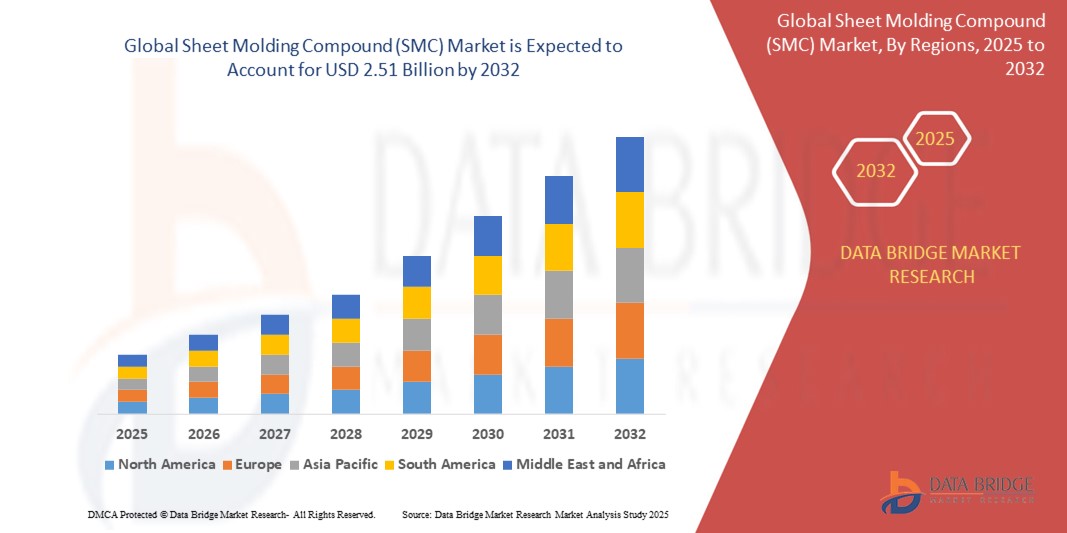

- The Global Sheet Molding Compound (SMC) Market size was valued at USD 1.54 Billion in 2024 and is expected to reach USD 2.51 Billion by 2032, at a CAGR of 5.6% during the forecast period

- The market growth is largely fueled by increasing consumption in modern construction projects

- Furthermore, the rising demand for commercial and passenger vehicles which are enveloped by stringent emission regulations, increasing penetration of carbon fiber for the development of low-density SMCs, growing demand for bio-based materials and compounds, are further anticipated to propel the growth of the Sheet Molding Compound (SMC) Market

Sheet Molding Compound (SMC) Market Analysis

- The sheet molding compound is a glass-fibre reinforced polyester material ready to be molded, which is primarily used in compression molding. It is generally used for larger components where greater mechanical strength is required.

- A fibre reinforced thermoset material is a sheet molding compound. The most important advantage of sheet moulding compound is its light weight when compared to other substances, such as metals and even other polyesters such as bulk molding compound.

- Asia-Pacific dominates the Sheet Molding Compound (SMC) Market with the largest revenue share of 38.21% in 2024, characterized by robust automotive manufacturing and infrastructure development in countries like China, Japan, and India.

- Asia-Pacific is expected to be the fastest growing region in the Sheet Molding Compound (SMC) Market during the forecast period due to rapid urbanization, increasing automotive production, and government initiatives promoting sustainable materials

- The glass fiber reflective films segment is expected to dominate the Sheet Molding Compound (SMC) Market with a market share of 63.4% in 2024, driven by its cost-effectiveness, high mechanical strength, and compatibility with various resins

Report Scope and Sheet Molding Compound (SMC) Market Segmentation

|

Attributes |

Sheet Molding Compound (SMC) Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Sheet Molding Compound (SMC) Market Trends

“Growing Adoption of SMC in Renewable Energy Applications”

- The demand for durable, lightweight, and corrosion-resistant materials in renewable energy sectors, such as wind and solar, is fueling SMC adoption.

- SMC is increasingly used for enclosures, paneling, and structural supports in solar panels and wind turbine components due to its dimensional stability and weather resistance.

- As governments promote clean energy initiatives and expand infrastructure, SMC's role as a material of choice is growing in tandem.

- This trend is strengthening the market's diversification beyond automotive and aerospace, opening long-term growth opportunities.

Sheet Molding Compound (SMC) Market Dynamics

Driver

“Rising Demand for Lightweight and Durable Materials in Automotive and Aerospace Industries”

- The automotive and aerospace sectors are increasingly seeking materials that offer high strength-to-weight ratios to improve fuel efficiency and performance.

- SMC provides an ideal solution, offering durability, corrosion resistance, and design flexibility, making it suitable for components like body panels, hoods, and structural parts.

- The shift towards electric vehicles (EVs) further amplifies this demand, as manufacturers aim to offset battery weight with lighter materials without compromising safety or performance.

- This trend is expected to continue, driving growth in the SMC market as industries prioritize lightweight and efficient materials.

Restraint/Challenge

“High Production Costs and Recycling Challenges for SMC Materials”

- The production of SMC involves high-quality resins and reinforcing fibers, leading to elevated raw material costs.

- Additionally, the manufacturing process requires specialized equipment and skilled labor, increasing capital investment and operational expenses.

- Recycling SMC poses environmental concerns, as thermoset composites like SMC cannot be easily remelted and reprocessed, unlike thermoplastics.

- These factors can deter small and medium-sized enterprises (SMEs) from adopting SMC, limiting market growth despite its advantageous properties.

Sheet Molding Compound (SMC) Market Scope

The market is segmented on the basis of fiber type, resin type, density, type, and end user.

- By Fiber Type

On the basis of fiber type, the sheet molding compound (SMC) market is segmented into glass fiber and carbon fiber. the glass fiber segment dominates the largest market revenue share of 63.4% in 2025, driven by its cost-effectiveness, high mechanical strength, and compatibility with various resins. it is extensively used in automotive and electrical components due to its dimensional stability and ease of processing. additionally, its widespread availability and proven performance across mass production lines sustain its dominance.

the carbon fiber segment is anticipated to witness the fastest growth rate of 10.3% from 2025 to 2032, fueled by rising demand for lightweight and high-performance materials in aerospace, defense, and premium automotive sectors. its superior strength-to-weight ratio and stiffness make it ideal for structural components in weight-sensitive applications.

- By Resin Type

On the basis of resin type, the SMC market is segmented into polyester, vinylester, and others. The polyester segment held the largest market revenue share in 2025, driven by its excellent chemical resistance, cost advantage, and suitability for high-volume molding. It is widely used in construction panels, automotive hoods, and appliance housings.

The vinylester segment is expected to witness the fastest CAGR from 2025 to 2032, driven by increasing applications in corrosion-resistant and high-temperature environments. Its superior toughness, water resistance, and mechanical properties support rising demand in marine and industrial sectors.

- By Density

On the basis of density, the SMC market is segmented into low density and mid and high density. The mid and high density segment dominates the largest market revenue share of 58.7% in 2025, driven by its application in load-bearing parts such as structural panels, engine covers, and electric housings. These grades offer better strength, durability, and thermal performance.

The low density segment is anticipated to witness the fastest growth rate of 9.6% from 2025 to 2032, fueled by increased focus on lightweighting in automotive and aerospace industries. These materials reduce vehicle weight, improve fuel efficiency, and meet stringent emission regulations.

- By Type

On the basis of type, the SMC market is segmented into general purpose, flame resistance, corrosion resistance, electronic insulators, and others. The general purpose segment held the largest market revenue share in 2025, driven by its versatility and wide usage across construction, automotive, and appliance sectors.

The flame resistance segment is expected to witness the fastest CAGR from 2025 to 2032, driven by stricter fire safety regulations in transport and building infrastructure. These compounds meet high flammability standards and are increasingly used in electrical enclosures, rail interiors, and public transport applications.

- By End User

On the basis of end-use industry, the SMC market is segmented into automotive, electrical and electronic, aviation and defence, construction, consumer goods, healthcare, and marine. The automotive segment dominates the largest market revenue share of 39.1% in 2025, driven by growing use of SMC in lightweight body panels, bumpers, and battery enclosures. The material supports fuel economy and EV range goals while providing design flexibility and impact resistance.

The aviation and defence segment is anticipated to witness the fastest growth rate of 10.8% from 2025 to 2032, fueled by demand for high-performance composite parts in aircraft interiors, UAVs, and military applications. These industries benefit from SMC’s fire resistance, dimensional accuracy, and superior strength-to-weight characteristics.

Sheet Molding Compound (SMC) Market Regional Analysis

- Asia-Pacific dominates the Sheet Molding Compound (SMC) Market with the largest revenue share of 38.21% in 2024, driven by robust automotive manufacturing and infrastructure development in countries like China, Japan, and India.

- The region's focus on lightweight materials for electric vehicles and construction applications propels market growth.

- Government initiatives promoting sustainable materials and increasing investments in renewable energy further support the demand for SMC.

China Sheet Molding Compound (SMC) Market Insight

The China Sheet Molding Compound (SMC) Market captured the largest revenue share of 82.41% in 2025 within Asia-Pacific, fueled by its expansive automotive industry and infrastructure projects. The government's emphasis on electric vehicle production and the "Made in China 2025" initiative bolster the adoption of advanced composite materials like SMC.

Europe Sheet Molding Compound (SMC) Market Insight

The European Sheet Molding Compound (SMC) Market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by stringent environmental regulations and the push for lightweight materials in automotive and construction sectors. Countries like Germany, France, and the UK are at the forefront, leveraging SMC for sustainable manufacturing practices.

U.K. Sheet Molding Compound (SMC) Market Insight

The U.K. Sheet Molding Compound (SMC) Market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by the automotive industry's shift towards electric vehicles and the need for lightweight, durable materials. Government policies supporting sustainable manufacturing and investments in infrastructure contribute to market expansion.

Germany Sheet Molding Compound (SMC) Market Insight

The German Sheet Molding Compound (SMC) Market is expected to expand at a considerable CAGR during the forecast period, fueled by the country’s strong automotive and industrial base drives the demand for SMC, especially in applications requiring high strength-to-weight ratios. The country's commitment to renewable energy and sustainable construction practices further accelerates SMC adoption.

Asia-Pacific Sheet Molding Compound (SMC) Market Insight

The Asia-Pacific Sheet Molding Compound (SMC) Market is poised to grow at the fastest CAGR of over 7.3% during the forecast period of 2025 to 2032, driven by rapid urbanization, increasing automotive production, and government initiatives promoting sustainable materials in countries like China and India are key growth drivers.

Japan Sheet Molding Compound (SMC) Market Insight

The Japan Sheet Molding Compound (SMC) Market is gaining momentum due to its advanced automotive sector and emphasis on lightweight materials for fuel efficiency. Technological innovations and the adoption of SMC in electric vehicles and construction applications support market growth.

India Sheet Molding Compound (SMC) Market Insight

India Sheet Molding Compound (SMC) Market accounted for the largest market revenue share in Asia Pacific in 2025, driven by increasing demand from automotive, electrical, and construction industries. Government initiatives like the National Electric Mobility Mission and infrastructure development projects boost the adoption of SMC.

Sheet Molding Compound (SMC) Market Share

The Sheet Molding Compound (SMC) Industry is primarily led by well-established companies, including:

- POLYTEC Holding AG (Austria)

- IDI Composites International (U.S.)

- Polynt (Italy)

- TEIJIN LIMITED. (Japan)

- Premix Group (Finland)

- MENZOLIT (Germany)

- Huayuan Advanced Materials Co., Ltd (China)

- Core Molding Technologies (U.S.)

- Changzhou City Jiangshi Composite Technology Co., Ltd. (China)

- Koninklijke Ten Cate bv (Netherlands)

- SHOWA DENKO K.K. (Japan)

- China International Composites Industrial Technical Expo (China)

- ASTAR (U.S.)

- Magna International Inc. (Canada)

- Continental Structural Plastics Inc. (U.S.)

- ISCOPE GmbH (Germany)

- Devi Polymers Private Limited (India)

- Mitsui Chemicals, Inc. (Japan)

- MCR Mixt Composites Recyclables (France)

- ZOLTEK (U.S.)

Latest Developments in Global Sheet Molding Compound (SMC) Market

- In March 2022, Evonik introduced the Pure Performance Battery, a next-generation battery pack for electric vehicles, featuring a lightweight design made from sheet molding compounds.

- In 2021, Patz Materials has been working with Lawrence Livermore National Laboratory to create carbon fiber monoliths for use in space satellite applications.

- In August 2020, Japan Composite Co., Ltd. revealed its agreement to acquire the sheet molding compound operations of DIC Kako Inc.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Sheet Molding Compound Smc Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Sheet Molding Compound Smc Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Sheet Molding Compound Smc Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.